Method of preparing titanium steel composite liquid route connecting tube of the complex construction connecting surface

A technology with complex structure and manufacturing method, which is applied in the field of manufacturing bimetal composite liquid pipes, can solve problems such as difficulty in realization, difficulty in coating, and limited welding depth of argon arc welding, so as to achieve high-strength diffusion welding, improve connection strength, Effect of increasing solder contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

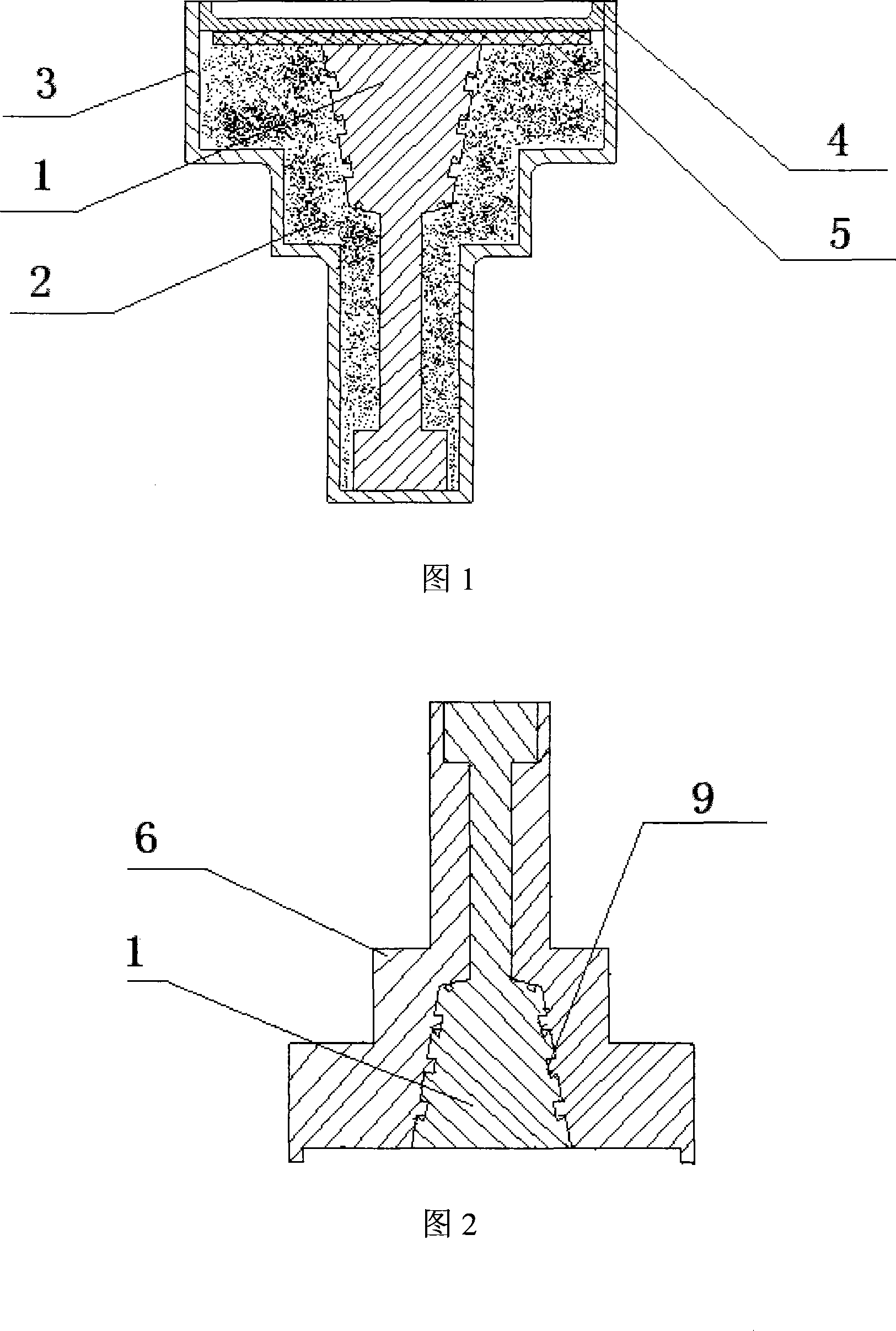

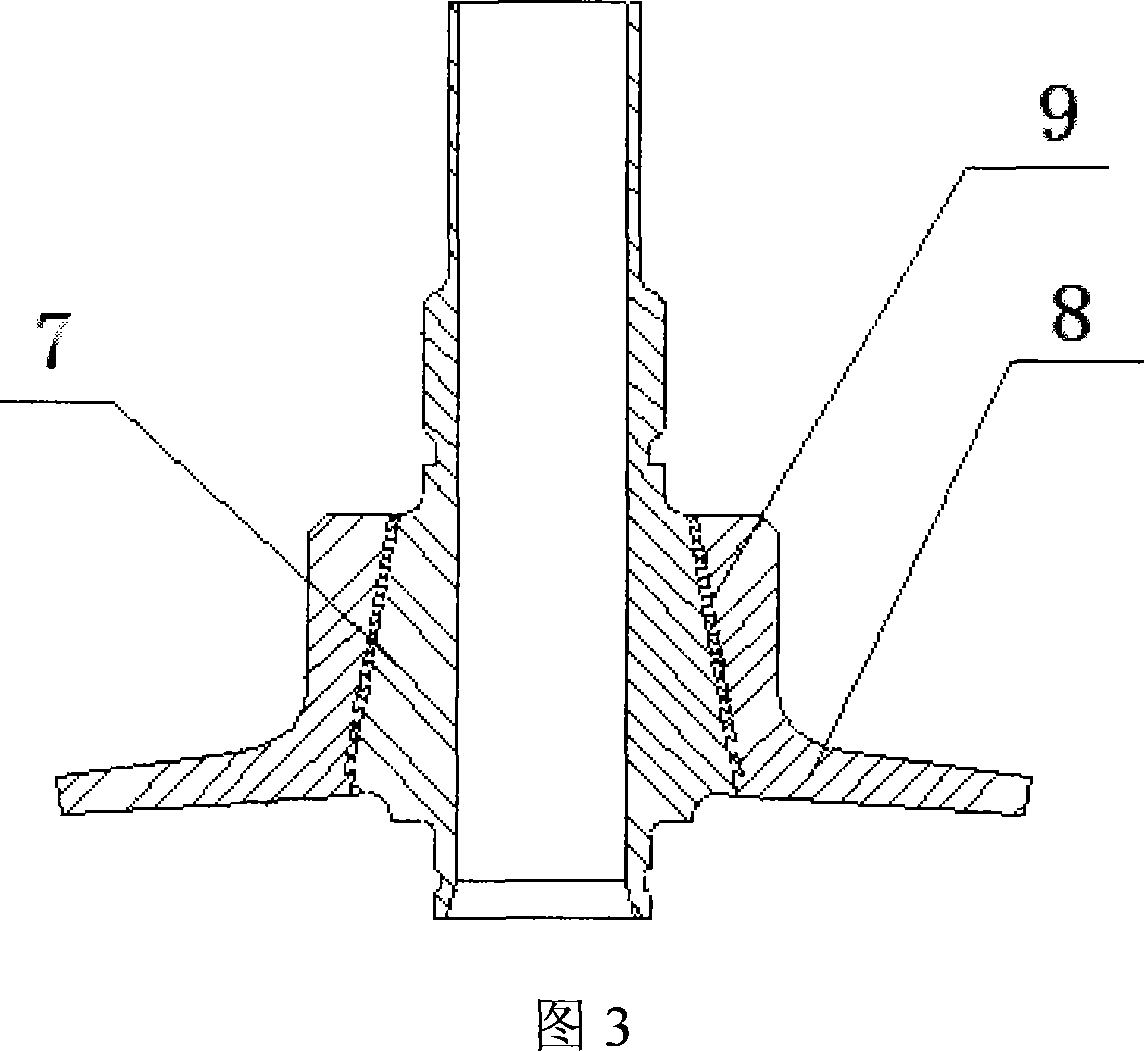

[0012] As shown in Figures 1, 2 and 3, a method for manufacturing a titanium-steel composite liquid pipe connecting surface with a complex structure includes the following steps:

[0013] (1) Add a transition layer on the surface of the steel blank

[0014] The surface of the steel blank 1Cr18Ni9Ti stainless steel 1 is cleaned, and a Ni transition layer is plated on the surface of the steel blank 1Cr18Ni9Ti stainless steel 1 by electroplating.

[0015] The steel blank 1Cr18Ni9Ti stainless steel 1 is a cylinder with a large diameter at both ends and a small diameter in the middle. One end and the middle part are cylinders, and the other end is a tapered cylinder. Increase; the surface of the tapered cylinder of 1Cr18Ni9Ti stainless steel 1 is evenly provided with four circles of dovetail grooves along the direction perpendicular to its axis.

[0016] Two criteria for selecting the transition layer metal (a) the value of the linear expansion coefficient of the transition layer ...

Embodiment 2

[0030] The difference with embodiment 1 is that the degree of vacuum in the step (3) is 1 * 10 -2 MPa, the holding time will be sealed and welded after 3 hours; the hot isostatic pressing temperature in step (4) is 850° C., the pressure is 105 MPa, and the holding time is 2.5 hours.

Embodiment 3

[0032] The difference with embodiment 1 is that the degree of vacuum in the step (3) is 4 * 10 -2 MPa, after holding time for 4 hours, it will be sealed and welded; the hot isostatic pressing temperature in step (4) is 950° C., the pressure is 160 MPa, and the holding time is 1 hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com