Span-free middle stand column steel trestle structure, pushing installation device and construction method

A construction method and trestle technology, applied to bridges, bridge parts, bridge construction, etc., can solve problems such as many uncontrollable factors, unsatisfactory economical application, slow progress of steel pipe piles, etc., to reduce costs and reduce construction operation difficulty , the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be clearly and completely described below in conjunction with the accompanying drawings, so that those skilled in the art can fully implement the present invention without creative work.

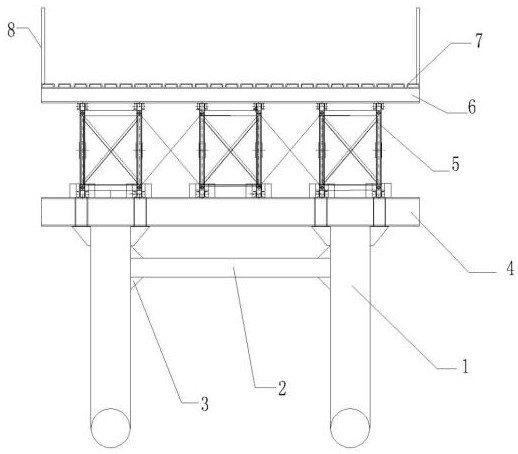

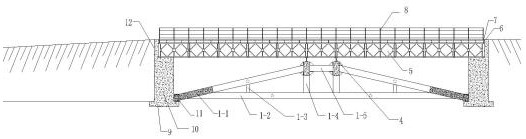

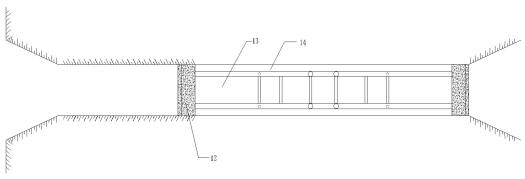

[0038] Such as Figure 1-12As shown, a steel trestle structure without mid-span columns comprises a trestle abutment, a trestle support 1, a load-bearing girder 4, a longitudinal girder 5, a distribution beam 6 and a bridge deck 7, and the trestle abutment includes buried below the ground Expand the foundation 9, the platform body 10 and the back wall 12 placed on the enlarged foundation 9 in turn, the trestle support 1 includes two sets of trapezoidal steel pipe supports, and the steel pipe support includes two oblique bars 1-1 and a main vertical bar 1 -4, auxiliary upright bar 1-3, horizontal bar, described horizontal bar comprises upper horizontal bar 1-5 and lower horizontal bar 1-2, and the length of described upper horizontal bar 1-5 is shorter than t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com