Rotary anode target for X-ray tube, preparation method and target assembly

A rotating anode and X-ray technology, which is applied to X-ray tube electrodes, X-ray tube components, X-ray tubes, etc., can solve the problems of affecting the life of X-ray tubes, affecting the life of bearings, and the temperature rise of metal balls. Avoid direct heat radiation, improve the service life, and have the effect of high loading power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] The invention also discloses a method for preparing a rotating anode target for an X-ray tube, comprising the following steps:

[0074] A. Roughening treatment on the surface of the weldment:

[0075] The surfaces to be welded of the target surface layer 3 and the substrate 2 are subjected to straight grain or net knurling treatment, and the depth of the straight grain or net knurling treatment is 0.1-0.2 mm.

[0076] B. High temperature vacuum degassing treatment:

[0077] After the treatment in step A, the target surface layer 3, the substrate 2 and the annular cover 4 are cleaned, and the cleaned target disk 1, the substrate 2 and the annular cover 4 are placed in a vacuum furnace for high-temperature vacuum degassing treatment. The gas treatment temperature is 1400-1600°C (such as 1420°C, 1450°C, 1480°C, 1500°C, 1520°C, 1550°C, 1580°C), and the holding time is 30-60min (such as 35min, 40min, 45min, 50min, 55min ), the vacuum degree of vacuum degassing treatment is...

Embodiment 1

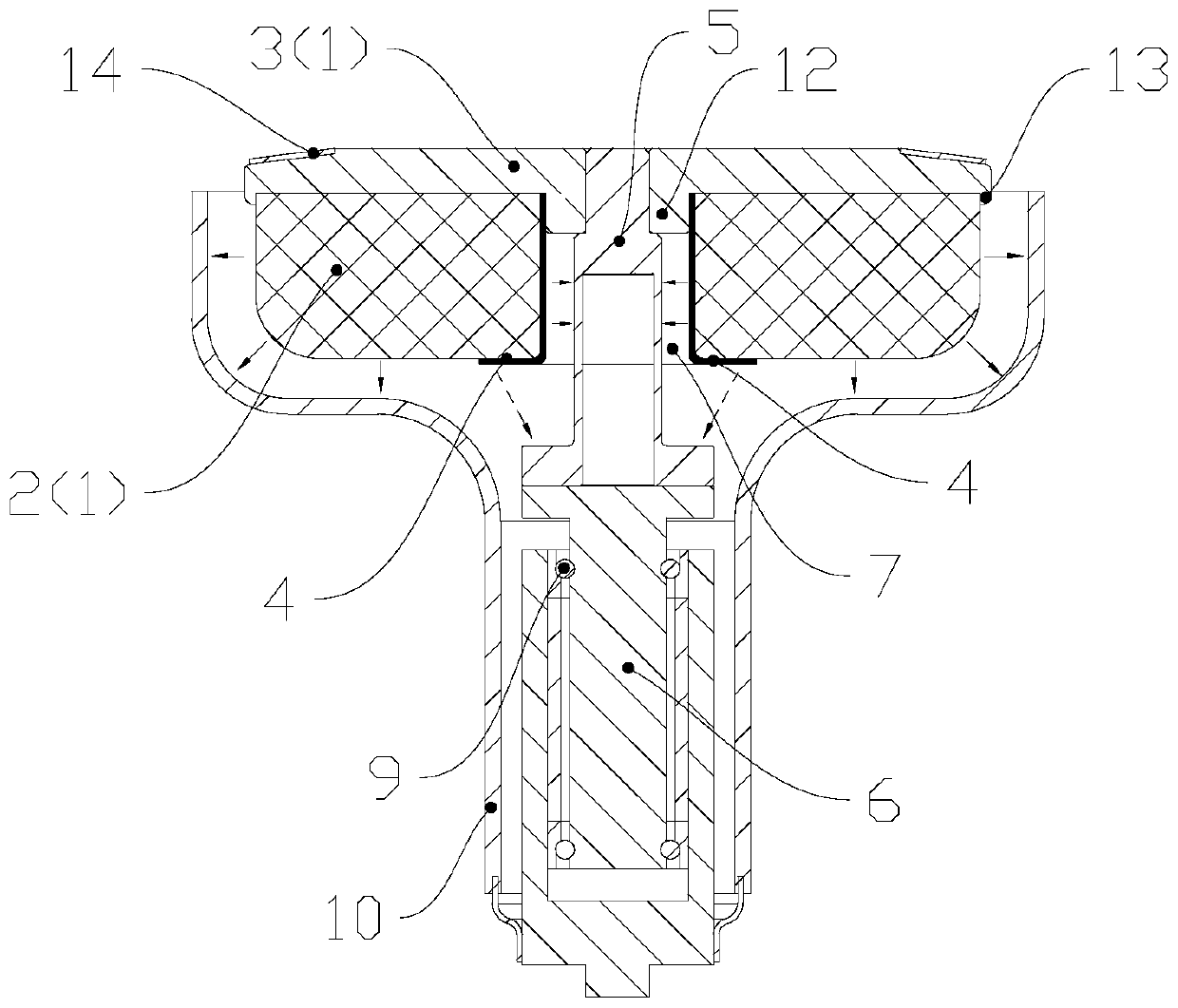

[0084] The rotating anode target assembly of this embodiment is such as figure 1 As shown, it includes a target disk 1 , an annular cover 4 , a rotating shaft 5 and a bearing assembly 6 . The metal balls 9 in the bearing assembly 6 are dry-lubricated with silver, and the corresponding limit operating temperatures are 450°C.

[0085] The preparation process of the rotating anode target in this embodiment is as follows:

[0086] A. Roughening treatment on the surface of the weldment:

[0087] The surfaces to be welded of the target surface layer 3 and the base body 2 that meet the size requirements of the target disc 1 after machining are subjected to knurling treatment, and the depth of the knurling is 0.15mm.

[0088] B. High temperature vacuum degassing treatment:

[0089] After the treatment in step A, the target surface layer 3, the substrate 2 and the annular cover 4 are cleaned, and the cleaned target disk 1, the substrate 2 and the annular cover 4 are placed in a vacu...

Embodiment 2

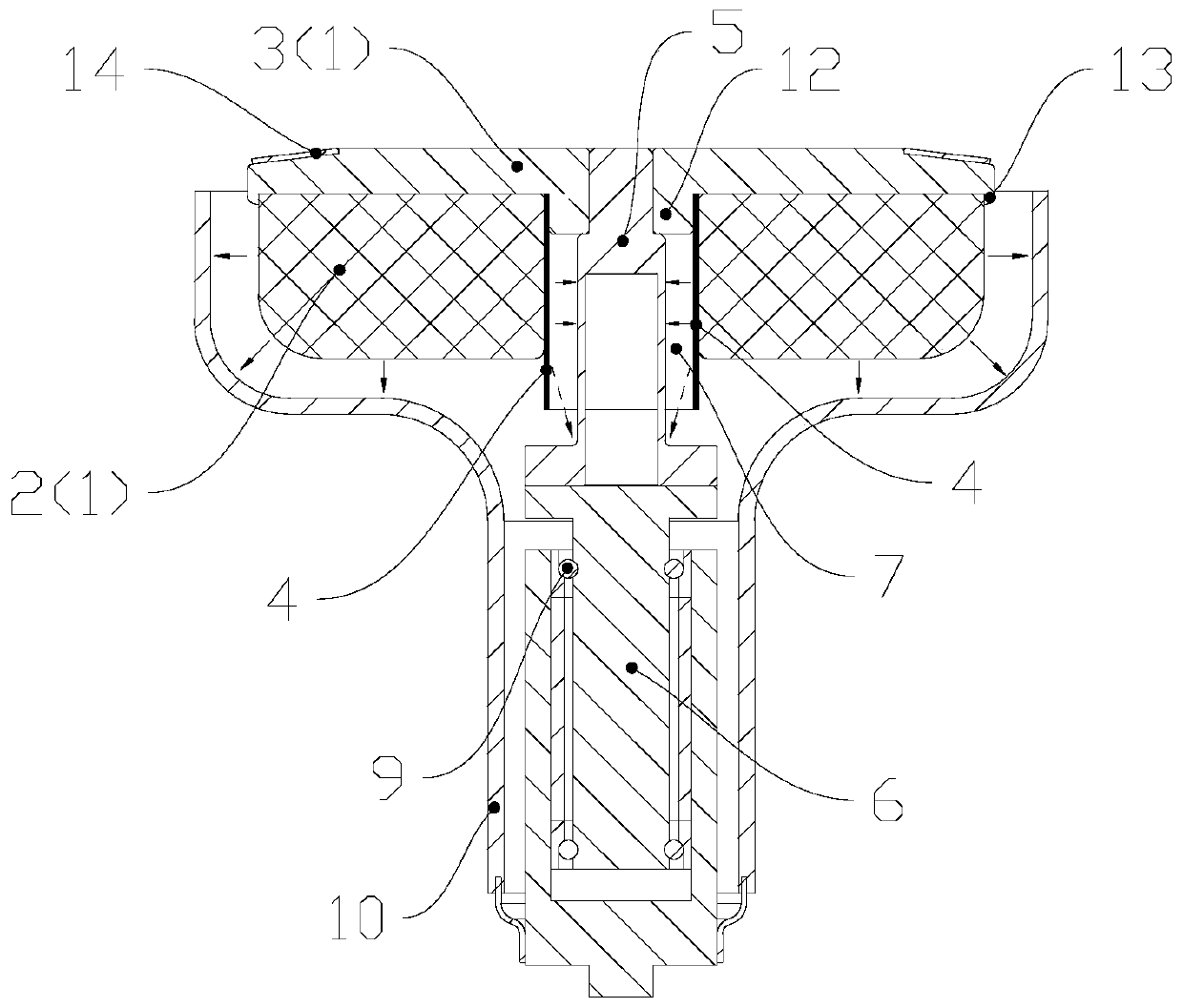

[0099] The anode target assembly of the present embodiment is as figure 2 As shown, it includes a target disk 1 , an annular cover 4 , a rotating shaft 5 and a bearing assembly 6 . The metal balls 9 in the bearing assembly 6 are dry-lubricated with silver, and the corresponding limit operating temperatures are 450°C.

[0100] The preparation process of the present embodiment target disc 1 is:

[0101] A. Roughening treatment on the surface of the weldment:

[0102] The surfaces to be welded of the target surface layer 3 and the substrate 2 that meet the size requirements of the target disc 1 after machining are subjected to knurling treatment, and the depth of the knurling is 0.20 mm.

[0103] B. High temperature vacuum degassing treatment:

[0104] After the treatment in step A, the target surface layer 3, the substrate 2 and the annular cover 4 are cleaned, and the cleaned target disk 1, the substrate 2 and the annular cover 4 are placed in a vacuum furnace for high-temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com