Electrolytic bath cathode steel bar connecting plate structure

A technology of cathode steel rod and connecting plate, applied in the field of component connection structure, can solve the problems of small welding connection area and unreliable connection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

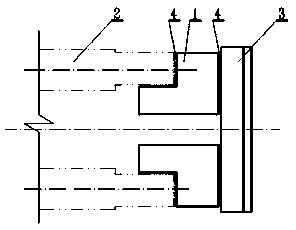

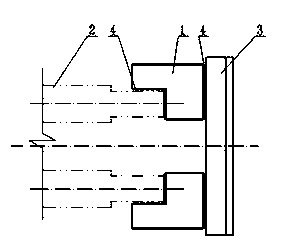

[0021] "L" shaped connecting plate 1 is to increase the welding contact area with the end face and side of the cathode steel rod 2; "L" shaped connecting plate 1 can be placed on the inner surface of the cathode steel rod 2, such as figure 1 , can also be placed on the outer side of the cathode steel rod 2, such as figure 2 .

Embodiment 2

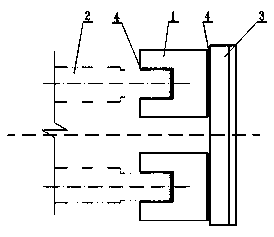

[0023] Two "L"-shaped connecting plates 1 form a "concave"-shaped connecting plate to increase the welding contact area with the end face and both sides of the cathode steel rod 2, such as image 3 . The figure shows that two "concave"-shaped connecting plates connect two cathode steel rods at the same time;

Embodiment 3

[0025] Two "L"-shaped connecting plates 1 form a "convex"-shaped connecting plate, which simultaneously connects the left and right cathode steel rods 2 and the steel-aluminum explosion welding block 3, such as Figure 4 , the weld between the connecting plate and the cathode steel rod is located on the inner surface and end surface of the cathode steel rod;

[0026] Such as Figure 5 , Two "L"-shaped connecting plates form a "concave"-shaped connecting plate, which connects the end faces, outer faces and steel-aluminum explosive welding blocks of two cathode steel rods at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com