Reinforced concrete-fiber reinforce plastic (FRP) pipe confined seawater sea sand recycled concrete combination column

A technology of recycled concrete and reinforced concrete, which is applied to arch beams, bridge door beams, etc., can solve the problems of insufficient rigidity, low cracking load, and low elastic modulus of FRP concrete structure, achieve low construction operation difficulty, and improve bearing capacity. and ductility, the effect of simple steps and science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

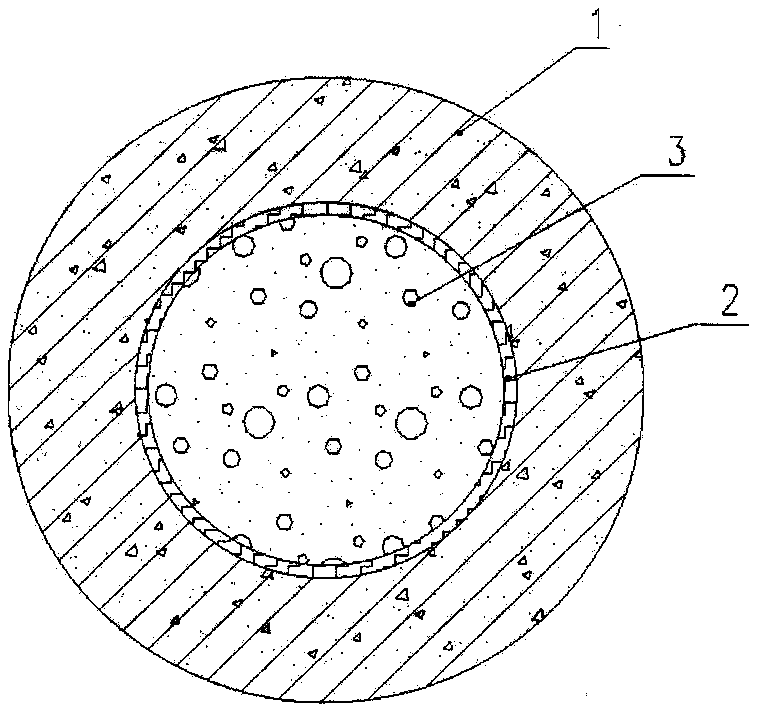

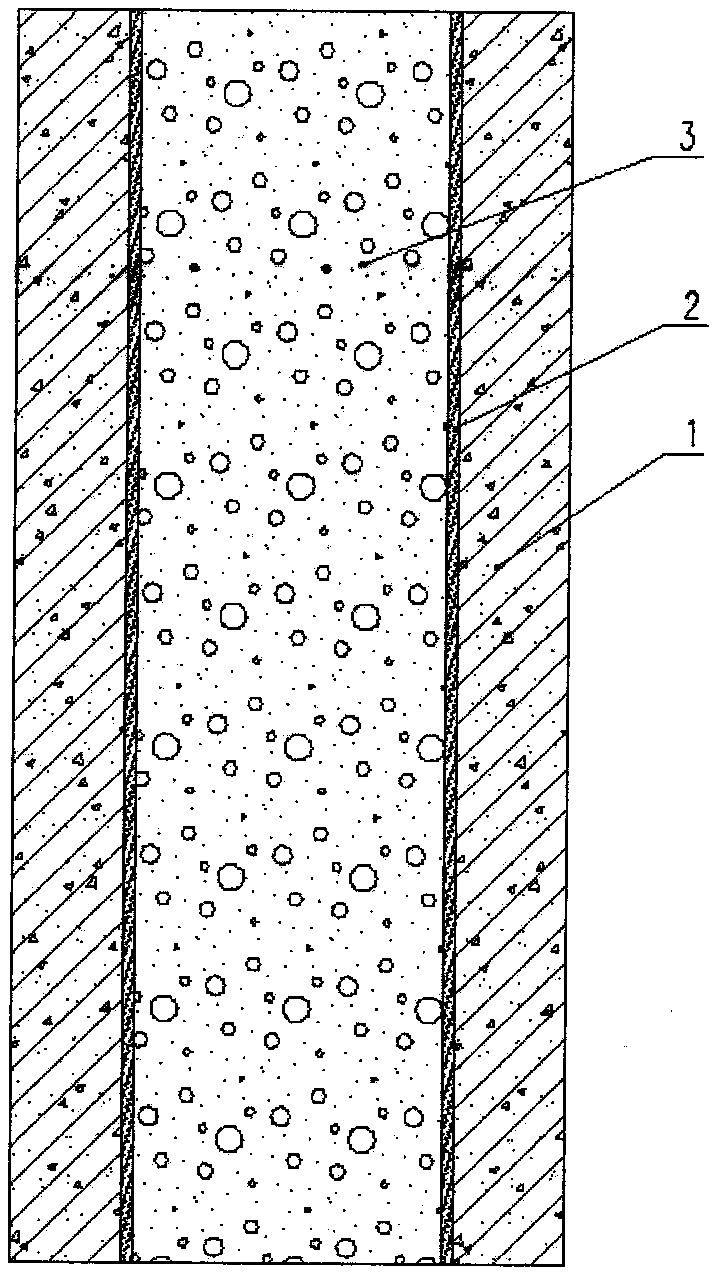

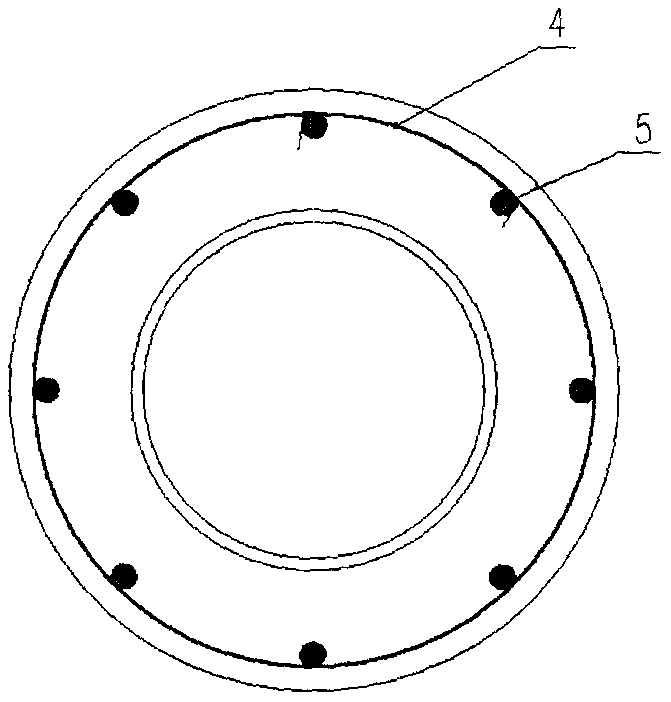

[0018] Such as Figure 1 to Figure 3 The reinforced concrete-FRP tube restrained seawater and sea sand recycled concrete column is a new type of combined structure. According to the actual size of the column, a wooden mold is prepared, combined with the GFRP tube, and the steel cage is fixed between the two. Configure ordinary recycled concrete and seawater sea sand recycled concrete with required strength, pour seawater sea sand recycled concrete into GFRP pipe, and vibrate evenly with a vibrator, pour ordinary recycled concrete between wood mold and GFRP pipe, and use The vibrating rod vibrates evenly, and finally the component is maintained for a period of time and the wooden mold is removed to obtain a reinforced concrete-FRP tube-constrained seawater and sea-sand recycled concrete composite column.

[0019] The above-mentioned embodiment is a preferred embodiment of the present invention, but the embodiment of the present invention is not limited by the above-mentioned em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com