Building energy-saving assembling module

A kind of technology for construction and shell, which is applied in the direction of buildings, building components, building structures, etc. It can solve the problems of house structure influence, poor wall flatness, and failure to reach 2cm, so as to avoid vibration and not dense, and the material performance is stable. , The effect of fire performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

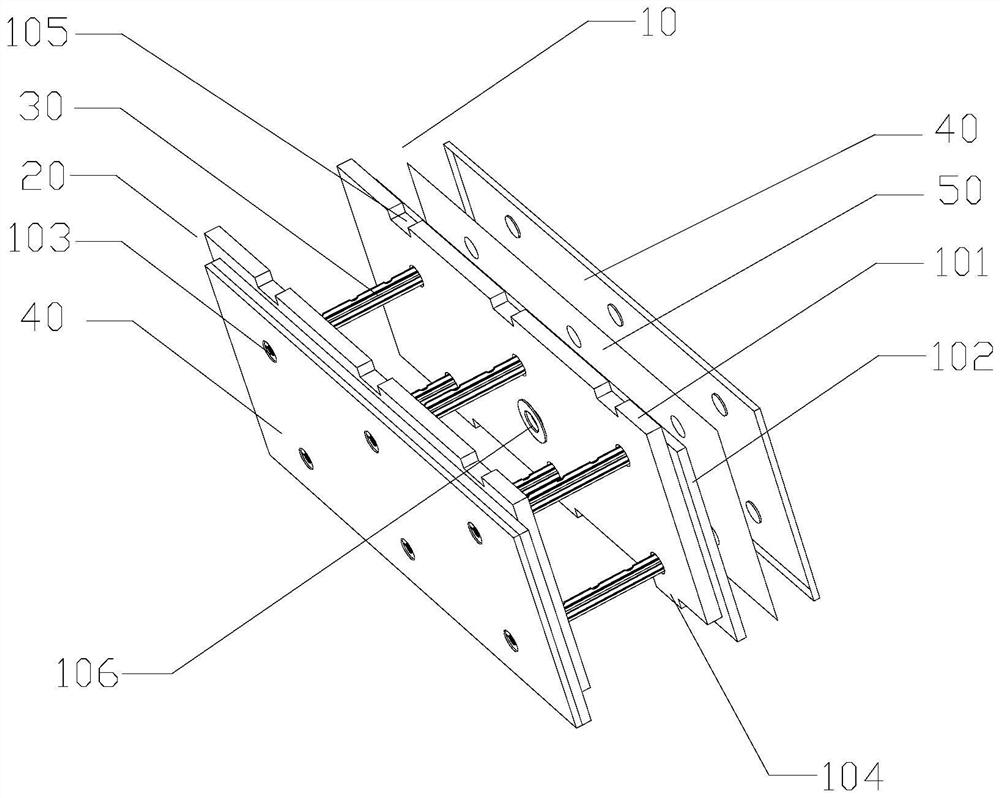

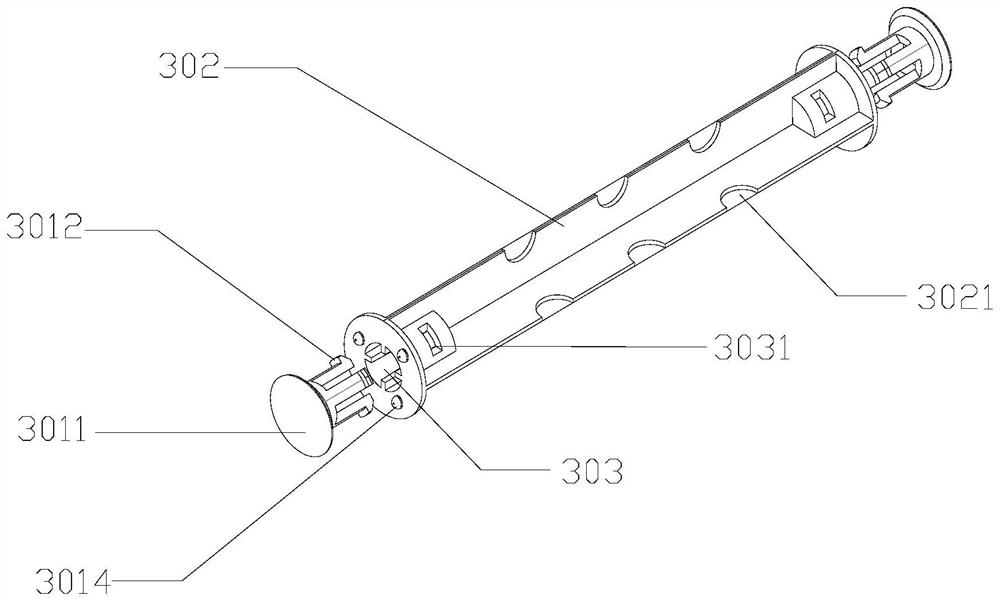

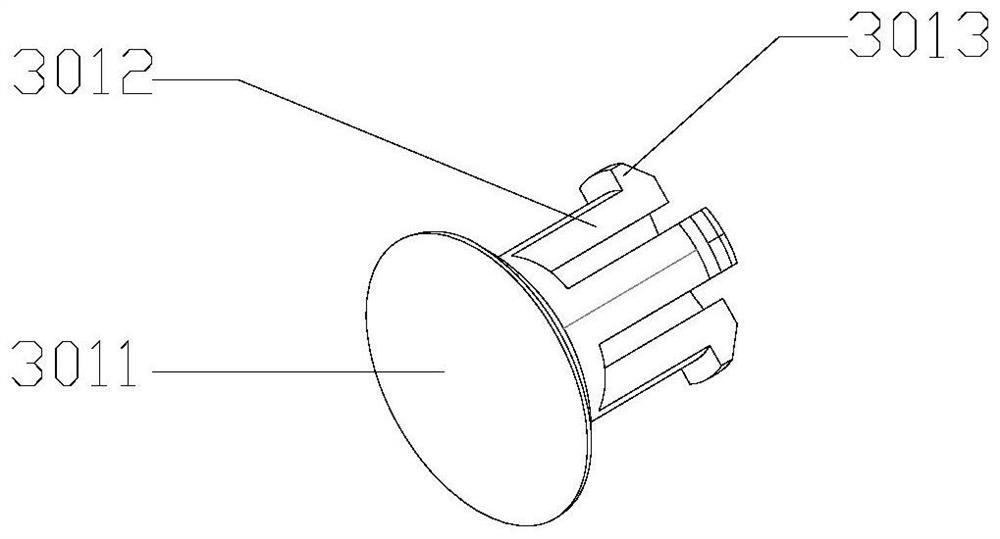

[0040] Such as figure 1 Shown, a kind of energy-saving assembly module (also can be referred to as straight mold) for straight plate building, the module of the present invention is to improve on the structure of traditional energy-saving assembly module, make the technology of self-built house more scientific, more environmental protection, Easier construction, more stable seismic performance. The module has excellent characteristics such as high strength, good thermal insulation, sound insulation, flame retardant, cold resistance, corrosion resistance, moisture resistance, and simple and quick construction.

[0041] Specifically, the energy-saving assembly module described in this embodiment is composed of an inner panel 10 and an outer panel 20, both of which are in the shape of a straight plate and made of energy-saving assembled materials.

[0042] More specifically, both inner and outer panels are composed of an inner panel 101 close to the concrete layer and an outer p...

Embodiment 2

[0057] refer to Figure 4 , the present embodiment provides an L-shaped building energy-saving assembled module (also called a corner form), the difference from Embodiment 1 is as follows: the shape of the inner panel 10 and the outer panel 20 are both L-shaped.

Embodiment 3

[0059] refer to Figure 5 , the present embodiment provides an L-shaped building energy-saving assembly module (also called a three-way mold), the difference from Embodiment 1 is as follows: the shape of the outer plate 20 is straight, and the shape of the inner plate 10 is L-shaped. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com