Integrated backfilling and pouring method for integral straight middle wall top of multi-arch tunnel

A multi-arch tunnel and integral technology, which is applied in the field of integrated backfilling and pouring of the integral straight middle wall and top of the multi-arch tunnel, can solve the problems of inability to ensure the compactness of the middle partition wall, unfavorable pressure transmission of the surrounding rock, and difficulty in realizing it. Achieve the effect of reducing the risk of cracks and water leakage, easy to control the construction quality, and reduce the difficulty of construction operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

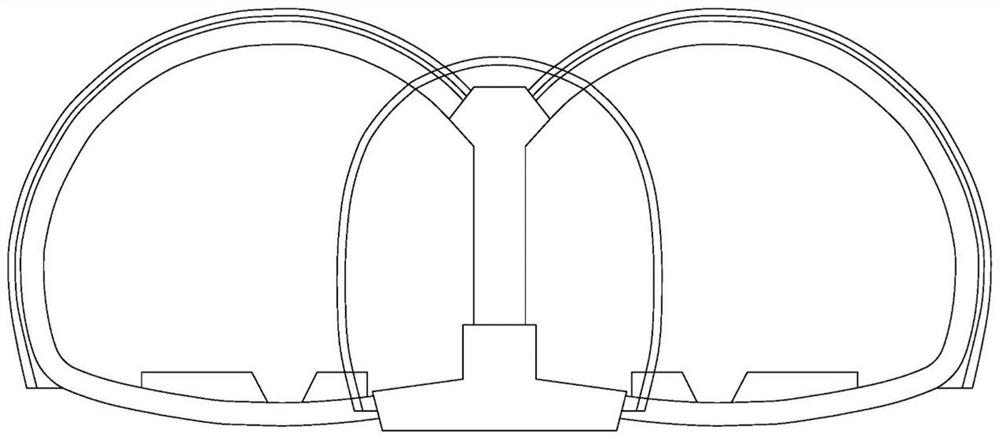

Image

Examples

Embodiment 1

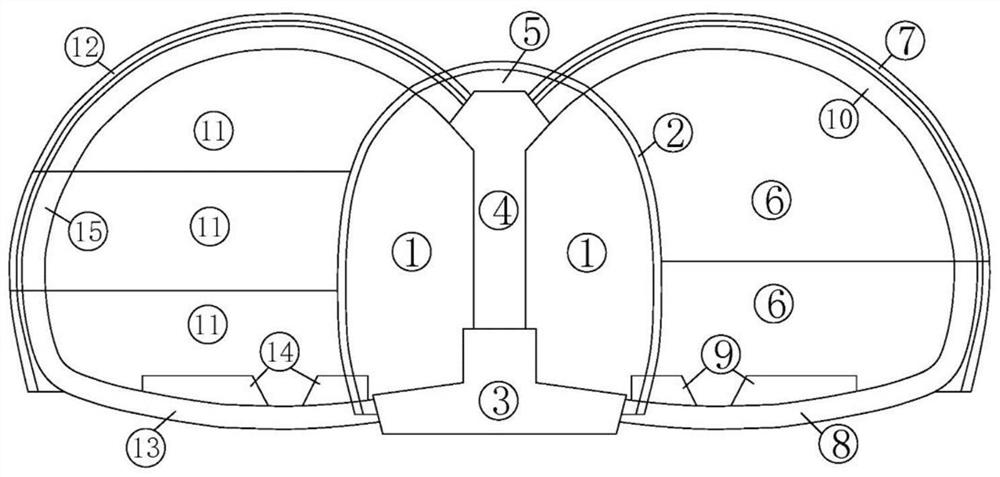

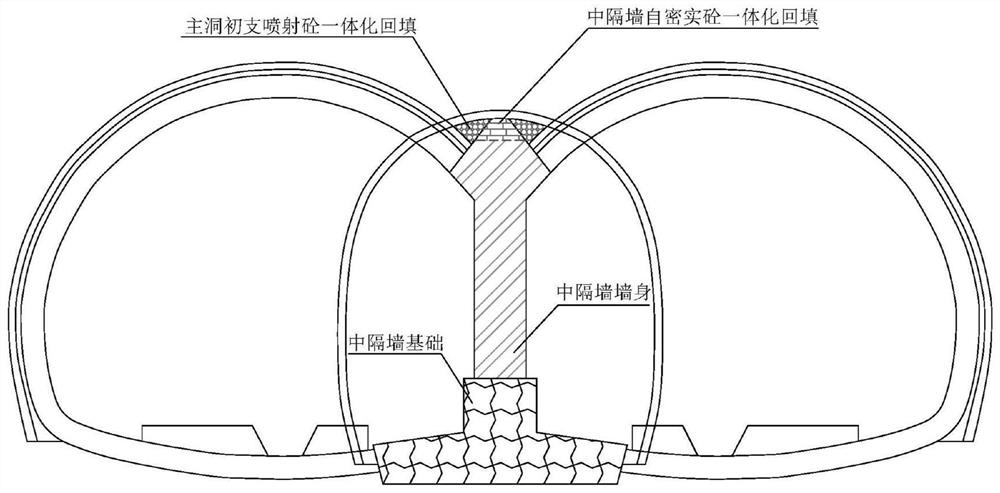

[0054] Embodiment 1 of the present invention: an integrated backfill pouring method for the integral straight middle wall and top of the multi-arch tunnel, which divides the space between the top of the middle partition wall and the initial support vault of the middle pilot tunnel into three areas, namely the top of the wall For the trapezoidal area and the triangular areas on both sides, after the foundation of the middle partition wall is poured, the trapezoidal area of the middle partition wall and the top of the wall will be poured to the vault of the middle pilot tunnel at one time. After the middle partition wall is poured, the main hole will be constructed. The integrated shotcrete backfilling construction of the area and the primary support of the main cave is reinforced by grouting with steel flower tubes, and the pouring of the middle partition wall and the top of the wall is completed. In order to prevent the possible lack of compactness in the integrated backfill ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com