High-voltage electrical device grounding system on multi-layer steel structure platform and arrangement method

A technology for high-voltage electrical equipment and grounding systems, applied in the direction of connecting contact materials, etc., can solve the problems of increasing the load of the steel platform, long installation period, and large amount of grounding wire layout and connection engineering, so as to reduce the number, reduce the load, and reduce the grounding. System simplicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

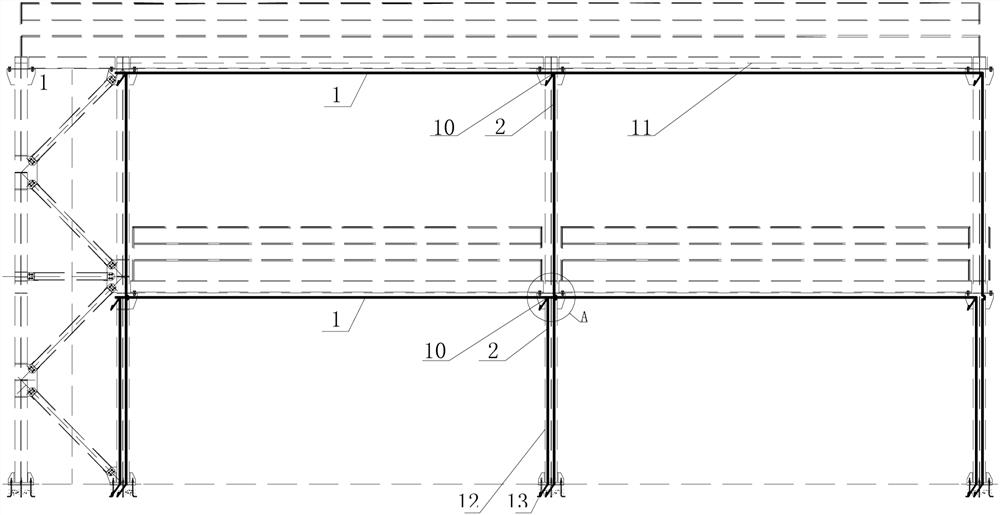

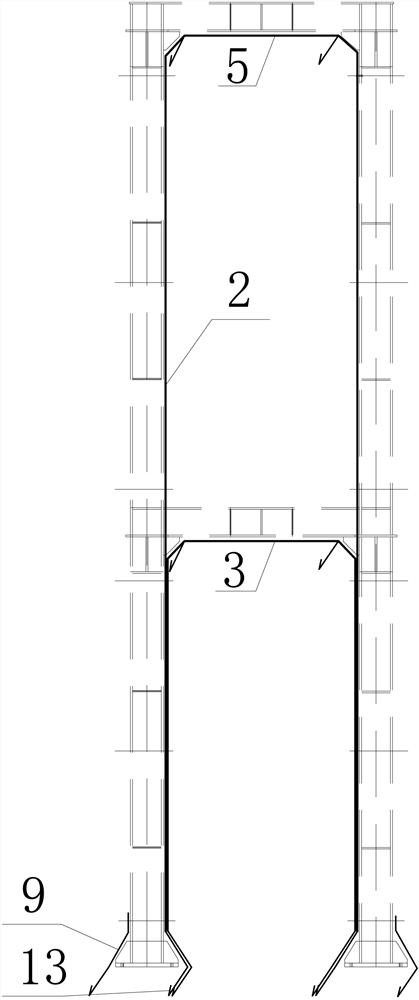

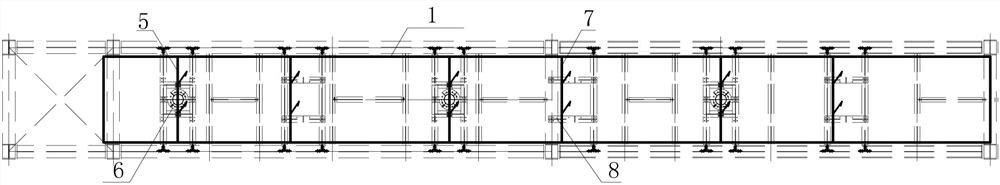

[0031] see Figure 1-5 , a grounding system for high-voltage electrical equipment on a multi-layer steel structure platform, which includes a grounding ring network flat copper 1 arranged on each steel platform 11; the grounding ring network flat copper 1 of each layer passes through the first silver-copper solder joint 10 respectively Connected with the corresponding grounding down-conductor flat copper 2 by welding or bolts, each of the grounding down-conductor flat copper 2 is respectively led to the underground grounding grid 13 along the steel platform column 12, and the steel platform column 12 The bottom is connected to the underground grounding grid 13 through the steel platform leg grounding downlead 9; the outdoor lightning arrester steel pillar 6 connected on the steel platform 11 is connected with the outdoor lightning arrester steel pillar grounding lead wire flat copper 5, and the outdoor lightning arrester The flat copper 5 of the steel pillar grounding lead-out...

Embodiment 2

[0036] The laying method of the grounding system is as follows:

[0037] The single-phase platform equipment and its steel pillar grounding flat copper on each floor are first led to the grounding ring network flat copper 1 of this layer, and each grounding ring network flat copper 1 is led down to the ground underground concealed grounding network along the steel platform legs 13. The laying method comprises the following steps:

[0038] Step 1: On each steel platform, use grounding flat copper to arrange a rectangular grounding ring network along the length and width of the platform to form a grounding ring network flat copper 1. Copper 1 is suspended and fixed on the lower surface of the platform steel grid with a clamp to make the upper surface of the platform simple and beautiful, and the ground flat copper can also be directly arranged on the upper surface of the platform steel grid;

[0039] Step 2: lead out the ground flat copper to the steel pillar on both sides of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com