A kind of manufacturing method of ceramic lined aluminum tube

A technology of ceramic lining and aluminum tube is applied in the field of manufacturing ceramic lining aluminum tube, which can solve the problems of high transportation cost and non-corrosion resistance on the outer surface, and achieve the effects of simple equipment, low cost and reduced transportation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

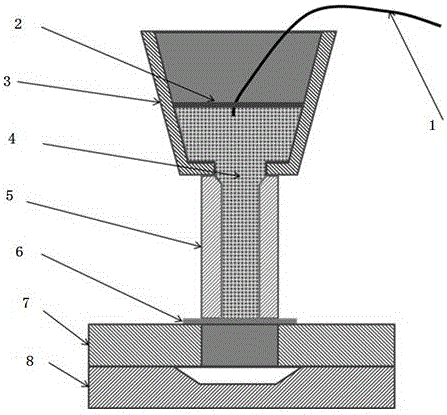

[0033] The aluminum tube to be formed is 6061, 80mm in length, 20mm in inner diameter, and 41mm in outer diameter. Process a pair of aluminum tube and crucible according to the steps. After preheating, follow the figure 1 Set up the device. Al+SnO with a mass fraction of 73% 2 (Strictly follow the reaction ratio, that is, the molar ratio is 4:3), 23% excess Al powder, 4% CaF 2 Pour the powder into the aluminum tube and crucible, insert the fuse, ignite and ignite to cause a self-propagating reaction. Under the action of gravity, the molten product is separated and deposited on the inner surface of the aluminum tube, and the self-propagating ceramic is completed. Preparation of lined composite aluminum tubes. The thickness of the obtained ceramic lining layer is about 1mm.

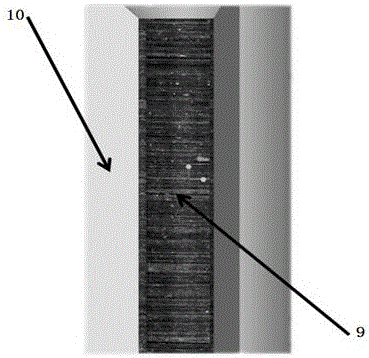

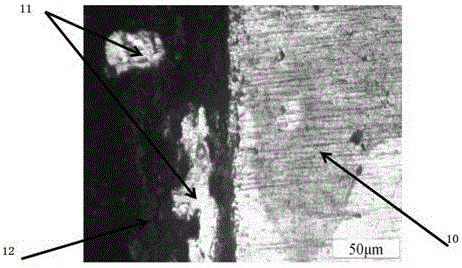

[0034] The prepared ceramic-lined aluminum tube sample was observed under a light microscope, which showed that the ceramic layer was tightly bonded to the aluminum substrate, but no obvious metal trans...

Embodiment 2

[0036] The aluminum tube to be formed is 6061, 80mm in length, 20mm in inner diameter, and 41mm in outer diameter. Process a pair of aluminum tube and crucible according to the steps. After preheating, follow the figure 1 Set up the device. Al+SnO with a mass fraction of 78% 2 (Strictly follow the reaction ratio, that is, the molar ratio is 4:3), 18% excess Al powder, 4% CaF 2 Pour the powder into the aluminum tube and crucible, insert the fuse, ignite and ignite to cause a self-propagating reaction. Under the action of gravity, the molten product is separated, and the inner surface of the aluminum tube is welded, that is, the self-propagating ceramic is completed. Preparation of lined composite aluminum tubes. The thickness of the obtained ceramic lining layer is about 1mm.

[0037] The prepared ceramic-lined aluminum tube sample was observed under a light microscope, which showed that the ceramic layer was tightly bonded to the aluminum substrate, but no obvious metal tr...

Embodiment 3

[0039] The aluminum tube to be formed is 6061, 80mm in length, 20mm in inner diameter, and 41mm in outer diameter. Process a pair of aluminum tube and crucible according to the steps. After preheating, follow the figure 1 Set up the device. Al+SnO with a mass fraction of 83% 2 (Strictly follow the reaction ratio, that is, the molar ratio is 4:3), 13% excess Al powder, 4% CaF 2 Pour the powder into the aluminum tube and crucible, insert the fuse, ignite and ignite to cause a self-propagating reaction. Under the action of gravity, the molten product is separated and deposited on the inner surface of the aluminum tube, and the self-propagating ceramic is completed. Preparation of lined composite aluminum tubes. The thickness of the obtained ceramic lining layer is about 1mm.

[0040] The prepared ceramic-lined aluminum tube sample was observed under a light microscope, which showed that the ceramic layer was tightly bonded to the aluminum substrate, but no obvious metal trans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com