Conical surface sealing cylindrical battery and preparation method thereof

A cylindrical battery and sealing technology, which is applied in the direction of cylindrical shell battery/battery, secondary battery manufacturing, battery pack components, etc., can solve the problem of limiting the available space of the electrode pack of high-capacity batteries, increasing material costs and operating costs, reducing The available space of the steel shell and other issues can be improved to improve the performance of high-current charging and discharging, the structure is novel, and the effect of increasing the available space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

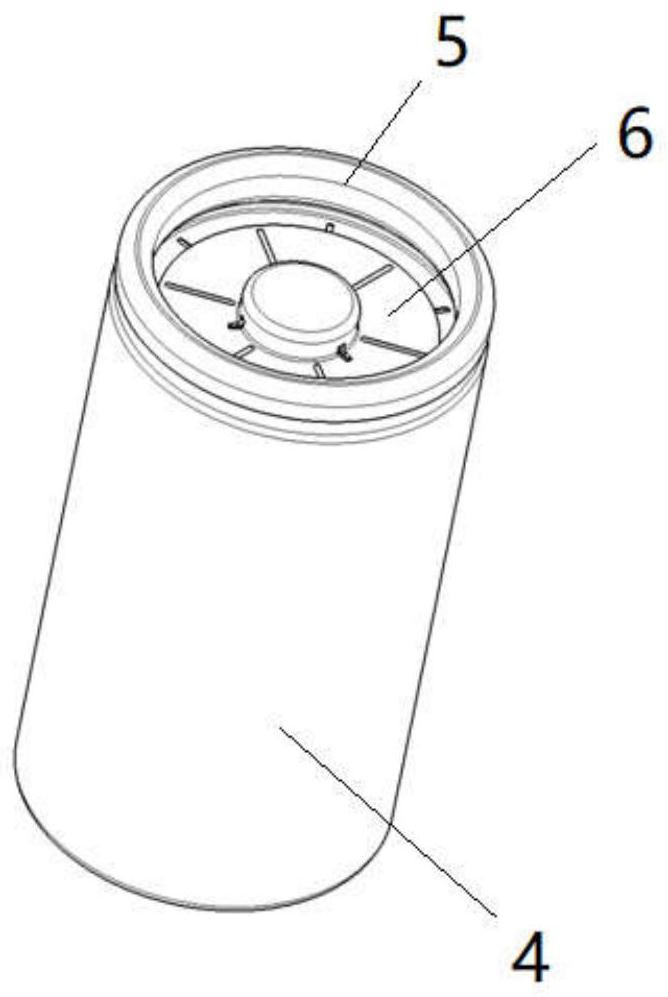

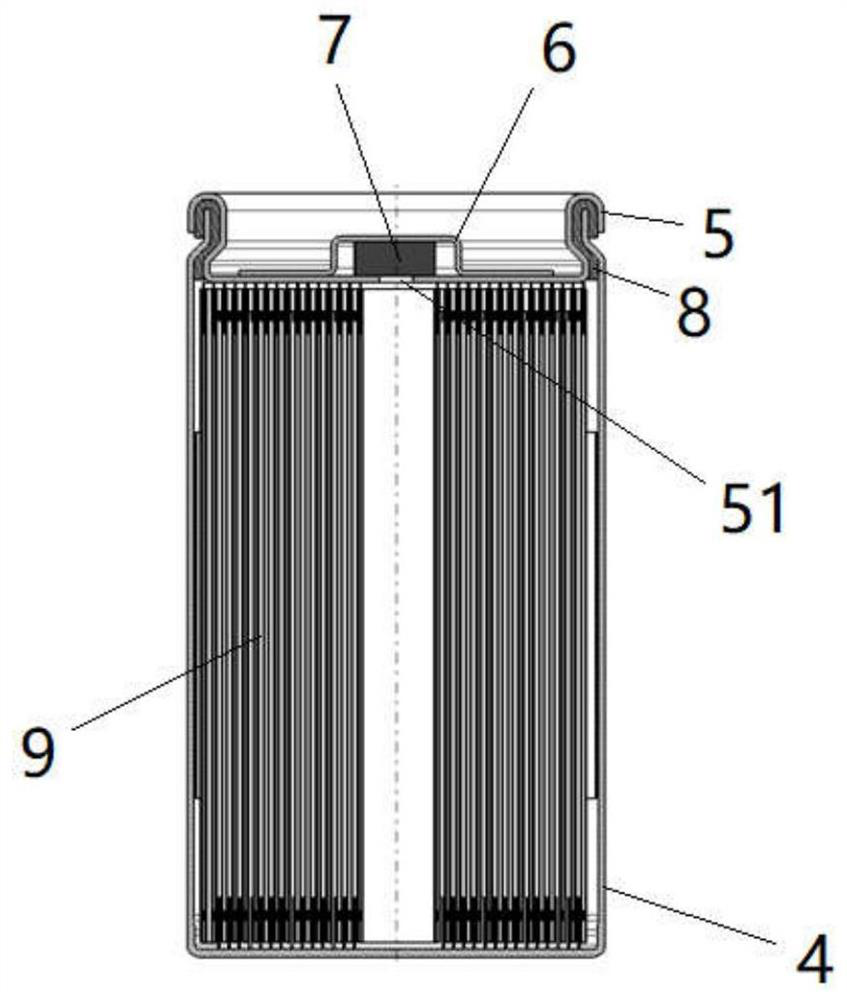

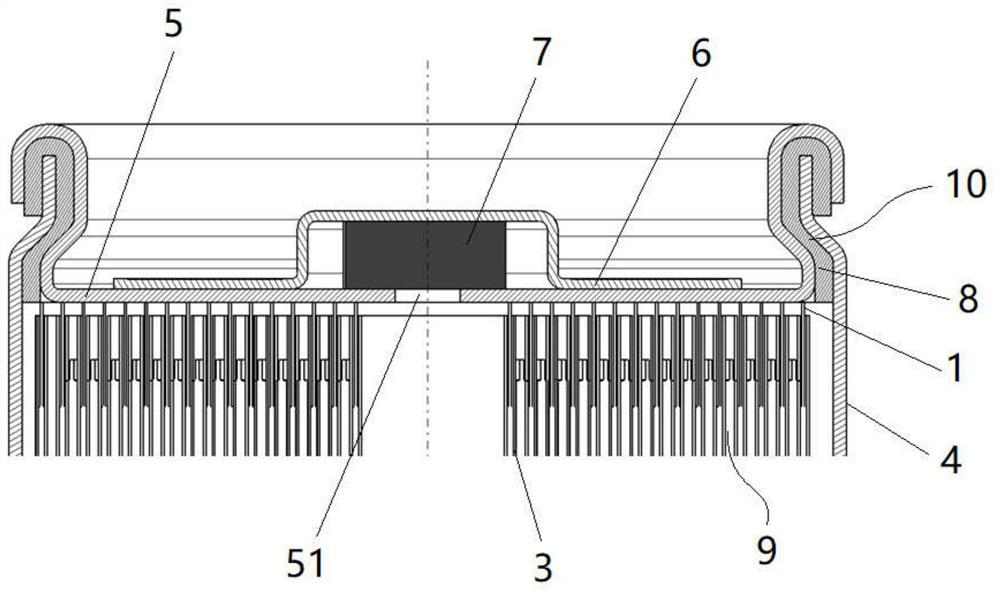

[0026] A cylindrical battery with conical sealing, such as figure 1 , figure 2 , image 3 , Figure 4As shown, including the positive plate 1, the negative plate 2, the diaphragm 3, the steel shell 4, the sealing structure 5, the sealing upper cover plate 6, the safety valve 7 and the sealing ring 8, the thickness of the bottom of the steel shell 4 is thicker than that of the side wall of the steel shell 4 The thickness is 0.1mm, the positive plate 1, the diaphragm 3, and the negative plate 2 are misaligned with the positive plate 1 and the negative plate 2, and the side of the positive plate 1 pole belt exceeds the diaphragm 3, and the side of the negative pole plate 2 pole belt exceeds the diaphragm 3 The pole group 9 is wound into the pole group 9 in the same way. The outermost ring of the pole group is in contact with the inner wall of the steel shell as the negative electrode piece. The pole group 9 is placed in the steel shell 4 with the positive end, that is, the par...

Embodiment 2

[0032] A cone-sealed cylindrical battery, the structure of which is similar to that of the cone-sealed cylindrical battery in Example 1, the difference being that the thickness of the bottom of the steel case is 0.2 mm thicker than the thickness of the side wall of the steel case, The outermost ring of the pole group is in contact with the inner wall of the steel case is the positive electrode piece, and the pole group is placed in the steel case with the negative end, that is, the part of the negative electrode piece beyond the diaphragm facing upward, that is, the upward end of the pole group after being placed in the steel case is At the negative end, the angle between the inclined surface of the extrusion part and the horizontal plane is 45°, the bottom of the extrusion part is at a certain distance from the upward end of the electrode group, that is, the negative end (the part of the negative electrode beyond the diaphragm), and the bottom of the sealing structure faces dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com