A self-anchored pipeline interface structure

A pipeline interface and self-anchoring technology, which is applied in the direction of pipes/pipe joints/fittings, engine seals, passing components, etc., can solve problems such as inability to rotate, poor installation of steel balls, and obstacles to smooth sliding of steel balls, etc., to achieve roundness The bead sliding channel is smooth, avoiding local narrow conditions, and reducing the difficulty of construction operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

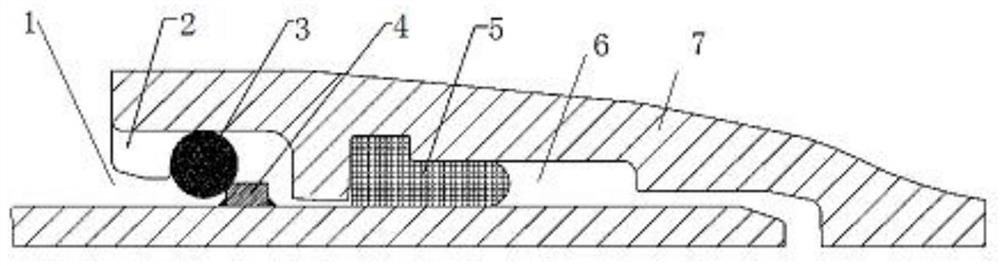

[0040] like figure 1 , figure 2 , image 3As shown, a self-anchored pipe interface structure in this embodiment includes a pipe body 7, one end of the pipe body 7 is a socket end 1, and the socket end 1 structure is reserved in the cast pipe body 7, The socket end 1 is matched with the socket end of the connecting pipe, and the socket end of the connecting pipe is inserted into the socket end 1. From the end face of the socket end 1, a ball installation port 2, a ball groove, Positioning groove 6, the ball 3 is installed in the ball groove, and the outer wall surface of the socket end of the connecting pipe is provided with a rigid ring 4, and the rigid ring 4 selects a material suitable for welding according to the material of the pipe, preferably iron or steel, The ball 3 is located in the cavity between the outer groove wall of the ball groove and the left side of the rigid ring 4 and can abut with the left corner of the rigid ring 4. The positioning groove 6 is located...

Embodiment 2

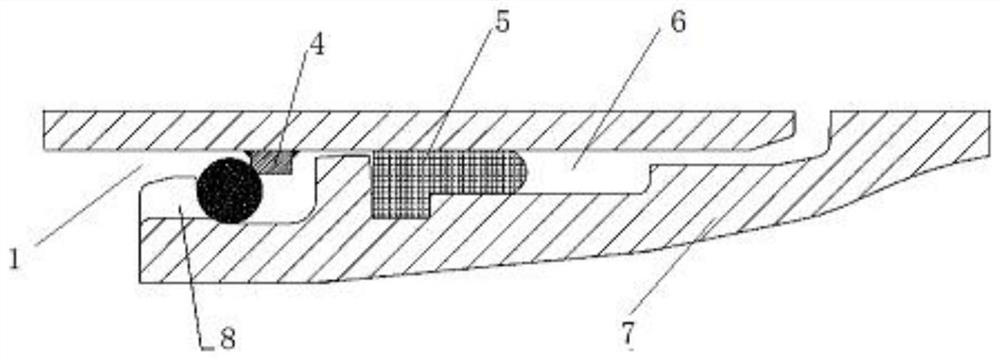

[0044] like Figure 4 , Figure 5 As shown, this embodiment is a further improvement to Embodiment 1, by Figure 4 , Figure 5 It can be seen that in this embodiment, the same as in Embodiment 1, the rigid ring 4 is also fixedly connected to the outer wall surface of the socket end of the connecting pipe by welding. The difference is that the part to be welded on the left side of the rigid ring 4 There is a chamfer 41 capable of accommodating solder.

[0045] In this embodiment, through the setting of the chamfer 41, at least a part of the solder can be accommodated, which prevents the local accumulation of the solder in the ball cavity from being too high, thereby largely avoiding the local narrowing that may occur in the ball sliding channel. Make the ball slide channel unobstructed.

Embodiment 3

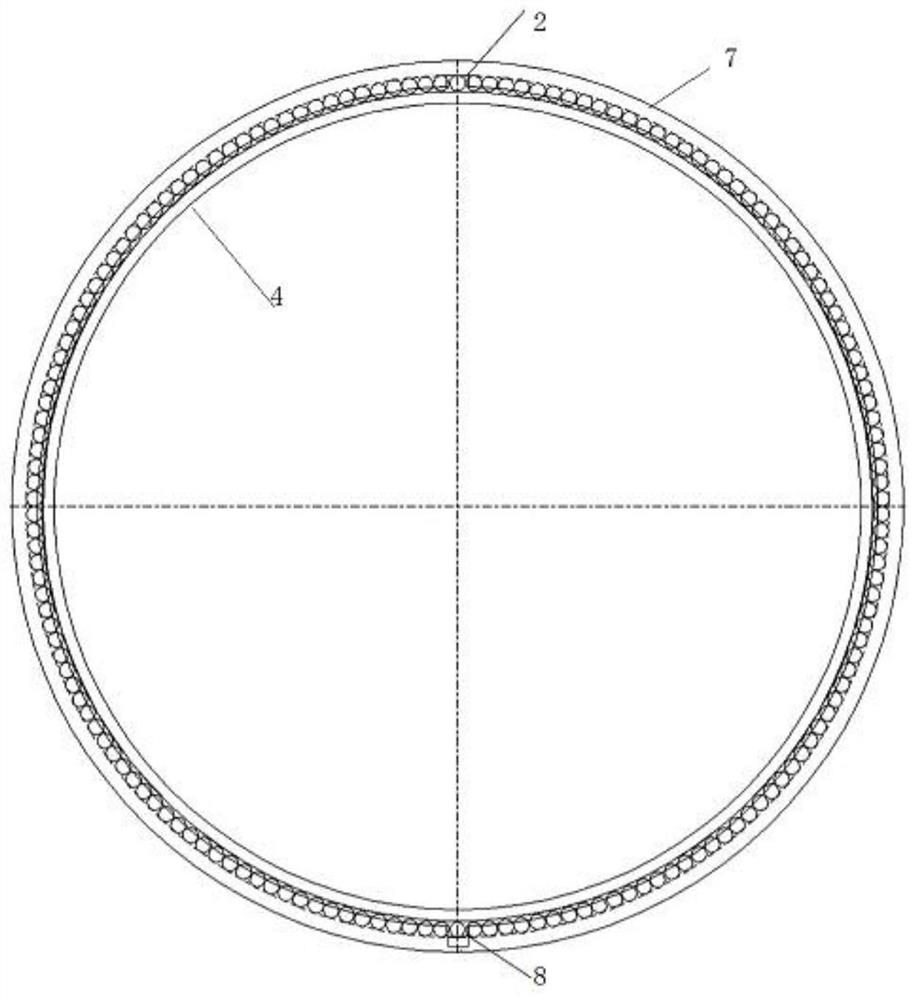

[0047] like Image 6 , Figure 7 As shown, this embodiment is a further improvement on the basis of Embodiment 2, by Image 6 , Figure 7 It can be seen that, in this embodiment, in addition to the chamfer 41 that can accommodate at least a part of the solder on the left side of the rigid ring 4 to be welded, there is also a chamfer 41 that can accommodate at least a part of the weld on the right side of the rigid ring 4 Solder chamfer 41.

[0048] In this embodiment, by setting the chamfers 41 on the left and right sides, the solder on both sides can be respectively accommodated, which not only prevents the local solder accumulation in the ball cavity from being too high, but also prevents the rigid ring when the pipe socket is just inserted into the pipe socket. 4. The situation where the right side cannot be close to the vertical wall of the ball groove, thus avoiding the possible local narrowness of the ball sliding channel to the greatest extent, and making the ball sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com