One-time molding construction method for reserved residential air duct without supporting formwork

A construction method and technology of air ducts, applied to vertical pipes, building components, buildings, etc., can solve problems such as mold expansion and vibration, non-compacting, and increased manual workload, and achieve low construction costs, simple procedures, and shortened construction time. The effect of the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The construction process flow of the embodiment of the present invention: Construction preparation → setting of reinforcing ribs at the corners → placing and fixing the embedded parts → review and inspection → concrete formwork removal → installation of air ducts → sealing the gaps around the openings.

[0023] 1) Construction preparation

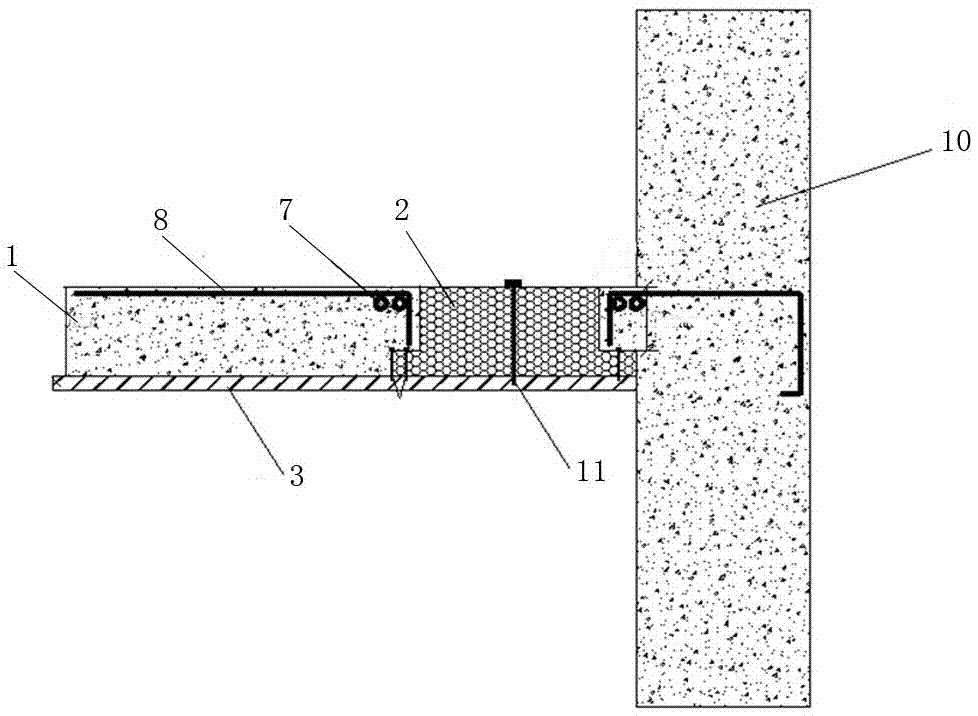

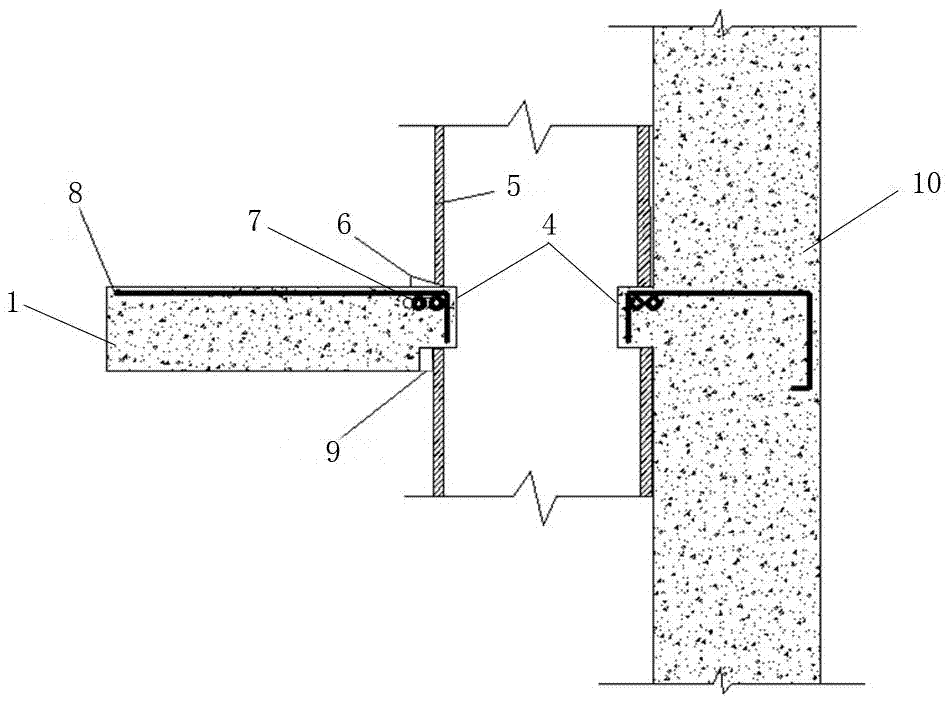

[0024] prefabricated embedded parts, figure 1 The embedded part 2 shown is a removable box made of extruded board with a "convex" cross section. The upper length of the embedded part 2 is smaller than the designed air duct size, and the lower part is longer than the designed air duct size, so that the pouring structure The reserved hole formed after the layer 1 forms the upper corner 4 protruding inward. In addition, the height ratio of the upper part and the lower part of the embedded part 2 is 7:3.

[0025] Taking the thickness of the floor structure layer as 100mm as an example, the upper part of the embedded part 2 has a cut th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com