Hydrolyzable polymer and epoxy resin heat-conducting material composition containing same

A technology of polymers and halogen compounds, applied in the field of composite material processing, can solve the problems such as the inability to realize the preparation of high-filling composite materials and the limited effect, and achieve the effects of improving storage stability, low cost of raw materials, and reducing the difficulty of construction and operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

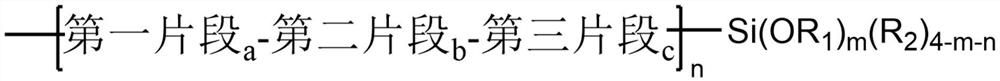

[0068] Hydrolyzable polymer 1 was prepared comprising the following structure:

[0069]

[0070] Weigh n-butyl-terminated polyether (53.8g, 0.1mol) and dissolve it in 75g of absolute ethanol, add it to a 250mL round-bottomed flask filled with 20mL of deionized water, stir well and add flake sodium hydroxide (6g , 0.15mol), stirred at room temperature for 2h under the protection of nitrogen, then warmed up to 78°C and refluxed for 2h, cooled to 45°C, added 1,3-dichloropropane (22.6g, 0.2mol), tetrabutylammonium bromide (0.9g , 0.003mol) was heated to 65°C, and the reaction was stirred for 12h. Spin dry extraction, dry the organic phase to obtain product A; weigh bisphenol A (22.82g, 0.1mol) and dissolve it in 90mL absolute ethanol, add flake sodium hydroxide (6g, 0.15mol), under nitrogen protection Stir at room temperature for 2 hours, heat up to 78°C for reflux reaction for 2h, cool down to 45°C, add product A and heat up to 65°C, stir for 12 hours, then add 3-chloropropen...

Embodiment 2

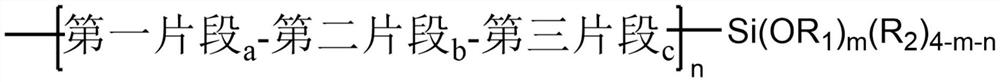

[0076] Hydrolyzable polymer 2 was prepared comprising the following structure:

[0077]

[0078] Weigh methyl-terminated polyether (55.8g, 0.1mol) and dissolve it in 75g of absolute ethanol, add it to a 250mL round-bottomed flask filled with 20mL of deionized water, stir well and add flake sodium hydroxide (6g, 0.15mol), stirred at room temperature for 2h under the protection of nitrogen, then heated to 78°C for reflux reaction for 2h, cooled to 45°C, added 1,3-dichloropropane (22.6g, 0.2mol), trioctylmethylammonium chloride (1.13 g, 0.003mol), the temperature was raised to 65°C, and the reaction was stirred for 12h. Spin dry extraction, dry the organic phase to obtain product A; weigh bisphenol A (22.82g, 0.1mol) and dissolve it in 90mL absolute ethanol, add flake sodium hydroxide (6g, 0.15mol), under nitrogen protection Stir at room temperature for 2 hours, heat up to 78°C for 2 hours, cool to 45°C, add product A, heat up to 65°C, trioctylmethylammonium chloride (1.13g, ...

Embodiment 3

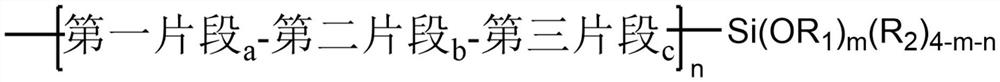

[0084] Hydrolyzable polymer 3 was prepared comprising the following structure:

[0085]

[0086] Weigh methyl-terminated polyether (50.3g, 0.05mol) and dissolve it in 75g of absolute ethanol, add it into a 250mL round-bottomed flask filled with 20mL deionized water, stir well and add flake sodium hydroxide (3g , 0.075mol), stirred at room temperature for 2h under the protection of nitrogen, then raised the temperature to 78°C for reflux reaction for 2h, cooled to 45°C, added 1,3-dichloropropane (11.3g, 0.1mol), dodecyltrimethyl chloride Ammonium (0.74g, 0.003mol) was heated up to 65°C and stirred for 12h. Spin dry extraction, dry the organic phase to obtain product A; weigh bisphenol A (11.41g, 0.05mol) and dissolve it in 90mL of absolute ethanol, add flake sodium hydroxide (3g, 0.075mol), under nitrogen protection Stir at room temperature for 2 hours, heat up to 78°C for reflux reaction for 2h, cool down to 45°C, add product A and dodecyltrimethylammonium chloride (0.74g,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com