Vehicle-mounted loop antenna apparatus and manufacturing method thereof

A loop antenna and antenna seat technology, applied in the direction of antenna support/mounting device, antenna grounding switch structure connection, welding/welding connection, etc., can solve the problems of antenna swing, easy to desoldering, etc. Soldering and desoldering, the effect of large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

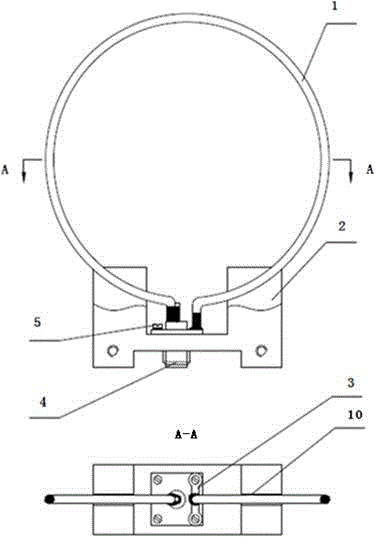

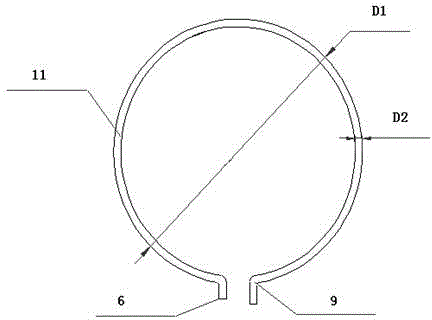

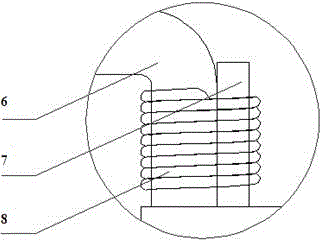

[0024] Please refer to Figure 1 to Figure 4 As shown, the vehicle-mounted loop antenna device of the present invention includes: an antenna vibrator 1 , an antenna base 2 and a high-frequency connector 4 . The antenna vibrator 1 includes an antenna vibrator metal ring 11, an antenna vibrator short solder leg 6 and an antenna vibrator long solder leg 9, wherein the antenna vibrator short solder leg 6 is welded to the high frequency connector socket solder pin 7, and the antenna vibrator long solder leg 9 Welded with the high-frequency connector flange plate, it adopts unique structural design and process to ensure the welding effect.

[0025] In the vehicle-mounted loop antenna device of the present invention, the short welding leg 6 of the antenna vibrator and the welding pin 7 of the high-frequency connector socket are overlapped, and then the bare copper wire 8 is wound firmly and then welded, which effectively increases the short welding leg 6 of the antenna vibrator and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com