Production process of high-efficient multi-grid welding strip

A production process and welding strip technology, which is applied to the production process field of multi-grid high-efficiency welding strips, can solve the problems of burning module cells, reducing the photoelectric conversion efficiency of modules, affecting the normal use of module cells, etc., so as to increase the welding contact area, Improve the effect of local overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

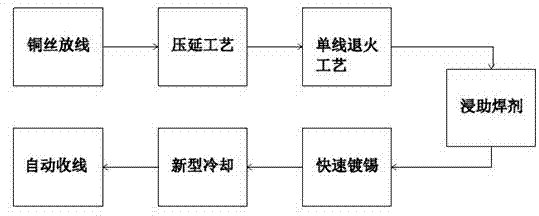

[0027] Such as figure 1 as shown,

[0028] Single line process:

[0029] Copper wire pay-off: the oxygen-free copper wire is unwound by a shaftless constant tension pay-off mechanism;

[0030] Calendering process: the hard copper wire is pressed into a hard flat wire by a calendering wheel (use software simulation technology to set the parameters initially, and then conduct repeated tests to determine the best parameters required for the product, and set the finishing rolling parameters according to product performance requirements);

[0031] Single-wire annealing process: pass the hard flat wire through the annealing chamber to make it into a soft flat wire [Using the principle of resistance heating (annealing temperature is 350°C-650°C), the hard flat wire becomes the required soft flat wire wire; the process must be guaranteed in an oxygen-free state, so a protective gas must be used to protect the annealed copper wire to avoid oxidation caused by contact with air];

[0...

Embodiment 2

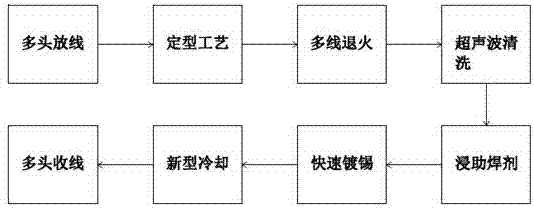

[0037] Such as figure 2 as shown,

[0038] Multi-line process:

[0039] Multi-head pay-off: use multi-axis oxygen-free copper wire to pay off with multi-head pay-off equipment (the pay-off mechanism has a guide shaft);

[0040] Shaping process: multiple groups of oxygen-free copper wires are turned into the required hard flat wires through eye mask equipment (this process turns hard round wires into hard flat wires);

[0041] Multi-wire annealing: multiple groups of hard flat wires undergo a tubular annealing process to turn hard flat wires into soft flat wires (this process changes hard flat wires into soft flat wires);

[0042] Ultrasonic cleaning: Ultrasonic cleaning of the soft flat wire with clean water;

[0043] Soldering flux: use the guide system to soak the soft flat wires that have been cleaned in multiple groups through the flux (there are two kinds of flux, one is a mixture of active agent and organic alcohol, this flux volatilizes quickly, without Residue, bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com