A casting method for super duplex stainless steel 5A impeller

A technology of duplex stainless steel and impeller, which is applied in the direction of casting molding equipment, casting mold, casting mold composition, etc., can solve the problems of sand slag hole and air hole defects, unfavorable feeding, high temperature of molten metal, etc., to solve crack defects, casting Reduce production cost and ensure the effect of casting structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

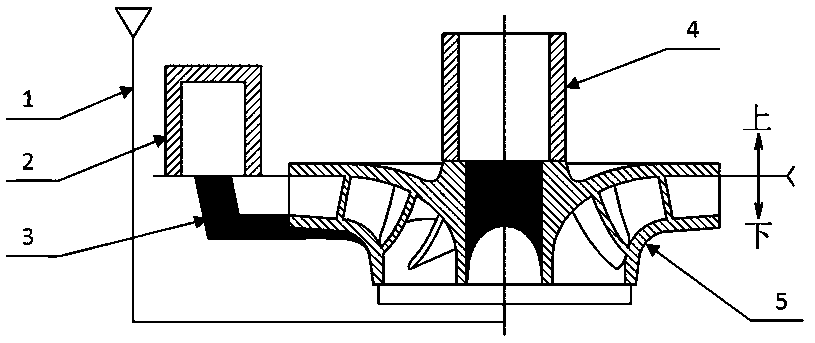

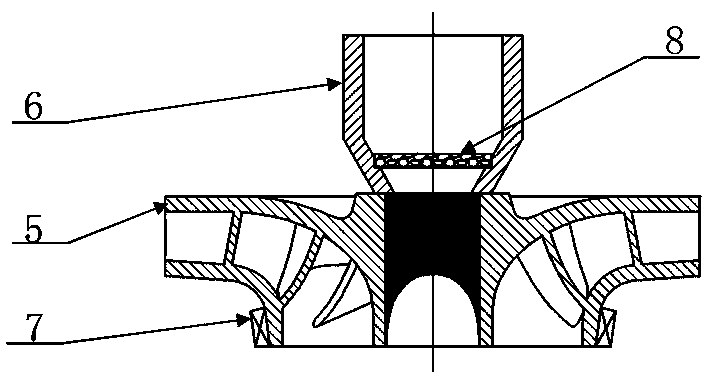

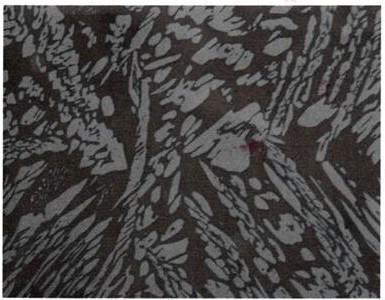

[0029] A casting method for an impeller made of super duplex stainless steel 5A, including internal control composition design, casting process, casting mold and sand core manufacturing process, smelting, pouring process, and heat treatment process for sand falling heat charging furnace.

[0030] (1) Design of internal control components: In order to improve the corrosion resistance of super duplex stainless steel castings, the content of ferrite phase and austenite phase should each account for about half (ferrite content is 40-60%). Control and design the content of austenite forming elements. The designed internal control composition range is: C≤0.025%, Si: 0.30~0.8%, Mn: 0.50~1.0%, P≤0.035%, S≤0.025%, Cr : 24.0~25.0%, Ni: 7.0~8.0%, Mo: 4.3~4.8%, N: 0.15~0.25%, PREN value: %Cr+3.3%Mo+16%N≥40.

[0031] (2) Manufacturing process of molds and sand cores: the molding materials of molds and sand cores are made of alkaline phenolic resin sand, and the molds and sand cores are mad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com