Manufacturing method of surface mounting capacitor for enhancing weldability

A technology of surface mounting and manufacturing methods, applied in capacitors, electrical components, etc., can solve problems such as virtual soldering, achieve the effects of increasing the soldering contact area, ensuring reliability, and reducing virtual soldering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

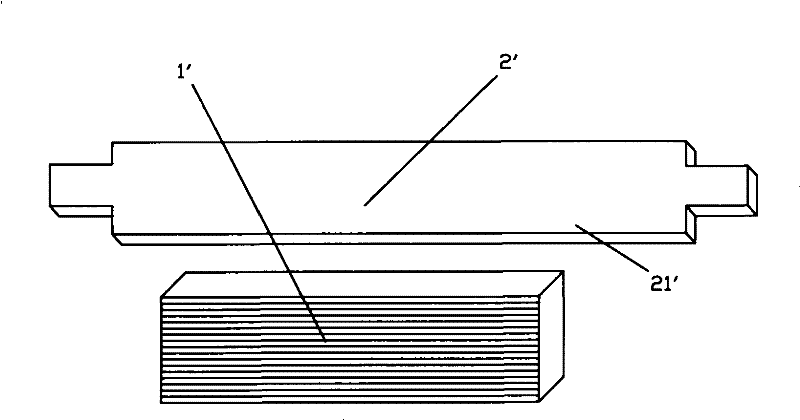

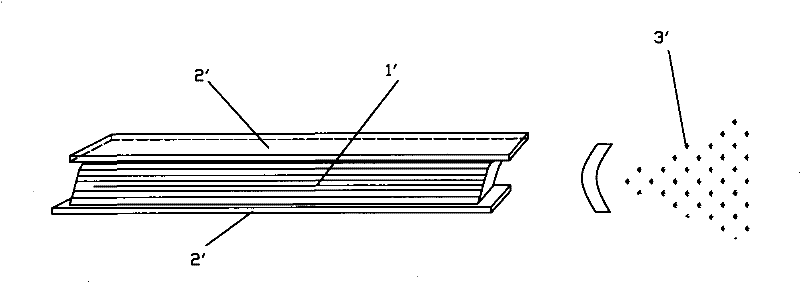

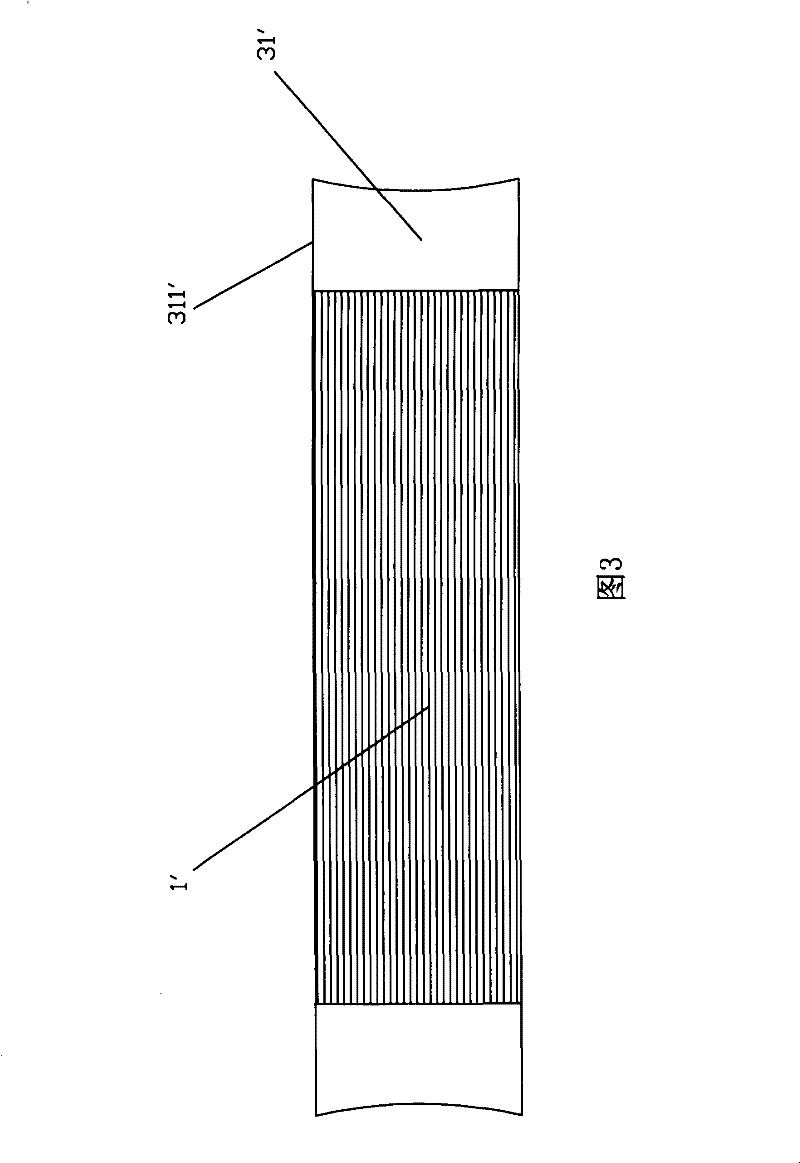

[0021] see Figure 4 to Figure 7 As shown, a method of manufacturing a surface mount capacitor that can enhance its solderability in the present invention is to use a special tooling 2 to clamp the laminated metal film 1 together, and then spray metal on the side end surface of the laminated metal film 1, so that The upper and lower ends of the gold-sprayed layer 3 formed by the side end surface of the laminated metal film 1 after spraying metal are respectively provided with an upward protrusion 31 and a downward protrusion 32 symmetrical to the upward protrusion along the horizontal plane.

[0022] The two side edges of the special tooling 2 are respectively provided with recessed parts 21, and the recessed parts 21 correspond to the outside of the side edge of the laminated metal film 1, that is, after the special tooling 2 clamps the laminated metal film 1 together, the special tooling 2 The recessed part 21 of the recessed part 21 is located outside the side edge of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com