Fixing method of locking foot of steel arch frame for primary support of tunnel

A technology of primary support and fixation, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., and can solve problems such as poor connection of locking foot anchor pipes, weakening of locking foot anchor pipe function, unsuitable control of locking foot angles, etc. , to achieve the effect of reducing the failure of the locking foot anchor tube, preventing sinking, and eliminating the exposed welding joint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

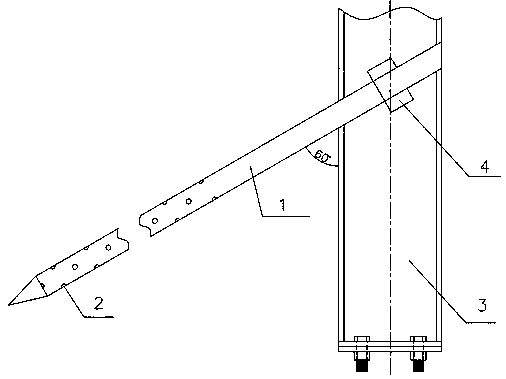

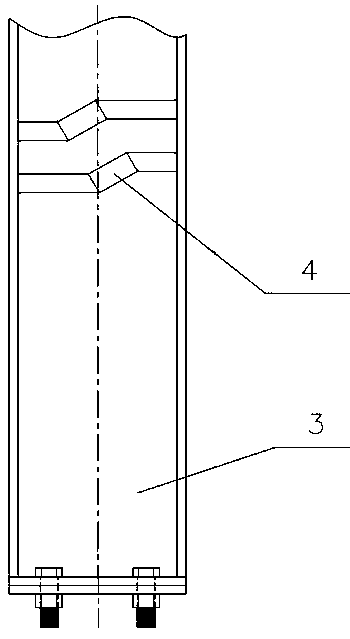

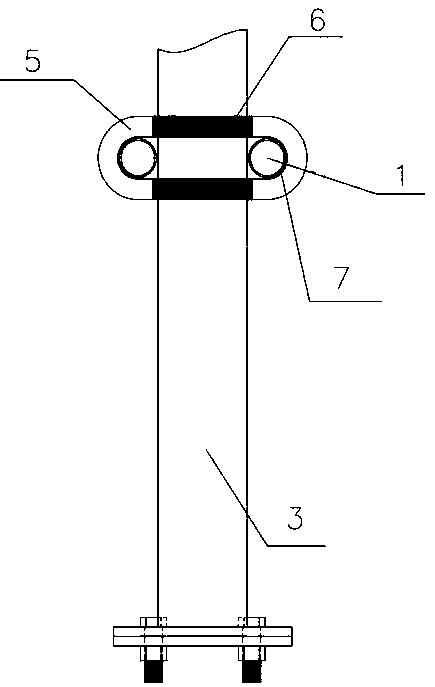

[0025] Such as Figure 1~4 As shown in the figure, the method of fixing the locking feet of the steel arch for the initial support of the tunnel includes the following steps:

[0026] ⑴Process the Φ42 seamless steel pipe into a fixed length, one end is processed into a sharp point, and the other end is processed into a 30 ο Beveled, and on the pipe wall at a distance of 40cm, the grouting holes 2 with a diameter of 8mm are arranged in a quincunx shape, and the locking foot anchor pipe 1 is obtained.

[0027] (2) Process a pair of square steel frame positioning holes 4 with a vertical spacing of 45mm and a size of 25mm×50mm on the web plate of the steel frame 3 by using a positioning plate. ο horn.

[0028] (3) Use Φ22mm, HRB400 threaded steel to make a U-shaped snap ring 5 with an inner diameter of the arc section of 45mm and a length of 38.6cm.

[0029] (4) Drill the drill pipe along the direction of the steel frame positioning hole 4 on the steel frame 3. After reaching t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com