Patents

Literature

38results about How to "Increased solder contact area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

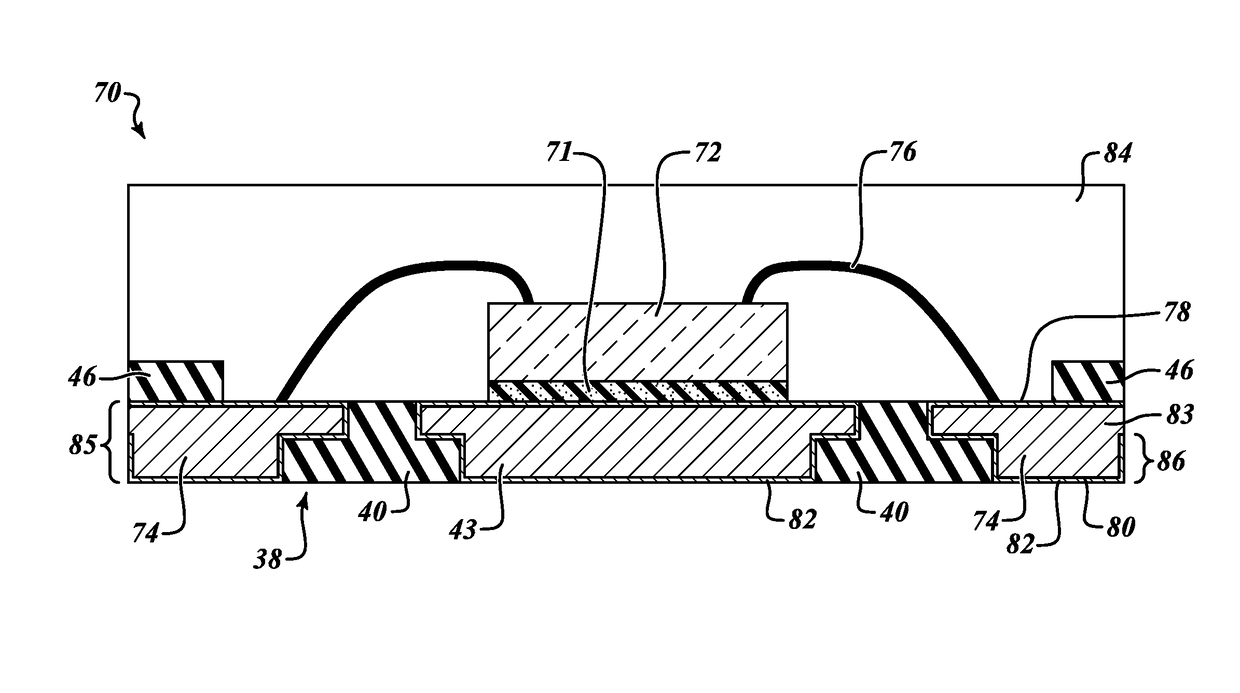

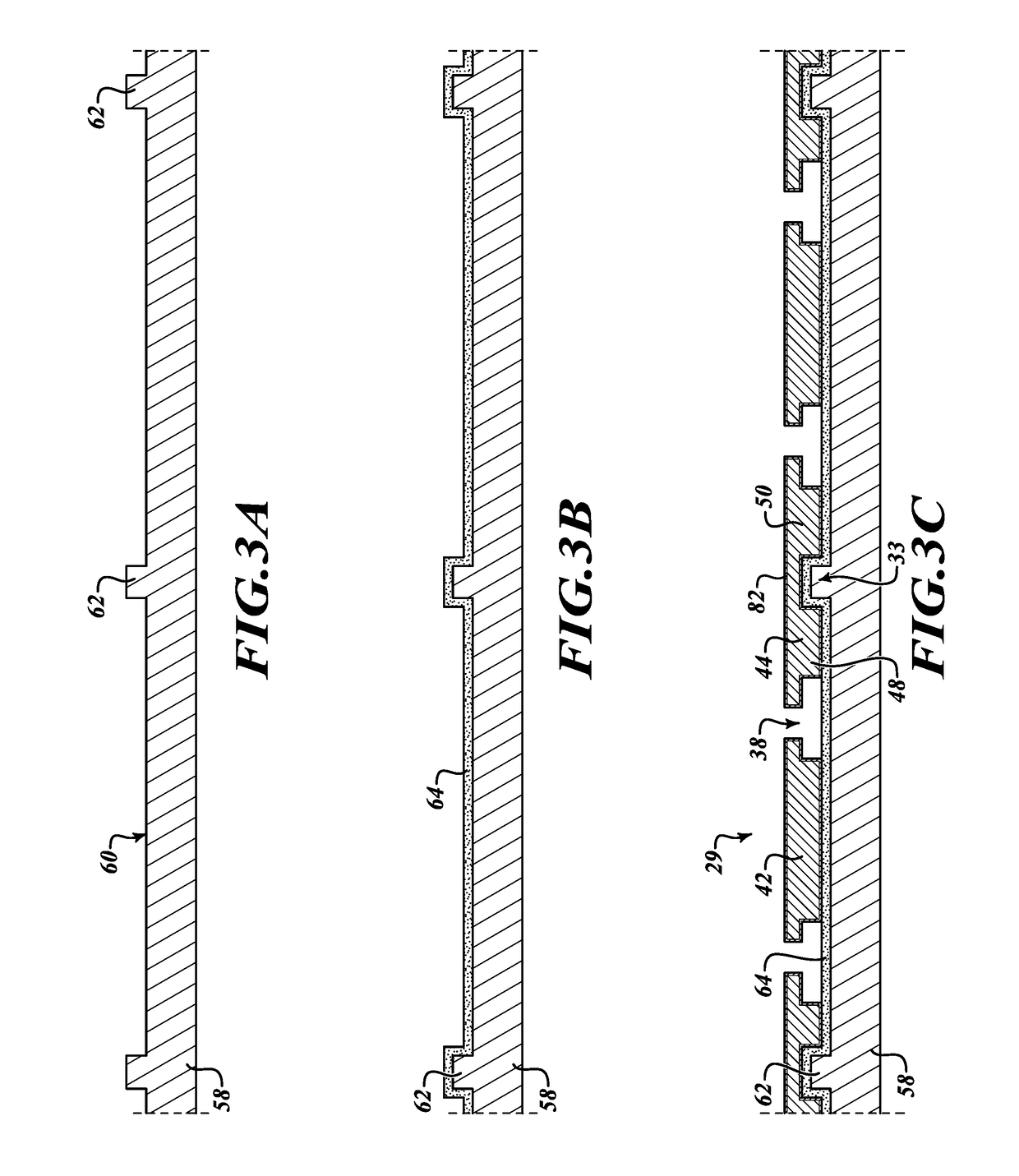

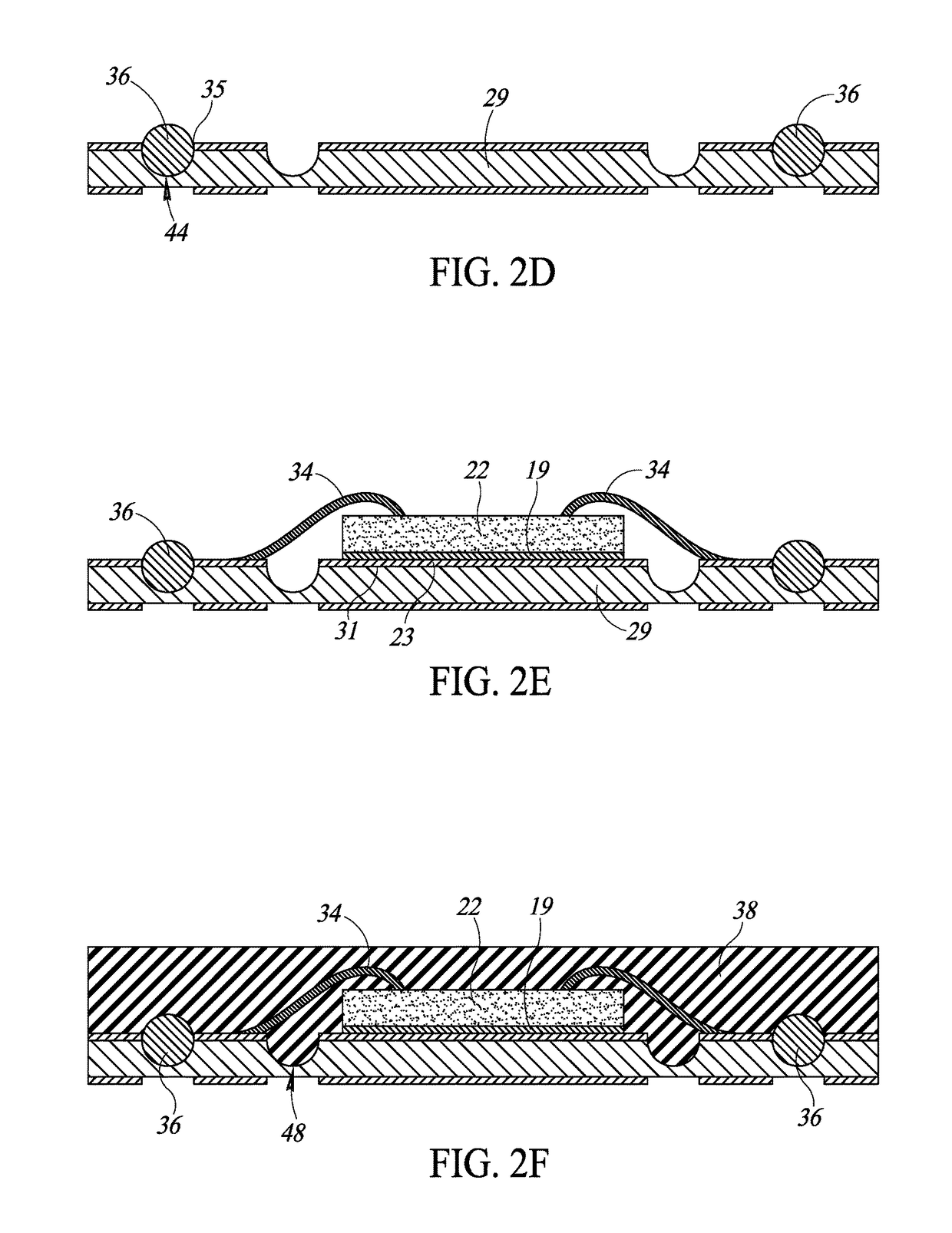

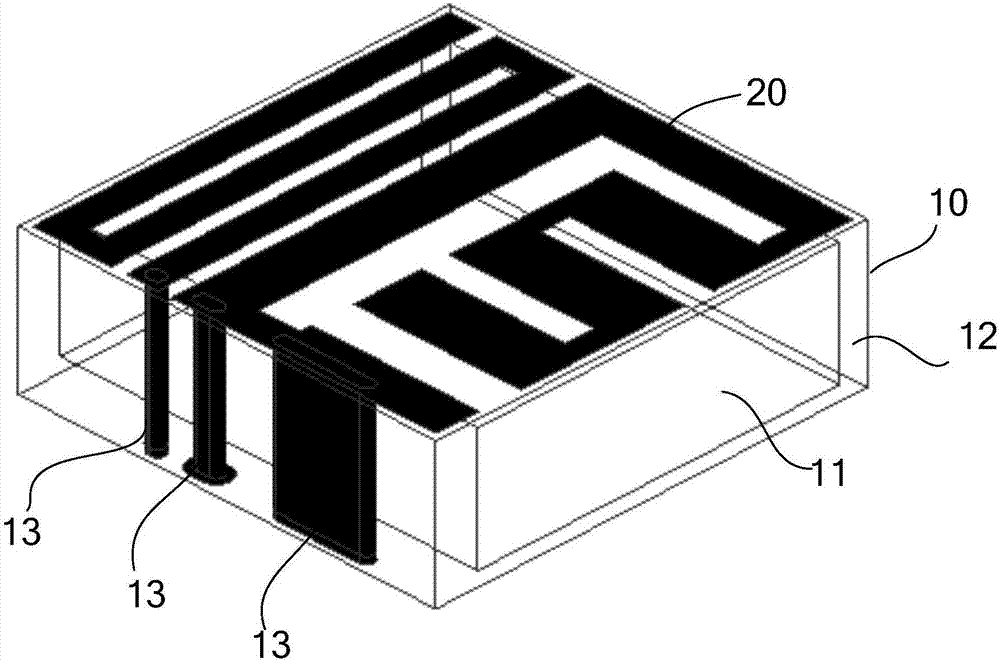

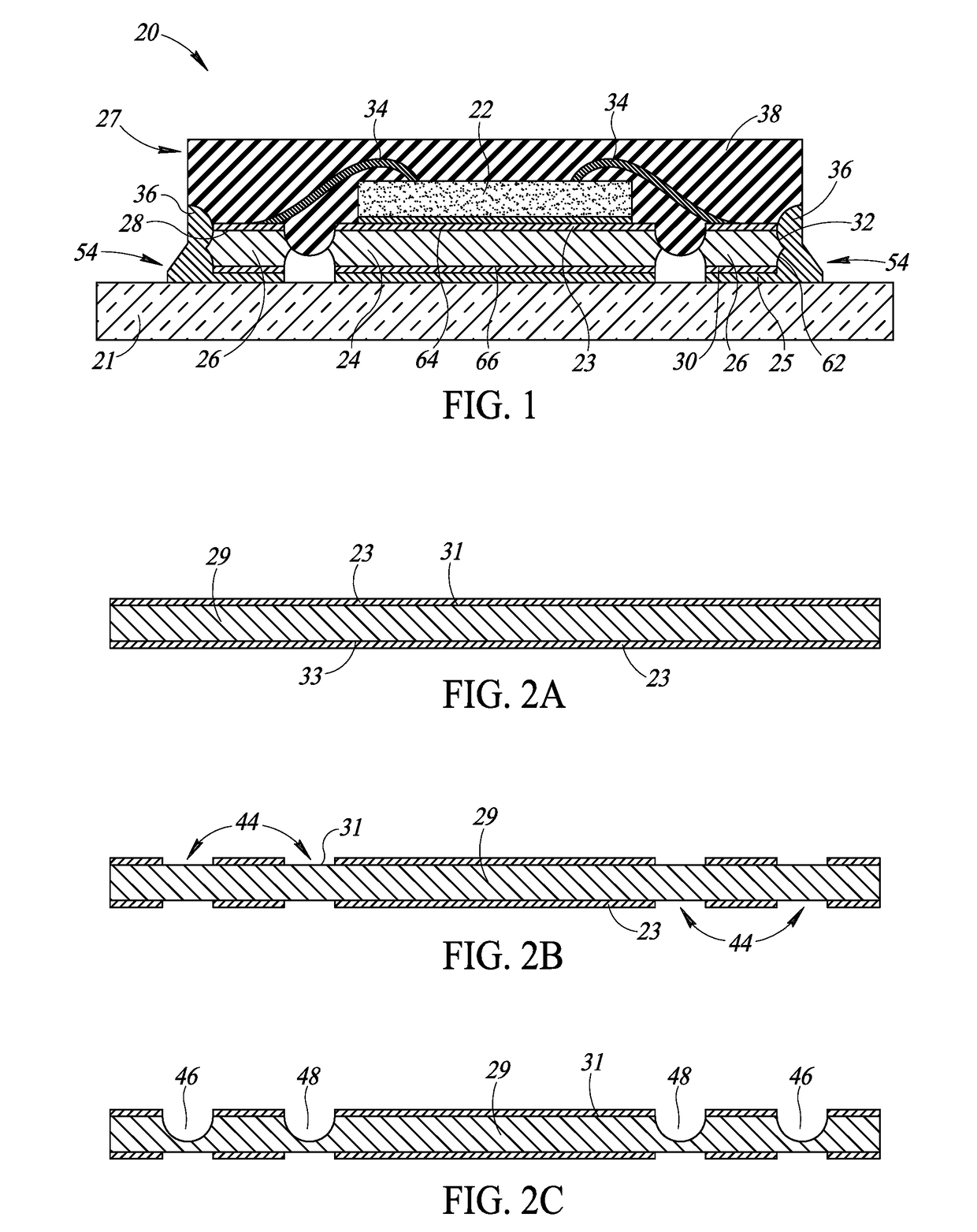

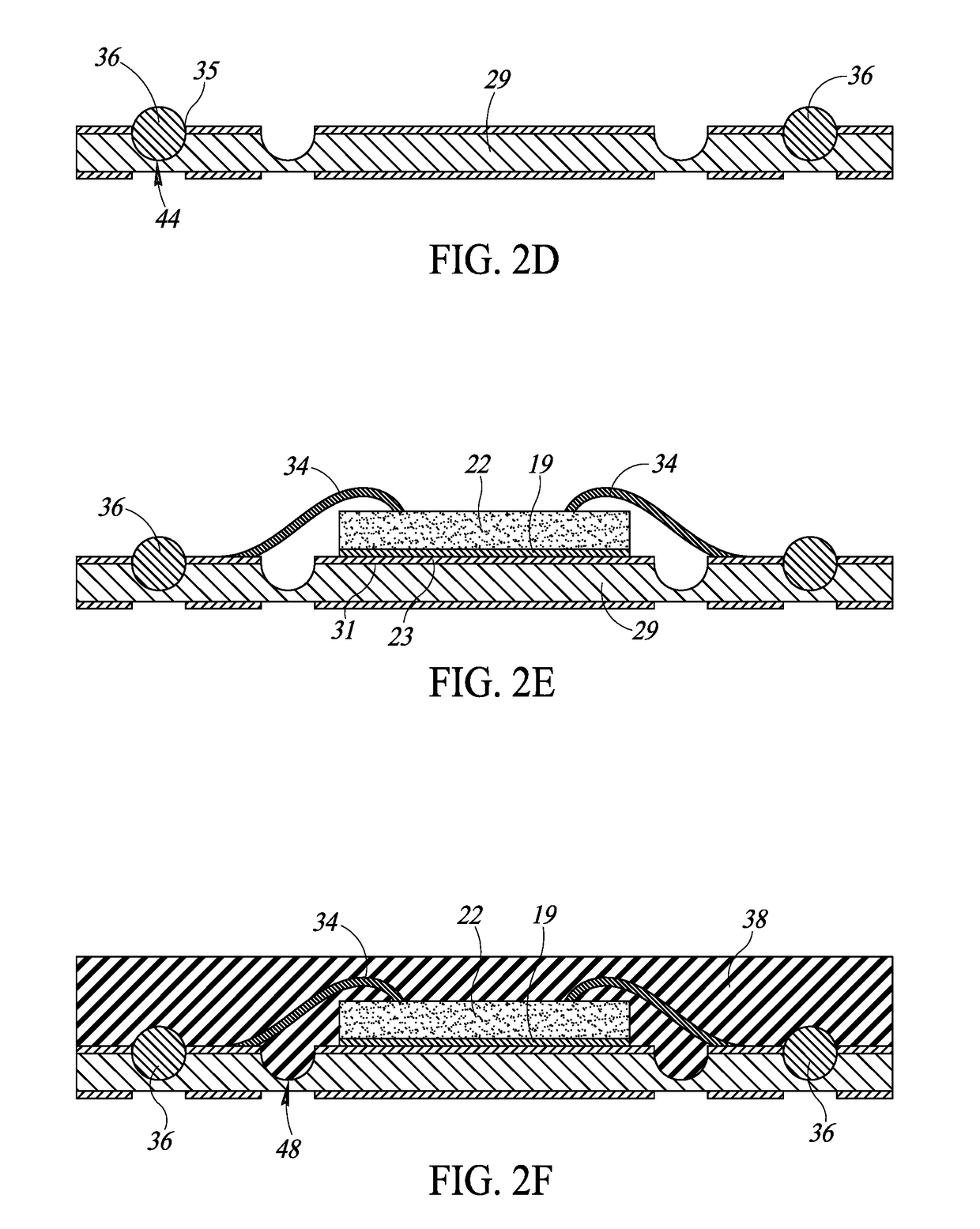

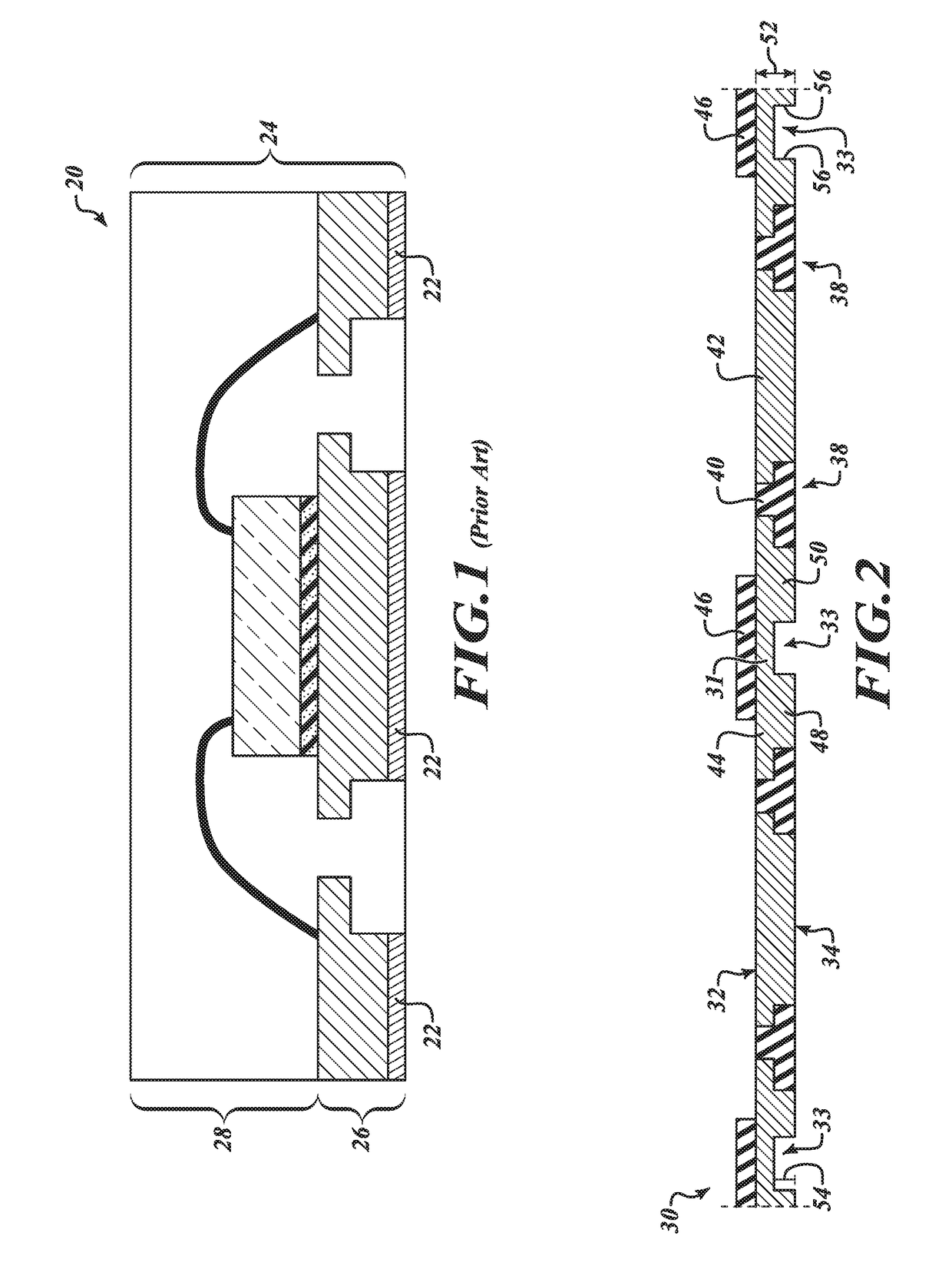

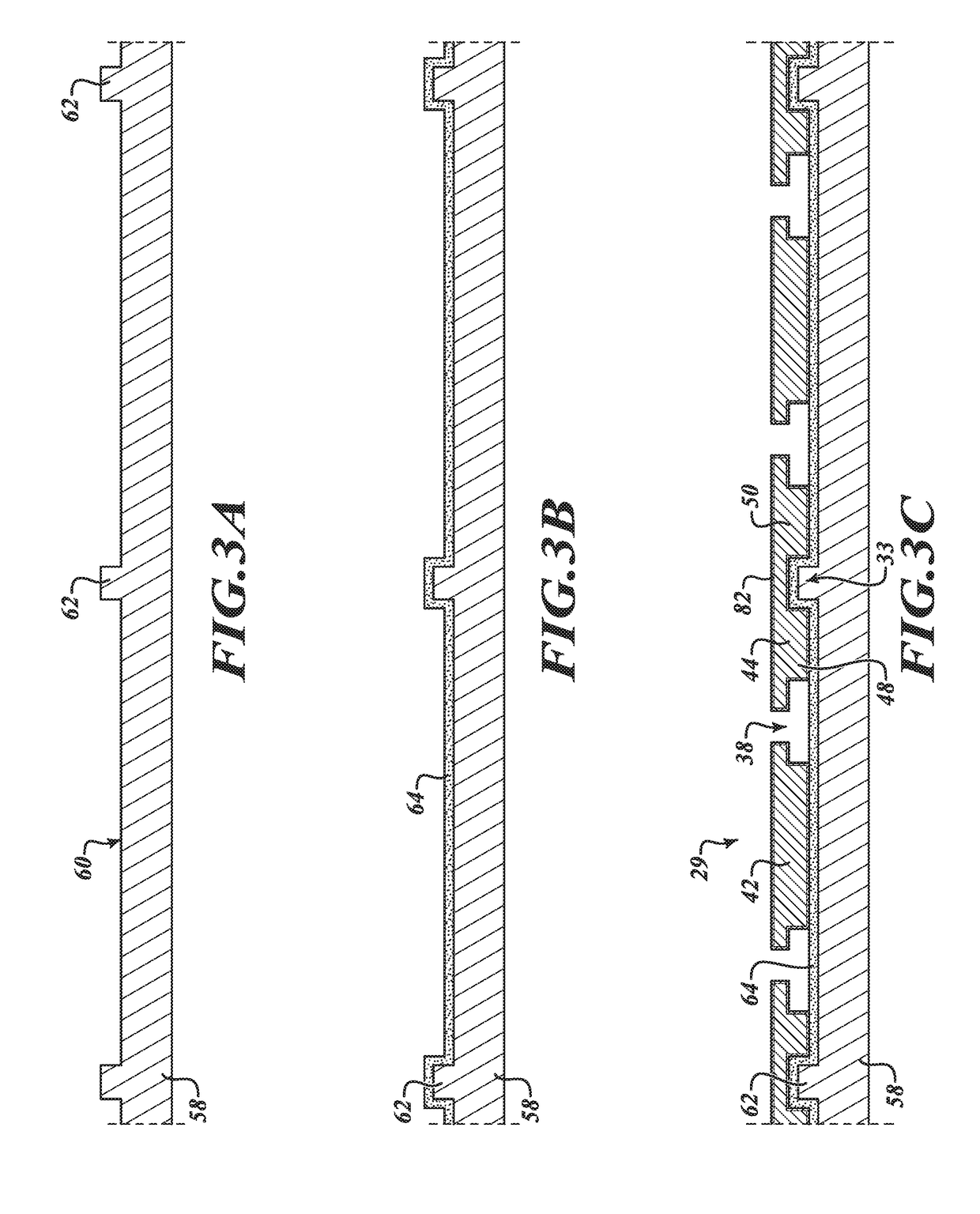

QFN pre-molded leadframe having a solder wettable sidewall on each lead

ActiveUS10079198B1Reduce the possibilityIncreased solder contact areaSemiconductor/solid-state device detailsSolid-state devicesEngineeringLead frame

The present disclosure is directed to a leadframe package having solder wettable sidewalls that is formed using a pre-molded leadframe and methods of manufacturing the same. A metal plated leadframe with a plurality of recesses and a plurality of apertures is placed into a top and bottom mold tool. A molding compound is then formed in the plurality of recesses and apertures in the leadframe to form a pre-molded leadframe. A plurality of die and wires are coupled to the pre-molded leadframe and the resulting combination is covered in an encapsulant. Alternatively, a bare leadframe can be processed and the metal layer can be applied after encapsulation. A saw or other cutting means is used for singulation to form leadframe packages. Each resulting leadframe package has a solder wettable sidewall for improving the strength of solder joints between the package and a circuit board.

Owner:STMICROELECTRONICS INT NV

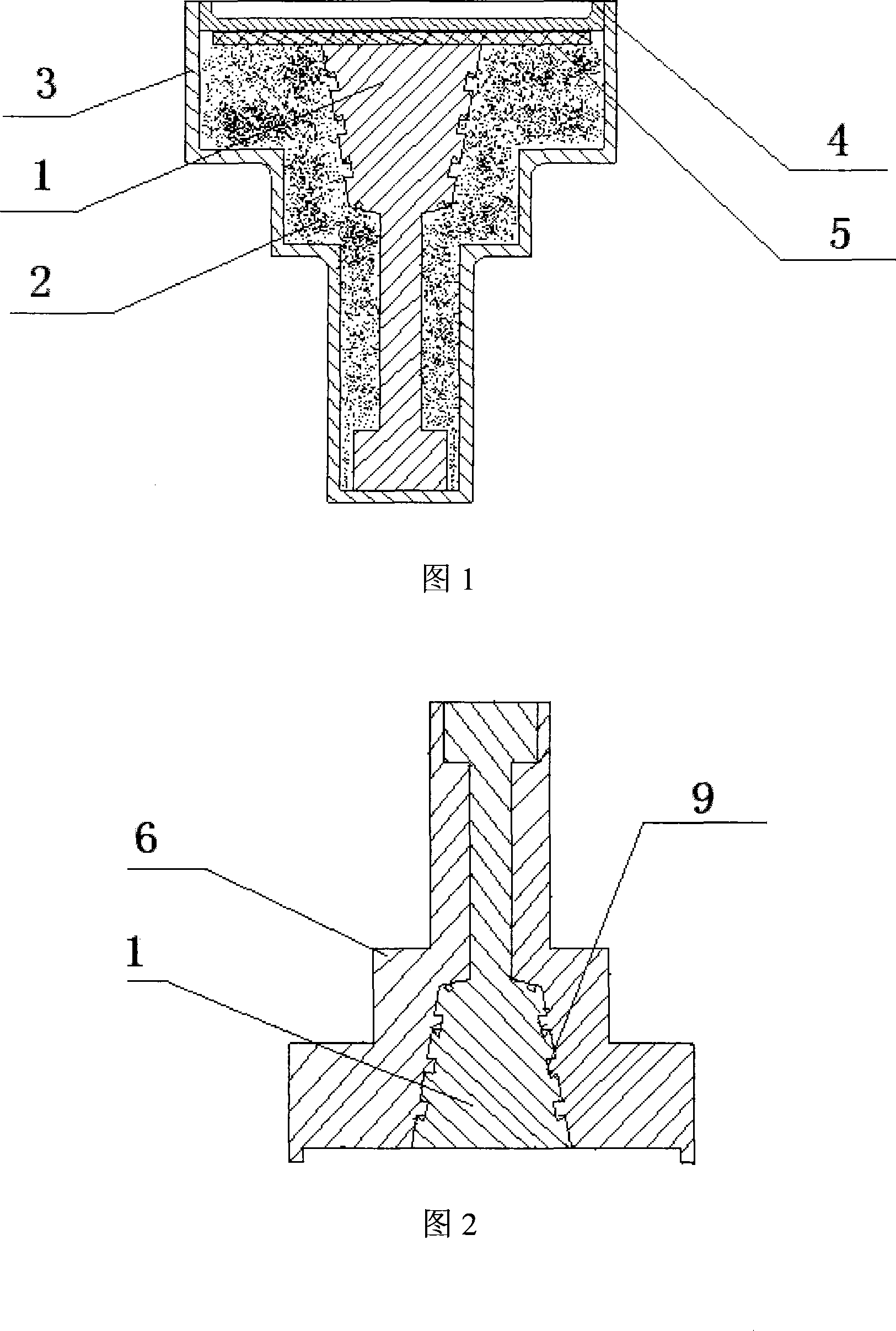

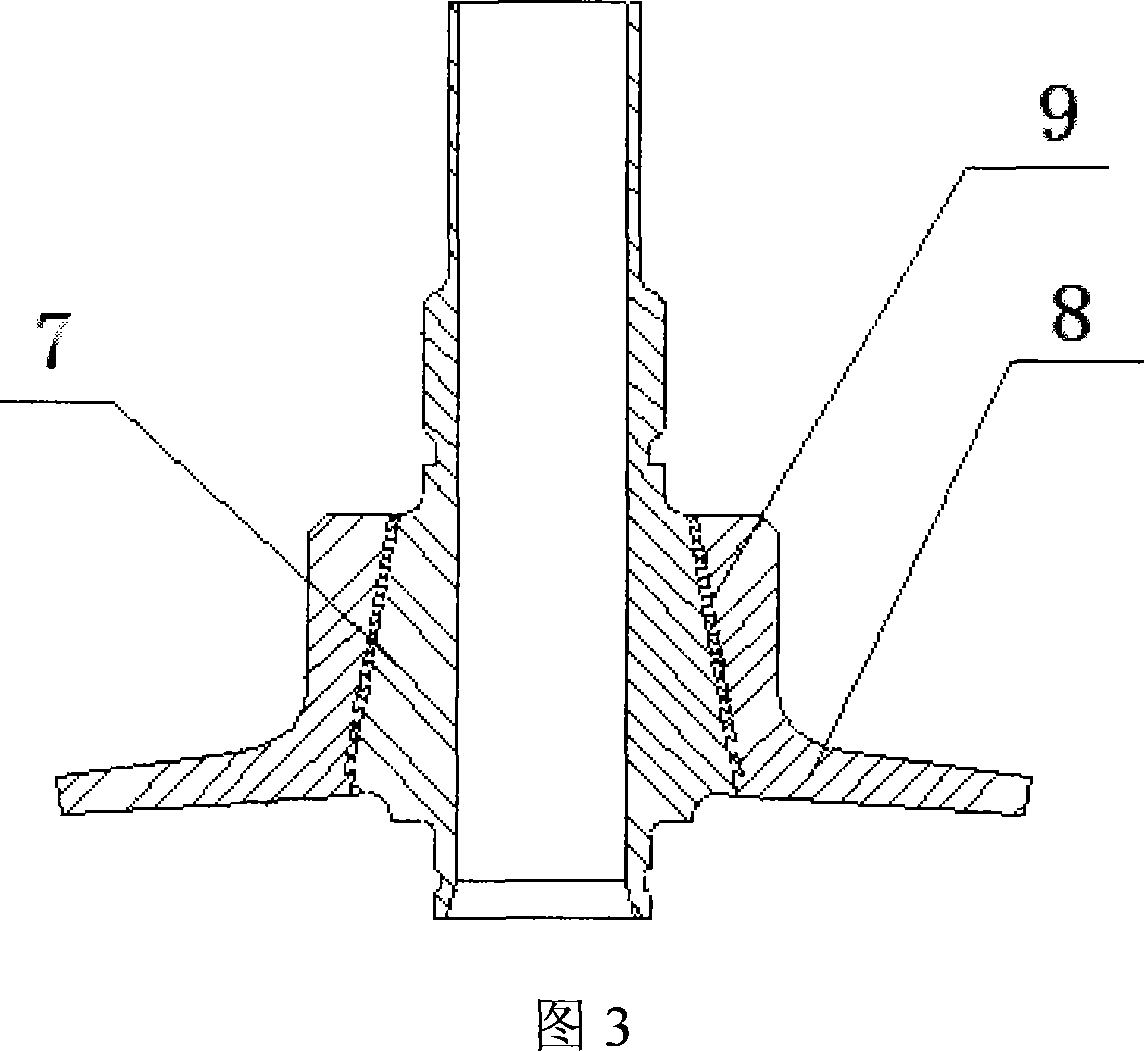

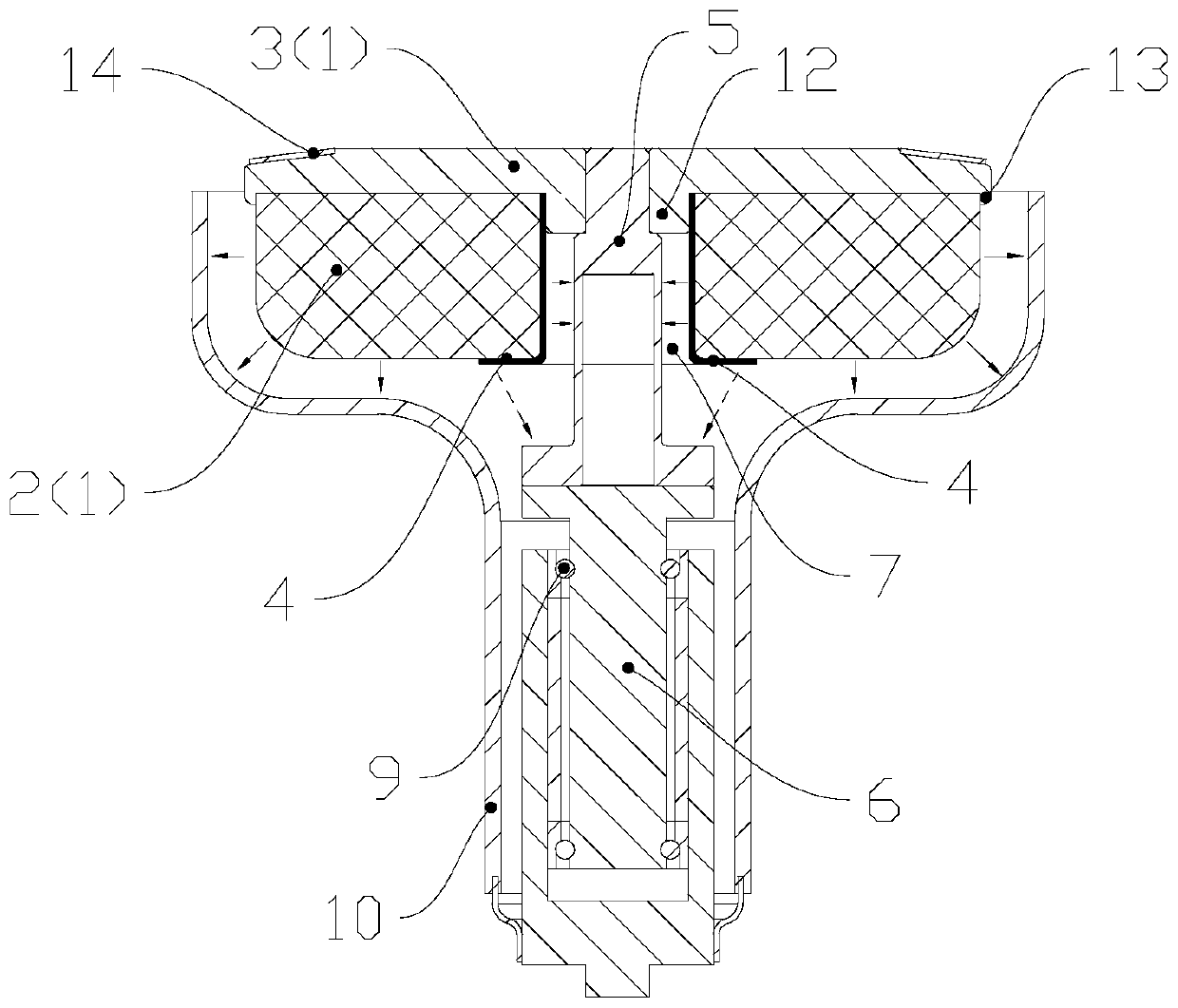

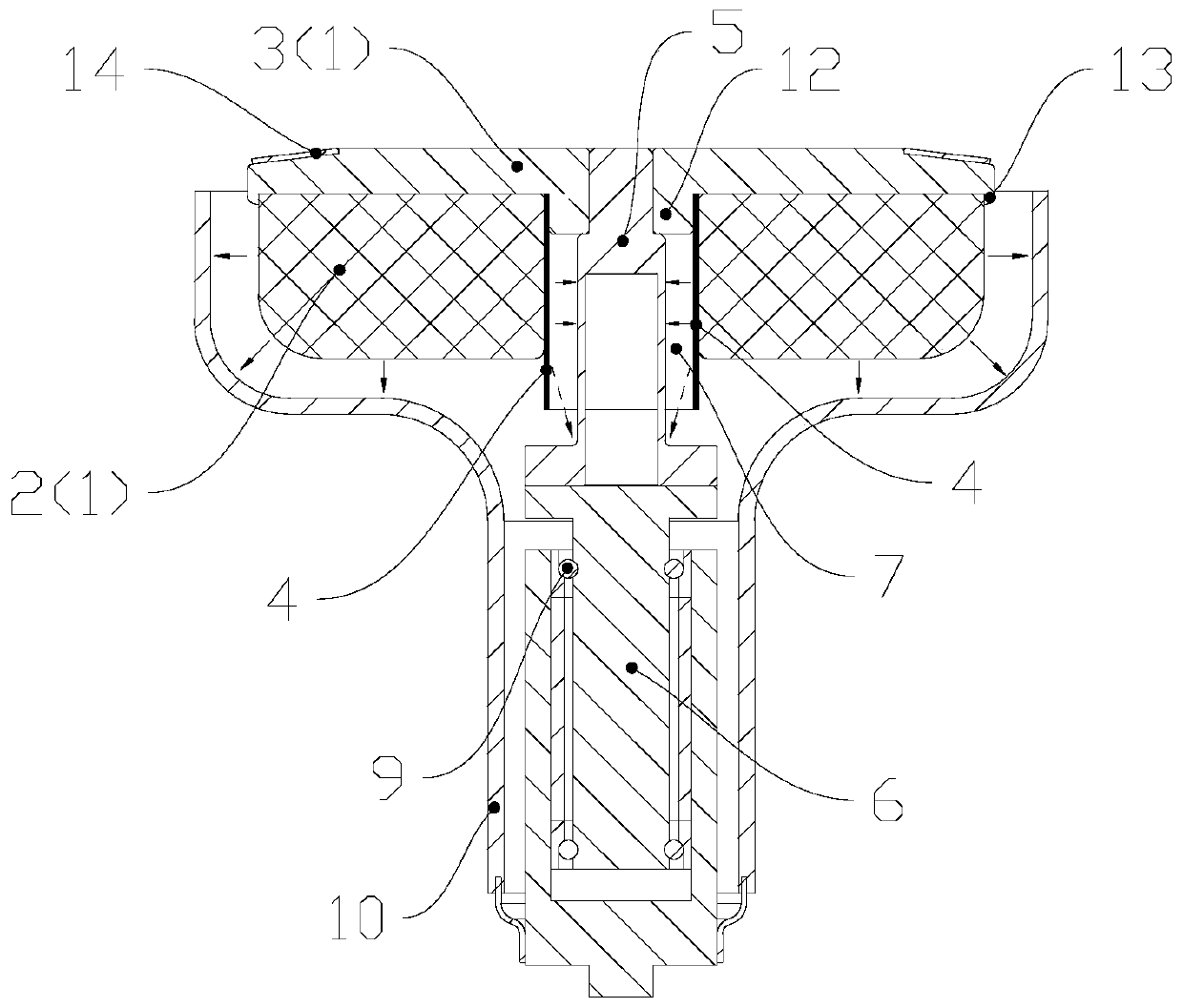

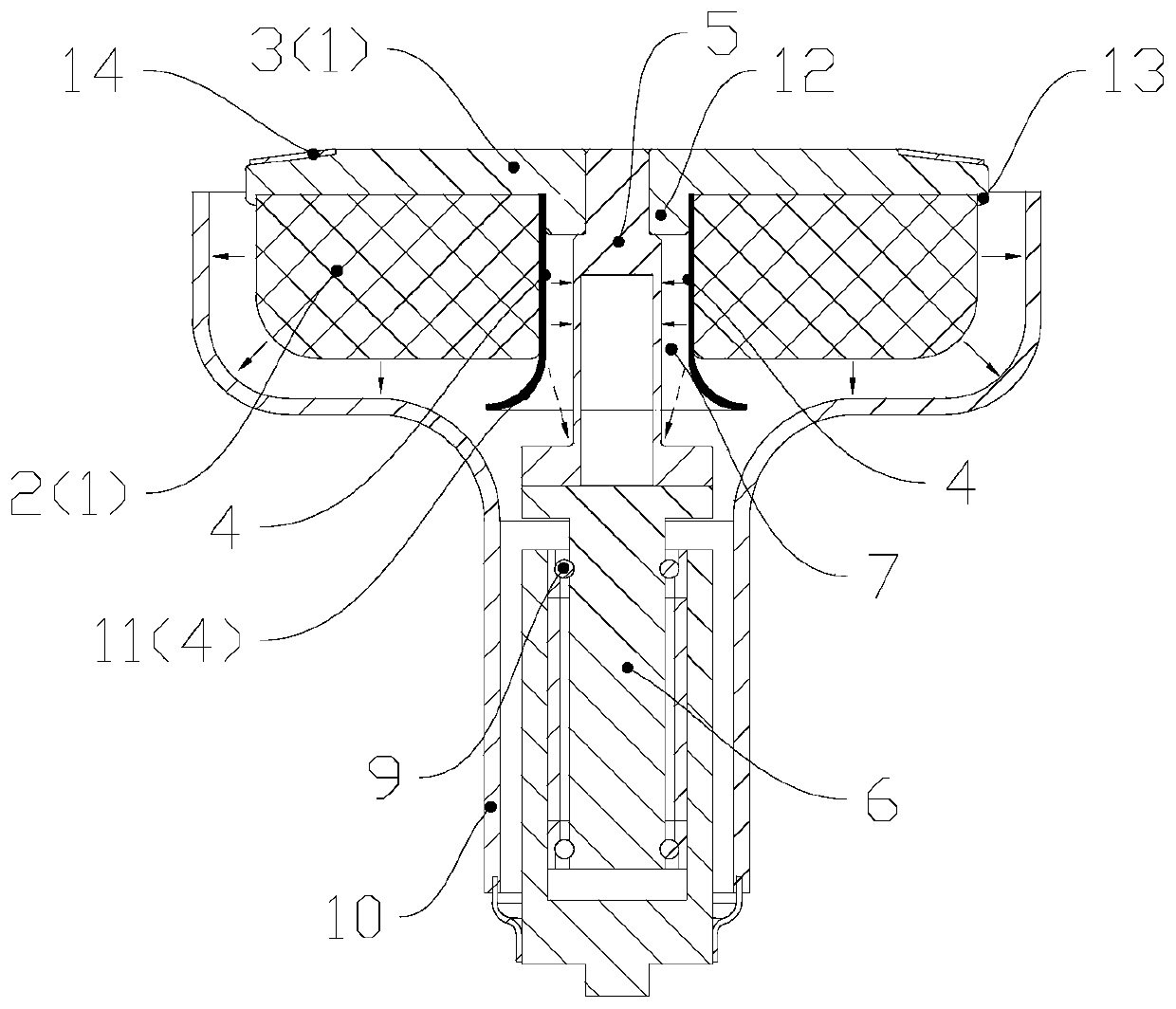

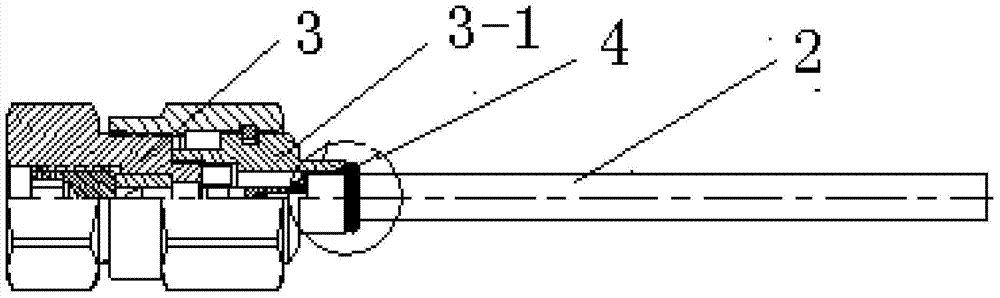

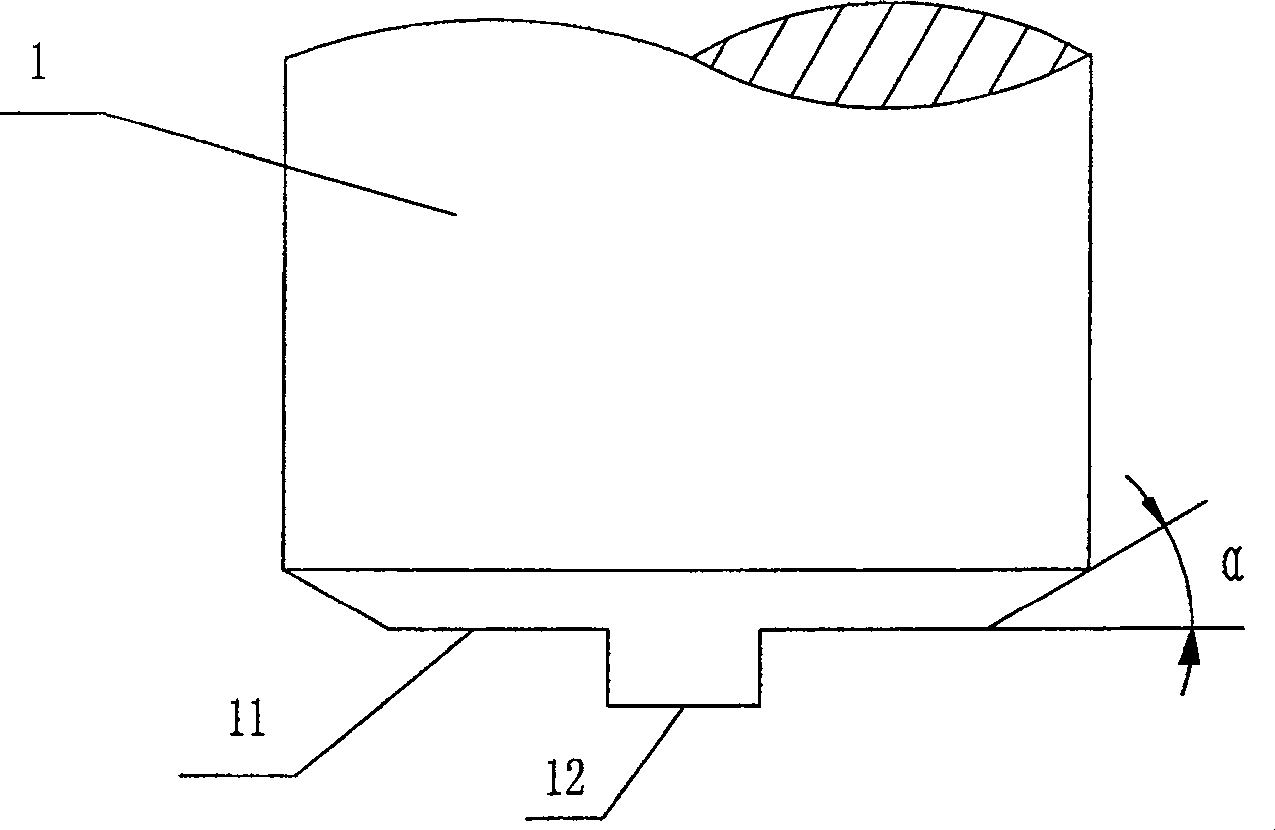

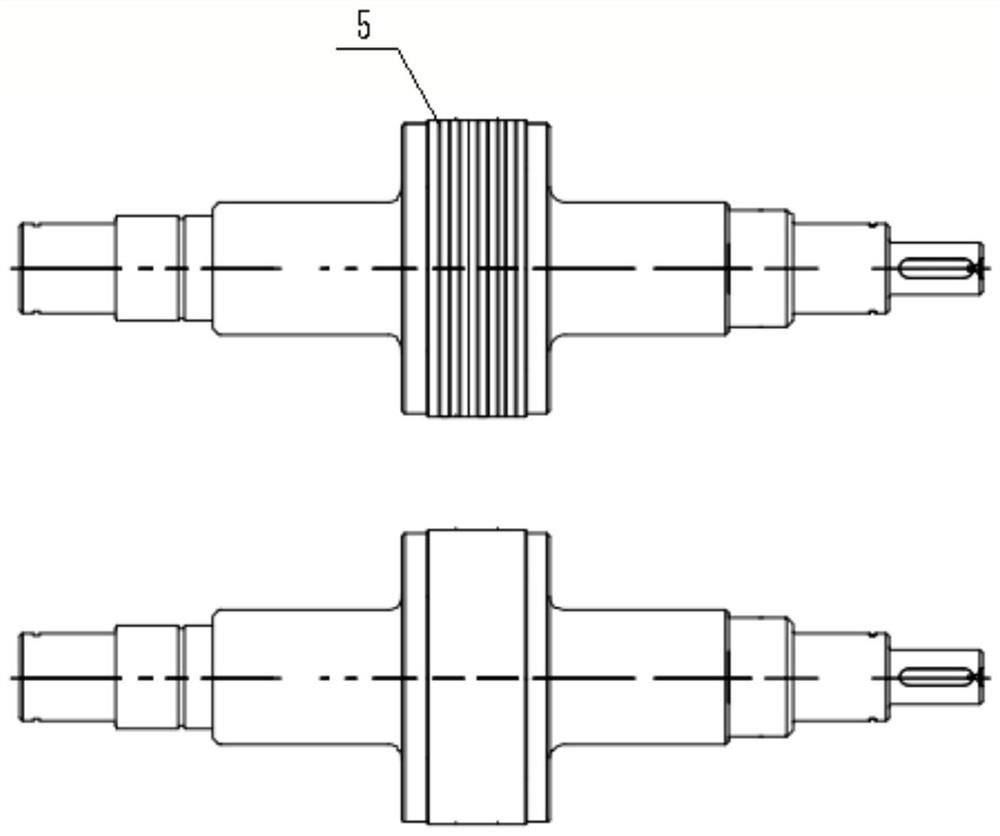

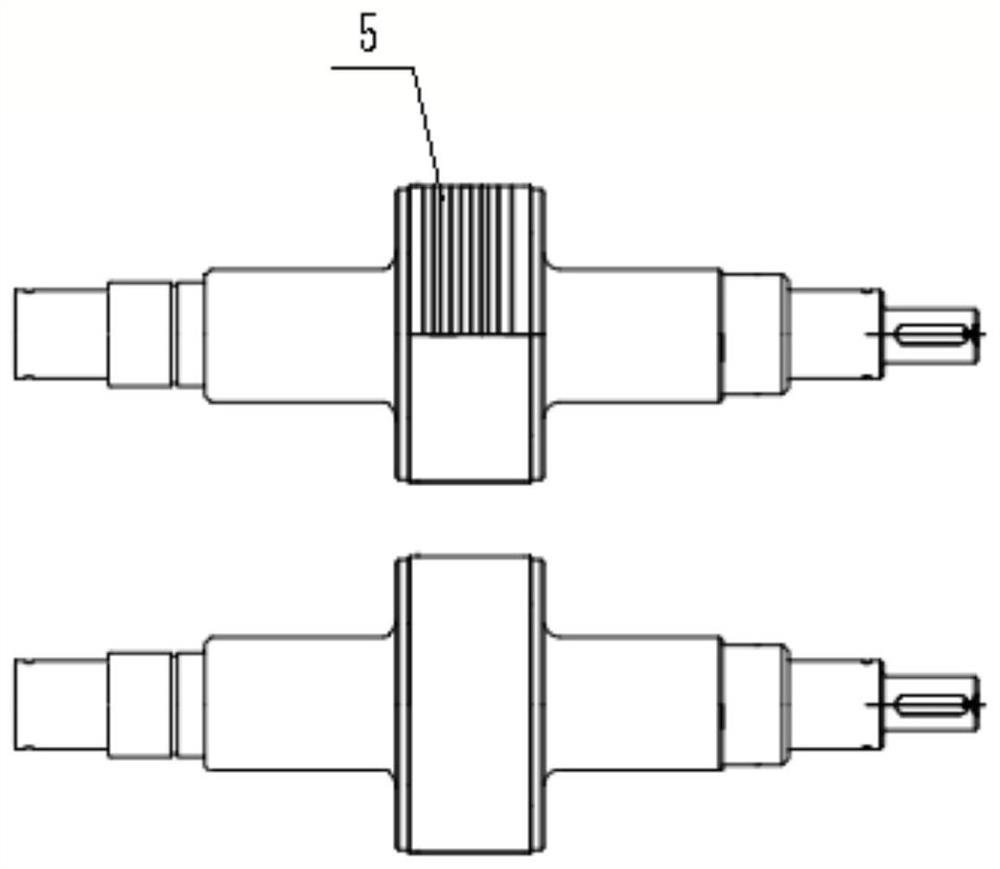

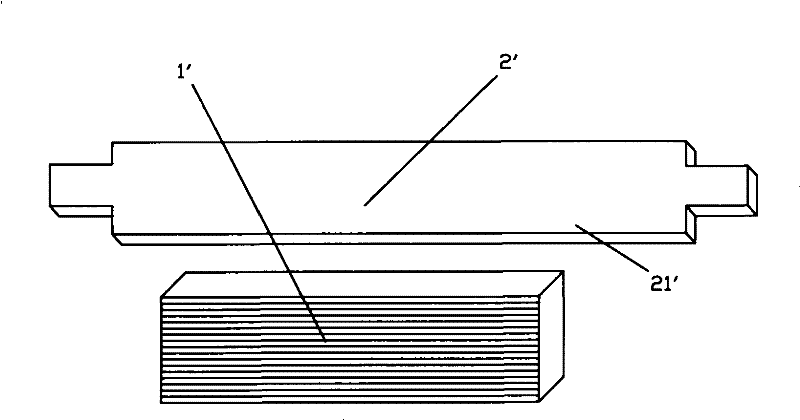

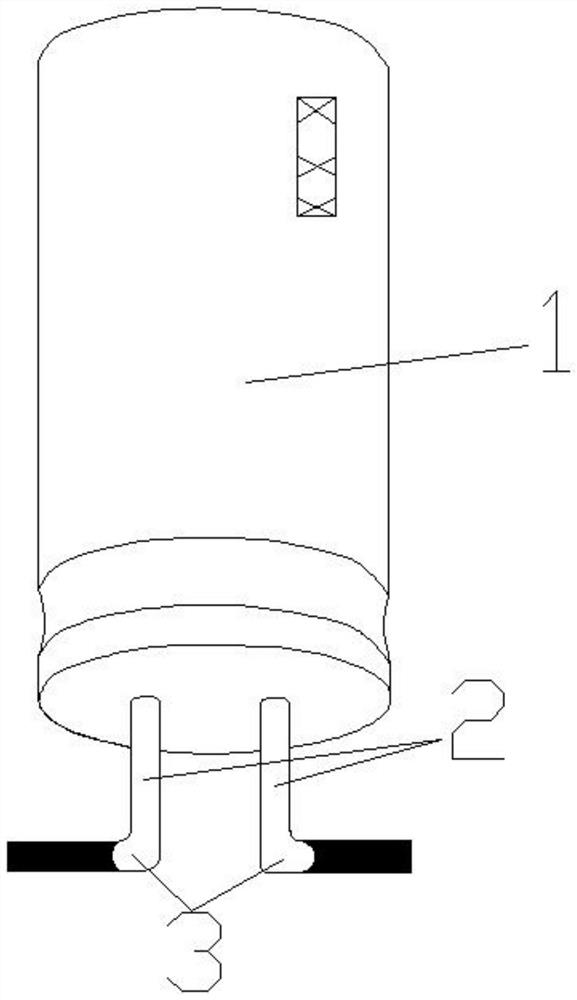

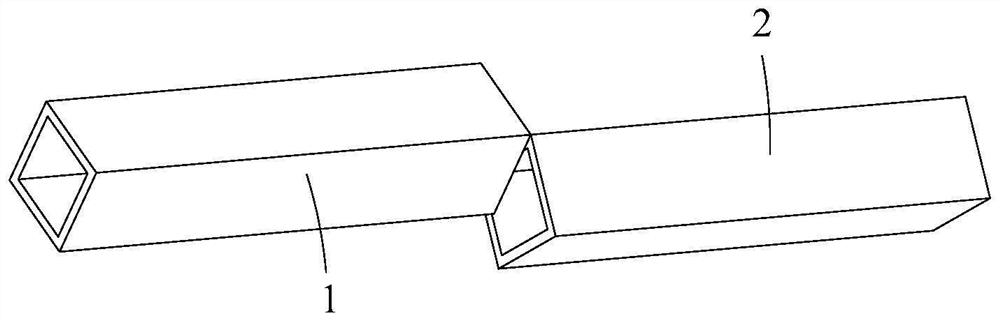

Method of preparing titanium steel composite liquid route connecting tube of the complex construction connecting surface

The present invention provides a method of manufacturing a compound liquid titanium steel nozzle whose joint surface has complicated structure, including procedures as following: (1) a surface of steel blank is provided with a transition layer; (2) the steel blank with the transition layer is put into a mold; (3) titanium alloy powder is arranged between the mold and the steel blank and the mold is sealed; (4) not isostatic pressing treatment for the sealed mold is practiced; (5) a blank of compound liquid titanium steel nozzle is taken out and made into the compound liquid titanium steel nozzle. The present invention adopts method of electroplate or ion plating to form a form a transition layer on the steel surface that is made up of Cu, Ni, Cr, Mo, and V, which not only increases contact area for titanium and steel but also forms a mechanical lock, thus, further improving joint strength of two metals mentioned-above. The present invention makes use of powder flowability of TC4 titanium alloy to realize that two metals can fully contact with each other at any complicated joint surface.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

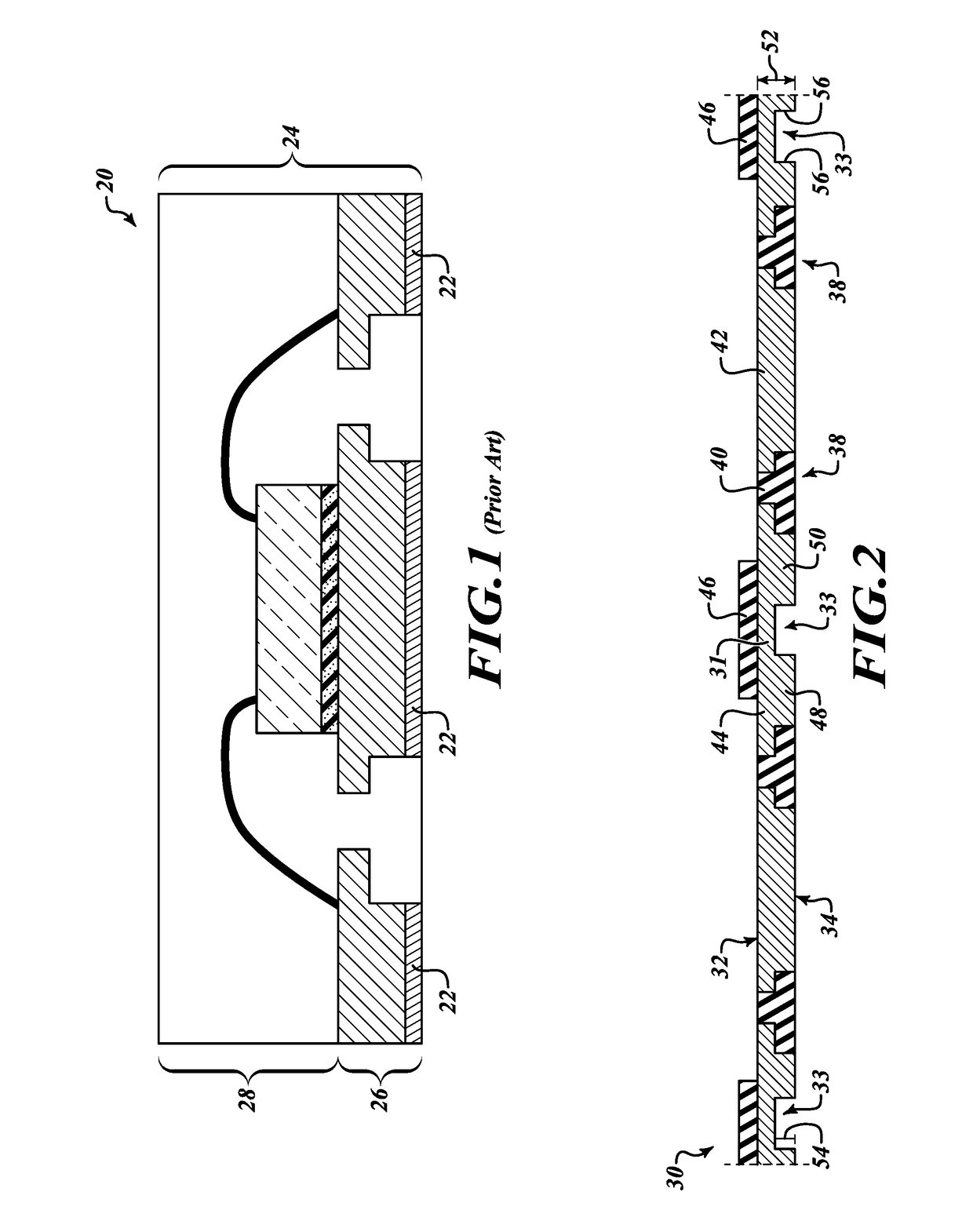

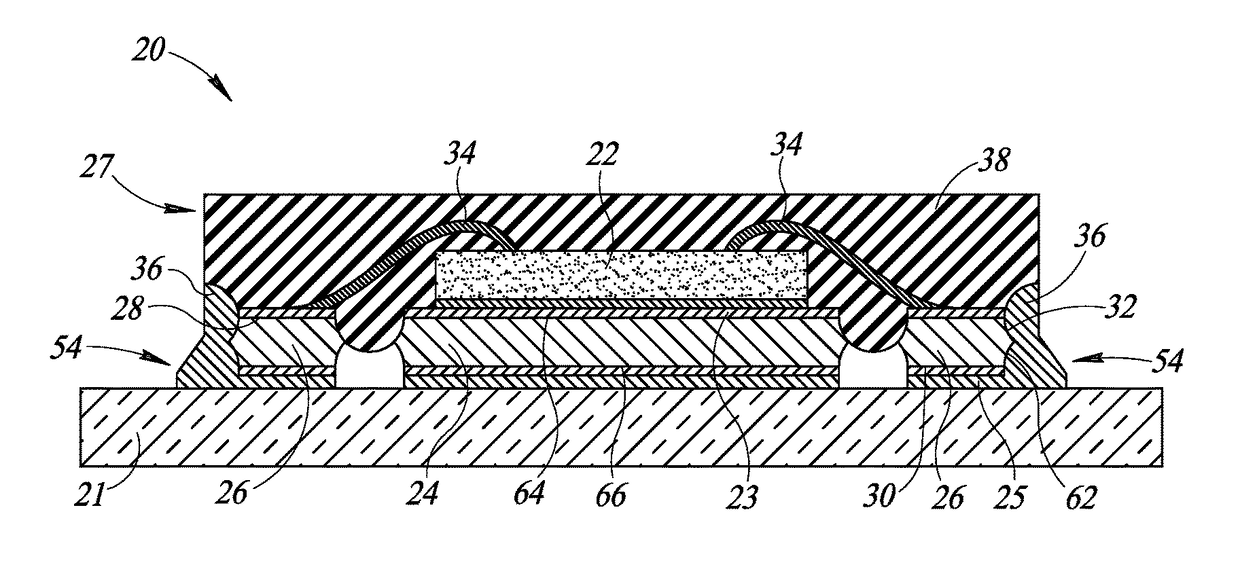

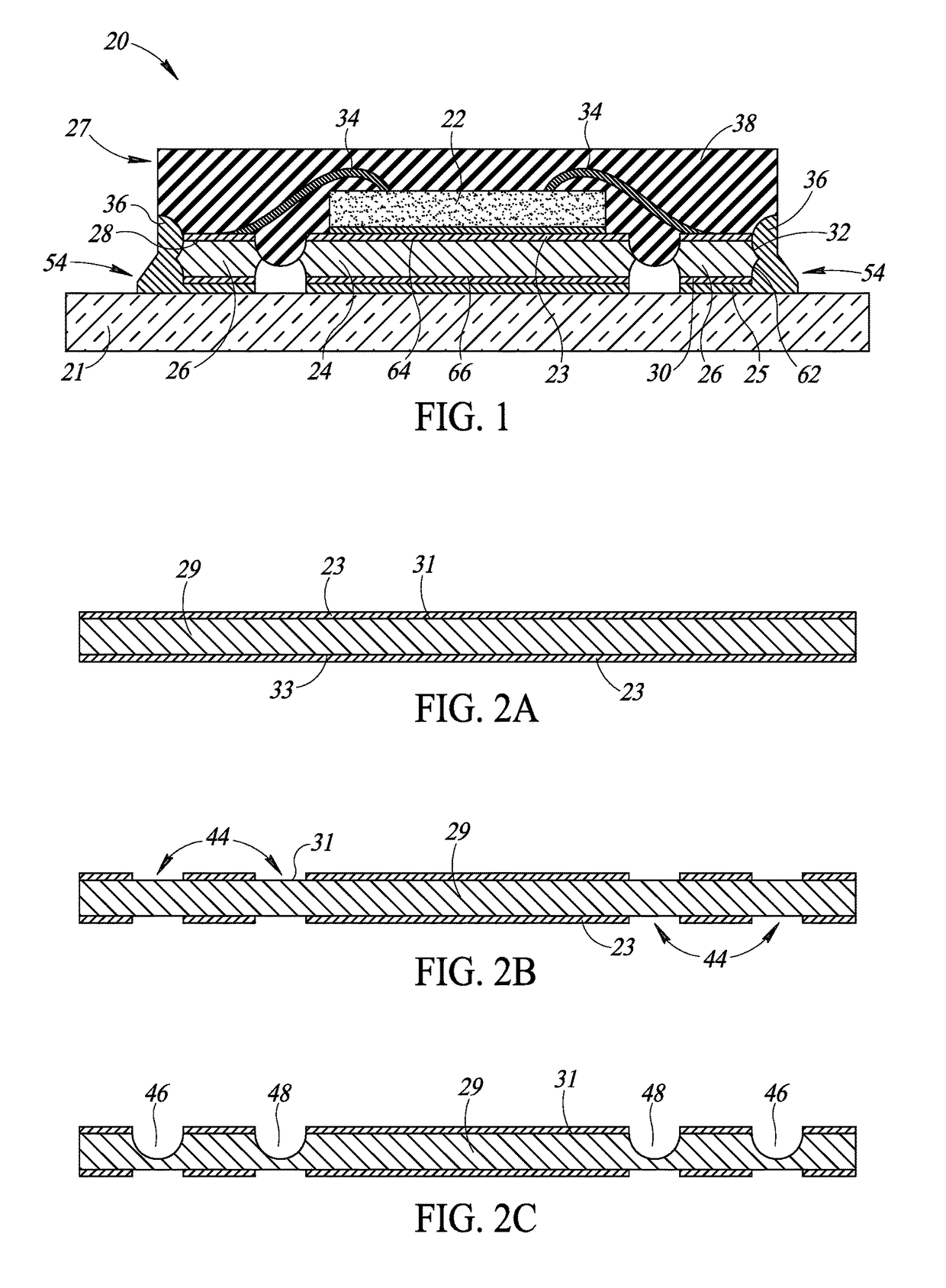

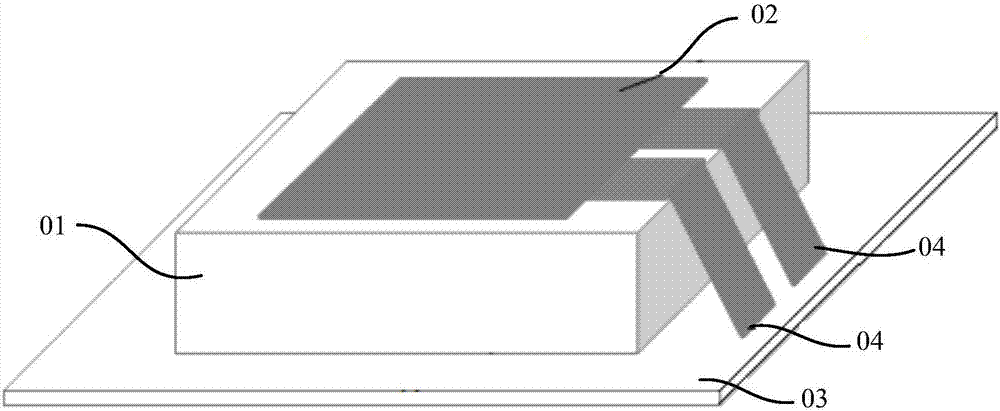

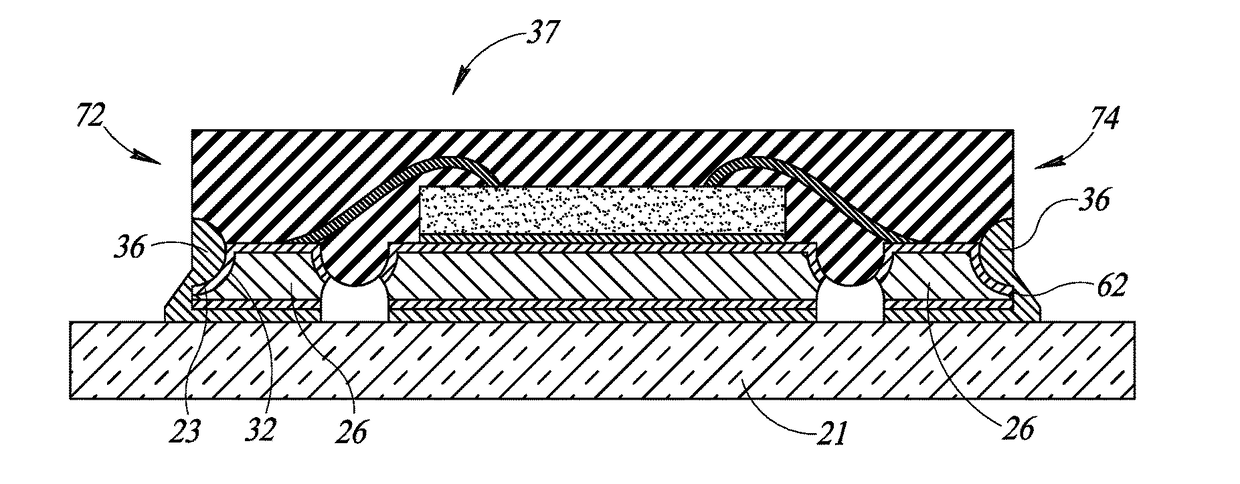

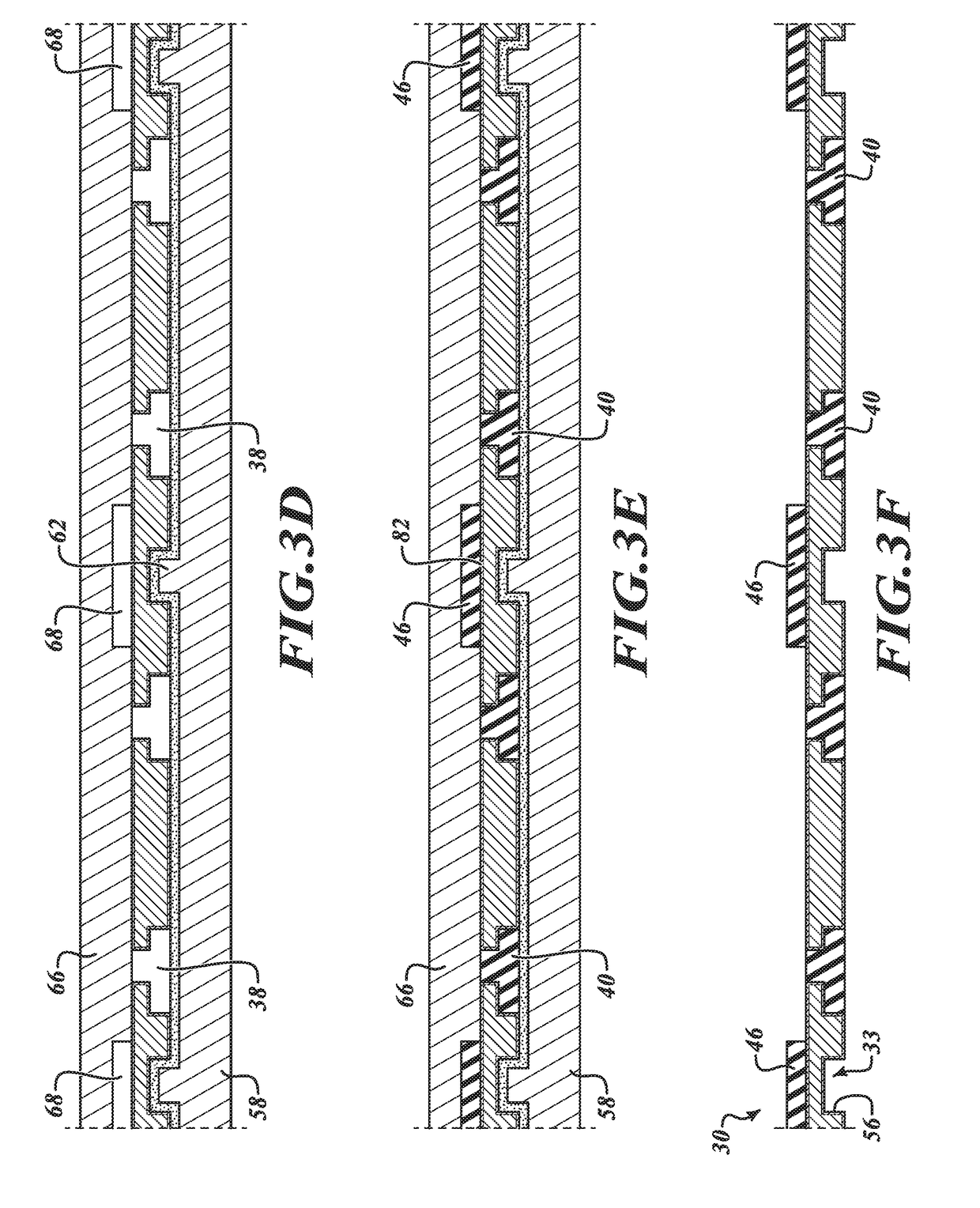

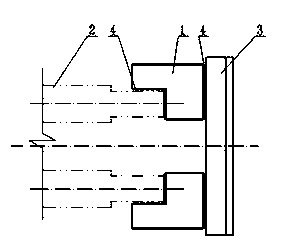

Leadframe package with side solder ball contact and method of manufacturing

ActiveUS9972558B1Increases solder contact areaLess resistantSemiconductor/solid-state device detailsSolid-state devicesSolder ballEngineering

The present disclosure is directed to a leadframe package having a side solder ball contact and methods of manufacturing the same. A plurality of solder balls are coupled to recesses in a leadframe before encapsulation and singulation. After singulation, a portion of each solder ball is exposed on sidewalls of the package. This ensures that the sidewalls of the leads are solder wettable, which allows for the formation of stronger joints when the package is coupled to a substrate. This increased adhesion reduces resistance at the joints and also mitigates the effects of expansion of the components in the package such that delamination is less likely to occur. As a result, packages with a side solder ball contact have increased life cycle expectancies.

Owner:STMICROELECTRONICS SRL

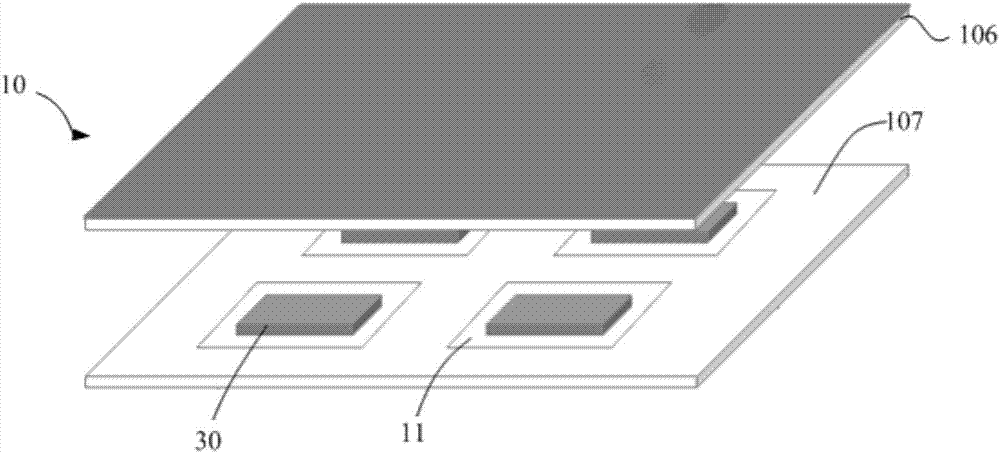

Antenna and wireless signal transceiver system

InactiveCN106876969AEnsure stabilityReduce decreaseRadiating elements structural formsIndoor communication adaptationElectricityTransceiver

The invention provides an antenna and a wireless signal transceiver system, and relates to the technical field of antennas. The influence of the internal material of an insulating substrate on the radiation efficiency, bandwidth and consistency of an antenna can be reduced. The antenna provided by an embodiment of the invention comprises an insulating substrate which consists of a first surface and a second surface opposite to the first surface. A radiating element layer is formed on the first surface. A hollowed-out area is formed inside the insulating substrate. The inner wall of the hollowed-out area is isolated from the first surface. The radiating element layer is connected with a grounding connector and a feeding connector. The antenna and the wireless signal transceiver system can be used in an indoor coverage system.

Owner:HUAWEI MACHINERY

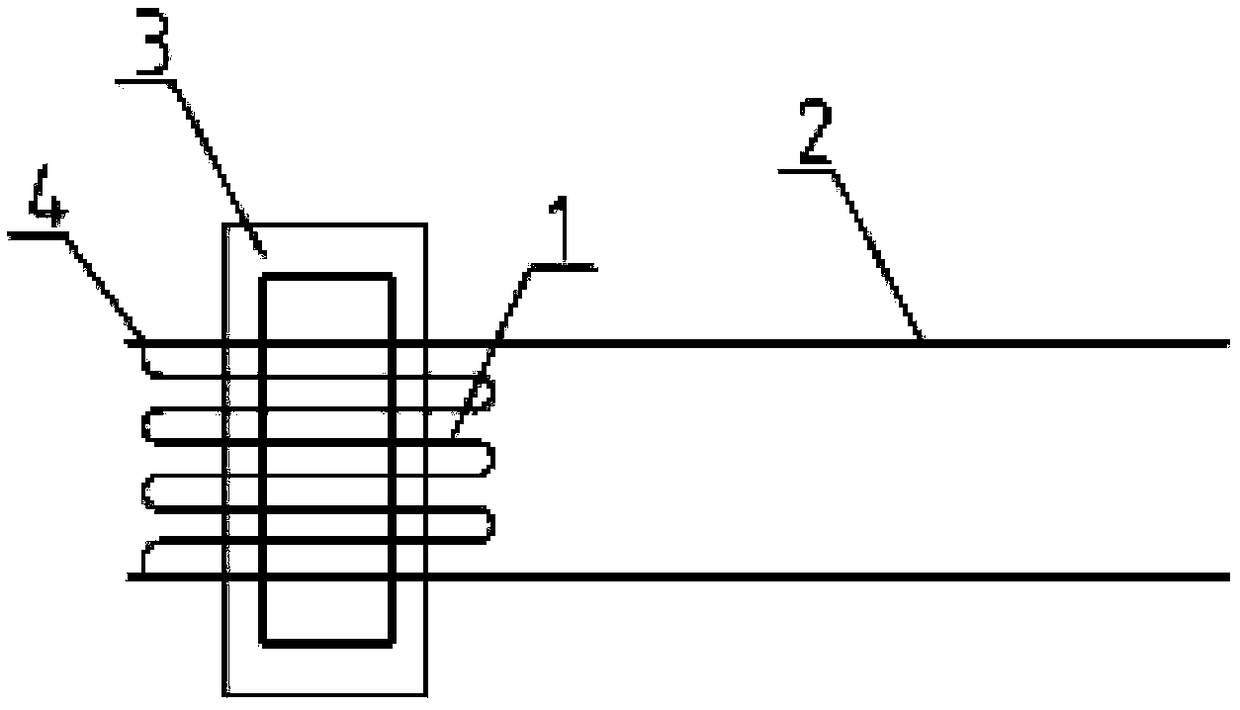

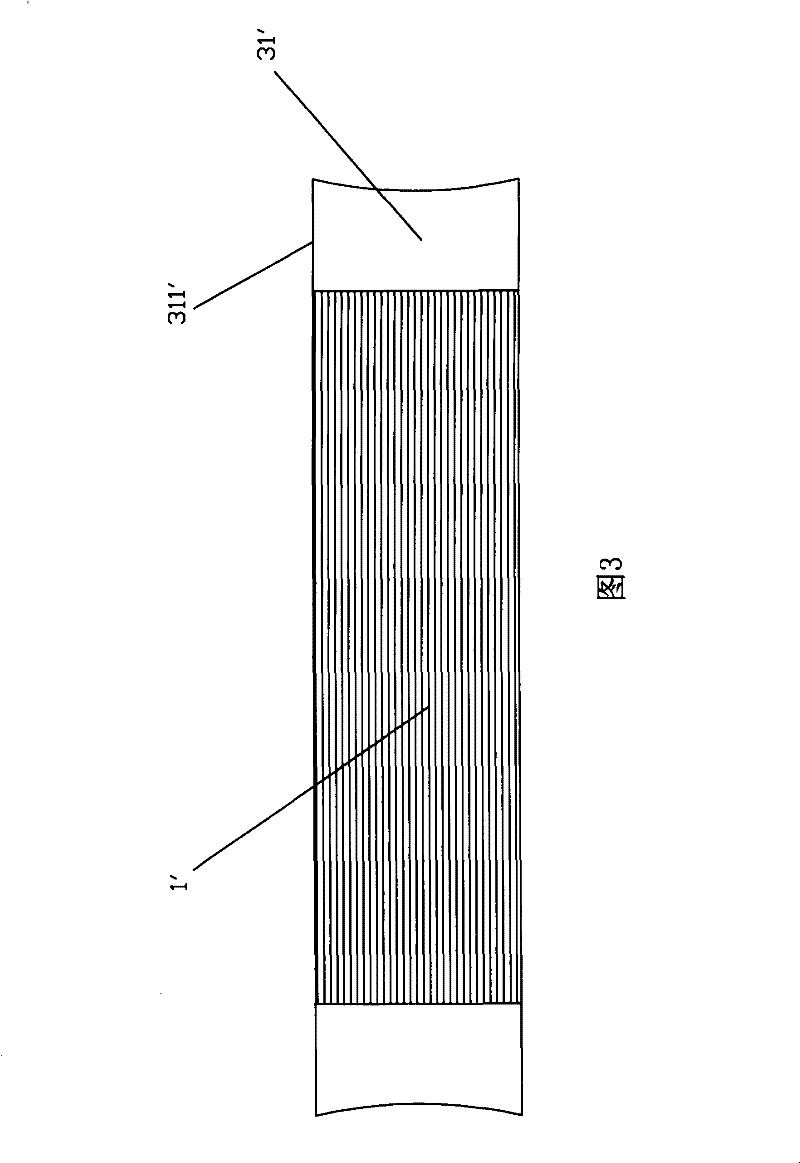

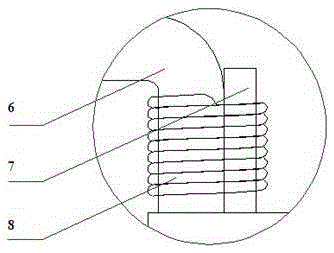

Temporary frame wire grid type high-temperature strain gauge and manufacturing and using method thereof

InactiveCN109059747AExcellent mechanical propertiesExcellent electrical propertiesElectrical/magnetic solid deformation measurementElectrical resistance and conductanceWire grid

The invention provides a temporary frame wire grid type high-temperature strain gauge and a manufacturing and using method thereof, and relates to the technical field of high-temperature strain testing. The temporary frame wire grid type high-temperature strain gauge comprises sensitive wire grid, lead wires, a temporary frame and welding spots. Wire materials are convoluted and wound into the shape of the sensitive wire grid through winding equipment; the sensitive wire grid and the lead wires are fused and tightly connected through resistance welding; and the sensitive wire grid and the leadwires are fixed on the temporary frame through nitrocellulose glue to form the temporary frame wire grid type high-temperature strain gauge. The high-temperature strain gauge is fixed on the surfaceof a tested piece through surface cleaning during using, primer or coating and curing, primary capping or coating and curing, integral capping or coating and curing. According to the temporary frame wire grid type high-temperature strain gauge and the manufacturing method thereof, resistance values are adjustable, the resistance dispersibility is less than + / -1 omega, and requirements of high-temperature strain measurement of room temperature at -1000 DEG C for a long time and 1000-1200 DEG C for a short time can be met.

Owner:UNIV OF SCI & TECH BEIJING

Rotary anode target for X-ray tube, preparation method and target assembly

PendingCN110556278AExtended service lifeAvoid direct heat radiationX-ray tube electrodesCold cathode manufactureTarget surfaceRadiation mode

The invention provides a rotary anode target for an X-ray tube, a preparation method and a target assembly. The anode target comprises a target disc and an annular cover. The target disc comprises a substrate and a target surface layer covering the substrate. A first center hole is formed in the center of the substrate. A second center hole is formed in the center of the target surface layer. Theannular cover covers the inner circumferential side wall of the first center hole and is connected with the substrate, and the annular cover is used for reducing or blocking the diffusion of the heatemitted by the substrate. The rotary anode target can reduce the heat transmitted to a rotating shaft or a bearing in a heat radiation mode, obviously reduces the temperature of a metal ball, and prolongs the service lives of the bearing and the X-ray tube. Moreover, the power continuously loaded by the X-ray tube is higher, and more patients can be scanned in unit time.

Owner:安泰天龙钨钼科技有限公司 +2

Leadframe package with side solder ball contact and method of manufacturing

ActiveUS20180286789A1Increased solder contact areaReduce in quantitySemiconductor/solid-state device detailsSolid-state devicesSolder ballEngineering

The present disclosure is directed to a leadframe package having a side solder ball contact and methods of manufacturing the same. A plurality of solder balls are coupled to recesses in a leadframe before encapsulation and singulation. After singulation, a portion of each solder ball is exposed on sidewalls of the package. This ensures that the sidewalls of the leads are solder wettable, which allows for the formation of stronger joints when the package is coupled to a substrate. This increased adhesion reduces resistance at the joints and also mitigates the effects of expansion of the components in the package such that delamination is less likely to occur. As a result, packages with a side solder ball contact have increased life cycle expectancies.

Owner:STMICROELECTRONICS SRL

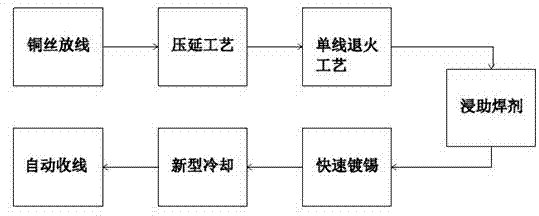

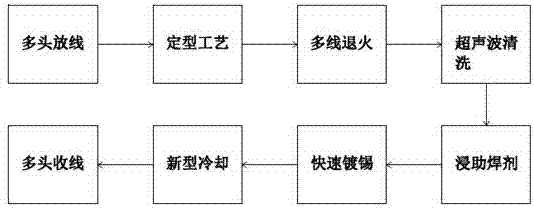

Production process of high-efficient multi-grid welding strip

InactiveCN107160058AImprove local overheatingIncreased solder contact areaHot-dipping/immersion processesWelding/cutting media/materialsCopper wireEllipse

The invention discloses a production process of a high-efficient multi-grid welding strip. The process comprises the following steps: 1) paying off copper wires; 2) carrying out calender setting; 3) annealing; 4) soaking in soldering flux; 5) quickly tin-plating; 6) cooling; 7) taking up the wires. According to the production process, under a condition of guaranteeing the specification of a round wire welding strip, the round wire is made into an ellipse wire, so that the welding contact area of the round wire and an assembly battery cell is increased; moreover, under a condition of guaranteeing the welding performance of the round wire, the local overheat phenomenon of the assembly battery cell is improved.

Owner:苏州赛历新材料科技有限公司

Qfn pre-molded leadframe having a solder wettable sidewall on each lead

ActiveUS20180358286A1Reduce the possibilityIncreased solder contact areaSemiconductor/solid-state device detailsSolid-state devicesEngineeringLead frame

The present disclosure is directed to a leadframe package having solder wettable sidewalls that is formed using a pre-molded leadframe and methods of manufacturing the same. A metal plated leadframe with a plurality of recesses and a plurality of apertures is placed into a top and bottom mold tool. A molding compound is then formed in the plurality of recesses and apertures in the leadframe to form a pre-molded leadframe. A plurality of die and wires are coupled to the pre-molded leadframe and the resulting combination is covered in an encapsulant. Alternatively, a bare leadframe can be processed and the metal layer can be applied after encapsulation. A saw or other cutting means is used for singulation to form leadframe packages. Each resulting leadframe package has a solder wettable sidewall for improving the strength of solder joints between the package and a circuit board.

Owner:STMICROELECTRONICS INT NV

Cable and cable connector welding process

InactiveCN103943974AIncreased solder contact areaImprove stabilitySoldered/welded conductive connectionsElectrical performanceContact position

The invention discloses a cable and cable connector welding process. The cable and cable connector welding process comprises the following steps of (a) pressing a tin wire to be flat and manufacturing a flat tin wire; (b) winding the flat tin wire on the contact position of a cable and a cable connector; (c) inserting the contact position of the cable and the cable connector into the cable connector; (d) wrapping a circle of non-pressed tin wire on the cable and enabling the non-pressed tin wire to tightly abut against the outer end of a casing of the cable connector; (e) heating the casing of the cable connector and finishing welding. The cable and cable connector welding process can enable the welding position to be evenly welded and accordingly improve the stability in a dynamic state. In addition, the welding time can be shortened, heat is prevented from influencing the matching size, and accordingly the electrical performance of the cable is improved.

Owner:EZCON TELECOM TECHCHANGZHOU

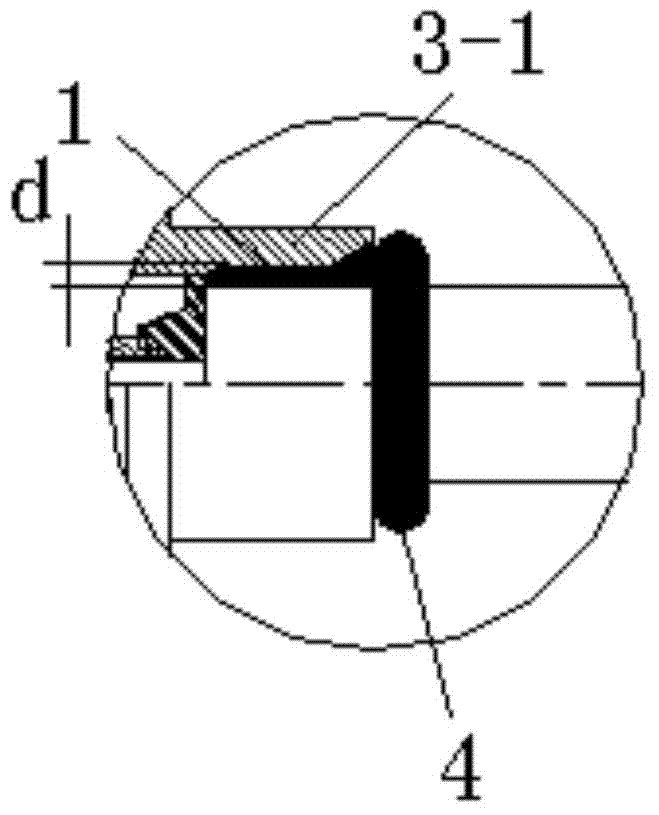

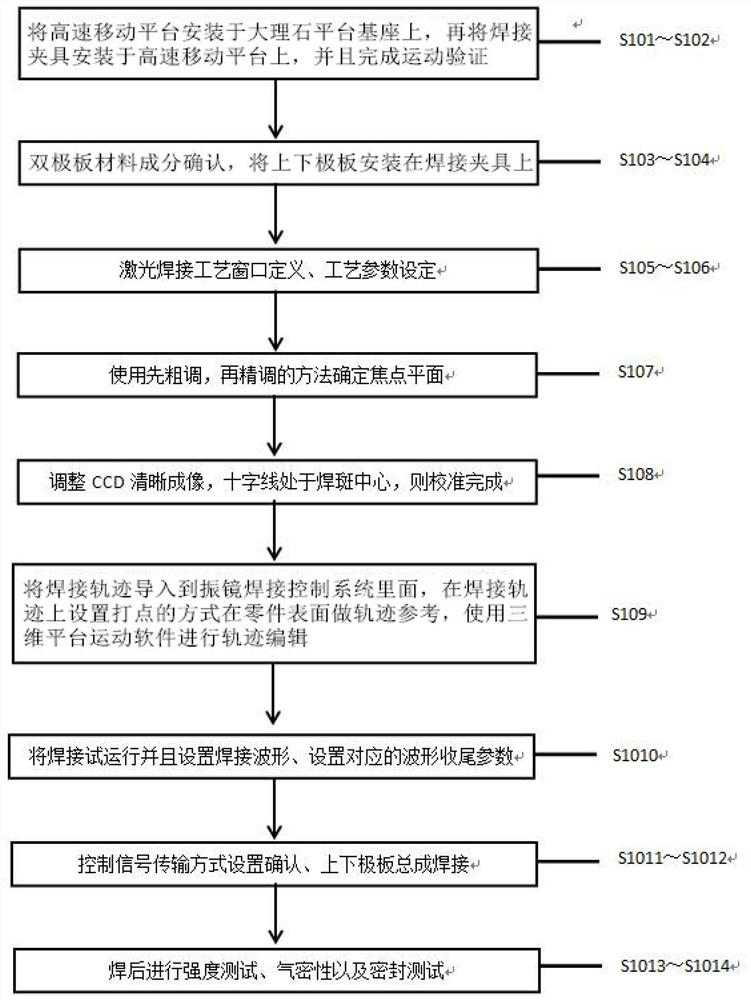

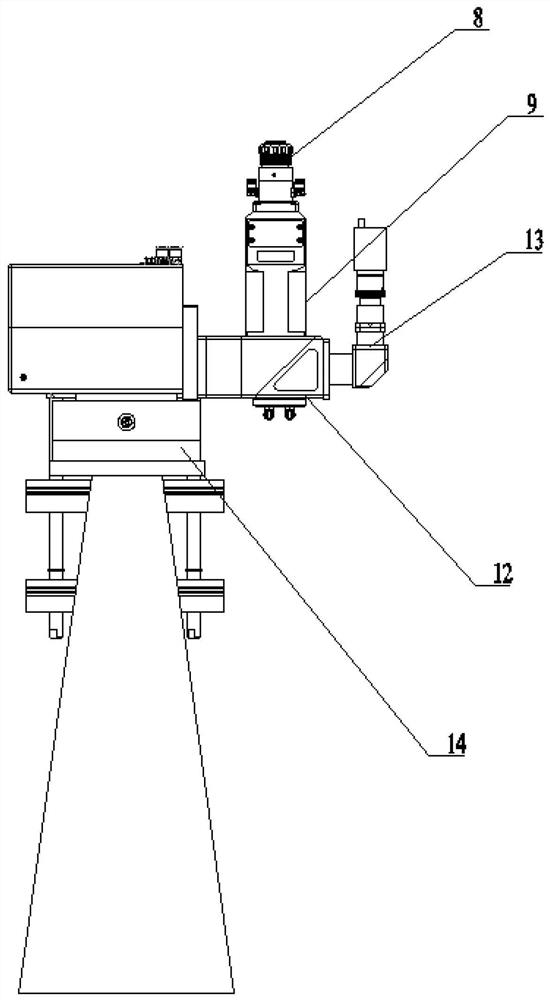

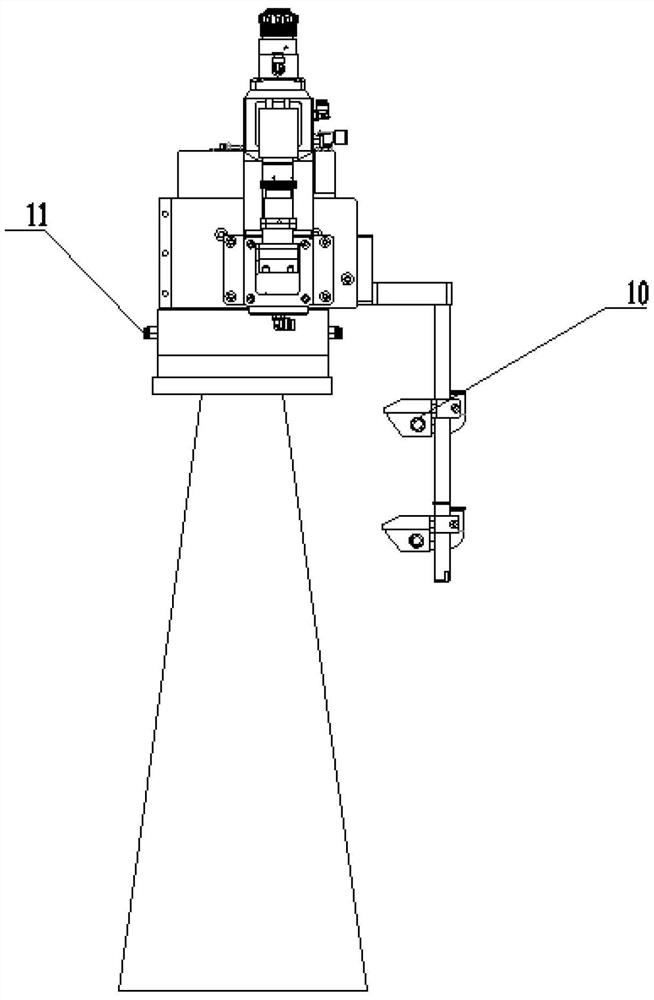

Hydrogen energy automobile bipolar plate ultrahigh-speed precision welding process and welding clamp thereof

ActiveCN113020794AIncrease profitIncreased solder contact areaLaser beam welding apparatusUltra high speedHydrogen fuel cell

The invention discloses a hydrogen energy automobile bipolar plate ultrahigh-speed precision welding process and a welding clamp thereof, and belongs to the field of hydrogen energy automobile production. A bipolar plate to be welded is included and installed on the welding clamp, the bipolar plate is moved to the mechanical welding position through a high-speed moving platform, characteristic information preset on the bipolar plate is grabbed after photographing and compared with characteristics in a photographing template, a laser beam passes through an axial lens of a galvanometer, a second shaft of the galvanometer drives the laser beam to move to the welding track end point from the welding track starting point, a complete welding line is finally formed along with movement of the galvanometer, an upper single-pole plate and a lower single-pole plate are welded together, and welding of the bipolar plate is achieved. When the process is used for welding the bipolar plate, the welding process and the welding line width are extremely stable, obvious fluctuation is avoided, the pseudo soldering problem is not likely to happen, the welding strength is high, the welding line is flat, the overcurrent capacity of the welding line is guaranteed, and the product performance of a hydrogen fuel cell is greatly improved.

Owner:龙俊耀

Method of welding electrode for vacuum consumable arc-melting

InactiveCN100493797CStrong after weldingPrevent fallingArc welding apparatusWelding/soldering/cutting articlesCrucibleEngineering

The invention discloses a welding method for an electrode used for consumable vacuum arc melting. The method relates to: lathing two ends of an upper part electrode and a lower part electrode that are butt welded; processing the welding end of the upper part electrode into a lug boss; processing the welding end of the lower part electrode into a groove; arranging the processed upper part electrode into a consumable vacuum arc furnace with the lug boss facing downwards; arranging the lower part electrode in a pot in the consumable vacuum arc furnace and locating with the groove surface facing upwards; arranging an arc striking material on a salient part at the core part of the lower part electrode, sealing the consumable vacuum arc furnace and welding after cacuumizing. The invention has a simple structure and a good centering effect between the upper part electrode and the lower part electrode; and when welding, an alloy liquor filling groove melted by arc starting can not overflow to the circle surface of the electrode, thus avoiding crack, 'nuble' or scrap rubber at the location of a welding line; thereby ensuring the welding quality. The welding contact area is large and can not generate rosin joint; the electrode after welded is firm and can avoid falling off when melting.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

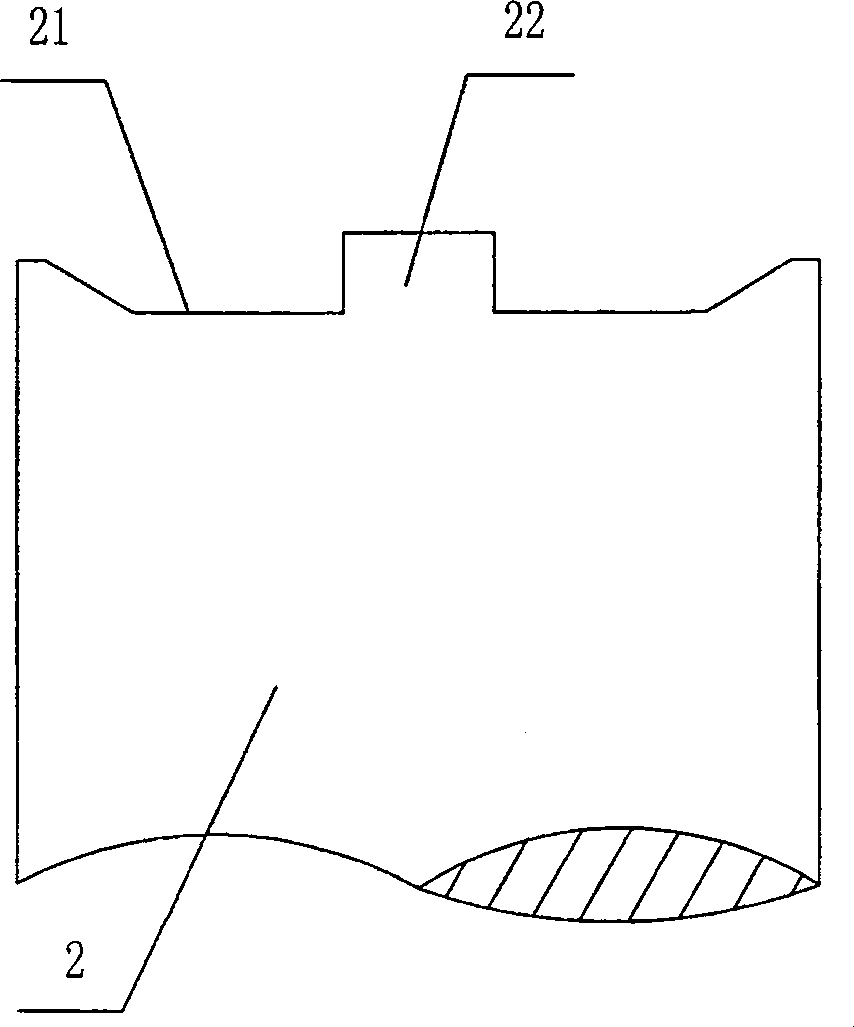

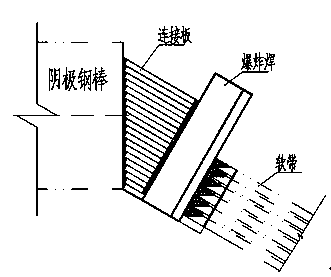

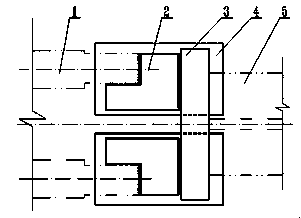

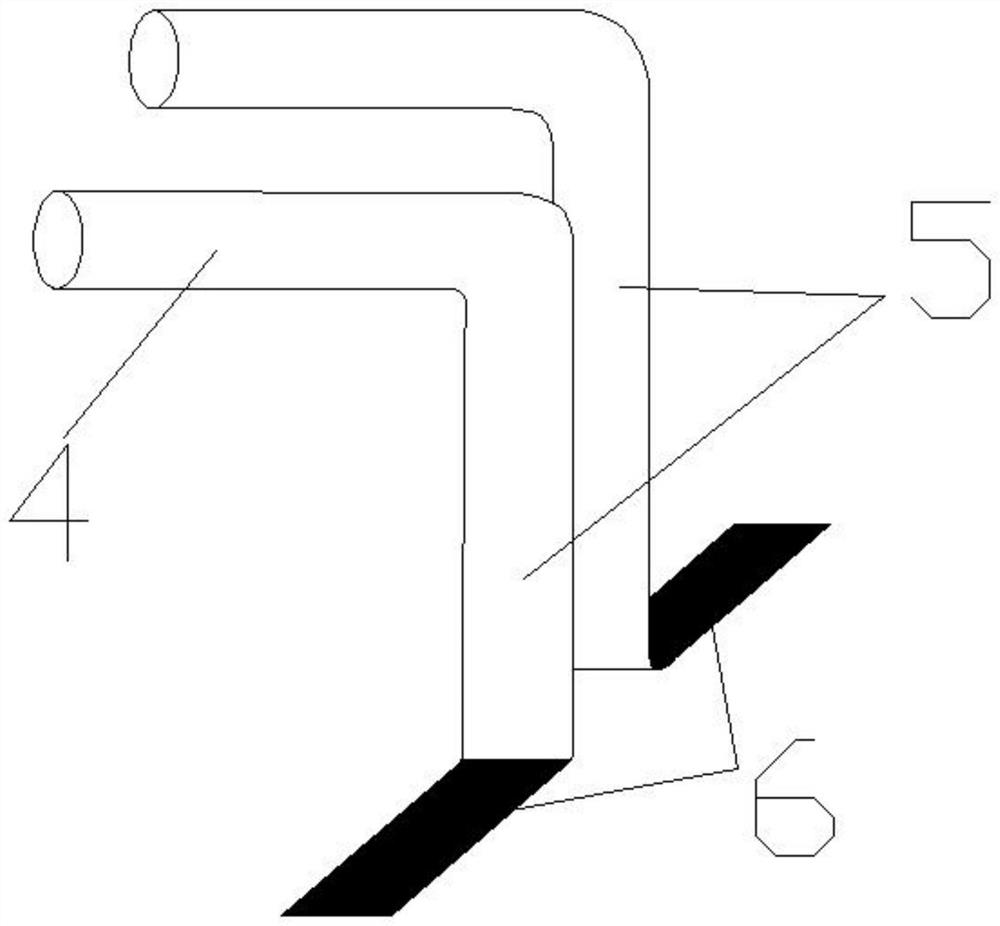

Electrolytic bath cathode steel bar and soft aluminum strip connection configuration structure

InactiveCN103510112ALower cathode pressure dropPlay a role in supporting the construction processSteel barWeld seam

The invention discloses an electrolytic bath cathode steel bar and soft aluminum strip connection configuration structure, which is characterized in that: cathode steel bars (1) and a soft aluminum strip (5) are connected through connecting plates (2), a steel-aluminum explosive welding block (3) and backing plates (4). Specifically, the cathode steel bars (1) and the connecting plates (2), and the steel-aluminum explosive welding block (3) and the soft aluminum strip (5) are connected by means of welding. The backing plates (4) are located below the connecting plates (2) and the steel-aluminum explosive welding block (3). The connecting plates (2), the steel-aluminum explosive welding block (3) and the backing plates (4) are connected by welding. The connecting plates (2) are rectangular or ''L'' shaped. By means of non-rectangular treatment on the connecting plates, the connecting plates are welded with the end faces and the sides of the cathode steel bars, the welding seam is increased, and the welding contact area is enlarged, thus reaching the purpose of lowering the electrolytic bath cathode drop. And the backing plates below the cathode steel bars and the steel-aluminum explosive welding block play a role of supporting the construction process.

Owner:GUIYANG AL-MG DESIGN & RES INST

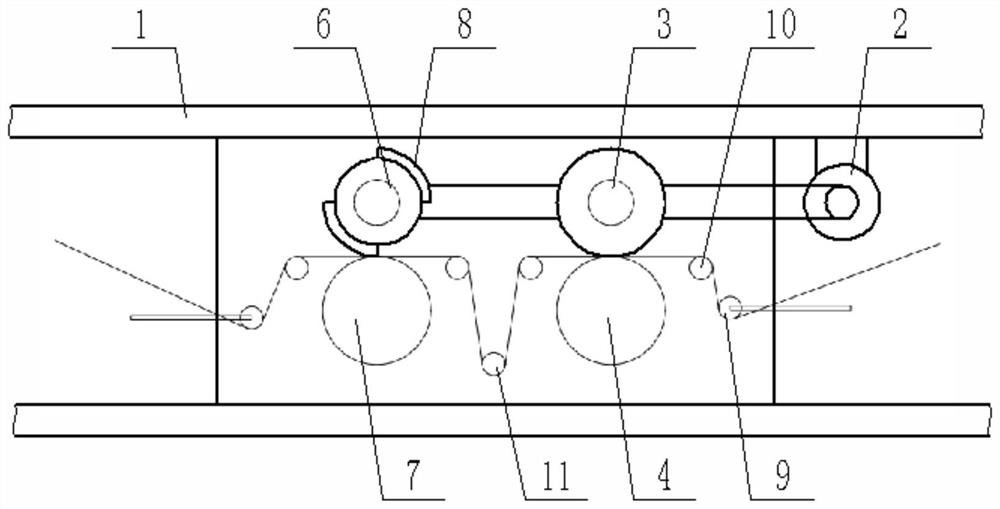

Segmented triangular welding strip machining device and method

ActiveCN112820800AGuaranteed uptimeConsistent speedFinal product manufactureSemiconductor devicesElectrical resistance and conductanceCopper wire

The invention discloses a segmented triangular welding strip machining device and method. The segmented triangular welding strip machining device comprises a support, a calendaring mechanism and a tin plating and blowing mechanism, the calendaring mechanism and the tin plating and blowing mechanism are installed on the support, the calendaring mechanism comprises a first pressing roller set and a second pressing roller set, a motor is fixedly installed on the support, and the first pressing roller set and the second pressing roller set are both in transmission connection with the motor. The two pressing roller sets operate stably and are driven by the same motor and driven by the synchronous belt, so that the two pressing roller sets are consistent in rotating speed, stable in length ratio of triangular sections to trapezoidal sections of products and consistent in cycle length. When the rolled rectangular section is used for welding the grid line on the back surface of the battery, the copper wire is flattened by the first upper roller and then is flattened by the second upper roller, so that the area of the flat section can be increased, the welding contact area is large, and the welding strength can be improved; meanwhile, the welding surface contact resistance is small, and the assembly power loss can be reduced. By setting an air knife. the problem of thick soldering tin on the inclined edges of the triangular area and the trapezoidal area of the triangular solder strip can be solved.

Owner:BAODING YITONG PV SCI & TECH

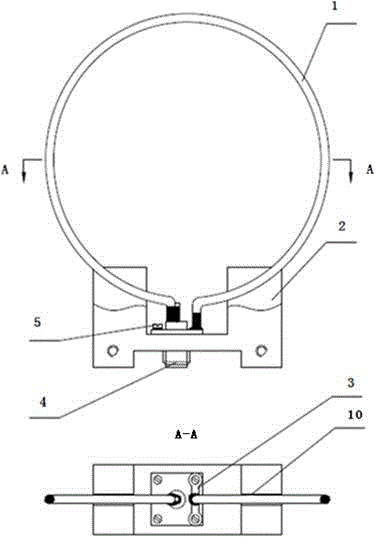

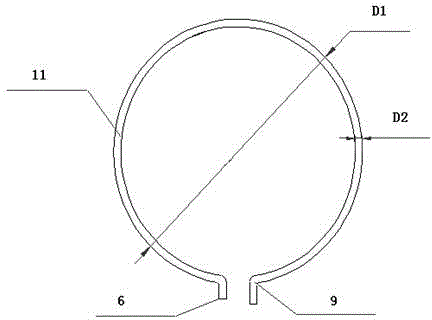

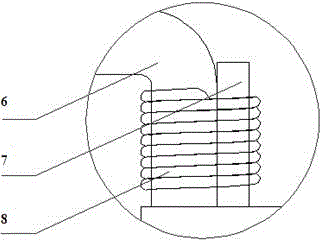

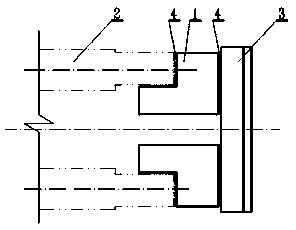

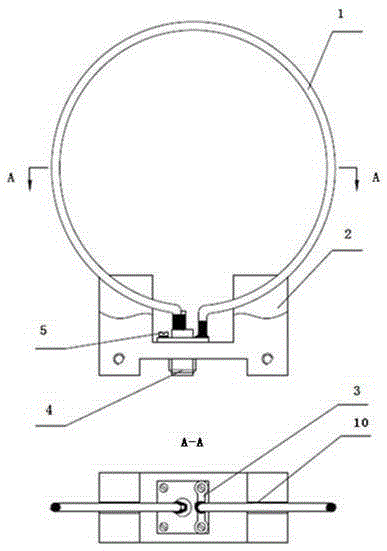

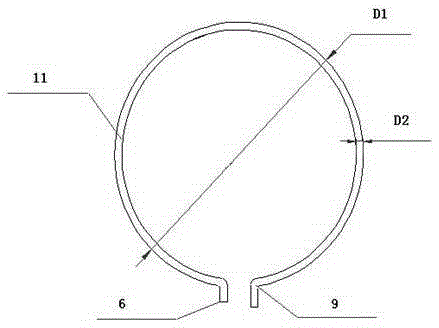

Vehicle-mounted loop antenna apparatus and manufacturing method thereof

ActiveCN103606727AImprove smoothnessInhibit false solderingAntenna supports/mountingsSoldered/welded conductive connectionsCopper wireButt joint

The invention provides a vehicle-mounted loop antenna apparatus and a manufacturing method thereof. The apparatus comprises an antenna oscillator, an antenna base and a high frequency connector, wherein the antenna oscillator and the high frequency connector are installed on the antenna base; the antenna oscillator comprises a metal ring, a short welding foot and a long welding foot; the high frequency connector comprises a high frequency connector socket welding needle, a high frequency connector flange plate and the like; and the short welding foot of the antenna oscillator and the high frequency connector socket welding needle are overlapped, are wound firmly through a bare copper wire and then are welded. The vehicle-mounted loop antenna apparatus is characterized by further comprising a plurality of welding sheets. One end of each welding sheet is fixed to the high frequency connector flange plate; the non-fixed end of each welding sheet is bent by an angle of 90 degrees towards the direction of the antenna oscillator; the distances between the bending parts of the welding sheets are the diameter of a antenna oscillator material; and the long welding foot of the antenna oscillator is inserted to the vertically bent butt joint position of the rail ends of the welding sheets and is firmly connected with the high frequency connector flange plate in a welding mode. The apparatus and the method provided by the invention solve the problems of easy unsoldering, antenna swinging and the like caused by unfavorable environments of vibration and impact of an external environment and the like during a use process of a conventional vehicle-mounted antenna.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

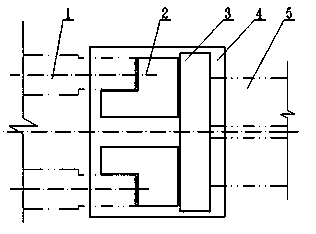

Electrolytic bath cathode steel bar connecting plate structure

The invention discloses an electrolytic bath cathode steel bar connecting plate structure, which adopts ''L'' shaped connecting plates (1). The ''L'' shaped connecting plates (1) connect cathode steel bars with a steel-aluminum explosive welding block (3) through a welding seam (4). The ''L'' shaped connecting plates (1) are placed on the inner sides of the cathode steel bars (2), or on the outer sides of the cathode steel bars (2). The two ''L'' shaped connecting plates (1) form a ''concave'' structure connecting plate, or form a ''convex'' structure connecting plate. The ''concave'' structure connecting plate or the ''convex'' structure connecting plate composed of the ''L'' shaped connecting plates (1) connects the two cathode steel bars (2) simultaneously. By welding the ''L'' shaped connecting plates with the end faces and the sides of the cathode steel bars, the welding seam can be elongated, and the welding contact area can be increased, thereby reaching the purpose of lowering the electrolytic bath cathode drop.

Owner:GUIYANG AL-MG DESIGN & RES INST

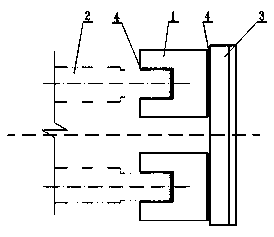

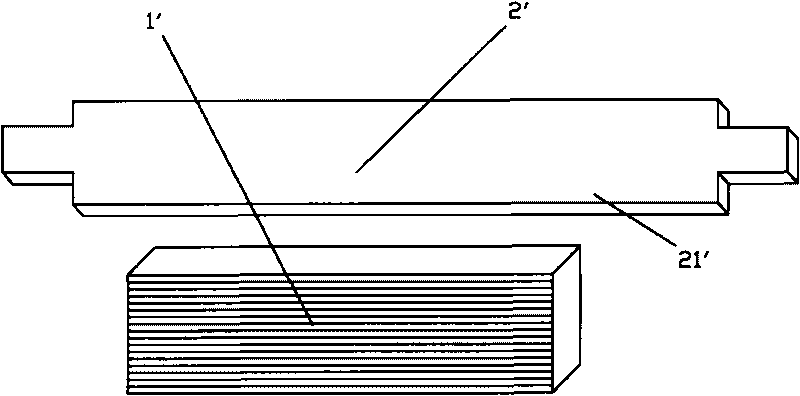

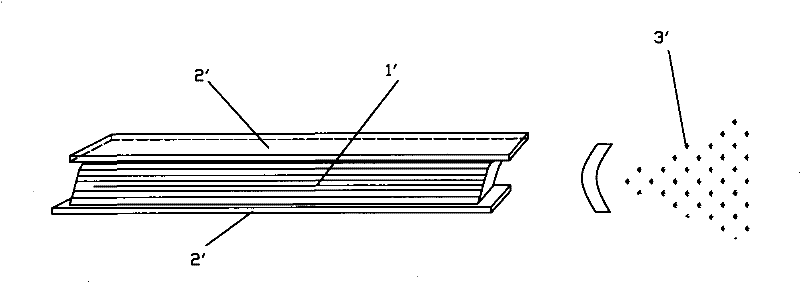

Manufacturing method of surface mounting capacitor for enhancing weldability

The invention discloses a manufacturing method of a surface mounting capacitor for enhancing weldability; laminated metal films are clamped together by adopting a special tooling, metal is sprayed on the side end surface of the laminated metal films, so as to lead the upper and lower ends of a metal spraying layer formed by spraying the metal on the side end surface of the laminated metal films to be respectively provided with an upward bulge and a downward bulge which is symmetrical with the upward bulge along the horizontal direction; a sunk part is arranged on the special tooling, the sunk depth of the sunk part is 0.07-0.13mm, the inner end of the sunk part is an inclined surface, the inclined surface and the sunk surface of the sunk part and the normal surface of the tooling are connected smoothly, the inclined surface of the sunk part and the normal surface of the tooling form an included angle with 30-50 degrees; by adopting the special tooling, the upper and lower end surfaces of the metal spraying layer at two ends of the laminated metal films are bulged, the welding contact area is increased, the welding reliability is ensured, and the probability of insufficient welding and tomb stone and the like of the surface mounting capacitor is greatly reduced.

Owner:XIAMEN FARATRONIC

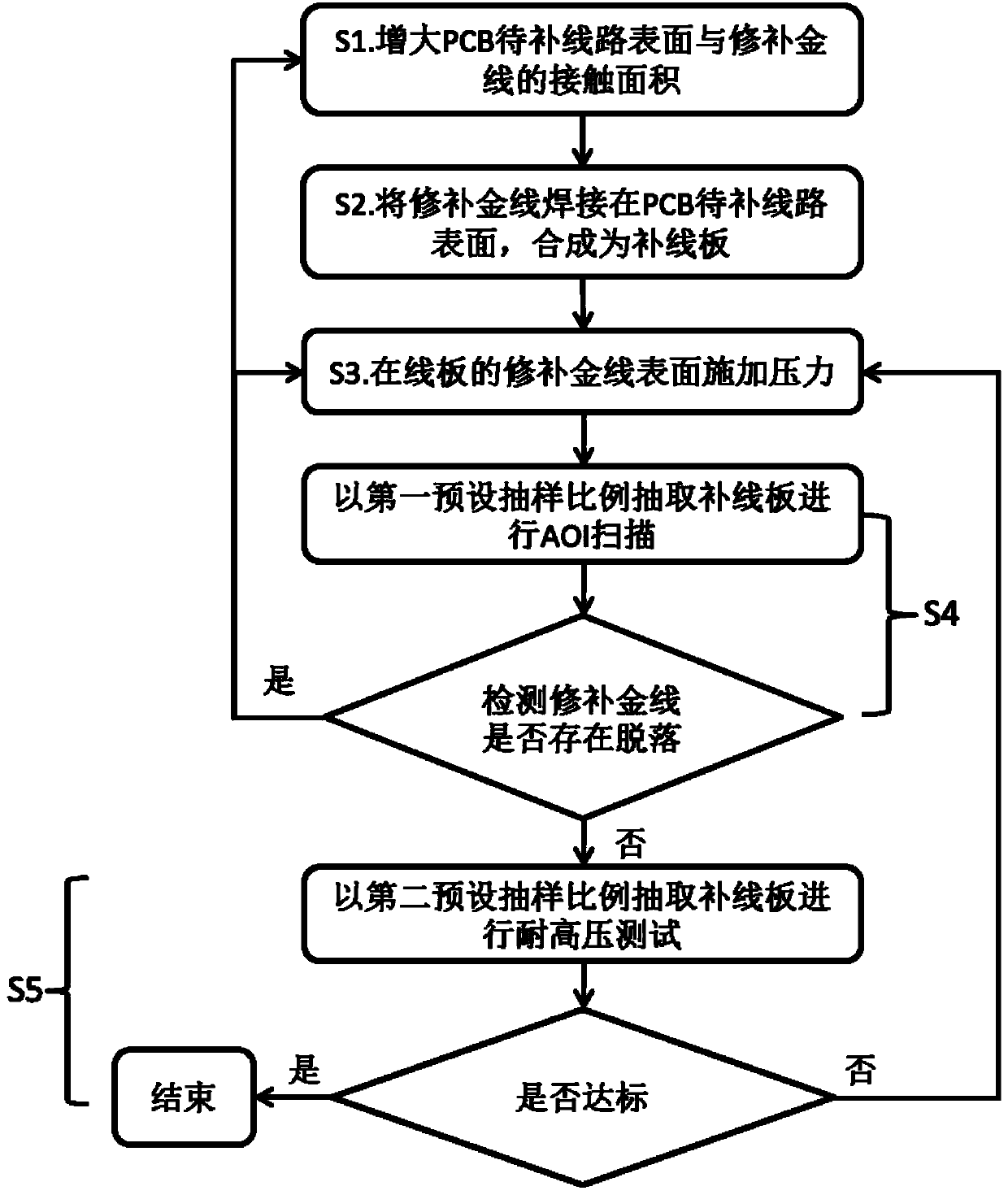

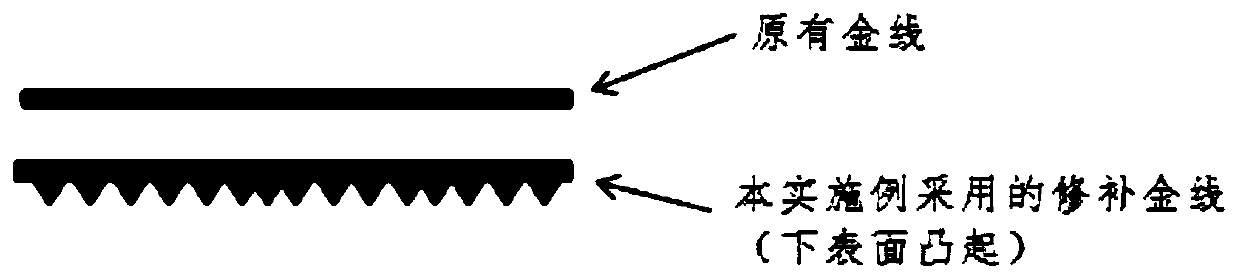

A circuit repair method for high-precision circuit pcb

ActiveCN109561599BIncreased solder contact areaLower resistancePrinted circuits repair/correctingElectrical resistance and conductanceMechanical engineering

The invention relates to the technical field of PCB circuit repair, and specifically discloses a circuit repair method for a high-precision circuit PCB. The circuit repair method comprises the following steps: increasing the contact area of the to-be-repaired circuit surface of the PCB and a repair gold wire; welding the repair gold wire to the to-be-repaired circuit surface of the PCB, and synthesizing a wire repair plate; applying pressure to the surface of the repair gold wire of the wire repair plate; extracting by using a first preset sampling proportion to complete AOI scanning for the repair wire plate in the previous step, and detecting whether the repair gold wire falls or not so as to increase the coarsening degree in the first step and / or increase the pressure applied in the third step. The circuit repair method has the obvious advantages that the to-be-repaired circuit surface and the surface of the gold wire are coarsened, so that the welding contact area of the gold wireand the circuit is increased, the resistance at the welding position can be reduced effectively, the electrification heat productivity is reduced, and the reliability of the product when in use is improved; the circuit and the surface of the gold wire are coarsened, the binding force between the gold wire and the circuit is improved, the gold wire is prevented from falling off in the subsequent procedure, and the internal proportion of the product is reduced.

Owner:GUANGDONG KINGSHINE ELECTRONICS TECH CO LTD

Manufacturing method of surface mounting capacitor for enhancing weldability

The invention discloses a manufacturing method of a surface mounting capacitor for enhancing weldability; laminated metal films are clamped together by adopting a special tooling, metal is sprayed on the side end surface of the laminated metal films, so as to lead the upper and lower ends of a metal spraying layer formed by spraying the metal on the side end surface of the laminated metal films to be respectively provided with an upward bulge and a downward bulge which is symmetrical with the upward bulge along the horizontal direction; a sunk part is arranged on the special tooling, the sunkdepth of the sunk part is 0.07-0.13mm, the inner end of the sunk part is an inclined surface, the inclined surface and the sunk surface of the sunk part and the normal surface of the tooling are connected smoothly, the inclined surface of the sunk part and the normal surface of the tooling form an included angle with 30-50 degrees; by adopting the special tooling, the upper and lower end surfacesof the metal spraying layer at two ends of the laminated metal films are bulged, the welding contact area is increased, the welding reliability is ensured, and the probability of insufficient weldingand tomb stone and the like of the surface mounting capacitor is greatly reduced.

Owner:XIAMEN FARATRONIC

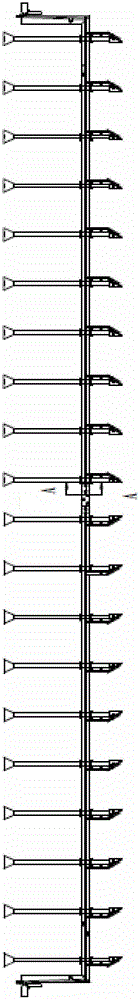

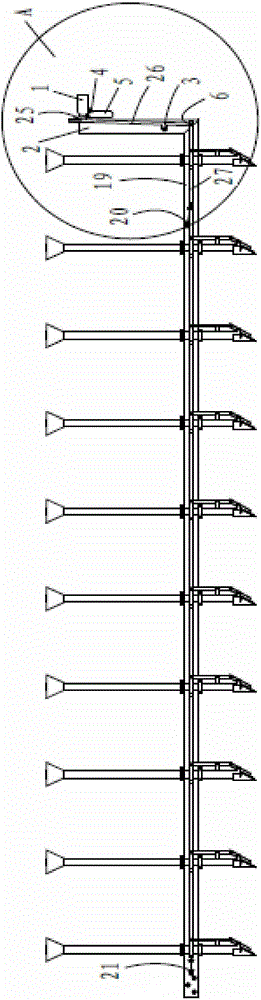

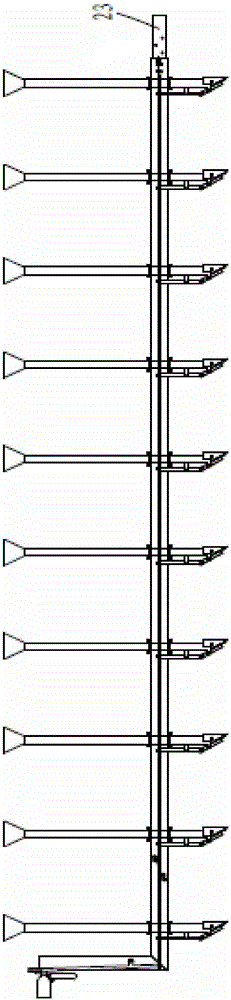

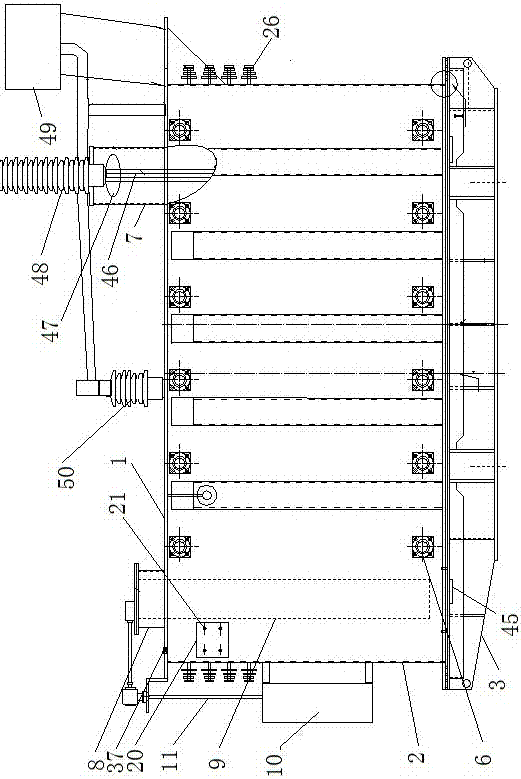

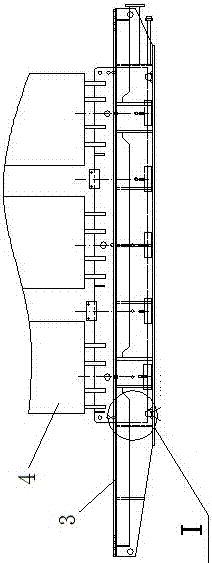

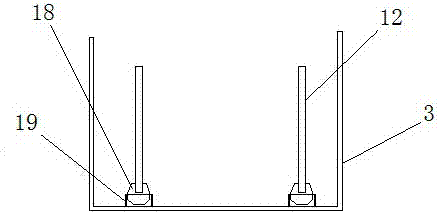

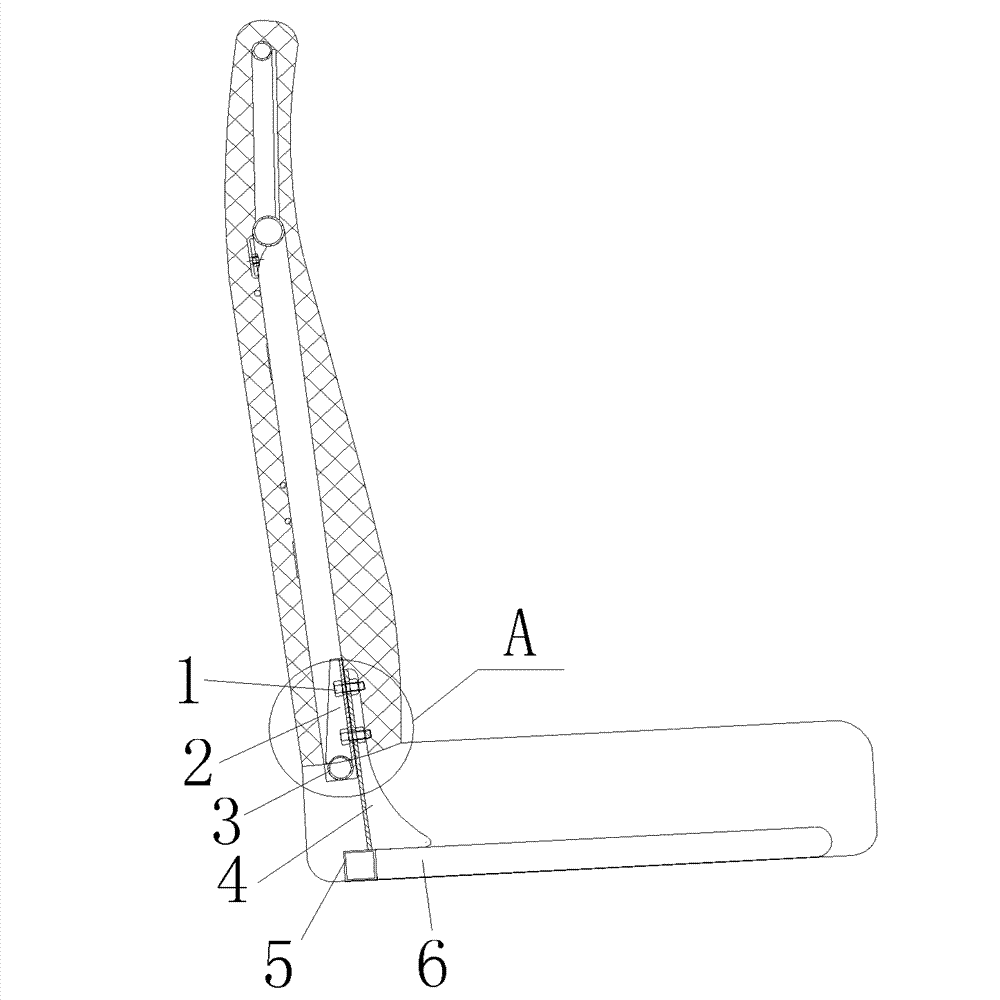

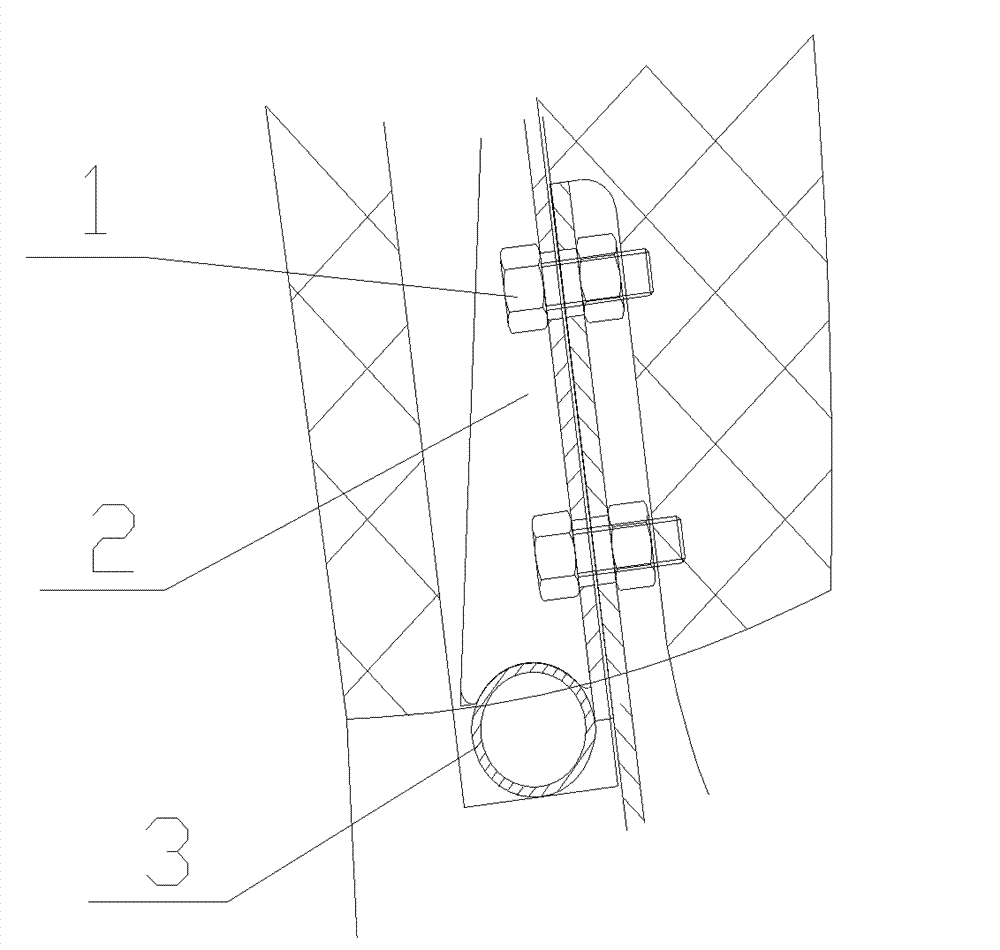

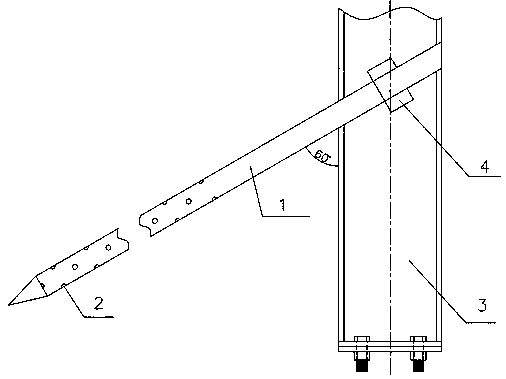

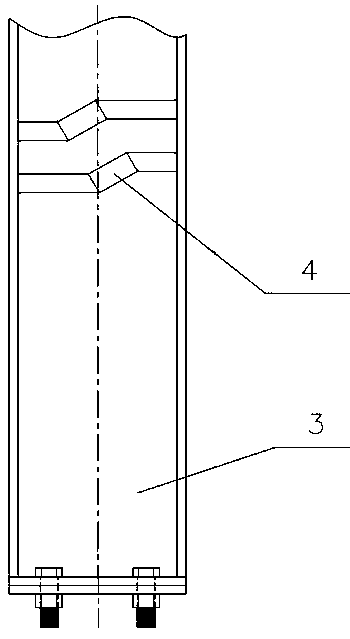

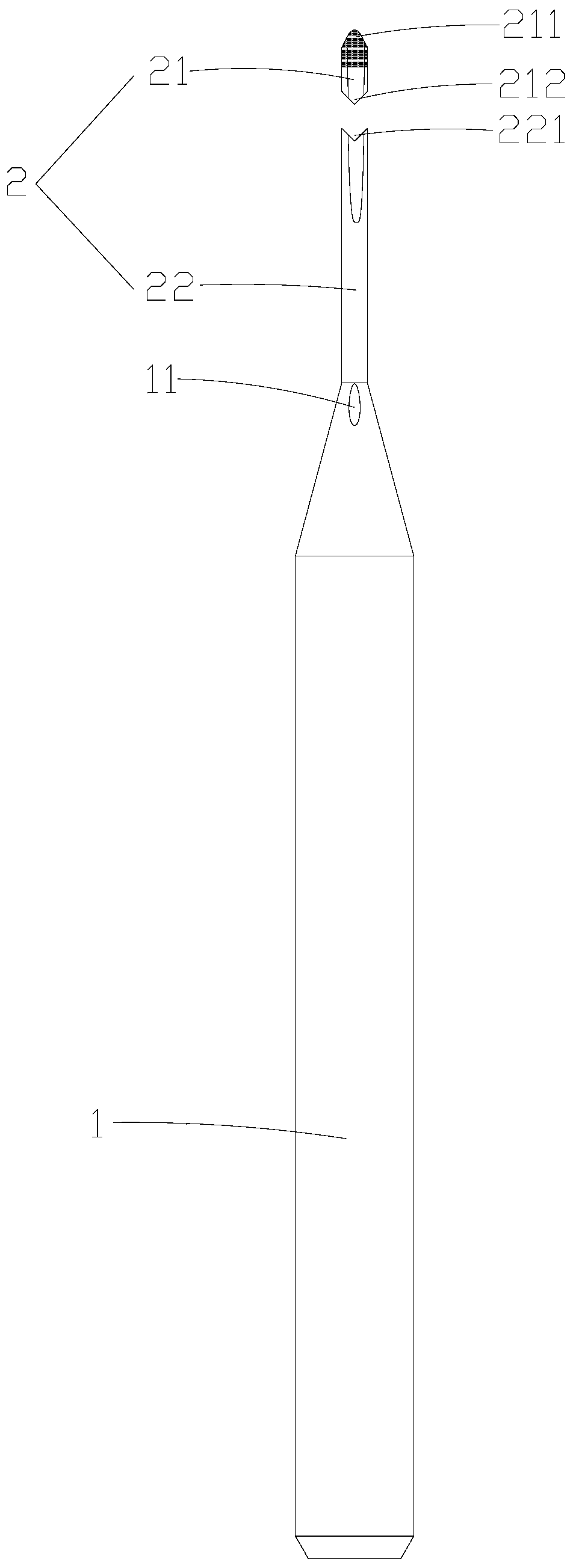

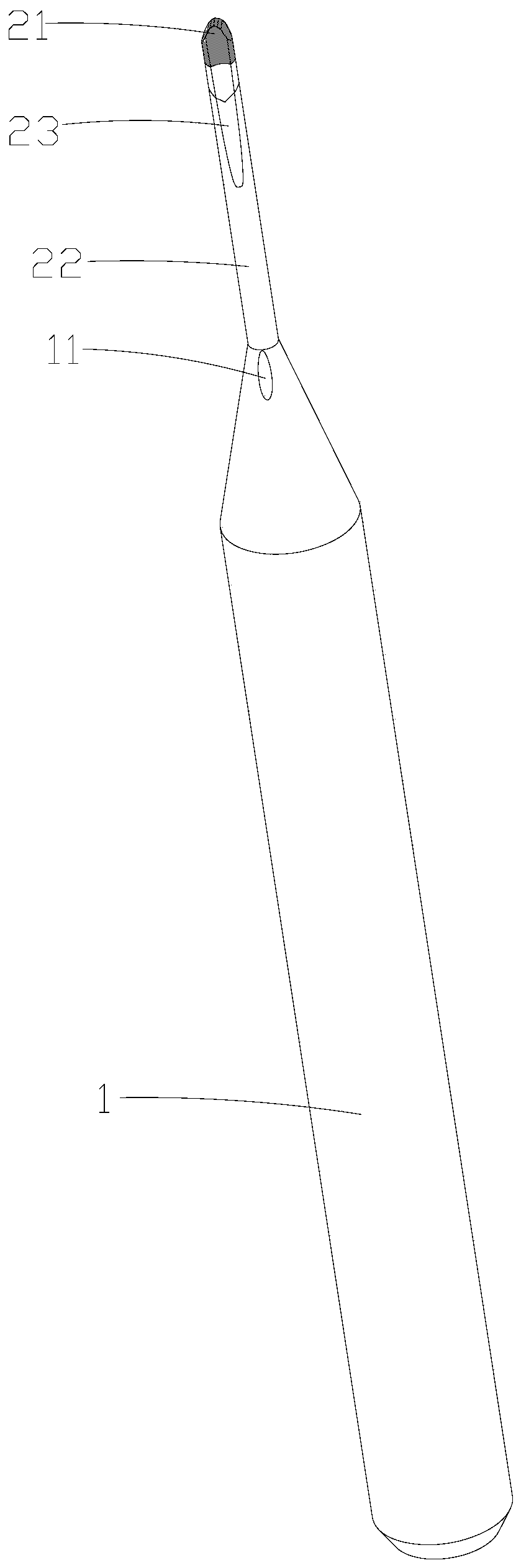

Human Efficient Corn Planter

The invention discloses a manual efficient corn planter which comprises a rack, seeders and trench openers, wherein the rack comprises a horizontal support rod and a vertical support rod; the vertical support rod is arranged at the end part of the horizontal support rod; the horizontal support rod is connected with the seeders; a handheld handle which is horizontally arranged is arranged on the upper side of the vertical support rod; seed falling control plates which are arranged in a downwards inclining manner in match are arranged on the inner sides of the lower parts of the trench openers; the control plates are connected with a control handle through a transmission mechanism; the control handle is connected with the handheld handle; the seeders comprise falling tubes; the falling tubes are connected with the horizontal support rod; the upper parts of the falling tubes are connected with seed funnels; the bottoms of the falling tubes are connected with the trench openers. As a plurality of independent main body parts of a planter are connected and used together, a plurality of trenches can be formed at one time through the mass of the planter self, the distances among plants are uniform, components and parts can be conveniently adjusted and replaced, the production efficiency is high, and the manual efficient corn planter is particularly applicable to experimental planting of novel corn varieties.

Owner:SHANDONG LIMING SEED TECH

high voltage transformer

ActiveCN106158276BNo increase in volumeLow costTransformers/inductances coolingTransformers/inductances magnetic coresFuel tankHigh voltage transformer

The invention provides a high-voltage transformer. The high-voltage transformer is characterized by comprising a tank cover, an upper-section oil tank and a lower-section oil tank, which are mounted together from top to bottom, wherein a sealed oil tank space is formed by the tank cover, the upper-section oil tank and the lower-section oil tank; the upper-section oil tank is internally provided with a coil; the coil is mounted on an iron core; clamping parts are mounted at the upper and lower ends of the iron core; the lower-section oil tank is provided with a plurality of jack mounting positions; the tank cover is provided with a wiring terminal connected with the coil; and an oil pillow for supplementing oil to the oil tank is mounted on the right side of the tank cover. The high-voltage transformer has the beneficial effects of complete functions, convenience for assembling and long service life.

Owner:SHANDONG HUACHI TRANSFORMER

Novel device for fixing seat cushion and backrest

InactiveCN102729869AIncreased resistance to deformationEasy to makeSeat framesBiomedical engineeringCushion

The invention relates to a novel device for fixing a seat cushion and a backrest, which comprises a base support mechanism and a backrest support mechanism, and the base support mechanism is connected with the backrest support mechanism through bolts. Compared with the prior art, the novel device has the advantages of firmness, durability, low production cost, convenience for maintenance and the like.

Owner:LONGHAI JIULONG SEAT

Capacitor and preparation method and installation method thereof

PendingCN114582627AAvoid breakingImprove cooling effectCapacitorsStructural engineeringMechanical engineering

The invention discloses a capacitor and a preparation method and an installation method of the capacitor, the capacitor comprises a capacitor body, a first pin and a second pin extend out of the right side end face of the capacitor body, the first pin and the second pin respectively comprise a protection pin, a heat dissipation pin and a welding pin which are the same, the length of the heat dissipation pin is larger than the radius of the capacitor body, and the length of the welding pin is larger than the radius of the capacitor body. The surface of the upper end of each welding pin is provided with a plurality of uniformly distributed through holes, each through hole is in a quadrangular frustum pyramid shape, the four side faces of each quadrangular frustum pyramid obliquely extend upwards by 30 degrees to form a circular hole channel, and the through holes and the circular hole channels are filled with soldering tin. The whole capacitor is good in heat dissipation effect, space-saving, tighter in welding, material-saving, and capable of reducing occupational diseases of workers. Potential safety hazards are reduced.

Owner:湖州新江浩电子有限公司

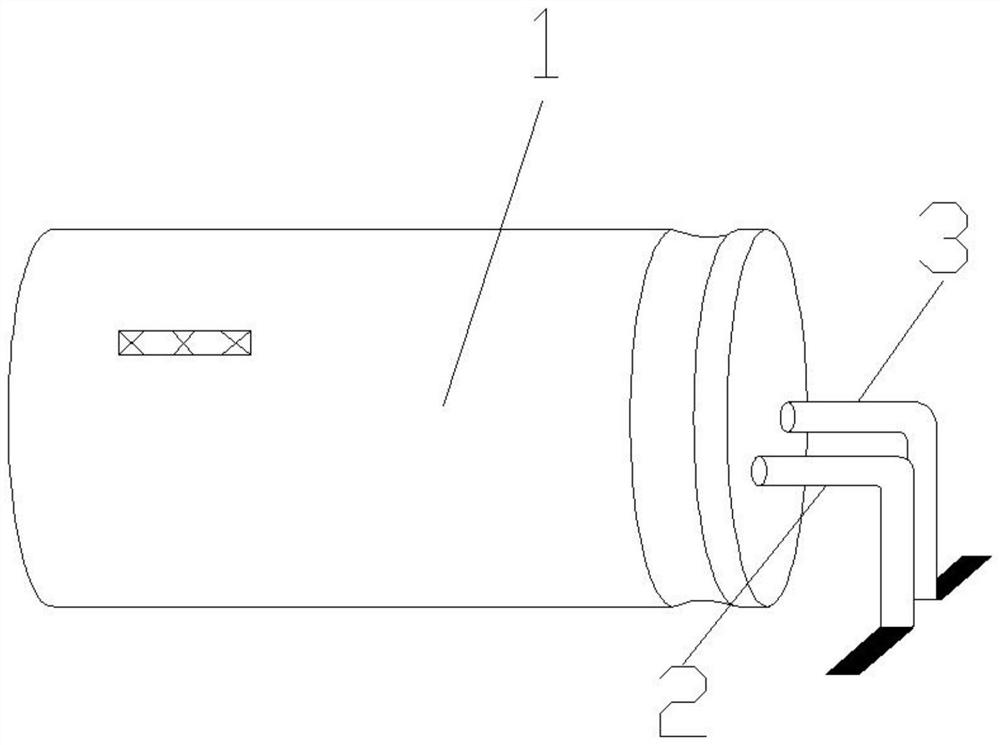

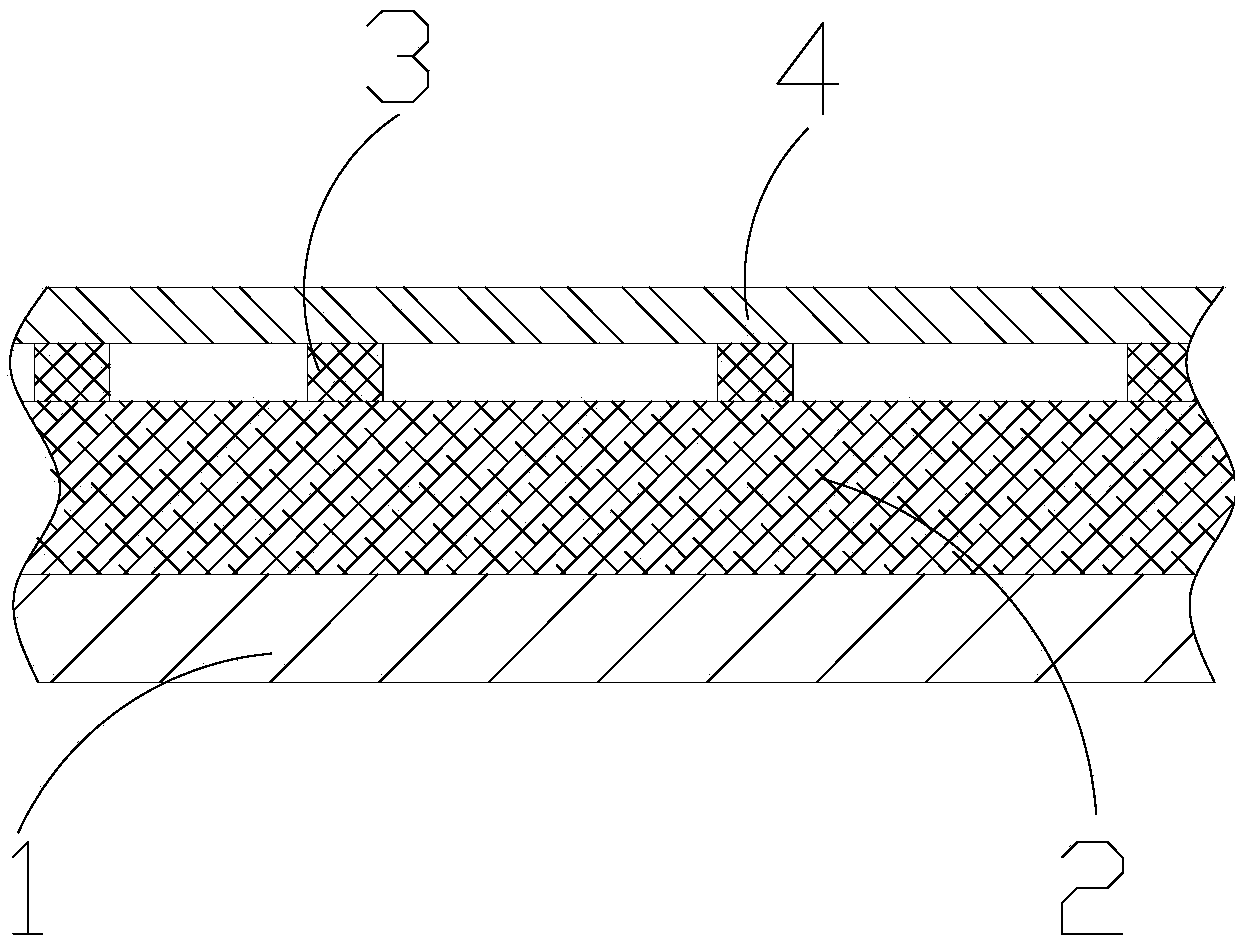

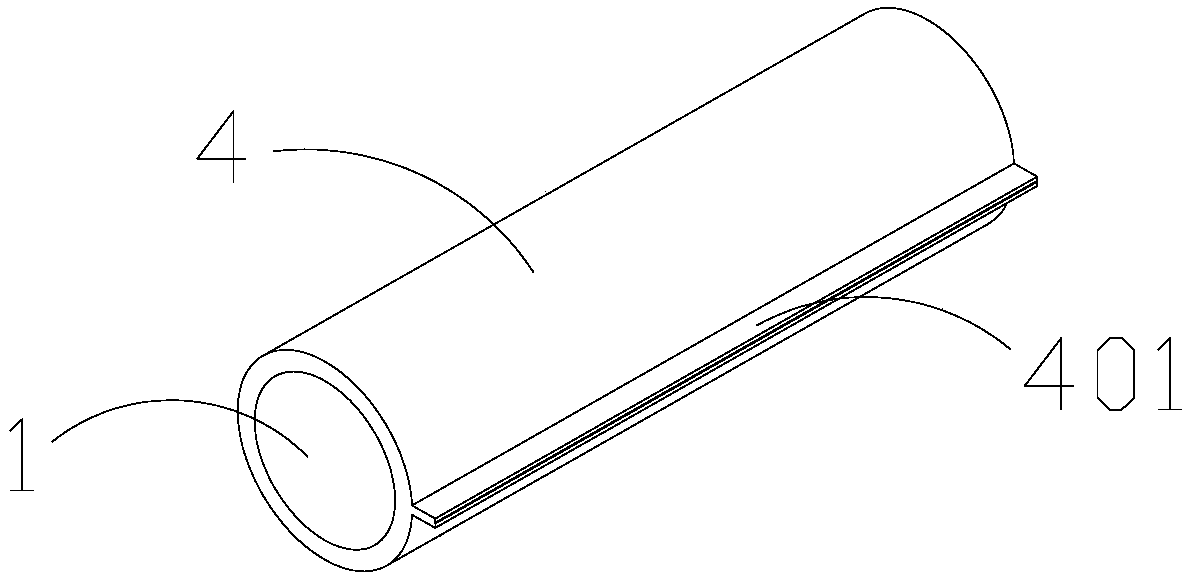

Heat insulating structure of pipeline

PendingCN108413182AImprove welding qualityEvenly wrappedThermal insulationPipe protection by thermal insulationEngineeringProtection layer

The invention provides a heat insulating structure of a pipeline in order to solve the problems that an existing heat insulating structure of the pipeline is complicated in procedure and high in assembly cost. The heat insulating structure of the pipeline comprises a foundation pipe, and an inner protection layer, a connection layer and an outer protection layer are sequentially arranged along thewall of the foundation pipe from inside to outside. The connection layer is two or more metal straps arranged in parallel, one sides of the metal straps are connected with the outer protection layerin a welded mode, and the other sides of the metal straps are in nailed or riveted connection with the inner protection layer. The outer protection layer is evenly provided with concave-convex parts,that is, pits are formed in one side of the outer protection layer, protrusions corresponding to the pits are arranged on the other side of the outer protection layer, and joints of the two ends of the outer protection layer are connected in a welded mode. By means of the heat insulating structure of the pipeline, the step of manually wrapping the pipeline with the inner protection layer is omitted, time is shortened, the assembly efficiency is improved, the assembly cost is reduced, and meanwhile the product quality is ensured.

Owner:重庆三二一绝热制品有限公司

Fixing method of locking foot of steel arch frame for primary support of tunnel

ActiveCN106640147BEasy to fixAvoid deformationUnderground chambersTunnel liningSteel frameOblique angle

The invention relates to a tunnel primary support steel arch frame lock foot fixing method. The method comprises the following steps that 1, a seamless steel pipe is machined to be the fixed length, one end of the seamless steel pipe is machined to be sharp, the other end of the seamless steel pipe is machined to be an oblique angle of 30 degrees, grouting holes are formed in the pipe wall in the shape of quincunx, and then a locking anchor pipe is obtained; 2, a positioning plate is adopted for machining a pair of square steel frame positioning holes on a web of a profile steel frame; 3, screw-thread steel is adopted for being prepared into U-shaped clamp rings; 4, a drill pipe drills holes in the direction of steel frame positioning holes, and after the holes reach the designed depth, installation is conducted in place; 5, the two U-shaped clamp rings oppositely penetrate through the steel frame positioning holes and are clamped on the locking anchor pipe, and U-shaped clamp ring arc welding connection surface, the locking anchor pipe and a U-shaped clamp ring arc welding connection surface are formed through welding separately; 6, grouting is conducted after connection of a grouting pipe and the locking anchor pipe, and finally a grout stop valve is installed. Accordingly, the fixation of the locking anchor pipe on the tunnel primary support section steel arch frame can be effectively improved, tunnel primary support sinking and deformation are prevented, and the safety factor of tunnel construction is strengthened.

Owner:GANSU ROAD & BRIDGE CONSTR GROUP +1

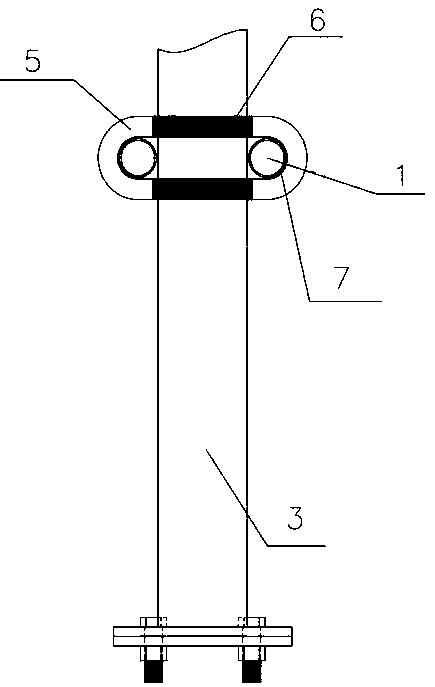

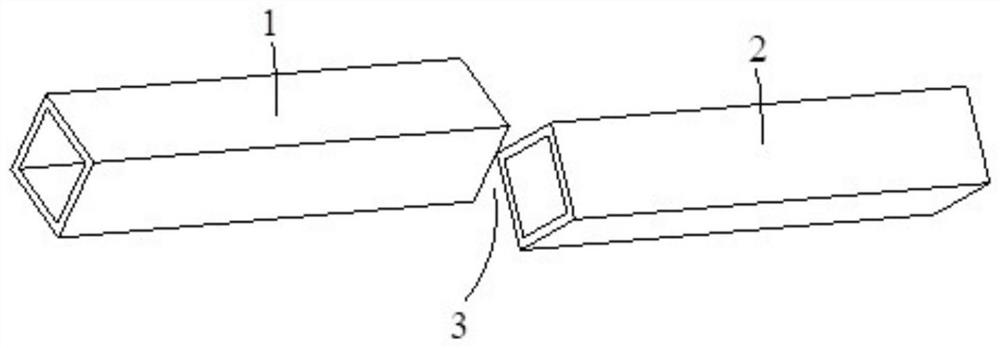

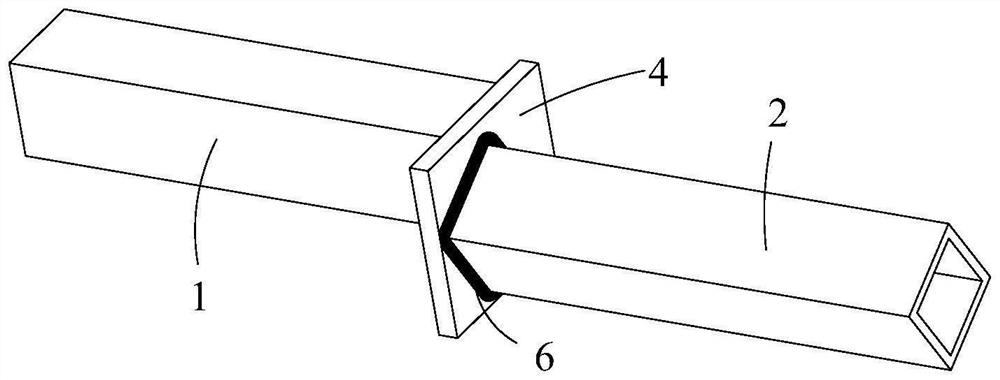

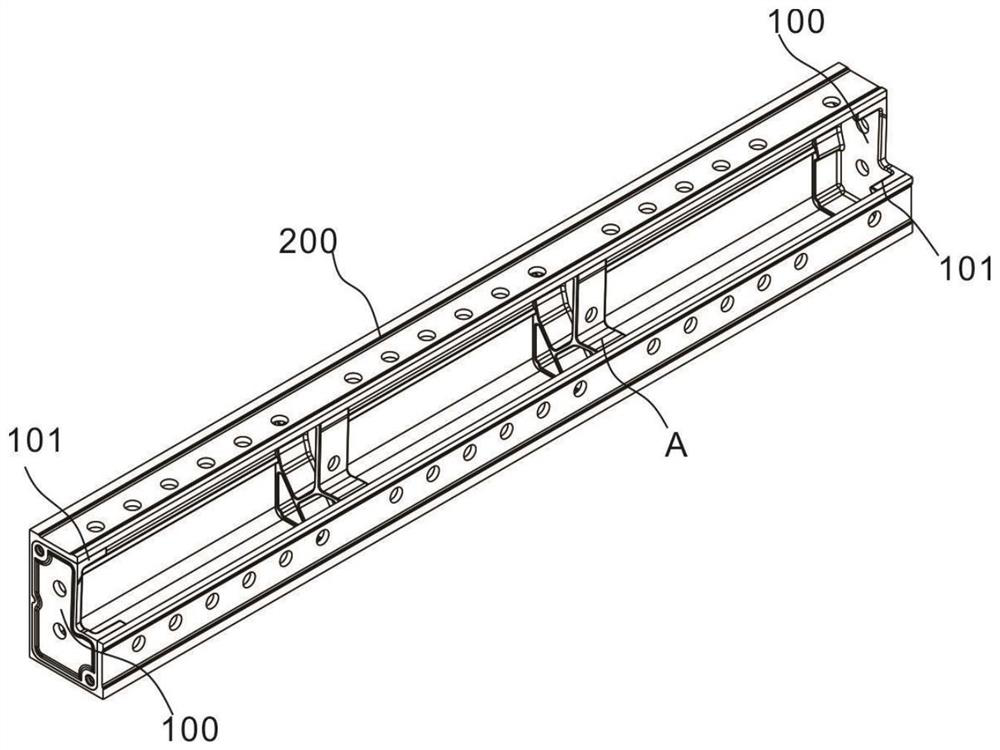

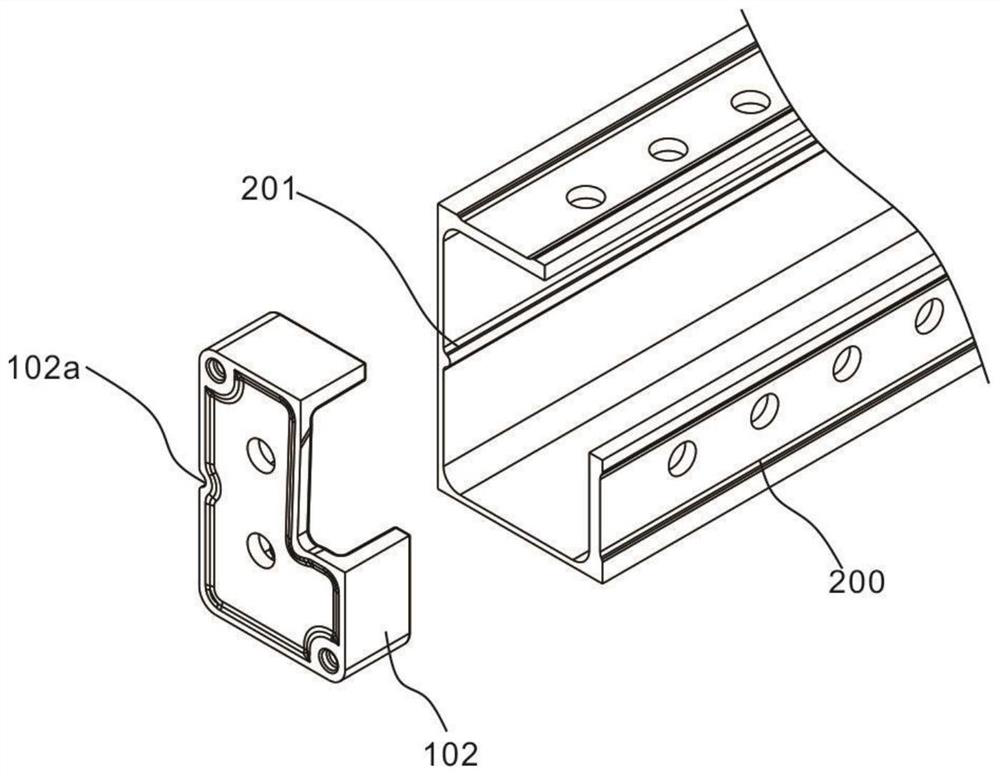

Keel butt joint structure and welding seam flexural capacity evaluation and safety design method thereof

PendingCN114459916AIncrease weld joint lengthIncreased solder contact areaMaterial strength using steady bending forcesBuilding constructionsButt jointKeel

The invention relates to the field of curtain wall keels, in particular to a keel butt joint structure and a welding seam flexural capacity evaluation and safety design method.The keel butt joint structure comprises a first keel and a second keel, a staggered joint is formed between the first keel and the second keel, and a first connecting piece is arranged in the staggered joint; and the first connecting piece is respectively welded with the first keel and the second keel. According to the keel butt joint structure, the first connecting piece is arranged between the first keel and the second keel which are staggered, so that the welding seam connecting length between the first keel and the second keel is increased, the welding contact area is increased, and the welding integrity and safety are improved.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

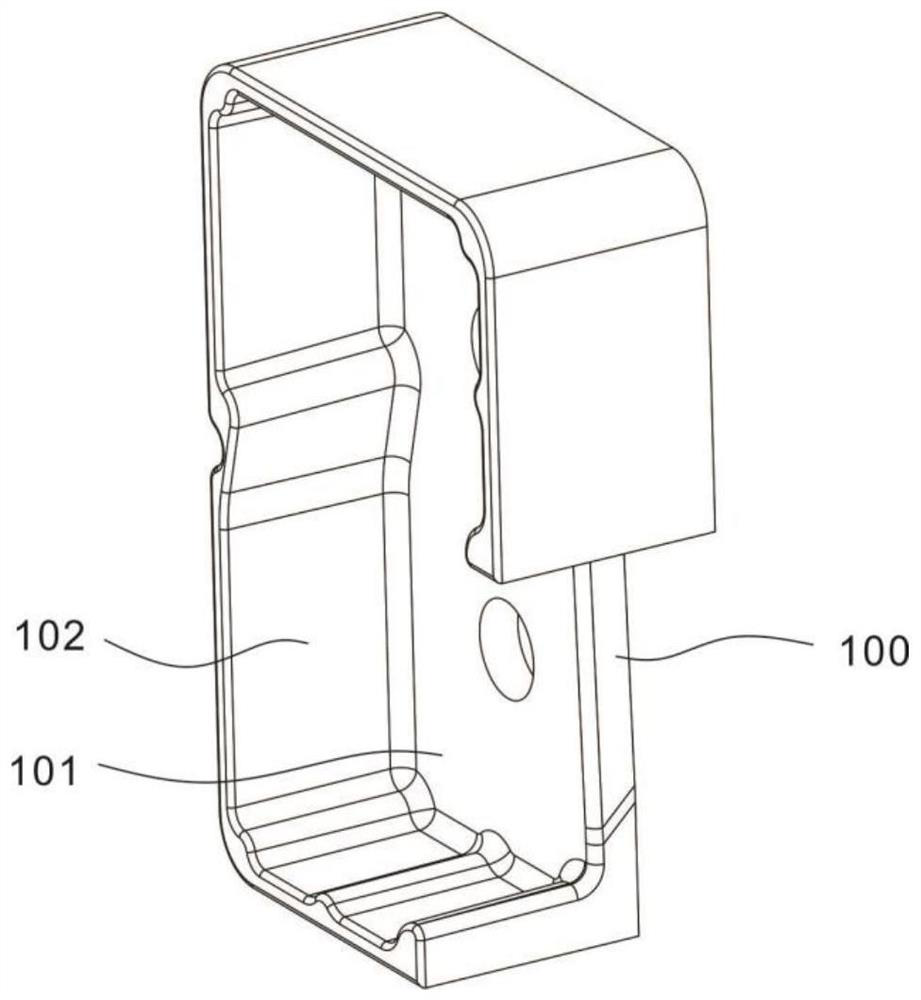

Aluminum alloy internal corner template and processing method thereof

PendingCN113756568AImprove structural rigidityReduce manufacturing costForms/shuttering/falseworksForming/stuttering elementsPressure castingStructural engineering

The invention discloses an aluminum alloy internal corner template and a processing method thereof. The aluminum alloy internal corner template comprises a connecting end face, the connecting end face comprises an end face plate, the end face plate is provided with a connecting boss along the periphery, and the end face plate and the connecting boss are integrally formed; the aluminum alloy internal corner template comprises the connecting end face and a connecting sectional material, the connecting boss is embedded into the connecting sectional material, and the outer side face of the connecting boss makes contact with the inner side face of the connecting sectional material. A protrusion extending in the length direction is arranged on the inner side of the connecting sectional material, a groove is formed in the connecting boss, and the protrusion is embedded into the groove. According to the aluminum alloy internal corner template and the processing method thereof, an internal corner end plate is formed through a pressure casting method, a complex structure can be formed, meanwhile, a product is high in structural rigidity and low in production cost, the boss extending out of the internal corner end plate can increase the welding contact area for friction stir welding, and the strength of the internal corner template is improved.

Owner:柳州市智甲金属科技有限公司

Vehicle-mounted loop antenna device and manufacturing method thereof

ActiveCN103606727BImprove smoothnessSecure Connection GuaranteeAntenna supports/mountingsSoldered/welded conductive connectionsButt jointCopper wire

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

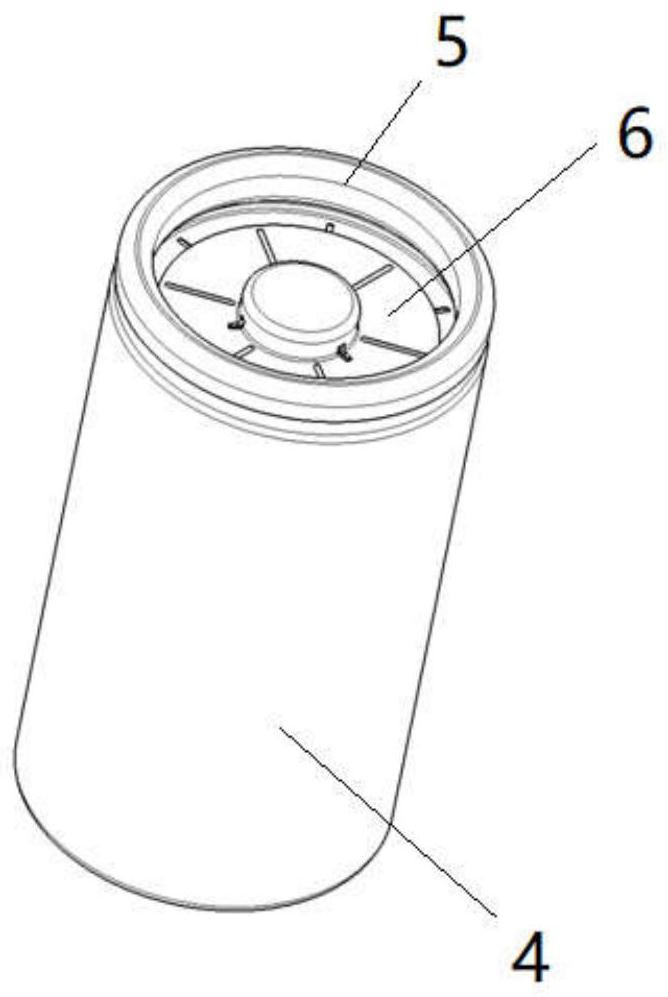

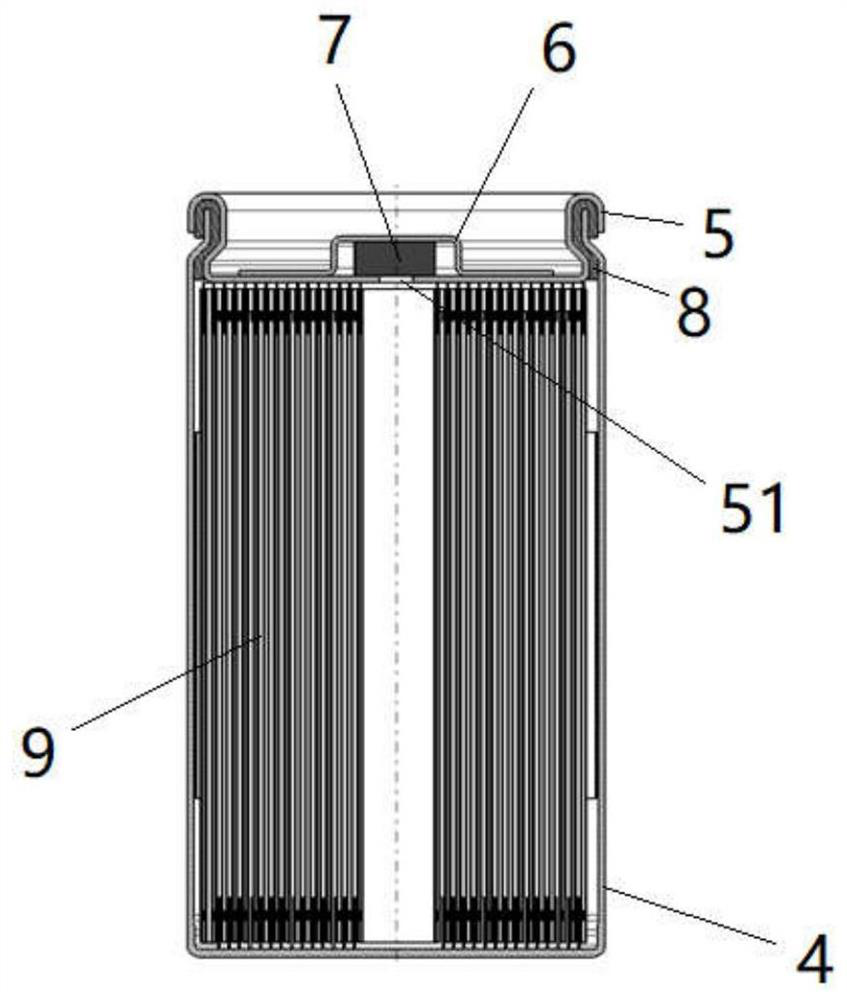

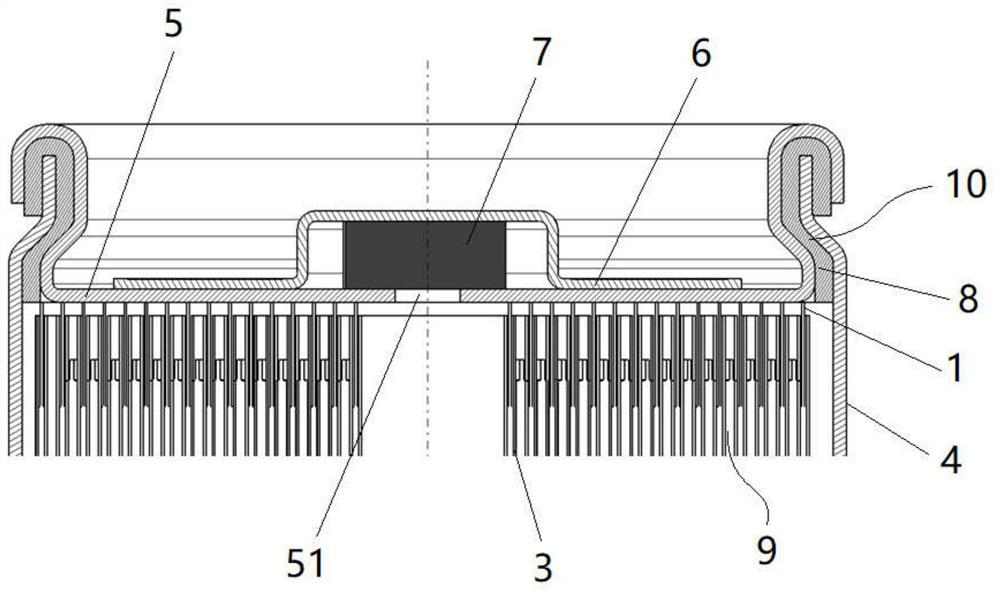

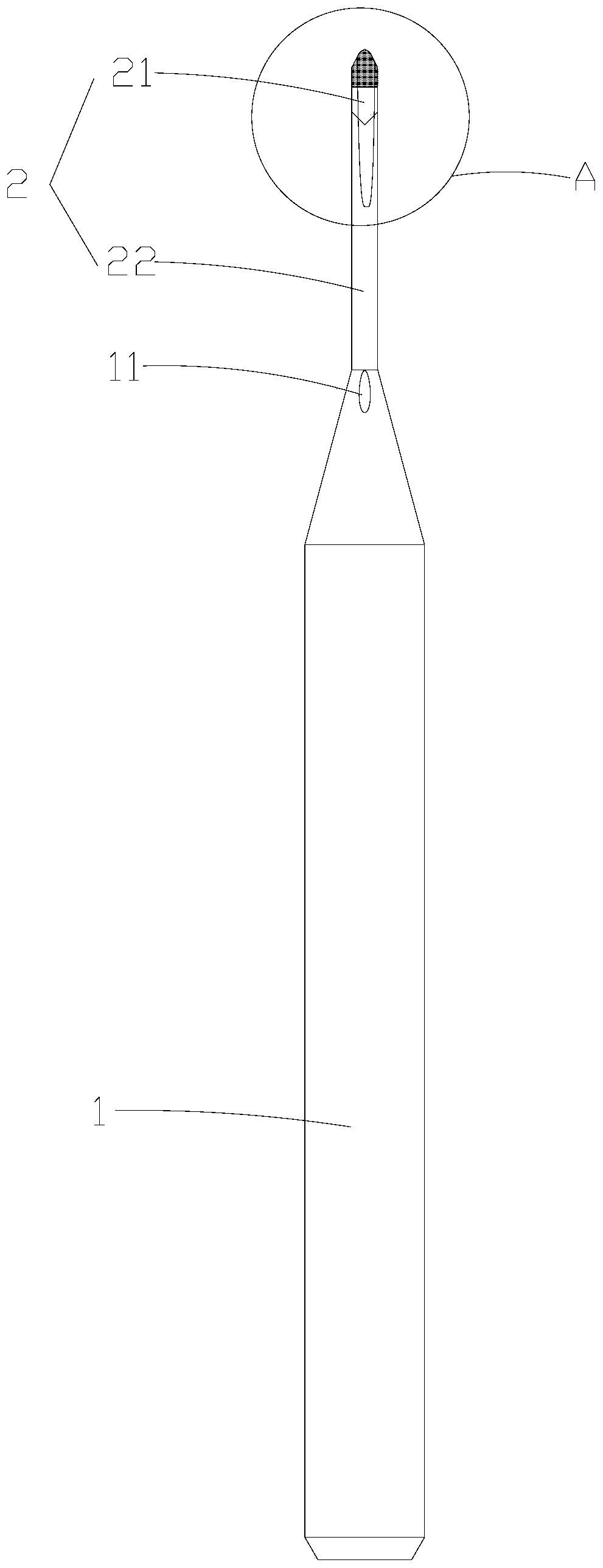

Conical surface sealing cylindrical battery and preparation method thereof

ActiveCN111900451BNovel structureIncrease heightFinal product manufactureSmall-sized cells cases/jacketsElectrolytic agentElectrical battery

The invention provides a cone-sealed cylindrical battery. The pole assembly is placed in a steel shell. The steel shell is filled with electrolyte. The sealing ring is matched in the steel shell. The sealing structural member is matched in the sealing ring. The steel shell The upper end, the corresponding sealing ring, and the side wall of the sealing structural member are extruded inward together to form an extrusion part with an inward inclined slope at the lower end and a vertical straight line at the upper end. The upper end of the sealing ring and the upper end of the side wall of the sealing structural member are jointly facing outward 180 ° Bend and tightly wrap the top of the steel shell to form a sealing part. The bottom of the sealing structural member is welded to the upward end of the pole assembly. The periphery of the base plate of the sealing upper cover is welded to the bottom of the sealing structural member. The safety valve is placed on In the space formed between the sealing upper cover plate and the sealing structural member, the downward end of the pole assembly is welded to the bottom of the steel shell. A method for preparing the battery of the present invention is also provided. The battery of the invention has a novel structure, low internal resistance, low cost, good sealing strength, and a relatively simplified preparation process.

Owner:先进储能材料国家工程研究中心有限责任公司

Straight slot PCD drill bit with cooling holes

PendingCN111391153AAvoid overall overheatingEasy to drillRevolution surface grinding machinesWorking accessoriesWaferingEngineering

The invention discloses a straight slot PCD drill bit with cooling holes. The straight slot PCD drill bit is used for drilling of semiconductor wafers. The straight slot PCD drill bit includes a drillshank and a drill rod formed by a combination of an extension rod and a drill point made of a PCB composite material, the drill shank is provided with at least one cooling holes, wherein cooling water can be introduced into the cooling holes, outlets of the cooling holes face the drill rod so that the cooling water flowing from the outlets of the cooling holes can cool the drill rod, the drill rod is provided with a straight groove for chip removal, and an apex angle is formed at the end of the drill point. The drill bit uses the straight groove instead of a spiral chip removal groove in a traditional PCD drill bit, fine cuttings generated during the grinding of the semiconductor wafers by the drill bit can be smoothly discharged out of the holes through the straight groove, so that the blockage due to sticking of the cuttings to the inner part of the groove is avoided. Meanwhile, by forming the cooling holes in the drill shank, the cooling water can be introduced into the cooling holes, the cooling water can be sprayed out from the outlets of the cooling holes toward the drill rod, so that the drill rod is cooled and prevented from overheating, frequent extraction for cooling isavoided, the drilling operation efficiency is improved, and the processing cycle is reduced.

Owner:厦门厦芝科技工具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com