Keel butt joint structure and welding seam flexural capacity evaluation and safety design method thereof

A technology of bearing capacity and keel, which is applied in the direction of testing material strength, building structure, force/torque/power measuring instrument by applying stable bending force, and can solve the problem of reducing welding area, reducing welding integrity and safety, etc. problems, to achieve the effect of increasing the welding contact area, improving integrity and safety, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

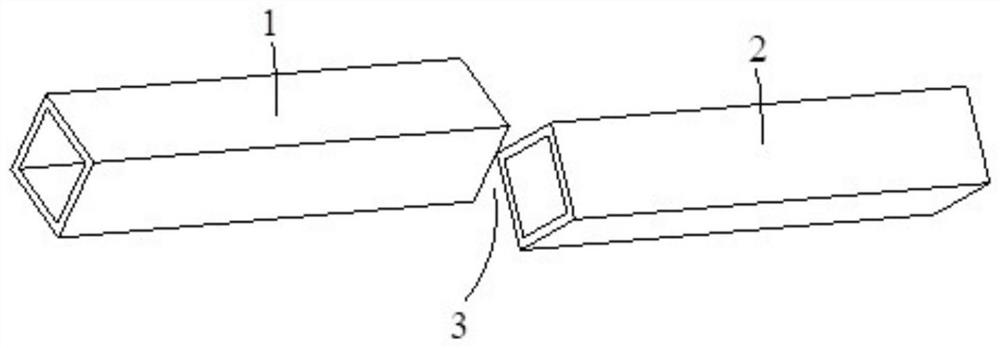

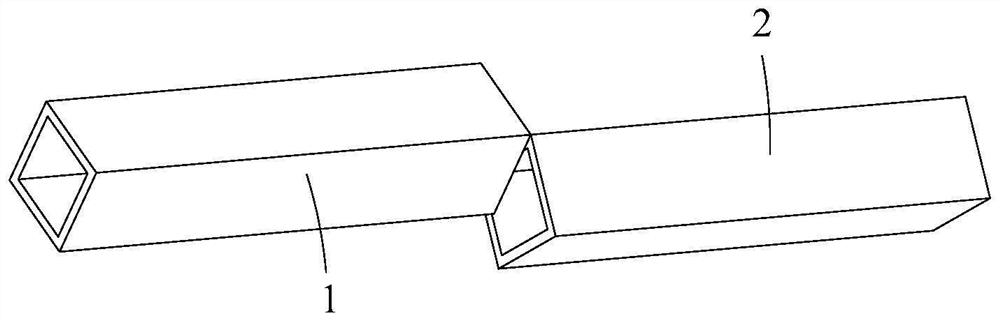

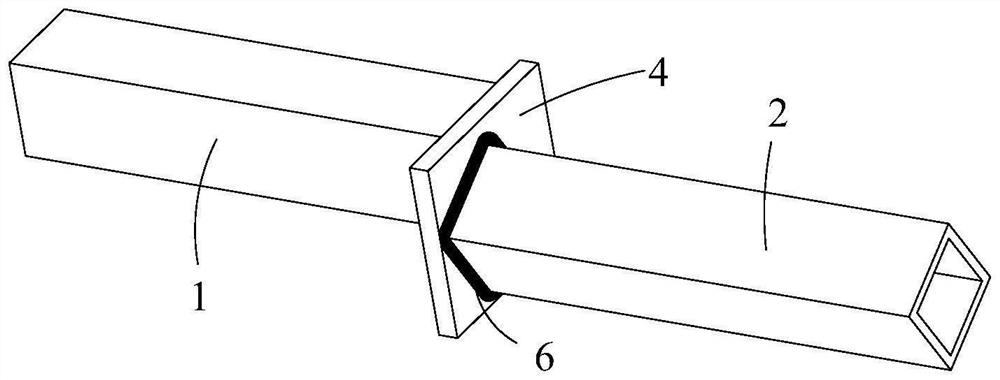

[0090] like image 3 As shown, a keel butt joint structure of this embodiment includes a first keel 1 and a second keel 2, there is a staggered seam 3 between the first keel 1 and the second keel 2, and a first connecting piece is arranged in the staggered seam 3 4. The first connecting piece 4 is welded to the first keel 1 and the second keel 2 respectively. Specifically, the first connecting piece 4 and the first keel 1 are connected to each other through at least two welding seams 6, and there is an angle between the two welding seams 6; and / or the first connecting piece 4 and the second keel 2 are connected to each other through at least two The strip welds 6 are connected to each other, and there is an included angle between the two welds 6; and / or the first connecting piece 4 and the first keel 1 are connected to each other by at least two welds 6, and the total length of the two welds 6 exceeds the first 1 / 4 of the circumference of the outer edge of the cross-section o...

Embodiment 2

[0092] like Figure 4-24 As shown, a method for evaluating the flexural bearing capacity of a weld for a keel butt joint structure in this embodiment includes the following steps: S1. Carry out a butt joint multi-directional fillet weld stress scale test on the keel butt joint structure of Example 1 , the actual stress, actual strain and actual hot spot stress of the keel butt joint multi-directional fillet weld are obtained, and a theoretical calculation model is established for the flexural bearing capacity of the keel butt multi-directional fillet weld, and the theoretical stress, Theoretical strain and theoretical hot spot stress;

[0093]S2. Compare the actual stress, actual strain, and actual hot spot stress with the theoretical stress, theoretical strain, and theoretical hot spot stress in step S1, and confirm the reliability of the theoretical calculation model based on the comparison deviation.

[0094] Step S1 specifically includes the following steps: S11. For the ...

Embodiment 3

[0107] This embodiment takes an actual specific case as an example to illustrate a method for evaluating the flexural bearing capacity of a weld for a keel butt joint structure: conduct a multi-directional fillet weld scale-down test with the keel butt joint structure of Example 1, and understand the content of the joint through the test The structural strength of the truss structure of the multi-directional fillet weld 6, the stress distribution and hot spot stress at the overall structure and the local details of the weld 6 under concentrated load, and the test to measure the bending capacity of the multi-directional fillet weld 6 through the test The method includes methods such as test steps, arrangement of measuring points, analysis and arrangement of test results, etc., and then the load-displacement curve, stress-strain curve and hot spot stress curve of the multi-directional fillet weld 6 are obtained through the test.

[0108] First, make a scaled-scale specimen, speci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com