A joint welding method between yg8 hard alloy tip and 40cr structural steel tip shank

A cemented carbide, welding method technology, applied in welding equipment, non-electric welding equipment, metal processing equipment and other directions, can solve the problems of low quality stability, large differences in chemical properties, hardened structure and cracks, etc., to achieve welding time Short, narrow heat-affected zone, effective in solving cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0021] A joint welding method between a YG8 cemented carbide tip and a 40Cr structural steel tip shank, characterized in that the welding method comprises the following steps:

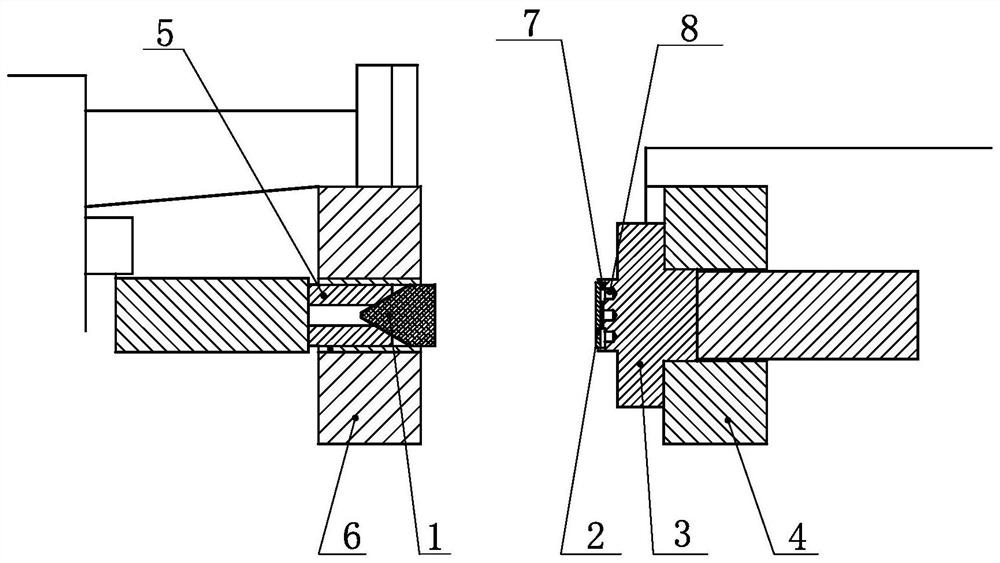

[0022] Pre-treat the 40Cr structural steel tip handle 3 and the transition layer metal material 2 to be welded, so that the welding surface of the 40Cr structural steel tip handle 3 forms a step hole 7, and clamp the YG8 hard alloy tip 1 to the rotating fixture 6, 40Cr The top handle 3 of the structural steel is clamped by the moving fixture 4, and the metal material 2 of the intermediate transition layer is placed in the step hole 7 on the welding surface of the top handle 3 of the 40Cr structural steel; the inertia friction welding is started, and the welded product is heat treated . Among them, the above-mentioned pretreatment process for the 40Cr structural steel tip handle 3 and the intermediate transition layer metal material 2 is: processing the 40Cr structural steel tip handle 3 so that the are...

Embodiment 1

[0040] A joint welding method of a YG8 hard alloy tip and a 40Cr structural steel tip shank comprises the following steps: a YG8 tungsten carbide tip with a diameter of 24mm and a matching 40Cr structural steel tip shank are selected for the weldment,

[0041] Pretreatment: Install the flywheel, rotating fixture and moving fixture, select the YG8 carbide tip with a diameter of 24mm, and process the 40Cr structural steel tip handle 3 and the previous transition layer metal material 2 to be welded to make the 40Cr structural steel tip handle 3 A stepped hole 7 is formed on the welding surface, and a plurality of uniformly distributed small holes 8 are arranged at the bottom of the stepped hole 7 . A plurality of small holes 8 are arranged in a ring around the small hole arranged in the center of the stepped hole 7 . The area of the transition layer metal material 2 is equal to the area of the step hole 7 in the 40Cr structural steel tip handle 3, the welding surface size of ...

Embodiment 2

[0045] A joint welding method of a YG8 hard alloy tip and a 40Cr structural steel tip shank comprises the following steps: a YG8 tungsten carbide tip with a diameter of 24mm and a matching 40Cr structural steel tip shank are selected for the weldment,

[0046] Pretreatment: Install the flywheel, rotating fixture and moving fixture, select the YG8 carbide tip with a diameter of 24mm, and process the 40Cr structural steel tip handle 3 and the intermediate transition layer metal material 2 to be welded to make the 40Cr structural steel tip handle 3 A stepped hole 7 is formed on the welding surface, and a plurality of uniformly distributed small holes 8 are arranged at the bottom of the stepped hole 7 . A plurality of small holes 8 are arranged in a ring around the small hole arranged in the center of the stepped hole 7 . The area of the transition layer metal material 2 is equal to the area of the step hole 7 in the 40Cr structural steel tip handle 3, the welding surface size...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com