Reinforcement structure of building foundation and construction method thereof

A technology for strengthening structures and buildings, which is applied in the fields of basic structure engineering, basic structure repair, construction, etc., can solve the problems that the durability of steel pipe piles cannot be guaranteed, it is difficult to meet the design requirements, and the welding operation is difficult, etc., to achieve Ensure the effective grouting volume, improve durability and reduce the difficulty of construction operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

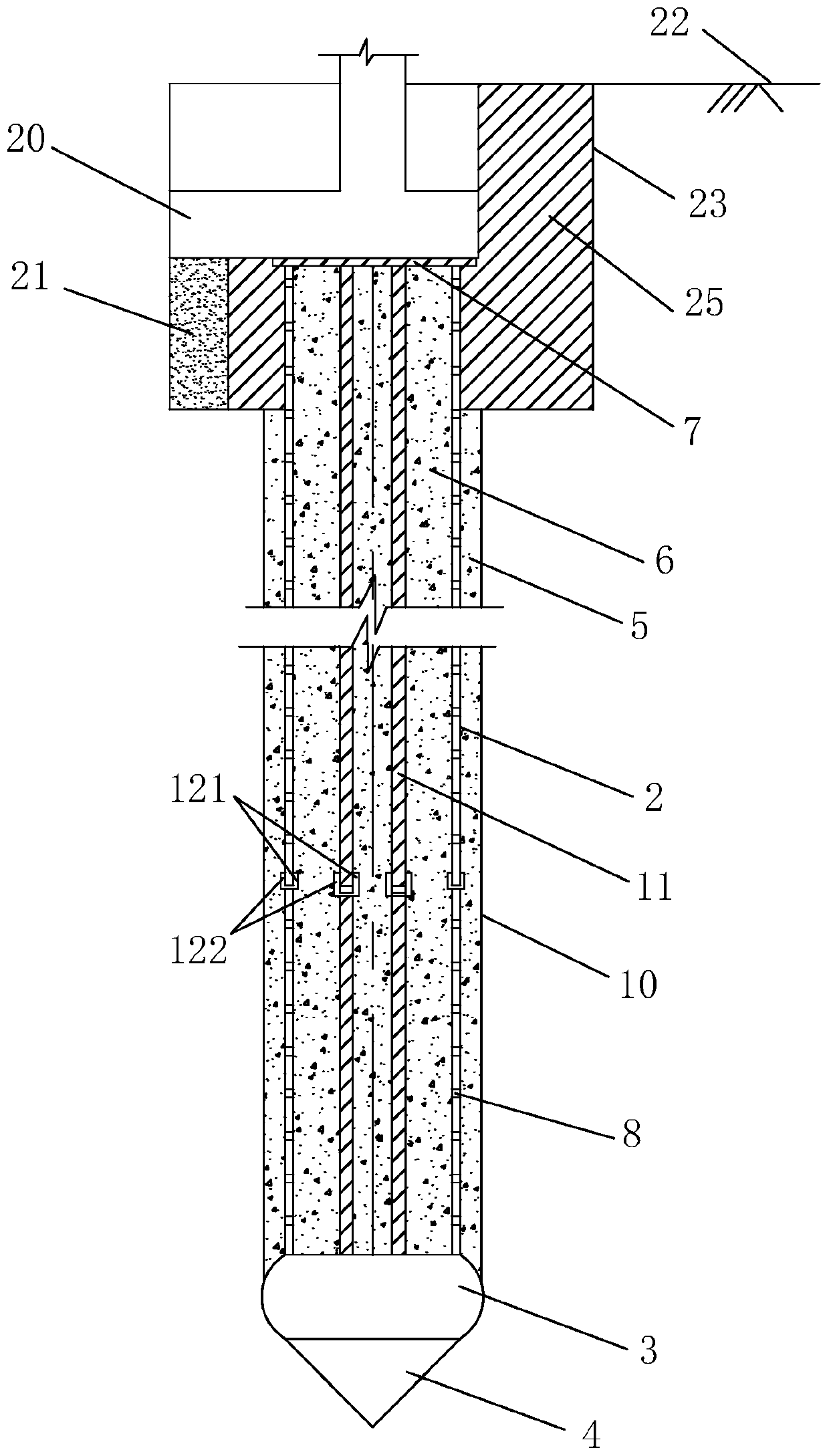

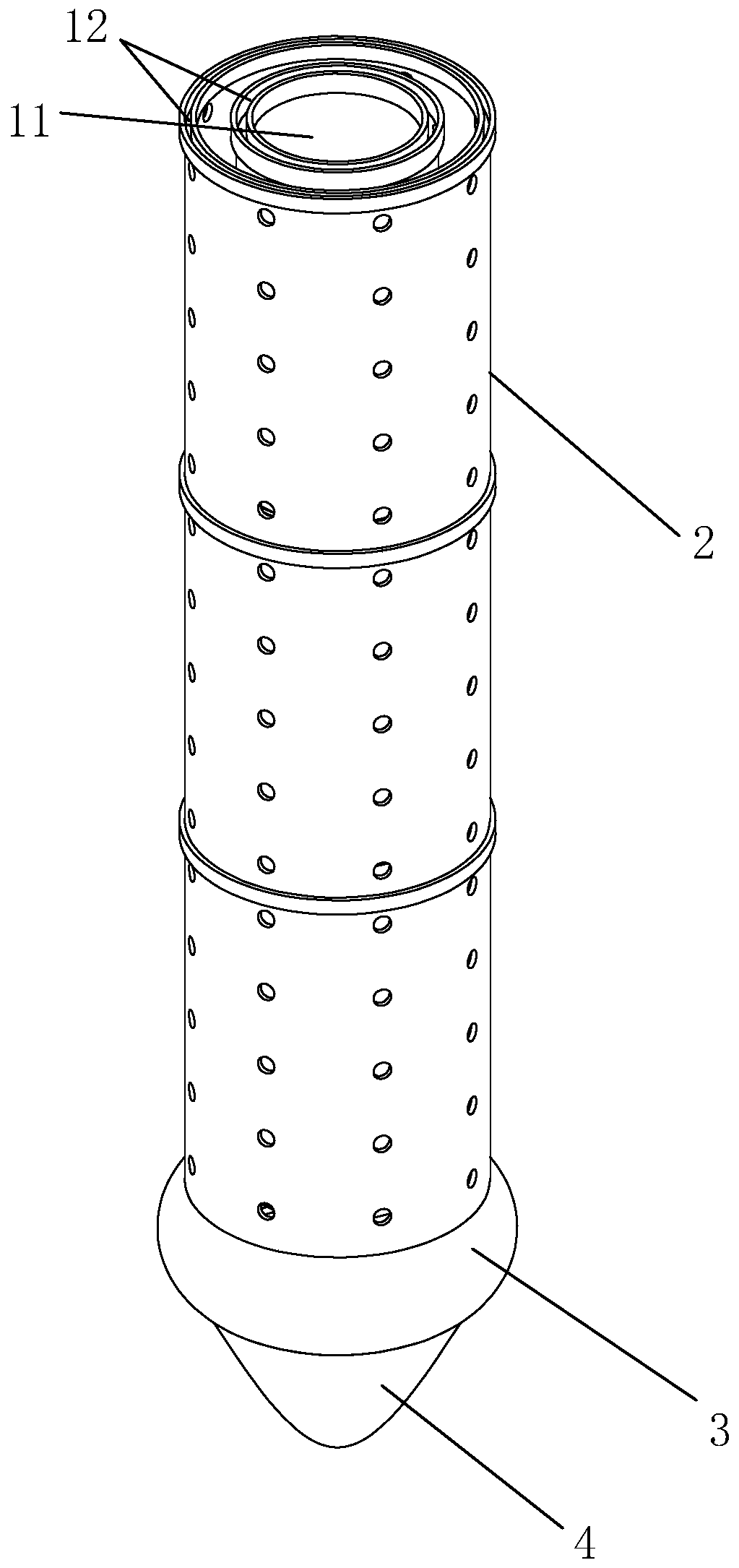

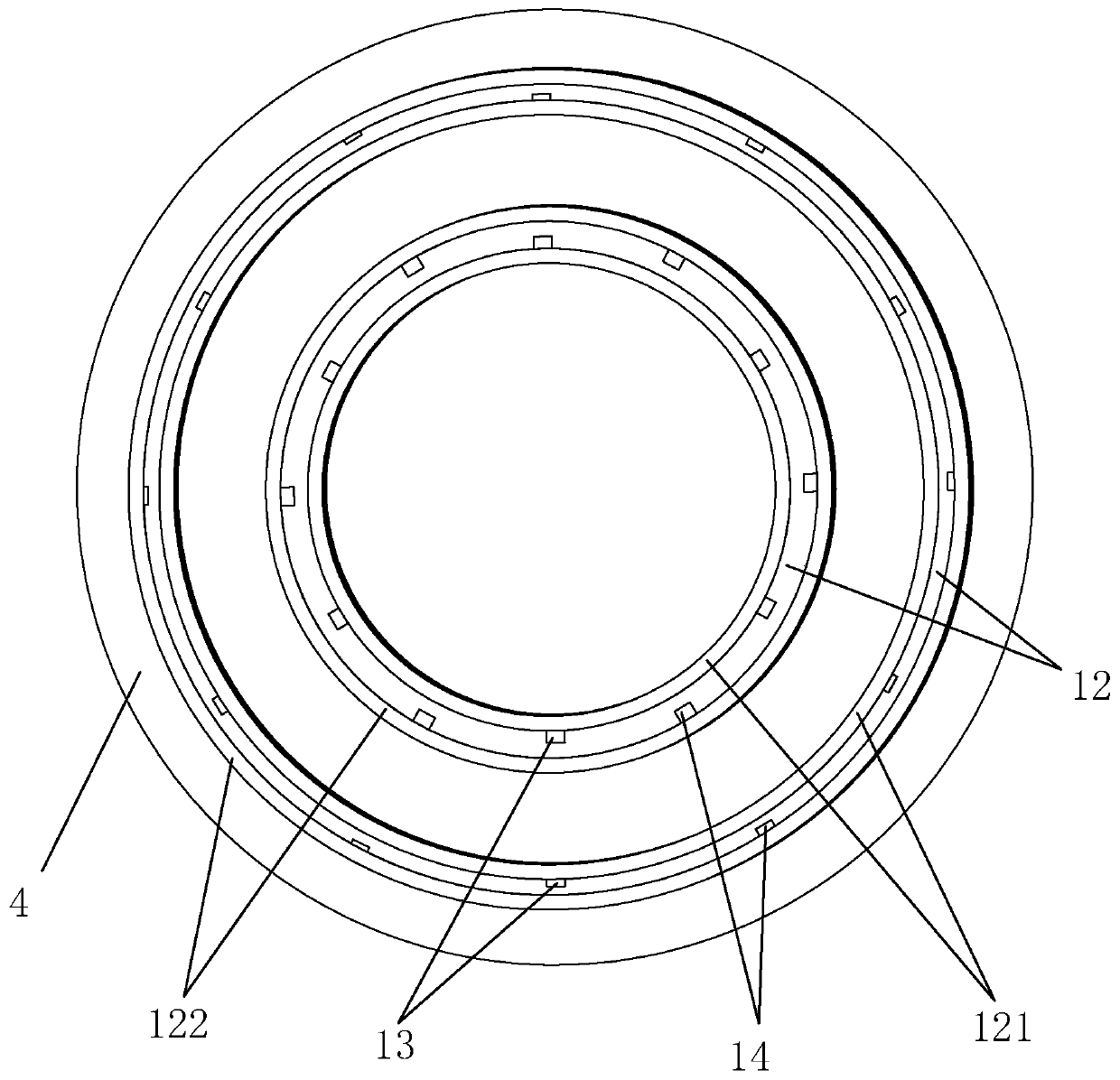

[0043] A reinforcement structure for building foundations, such as figure 1 and figure 2 As shown, it includes a static pressure pile welded from the end to the end of several steel pipes 11, a protective pipe 2 that is concentrically and vertically sleeved on the outside of each steel pipe 11 of the static pressure pile, and a thick middle section welded at the bottom of the static pressure pile and the protective pipe 2. And the upper and lower expansion parts 3, the pile head 4 smoothly welded on the bottom of the expansion part 3, the cement reinforcement layer 5 arranged between the protective pipe 2 and the surrounding soil layer 10, and the cement reinforcement layer 5 filled between the protective pipe 2 and the static pressure pile Cement protective layer 6. Concrete reinforcement slurry is poured into the steel pipe 11 forming the static pressure pile to obtain a static pressure pile with reinforcement filling, and the ends of several protective pipes 2 are welded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com