A kind of installation method of large tank body

An installation method and tank technology, applied in the directions of transportation and packaging, load hanging components, etc., can solve problems such as installation and construction not suitable for production workshops, and achieve the effects of reducing construction costs, occupying a small site area, and having a high safety factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

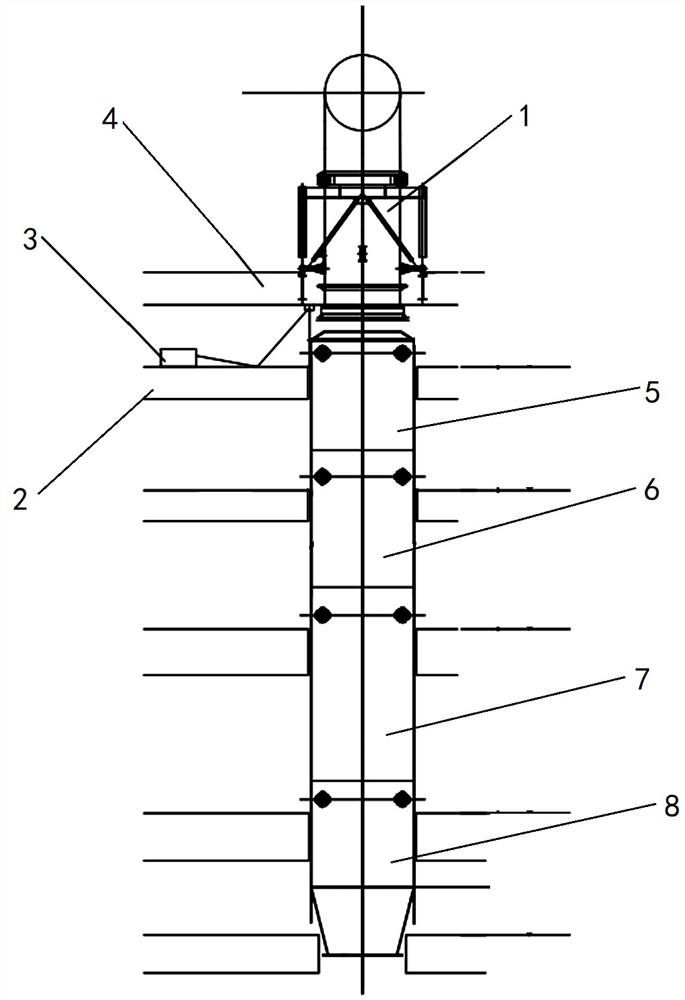

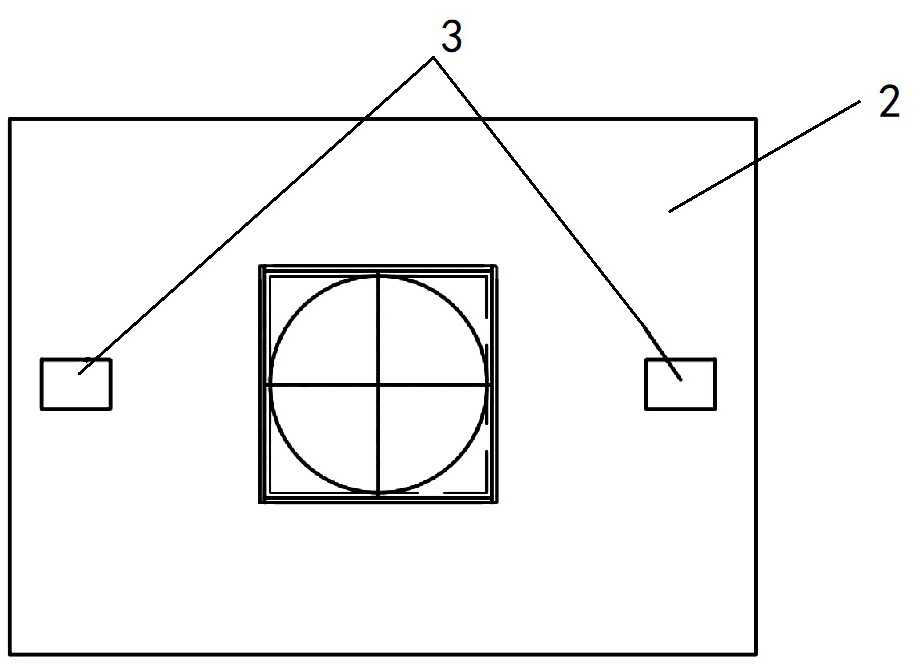

[0022] Such as figure 1 and figure 2 As shown, the present invention takes the installation of an evaporative cooler supporting a 300t converter in a steel plant as an example. The main function of the evaporative cooler is to control the temperature of the flue gas generated during converter smelting within a specified range, and then enter the electrostatic precipitator for final dust removal , which is in the shape of a tank, with a diameter of 6000mm and a total length of 36529mm, divided into the upper part of 19670mm and a wall thickness of 10mm; the lower part of 16859mm and a wall thickness of 12mm. Installed behind the flue 1 at the end of the converter, it is connected to the flue 1 at the end by using an expansion adjustment device (soft connection), and runs through multiple platforms 2 in the converter workshop as a whole. Since the converter workshop has been put into production, there is no crane station in the workshop, and the crane cannot be used for instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com