Large-angle high-thickness slope surface concrete pouring graded grid

A concrete, large-angle technology, applied in the fields of municipal engineering and water conservancy, can solve the problems of driving safety threats, concave bank subgrade brushing, serious problems, etc., and achieve the effect of improving construction work efficiency, saving construction costs, and reducing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation of the sub-grid of the present invention will be further described below in conjunction with the accompanying drawings.

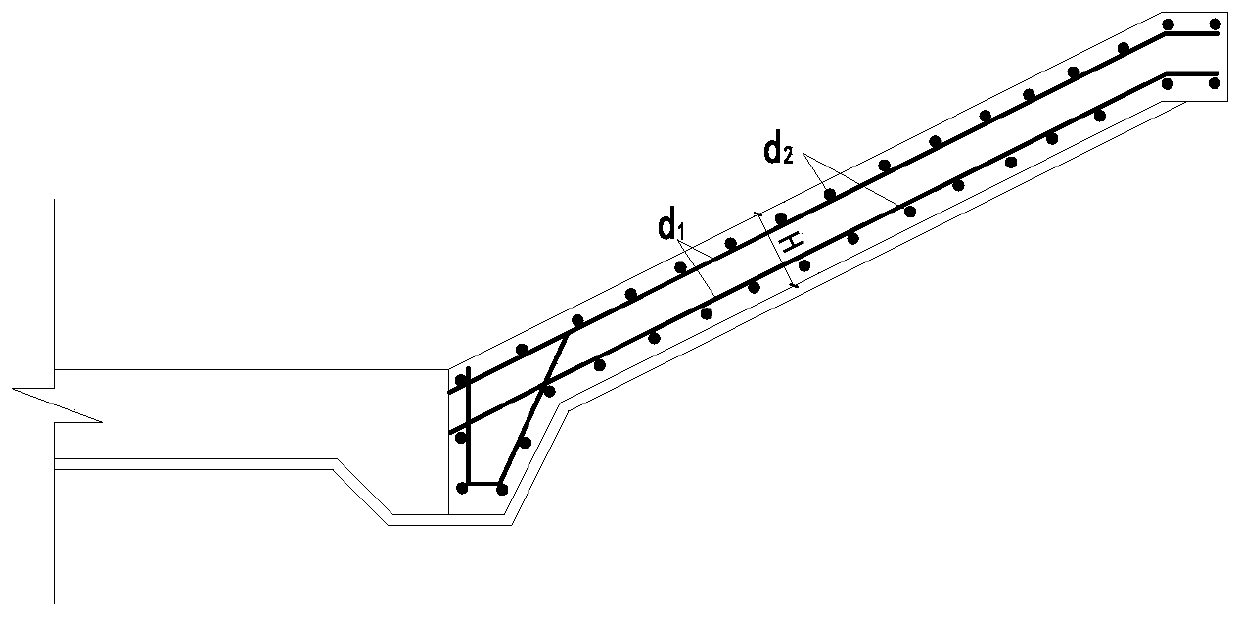

[0026] First determine the processing size of the sub-grid according to the drawing L=H-2*d1-2*d2-2*d3, d: mesh processing size, h: slope thickness, d1: protective layer thickness, d2: longitudinal reinforcement thickness , d3: transverse rib thickness), such as figure 1 shown.

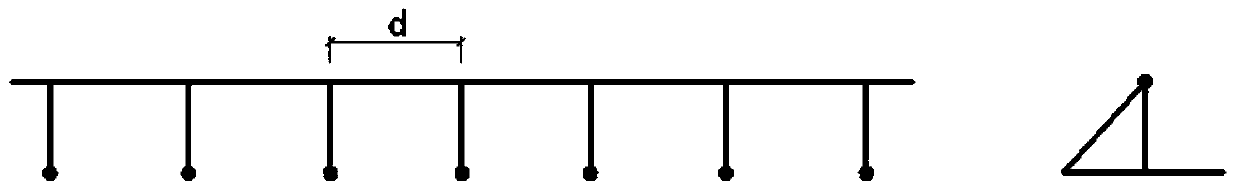

[0027] According to the above calculation size, the mesh cutting and support system, that is, the processing of vertical bars, the processing style of vertical bars, the upper part is horizontal steel bars, the lower part is right-angled triangular supports, and the distance between triangular supports d = 0.2m. For details, see figure 2 shown.

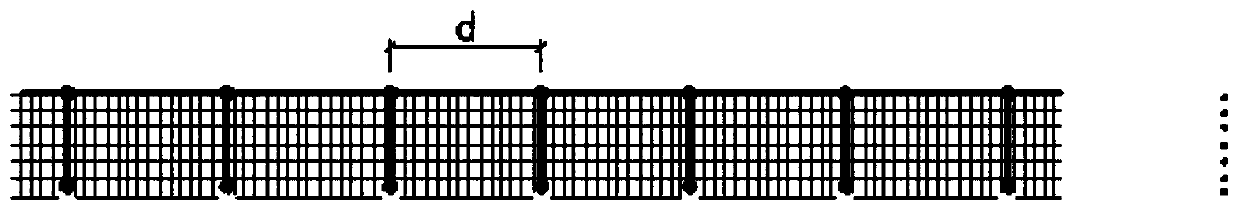

[0028] Then bind the cut steel wire mesh on the right-angled edge of the triangular support of the erecting bar, the binding spacing is the same as the spacing between the supporting steel bars of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com