Continuous casting machine and method using molten mold flux

A technology of mold slag and continuous casting machine, which is used in casting melt containers, casting equipment, manufacturing tools, etc., can solve problems such as the limitation of supply of molten slag in molten state, and achieve the effect of preventing turbidity of cooling water and improving the casting environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

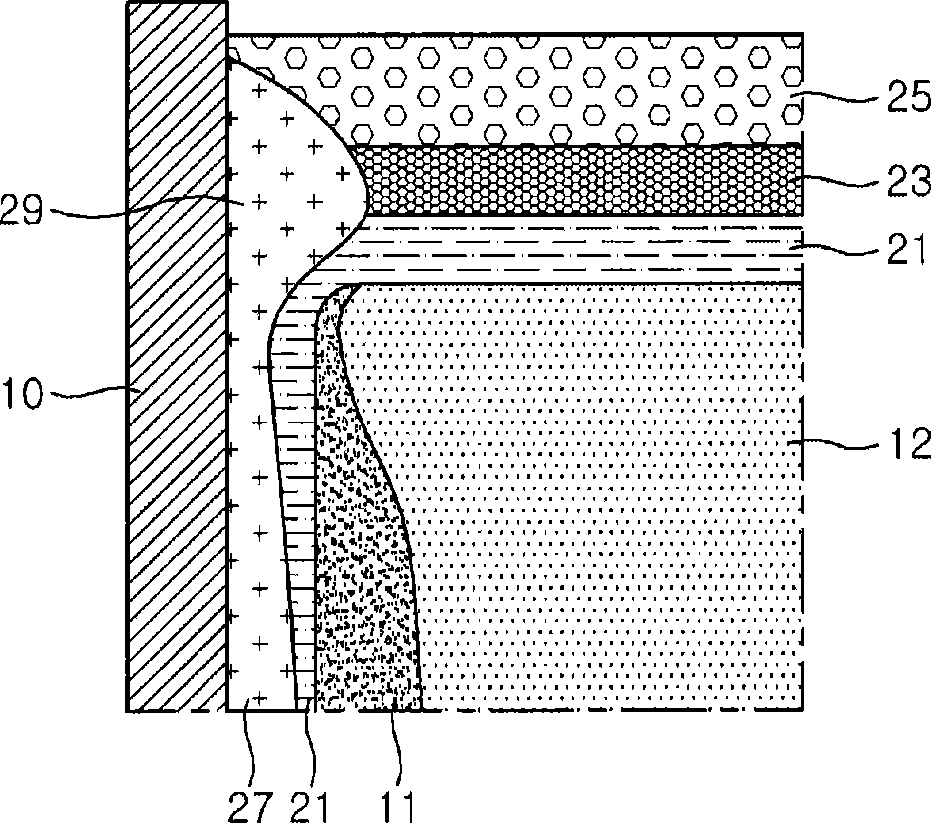

[0032] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. However, the present invention is not limited to the embodiments disclosed below, but can be implemented in various forms. These examples are provided only for the purpose of illustration and for those skilled in the art to fully understand the scope of the present invention. Throughout the drawings, the same reference numerals are used to designate the same elements.

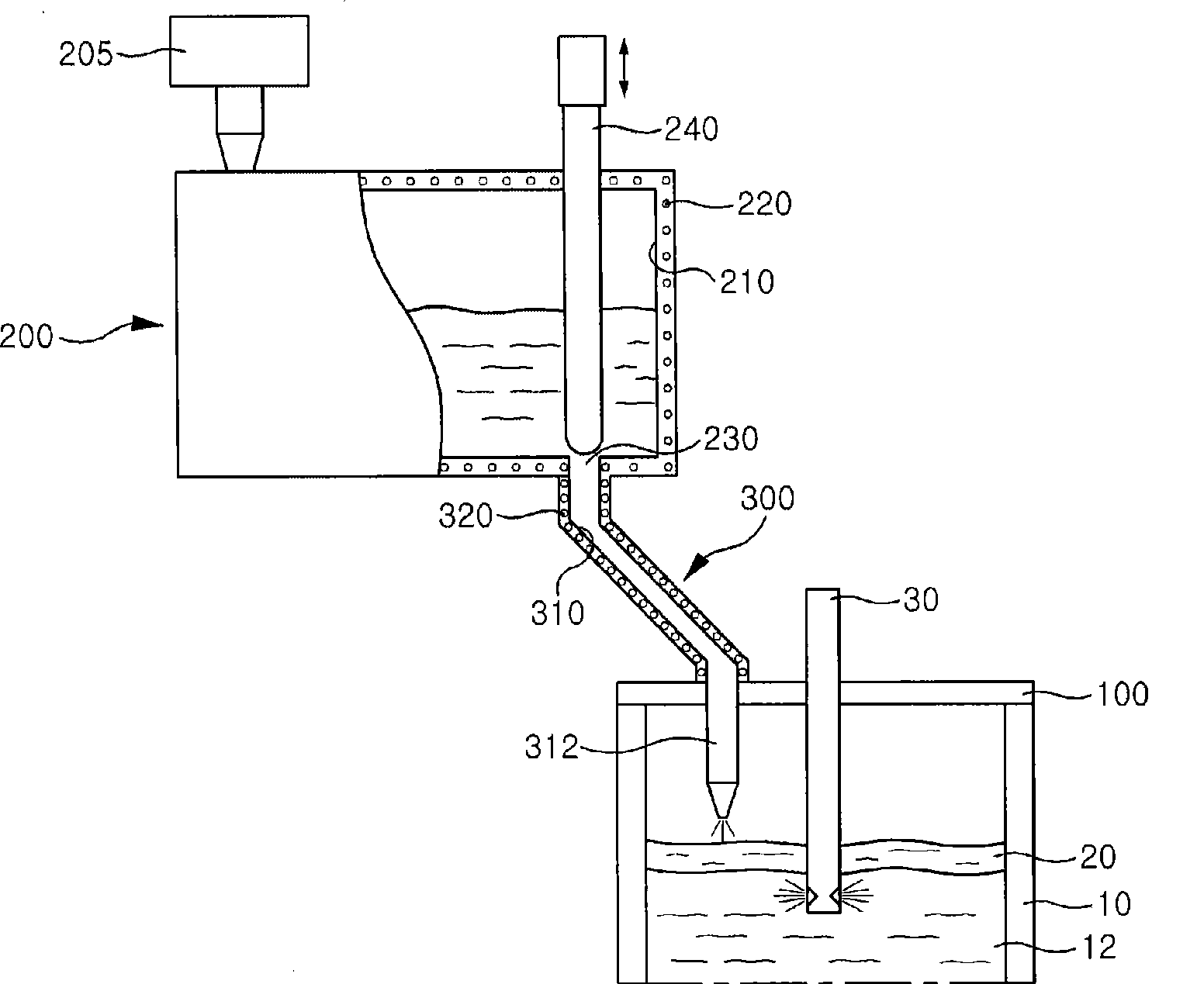

[0033] figure 2 is a schematic diagram showing a continuous casting machine according to the present invention. The continuous casting machine of the present invention comprises: a mold 10; a submerged nozzle 30 for supplying molten steel into the mold 10; a mold cover 100 for covering the upper part of the mold 10; a mold slag melting unit 200 for melting the mold flux to be supplied into the mold;

[0034] In the above configuration, the mold 10 and the submerged noz...

PUM

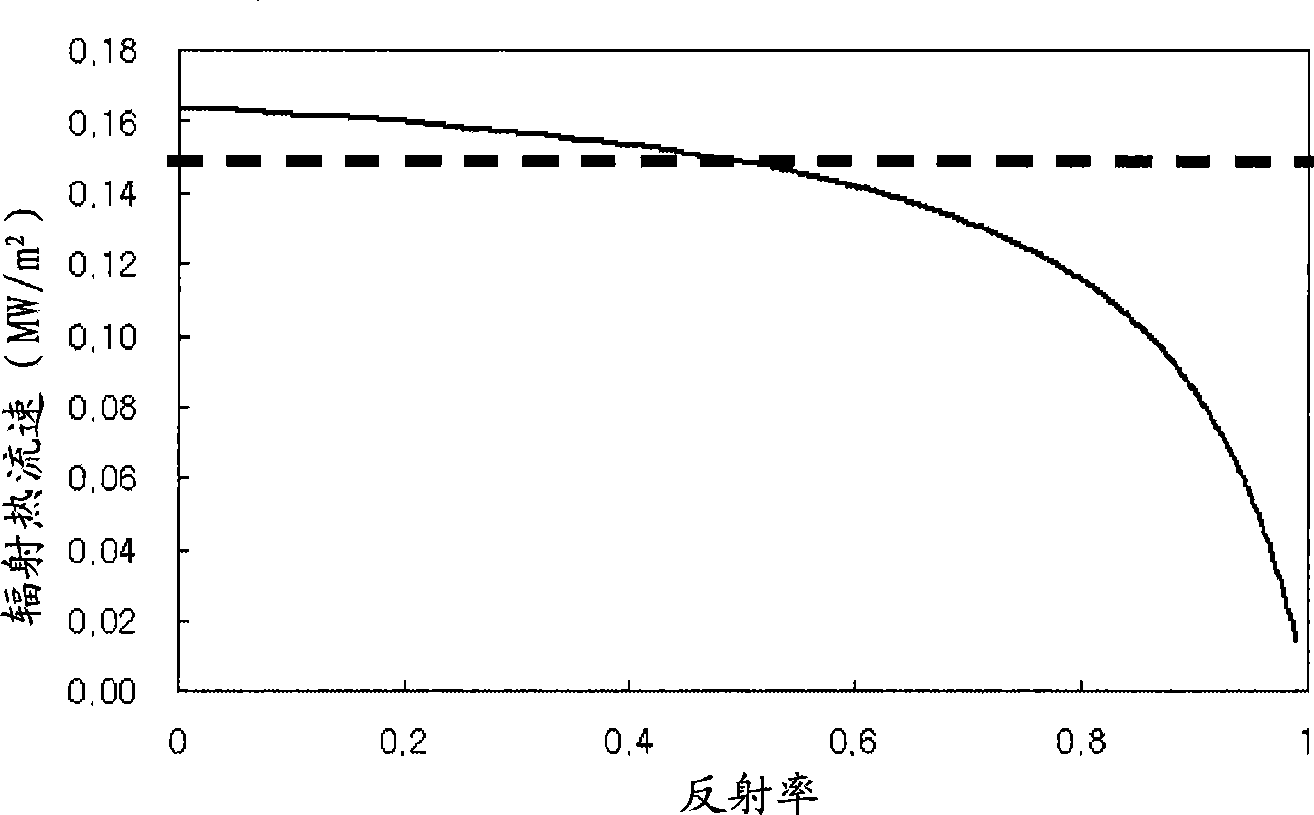

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com