Building boundary beam frost heaving prevention structure and construction method thereof

An anti-frost heave and edge beam technology, which is applied in infrastructure engineering, buildings, protective devices, etc., can solve the problems of excessive frost heave of foundation soil, achieve the effects of overcoming frost heave, simple construction, and reduced construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

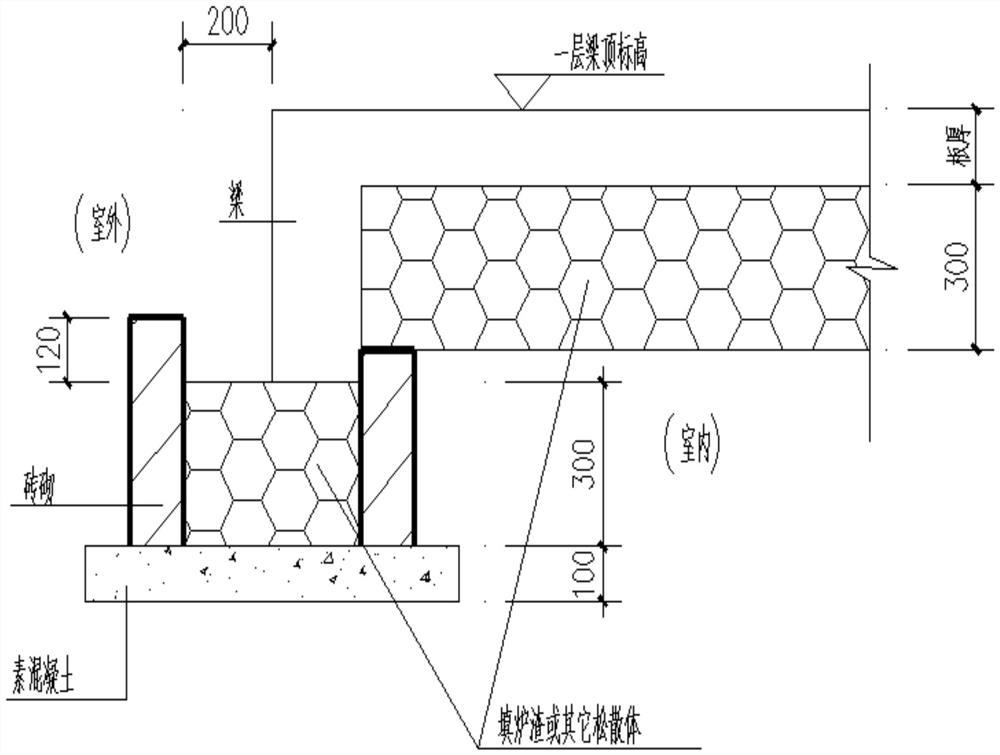

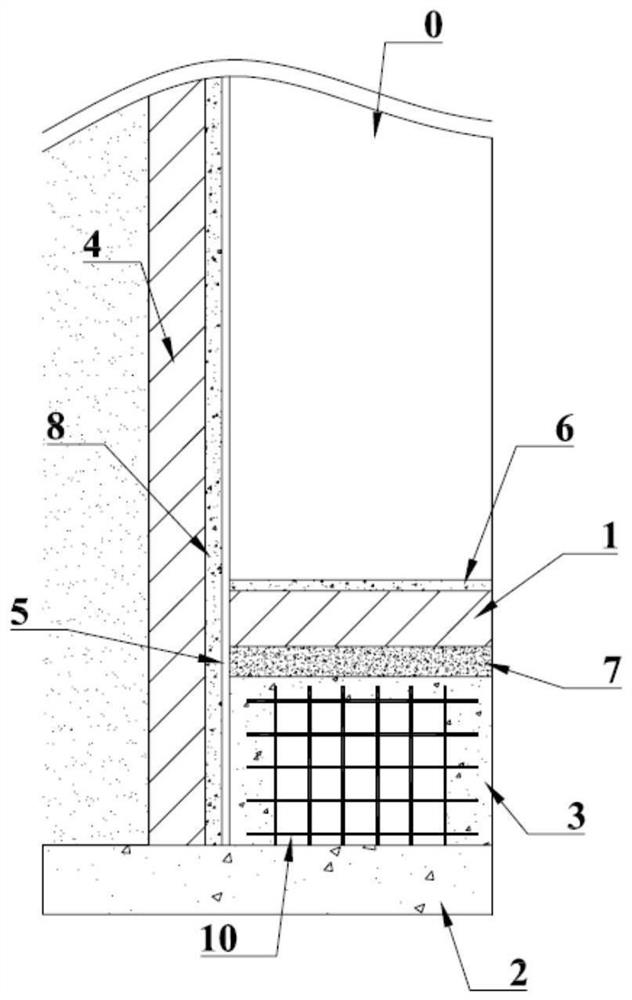

[0039] Embodiment 1: as figure 2 As shown, the anti-frost heaving structure of the side beam of this building includes the beam bottom insulation layer 1, cushion layer 2, filling layer 3 between the bottom of the side beam 0 and the bottom of the excavation pit, the beam outer insulation layer 4 on the outside of the side beam 0, asphalt isolation Layer 5, wherein, the beam bottom insulation layer 1 is arranged on the bottom surface of the side beam 0, the cushion layer 2 is arranged on the bottom surface of the excavation pit, and the filling layer 3 is filled in the beam bottom insulation layer 1 and the cushion layer 2; the asphalt insulation layer 5 is arranged on the outside of the overall structure formed by the side beam 0, the beam bottom insulation layer 1, and the filling layer 3, and the beam outer insulation layer 4 is arranged on the outside of the asphalt insulation layer 5; the beam bottom Both the insulation layer 1 and the beam outer insulation layer 4 are e...

Embodiment 2

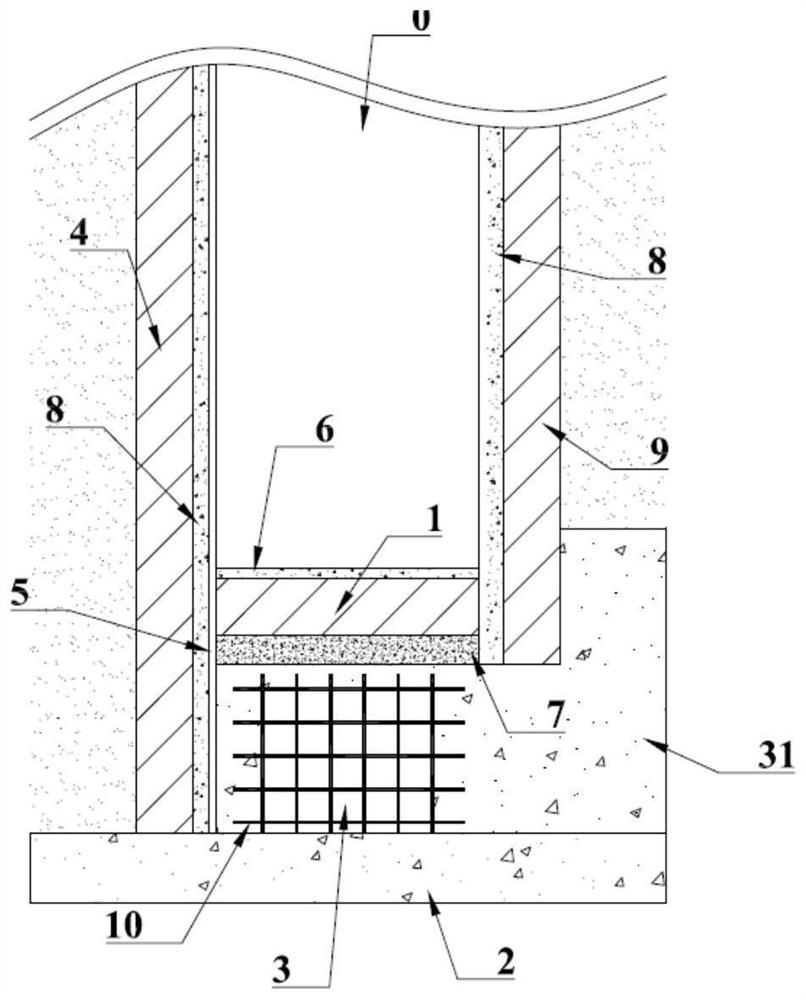

[0041] Embodiment 2: as image 3 As shown, the inside of the side beam 0 of the side beam anti-frost heave structure of this building is provided with a beam inner insulation layer 9, an asphalt isolation layer 5 and a reinforcement pier 31, and the reinforcement pier 31 is integrated with the bottom and the filling layer 3. Adding the insulation board inside the beam can eliminate the horizontal and tangential frost heaving force inside the foundation beam, and strengthen the pier and bottom and the filling layer to improve the integrity and stability of the beam bottom structure. The remaining structures and components are as described in Embodiment 1 and will not be described again.

Embodiment approach 1

[0042] Implementation mode 1: if Figure 4 As shown, for the anti-frost heave structure of the building edge beam in embodiment 1, its concrete construction method comprises the following steps,

[0043] S1 earthwork excavation: Excavate the outer earthwork of the side beam to be treated until the lower surface of the side beam is exposed, and continue to excavate 100cm downward, and excavate the inside and bottom of the excavation pit to form a vertical surface on the inside and a plane on the bottom. excavation pit;

[0044] S2 Cushion pouring: set concrete formwork on the bottom surface of the excavation pit, pump commercial concrete to the formwork to form a cushion, and mechanically vibrate for compaction;

[0045] S3 Beam Bottom Insulation Layer Laying and Protective Layer: After the beam bottom is treated, the side beams are positioned and laid out, and the beam bottom insulation board is laid on the beam bottom. The bottom insulation board is combined with a polymer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com