Downhole rotary impact tool based on magnetic force and method

A technology of impact tools and magnetic force, which is applied in drilling equipment, earthwork drilling, and driving devices for drilling in boreholes, etc. It can solve the mismatch of effective working time of drill bits, easy failure of impact mechanism, unstable performance of rotary punching tools, etc. problems, to achieve the effect of improving downhole applicability, improving work stability, and improving rock breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

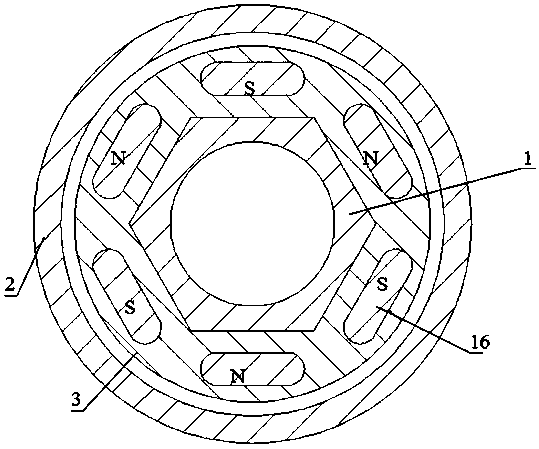

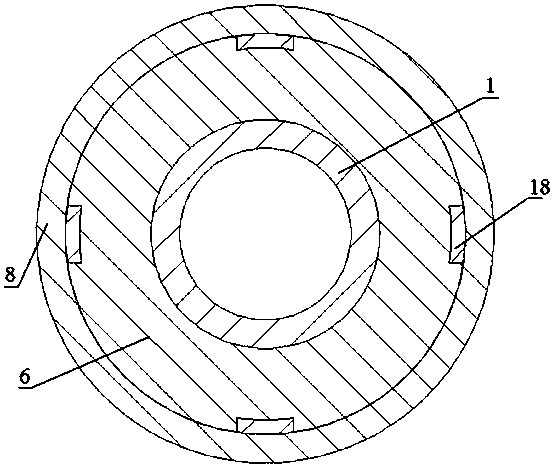

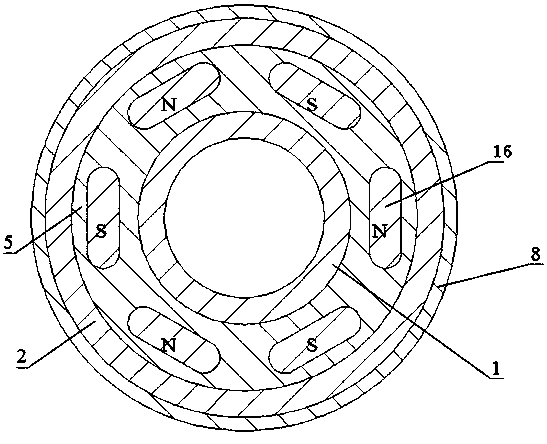

[0018] Example 1: Combining figure 1 , the magnetic-based downhole rotary impact tool mentioned in the present invention has a technical solution: including a transmission central shaft, a tool outer cylinder, an upper magnetic ring 3, an auxiliary spring 4, a lower magnetic ring 5, a hard alloy bushing 6, an output The joint 9, the transmission central shaft includes the upper transmission central shaft 1 and the lower transmission central shaft 7, the upper transmission central shaft 1 and the lower transmission central shaft 7 are connected by threads, and a tool outer cylinder is arranged outside the transmission central shaft 1, and the tool outer cylinder It includes the tool upper outer cylinder 2 and the tool lower outer cylinder 8, the tool upper outer cylinder 2 and the tool lower outer cylinder 8 are connected by threads, and a connecting head 17 is arranged on the upper part of the upper transmission central shaft 1, and the screw drilling tool is connected to the s...

Embodiment 2

[0026] Embodiment 2: The difference from Embodiment 1 is that the central hole of the cemented carbide bushing 6 is circular, the outer section of the cemented carbide bushing 6 is a regular hexagon, the inner section of the tool outer cylinder is a regular hexagon, and the tool The outer cylinder is sleeved on the cemented carbide bushing 6 to ensure that the cemented carbide bushing 6 can only move along the central axis.

[0027] The tool structure is simple and easy to implement, the construction operation is less difficult and the underground applicability is improved. The invention introduces the magnetic force to control the impact mechanism, which can realize the non-contact arrangement of the impact function and greatly improve the service life of the impact mechanism. The upper magnetic force ring rotates with the central axis of the transmission , the strong magnetic blocks are staggered and arranged at equal intervals in the circumferential direction. The lower magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com