Barging-out method for non-self-floating immersed tube

A technology of floating and sinking tubes and semi-submerged barges, which is applied to artificial islands, buildings, ships, etc., can solve the problems of twisting and moving non-self-floating and sinking tubes, and achieve the effects of reducing the difficulty of docking, simplifying the operation process, and high efficiency

Active Publication Date: 2022-01-04

CCCC FOURTH HARBOR ENG CO LTD +2

View PDF15 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The purpose of the present invention is to provide a non-self-buoyant sinking tube for the problem that the existing technology cannot directly twist and move the non-self-buoyant sinking tube on the semi-submerged barge Dispute method

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

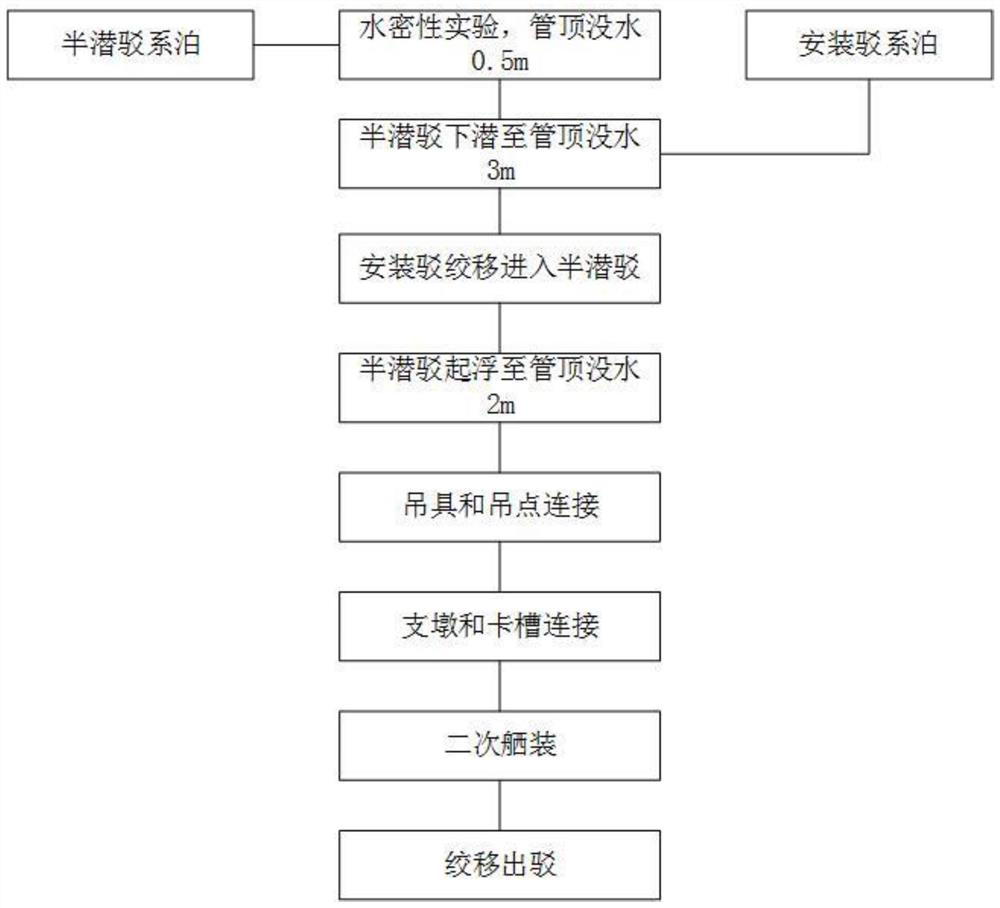

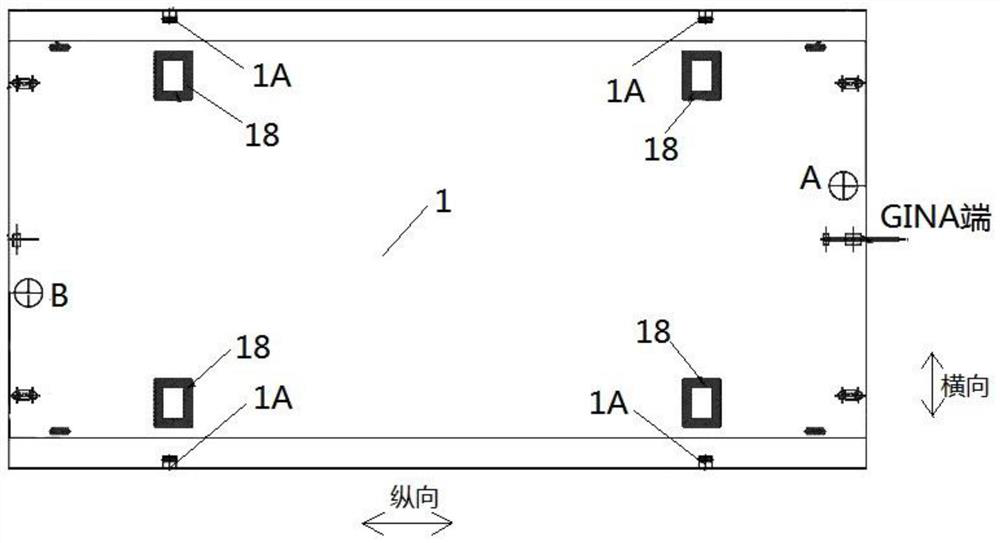

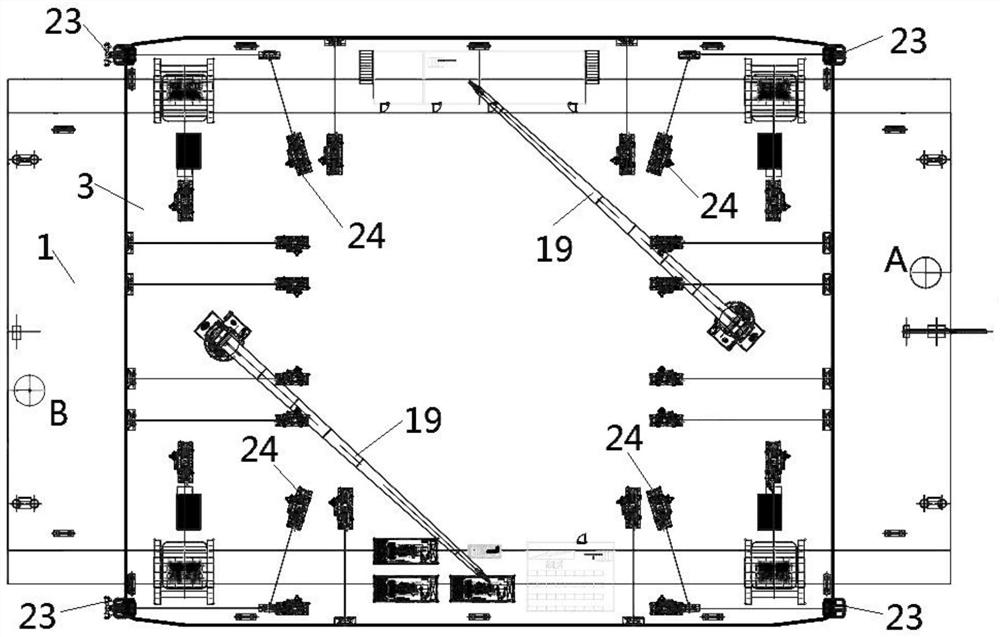

[0062] Because the non-self-floating sinking tube 1 cannot float by itself, the installation of the barge 3 must be completed on the semi-submersible barge 2 before the pipe section can be unbarged. This embodiment provides a non-self-floating-sinking tube barging method, such as Figure 1-Figure 4 , including the following steps:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the technical field of immersed tube tunnels, in particular to a barging-out method for a non-self-floating immersed tube. The method comprises the following steps of: submerging the non-self-floating immersed tube along with a semi-submersible barge, twisting and moving a mounting barge to sleeve the non-self-floating immersed tube and then butting the mounting barge with the non-self-floating immersed tube, performing secondary fitting-out operation, providing hoisting force for the non-self-floating immersed tube by using the mounting barge, and then driving the non-self-floating immersed tube to realize barging-out through the twisting and moving mounting barge. Thus, safe barging-out of the non-self-floating immersed tube which cannot automatically float is realized, and a working procedure is simple and rapid. Compared with a traditional mode that the self-floating immersed tube is directly twisted and moved out of a barge, the invention has the advantages that the mounting barge is twisted and moved out of the barge, a mooring winch system does not need to be arranged on the tube top of the non-self-floating immersed tube, tube top outfitting pieces are few, and outfitting operation procedures are few; and compared with a traditional mode that secondary outfitting is conducted after the tube joints of the self-floating immersed tube are unloaded, secondary outfitting operation is conducted on the semi-submersible barge before unloading, so the sequence of the secondary outfitting operation procedures is changed, and in this way, the non-self-floating immersed tube does not need to be moored again after being unloaded, and operation procedures are simplified.

Description

technical field [0001] The invention relates to the technical field of immersed tube tunnels, in particular to a non-self-floating immersed tube unloading method. Background technique [0002] Conventional immersed tubes are self-floating and sinking tubes, which are usually prefabricated in dry docks. After the prefabrication is completed, the dry docks are filled with water, and the immersed tubes can float naturally. It can be towed to the swirling waters for outfitting and sinking operations, and it can also be quickly transported to the swirling waters by semi-submersible dry barge, and the immersed tube can be directly winched and moved out of the barge, and then temporarily moored in the swirling waters for secondary outfitting operations; among them, The secondary outfitting of self-floating and sinking tubes requires the cooperation of crane ship + engineering barge. The secondary outfitting operations include the installation of measurement towers, calibration of f...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B63C3/00B63C3/06E02D29/073

CPCB63C3/00B63C3/06E02D29/073

Inventor 陈福斌甘世行陈猛姜政遥梁邦炎李汉渤刘锦宁张宽肖阳春黄梓雄杨光彩李文昌邱燕群

Owner CCCC FOURTH HARBOR ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com