Rare earth hydrogen storage alloy containing Mg and preparing method thereof

A hydrogen storage alloy and rare earth technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of unstable control of alloy composition, deviation between alloy composition and design, low vapor pressure, etc., and achieve easy-to-control production process, simple method, The chemical composition of the alloy is uniform and stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

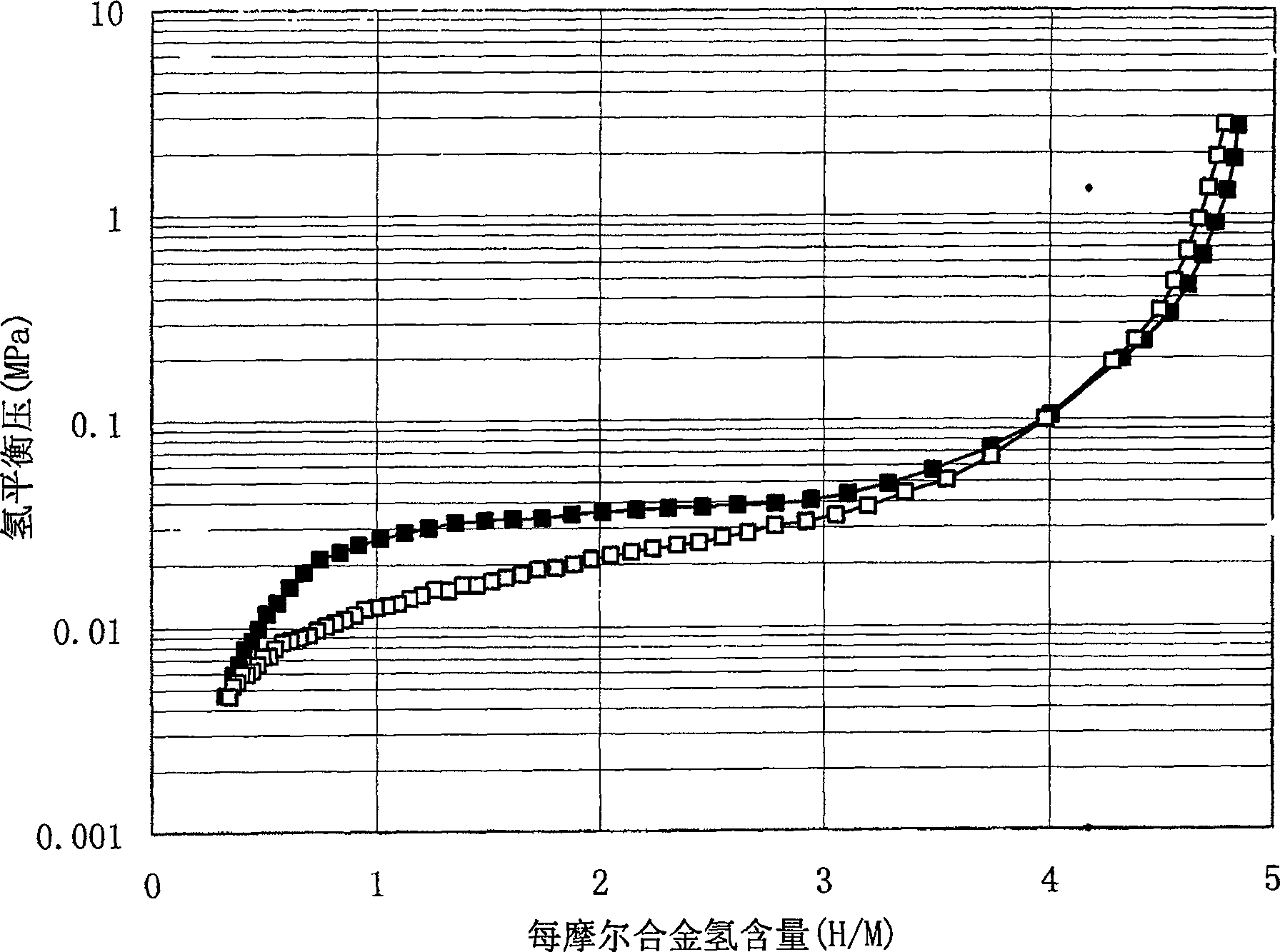

Image

Examples

Embodiment 1

[0015] The chemical structural formula of magnesium-containing rare earth hydrogen storage alloy is La 0.5 PR 0.1 Nd 0.2 Mg 0.2 (NiCoAlZr) 3.6 .

[0016] Its preparation method is:

[0017] 1) The chemical structural formula La of the designed Mg-containing rare earth hydrogen storage alloy 0.5 PR 0.1 Nd 0.2 Mg 0.2 (NiCoAlZr) 3.6 For batching, the purity of raw materials is greater than 99%.

[0018] 2) Put the rare earth metals, Mg, Ni, Co, Al, and Zr into the vacuum induction melting furnace together, wherein Mg is placed in the auxiliary feeding bin in the furnace, and other metals are directly added into the crucible, and the vacuum is evacuated to 0.5Pa. Stop vacuuming, fill in the inert gas Ar, control the pressure to 0.05MPa, start heating, when all the raw metals are melted evenly, stop heating and cooling;

[0019] 3) After the surface of the alloy melt is formed, add metal Mg and start heating. After the alloy is completely melted and uniform, reduce the g...

Embodiment 2

[0023] The chemical structural formula of magnesium-containing rare earth hydrogen storage alloy is La 0.4 PR 0.2 Nd 0.2 Mg 0.2 (NiCoAlY) 3.6 .

[0024] Its preparation method is:

[0025] 1) The chemical structural formula La of the designed Mg-containing rare earth hydrogen storage alloy 0.4 PR 0.2 Nd 0.2 Mg 0.2 (NiCoAlY) 3.6 For batching, the purity of raw materials is greater than 99%.

[0026] 2) Put rare earth metals, Mg, Ni, Co, Al, and Y into the vacuum induction melting furnace together, among which Mg is first placed in the auxiliary feeding bin in the furnace, and other metals are directly added into the crucible, and the vacuum is evacuated to 0.5Pa , stop vacuuming, fill in the inert gas Ar, control the pressure to 0.07MPa, start heating, when all the raw metals are melted evenly, stop heating and cooling;

[0027] 3) After the surface of the alloy melt is formed, add metal Mg and start heating. After the alloy is completely melted and uniform, reduce t...

Embodiment 3

[0031] The chemical structural formula of magnesium-containing rare earth hydrogen storage alloy is La 0.5 PR 0.2 Nd 0.1 Mg 0.2 (NiCoAlZrFe) 3.4 .

[0032] Its preparation method is:

[0033] 1) The chemical structural formula La of the designed Mg-containing rare earth hydrogen storage alloy 0.5 PR 0.1 Nd 0.2 Mg 0.2 (NiCoAlZrFe) 3.4 For batching, the purity of raw materials is greater than 99%.

[0034] 2) Put rare earth metals, Mg, Ni, Co, Al, and Y into the vacuum induction melting furnace together, among which Mg is first placed in the auxiliary feeding bin in the furnace, and other metals are directly added into the crucible, and the vacuum is evacuated to 0.5Pa , stop vacuuming, fill in the inert gas Ar, control the pressure to 0.04MPa, start heating, when all the raw metals are melted evenly, stop heating and cooling;

[0035] 3) After the surface of the alloy melt is formed, add metal Mg and start heating. After the alloy is completely melted and uniform, re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com