Method of welding electrode for vacuum consumable arc-melting

A technology of vacuum consumable arc and welding method, which is applied in the direction of arc welding equipment, welding equipment, welding/welding/cutting items, etc., which can solve the problems of equipment and material loss, point-like pits, equipment impact, etc., and achieve Good effect, strong after welding, large welding contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

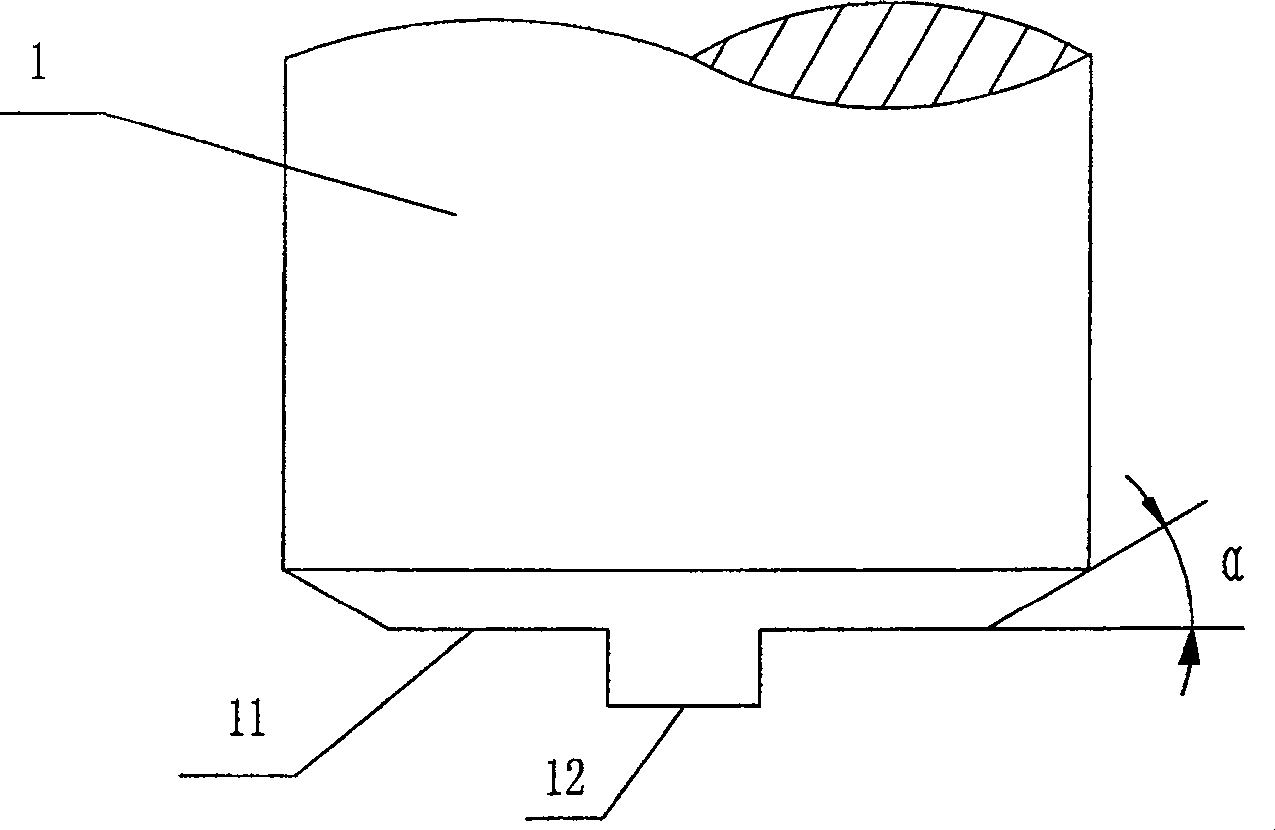

[0017] like figure 1 As shown, the welding end of the upper electrode 1 is turned downward and the welding end is turned into a boss 11. The middle part of the boss 11 is processed with a raised part 12 at the center of the upper electrode, and the outer circumference of the welding end of the upper electrode 1 is inverted. Angle α.

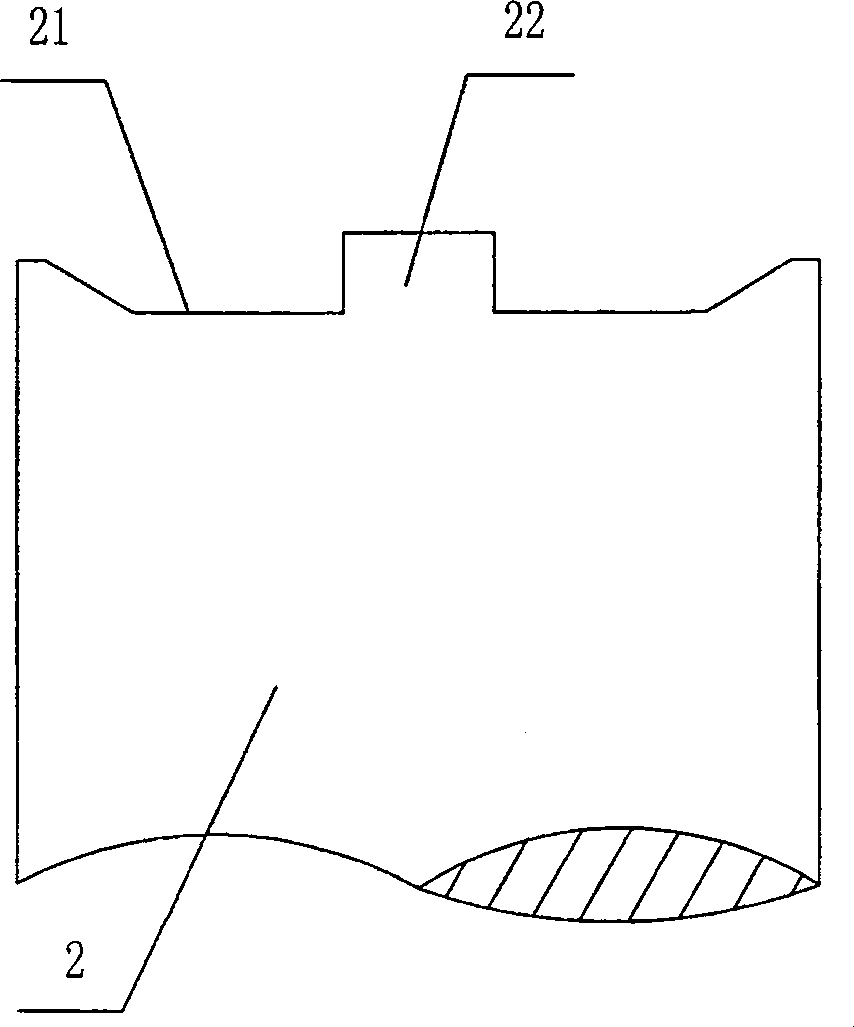

[0018] like figure 2 As shown, the welding end of the lower electrode 2 is turned upwards, and the welding end is turned into a groove 21 , and the middle part of the groove 21 is processed with a lower electrode core protrusion 22 .

[0019] Taking Φ160mm electrode welding as an example, a welding method for electrodes used in vacuum consumable arc melting of refractory metal alloys, the preparation process includes:

[0020] (1) According to the sequence of electrode melting, the two ends of the butt-welded upper ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com