Segmented triangular welding strip machining device and method

A processing device and delta welding technology, applied in the direction of sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve problems such as unusable, cycle length errors, and equipment not operating normally and stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

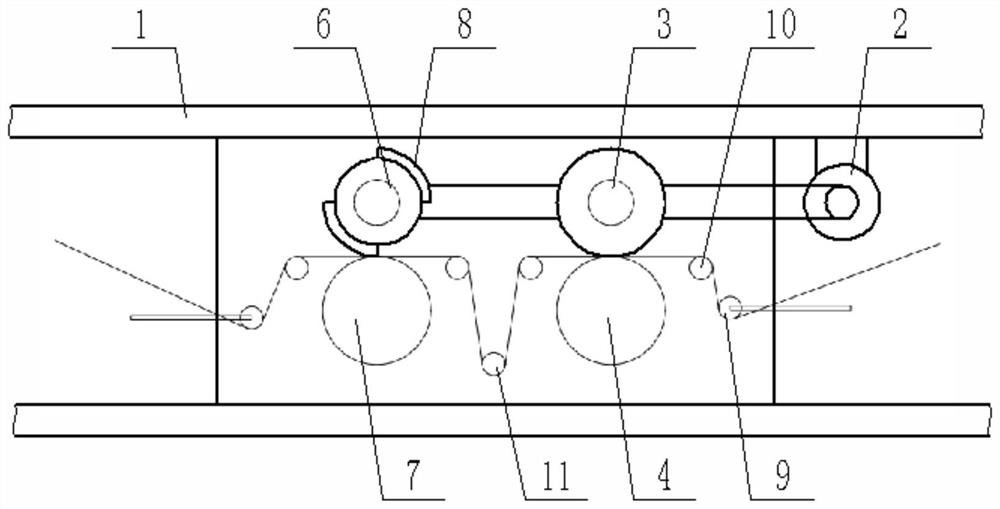

[0034] The present invention provides a segmented triangular ribbon processing device, which includes a bracket 1, a rolling mechanism installed on the bracket 1 and a tin-plating and tin-blowing mechanism. The rolling mechanism includes a first roller set and a second roller set. The second pressure roller group is located between the first pressure roller group and the tin-plating and tin-blowing mechanism; a motor 2 is fixedly installed on the support 1, and the first pressure roller group and the second pressure roller group are both It is connected with the motor 2 in transmission.

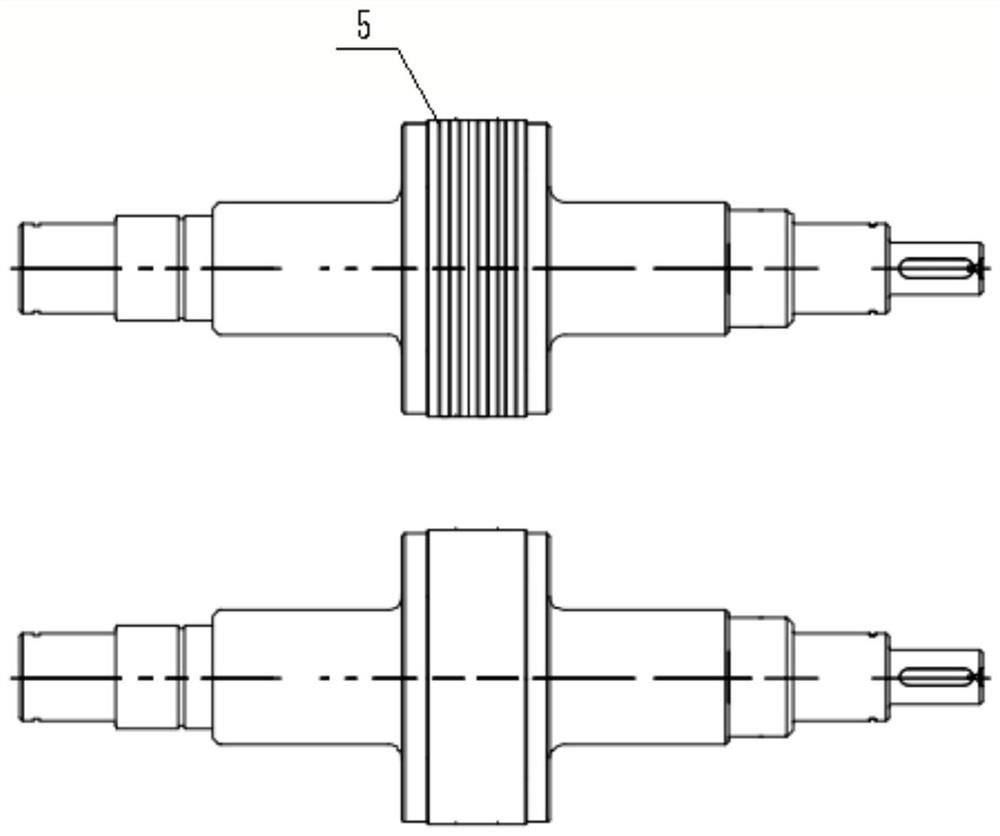

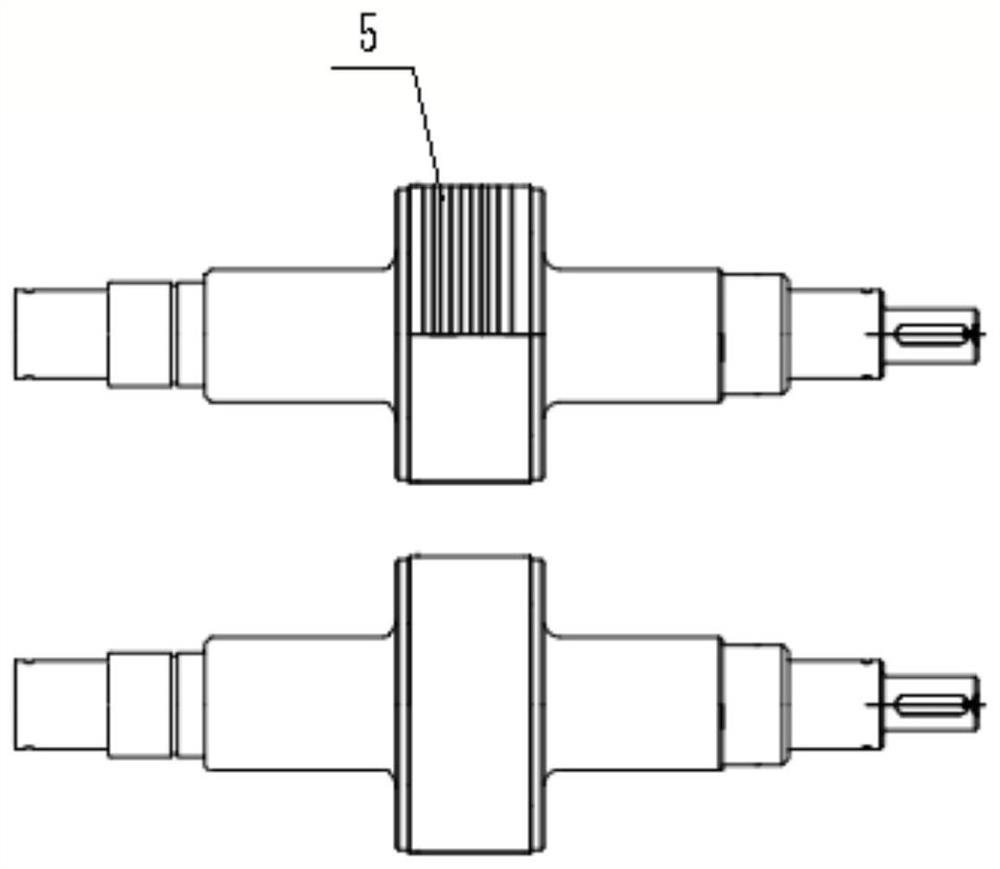

[0035] Further, the first pressure roll group includes a first upper roll 3 and a first lower roll 4 corresponding to the first upper roll 3, the central axis of the first upper roll 3 and the first lower roll The central axis of the roll 4 is in the same vertical plane, and the first upper roll 3 is provided with four triangular grooves 5 in the circumferential direction, and the distance be...

Embodiment 2

[0046] The present invention provides a segmented triangular ribbon processing device, which includes a bracket 1, a rolling mechanism installed on the bracket 1 and a tin-plating and tin-blowing mechanism. The rolling mechanism includes a first roller set and a second roller set. The second pressure roller group is located between the first pressure roller group and the tin-plating and tin-blowing mechanism; a motor 2 is fixedly installed on the support 1, and the first pressure roller group and the second pressure roller group are both It is connected with the motor 2 in transmission.

[0047] The first pressure roll group includes a first upper roll 3 and a first lower roll 4 corresponding to the first upper roll 3, the central axis of the first upper roll 3 and the first lower roll 4 The central axis is in the same vertical plane, and four triangular grooves 5 are arranged side by side on the upper circumference of the first upper roller 3, and the distance between two adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com