Casting and cooling system and cooling method of high-carbon steel thin-walled annular casting

A technology of cooling system and ring casting, applied in the direction of casting mold, casting mold composition, casting molding equipment, etc., can solve the problems of easy cracks and shrinkage porosity, and achieve the effect of increasing the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

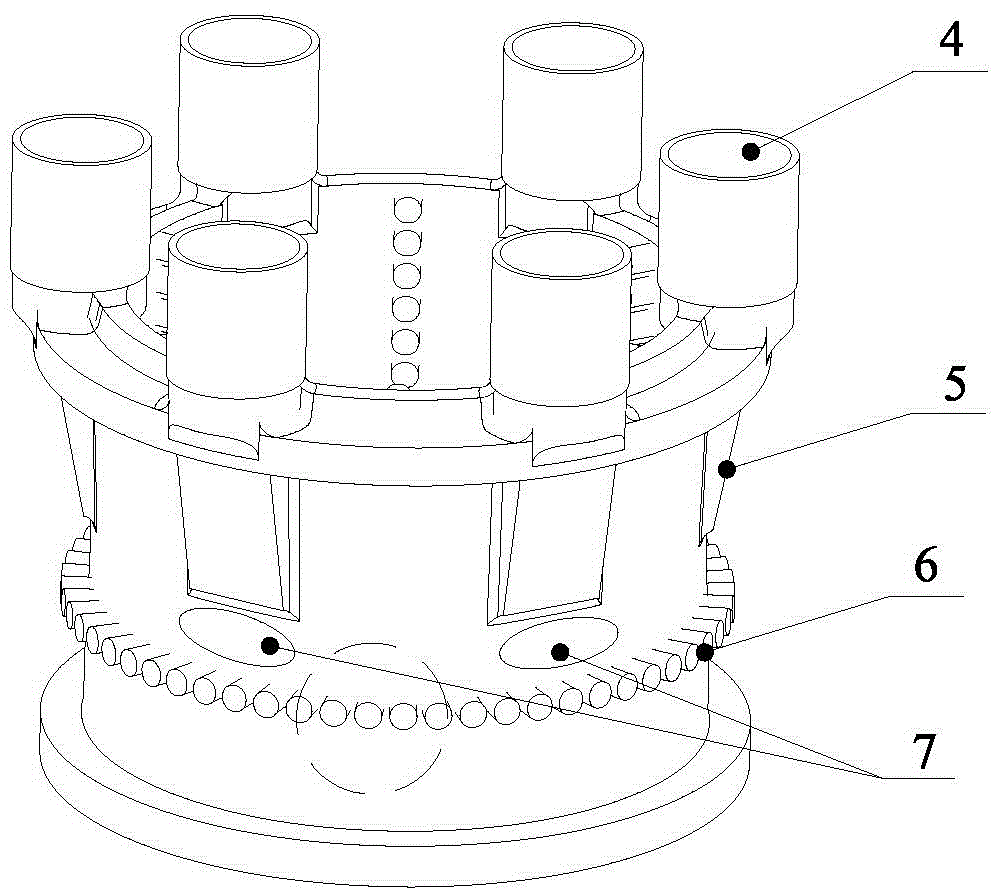

[0020] Such as Figure 4 — Figure 8 As shown, it is the pouring cooling system of the high carbon steel thin-walled annular casting of the present invention. In this system, an annular cooling channel 8 is arranged at intervals near the thinnest wall thickness inside the thin-walled cavity of the casting. The annular cooling channel 8 is provided with Extending to the air inlet pipe 9 and the air outlet pipe 10 outside the sand box, the air inlet pipe 9 is connected with the compressed air source; on the outside of the thin-walled cavity of the casting, a number of tie bars 12 connected with the casting cavity are pasted, and the length direction of the tie bars 12 It is arranged along the axial direction of the annular thin wall.

[0021] In order to further promote the uniform cooling and solidification of the thin-walled parts, the above-mentioned annular cooling channel 8 includes several layers of arc-shaped cooling pipes arranged at intervals along the axial direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com