Production method of calcined kaolin for glass fibers

A technology for calcining kaolin and a production method, applied in the field of inorganic materials, can solve the problems of high COD value, unstable quality and high mullite phase content of kaolin used for glass fiber, so as to reduce energy consumption, reduce production cost and increase output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The kaolin raw materials include: by mass percentage, 20% of 1# kaolin (rock), 50% of 2# kaolin (rock) and 30% of 3# kaolin (rock).

[0047] The composition content of 1# kaolin (rock) is as follows: the following are mass percentages

[0048]

[0049] The composition content of 2# kaolin (rock) is as follows:

[0050]

[0051] The composition content of 3# kaolin (rock) is as follows:

[0052]

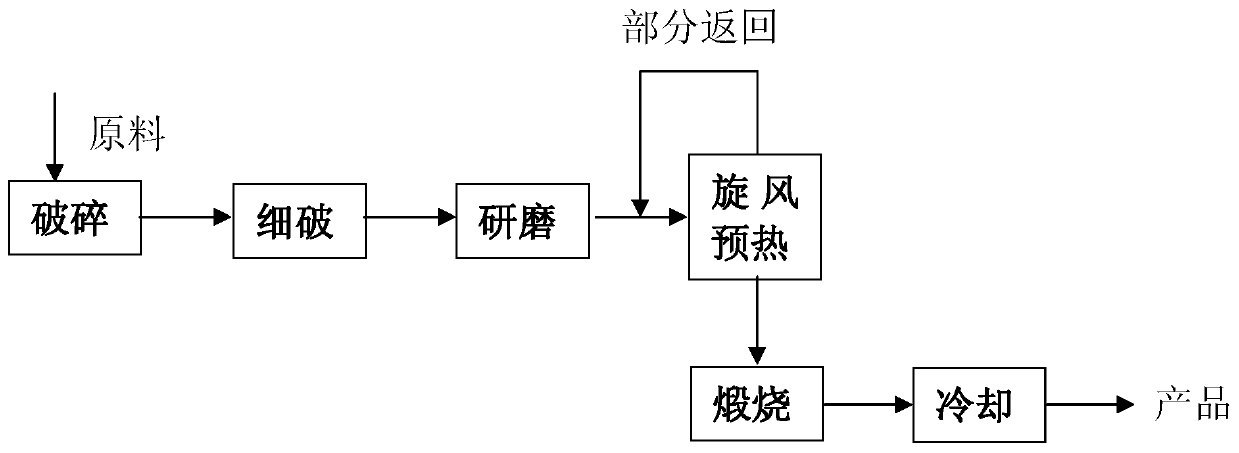

[0053] 1) Break the above three kinds of kaolin raw materials into small pieces less than 100mm, put them into their respective silos, and transport them to the upper material hopper of the fine crushing equipment with a metering belt, mix the small pieces and transport them to the rollers The machine is finely broken into granules below 10mm, and the granules enter the ball mill or vertical mill to be ground into 500-mesh fine powder.

[0054] 2) The fine powder enters the three-stage continuous cyclone preheating system. The preheating temperature of the first-stag...

Embodiment 2

[0057] The kaolin raw material is the same as that used in Example 1. Among them, 1# kaolin (rock) 20%, 2# kaolin (rock) 60% and 3# kaolin (rock) 20%.

[0058] 1) Break the above three kinds of kaolin raw materials into small pieces less than 100mm, put them into their respective silos, and transport them to the upper material hopper of the fine crushing equipment with a metering belt, mix the small pieces and transport them to the rollers The machine is finely broken into granules below 10mm, and the granules enter the ball mill or vertical mill to be ground into 300-mesh fine powder.

[0059] 2) The fine powder enters the three-stage continuous cyclone preheating system. The preheating temperature of the first-stage cyclone is 300°C, the preheating temperature of the second-stage cyclone is 380°C, and the preheating temperature of the third-stage cyclone is 460°C. Control the preheating time so that the loss on ignition of the intermediate product from the preheating cyclon...

Embodiment 3

[0062] The kaolin raw material is the same as that used in Example 1. Among them, 1# kaolin (rock) 20%, 2# kaolin (rock) 50% and 3# kaolin (rock) 30%.

[0063] 1) Break the above three kinds of kaolin raw materials into small pieces less than 100mm, put them into their respective silos, and transport them to the upper material hopper of the fine crushing equipment with a metering belt, mix the small pieces and transport them to the rollers The machine is finely broken into granules below 10mm, and the granules enter the ball mill or vertical mill to be ground into 1250 mesh fine powder.

[0064] 2) The fine powder enters the 3-stage continuous cyclone preheating system. The preheating temperature of the first-stage cyclone is 425°C, the preheating temperature of the second-stage cyclone is 500°C, and the preheating temperature of the third-stage cyclone is 600°C. Control the preheating time so that the loss on ignition of the intermediate product from the preheating cyclone i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com