Bilateral self-bearing building template system

A building formwork and self-supporting technology, which is applied in the direction of construction, building structure, formwork/formwork/work frame, etc., can solve the problems of grout leakage, different width of pin joints, negative tolerance cannot be eliminated, etc. Good uniformity of force, prolonging service life and reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

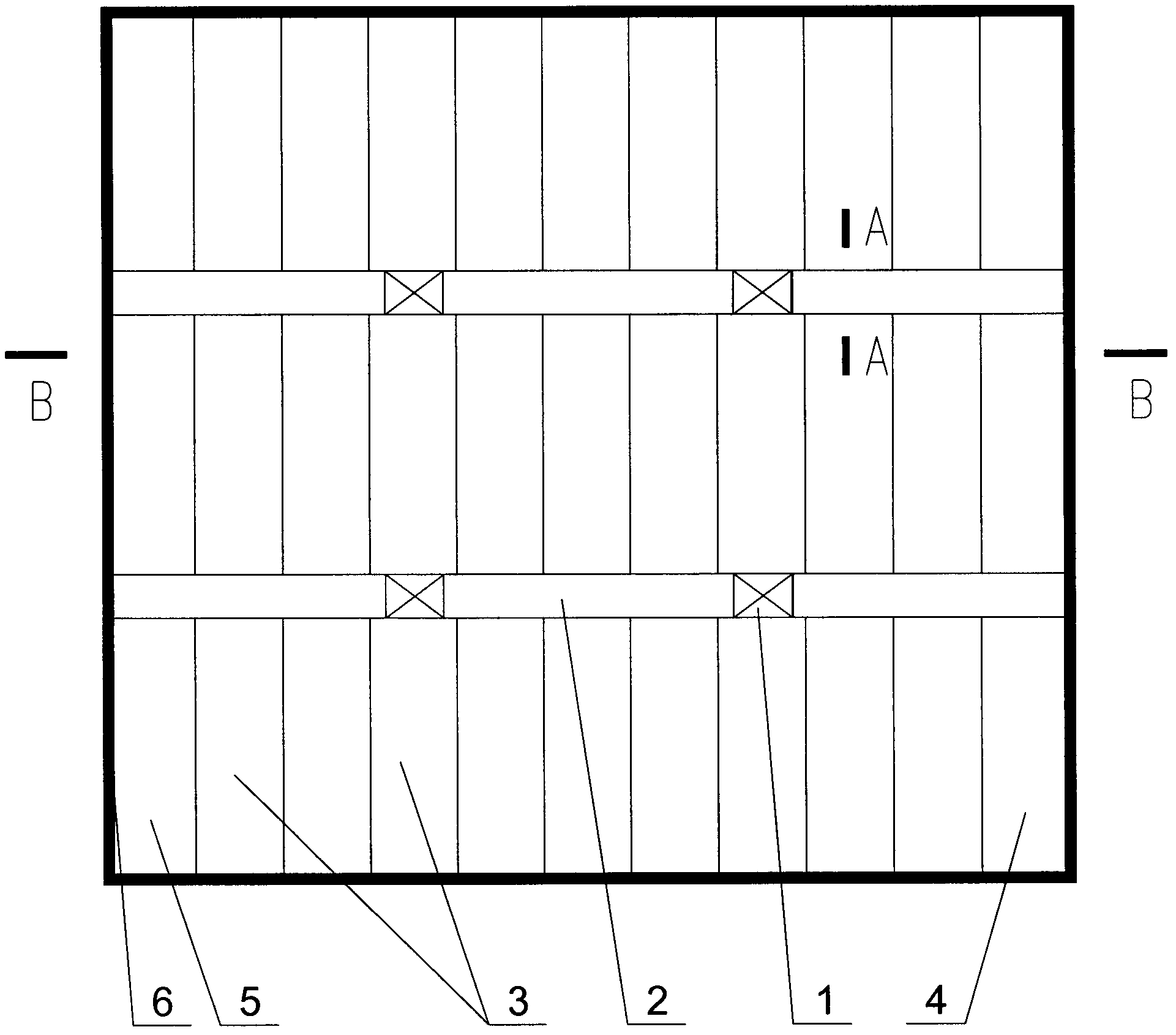

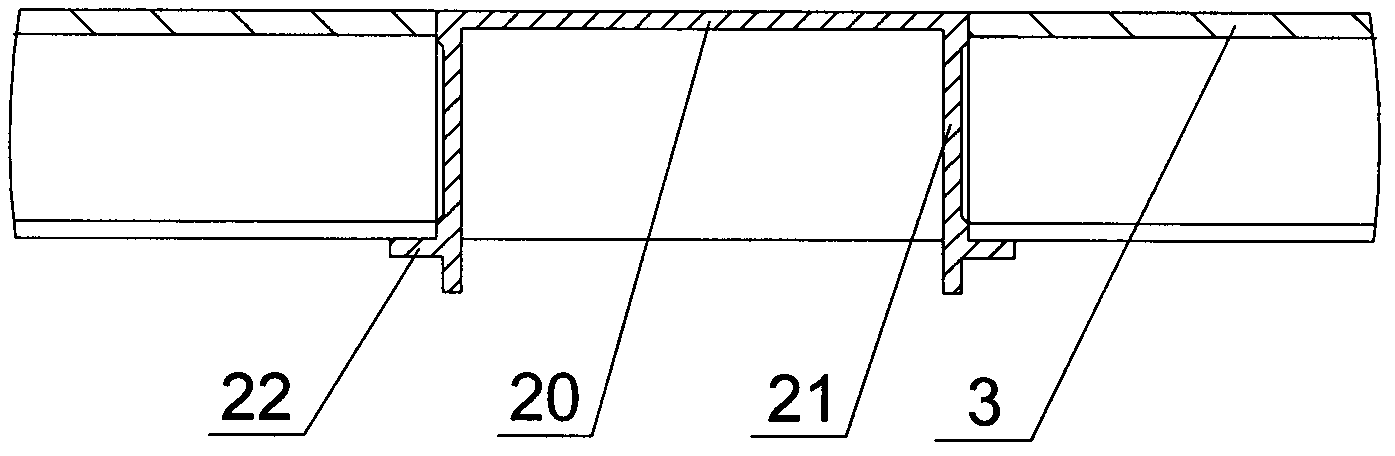

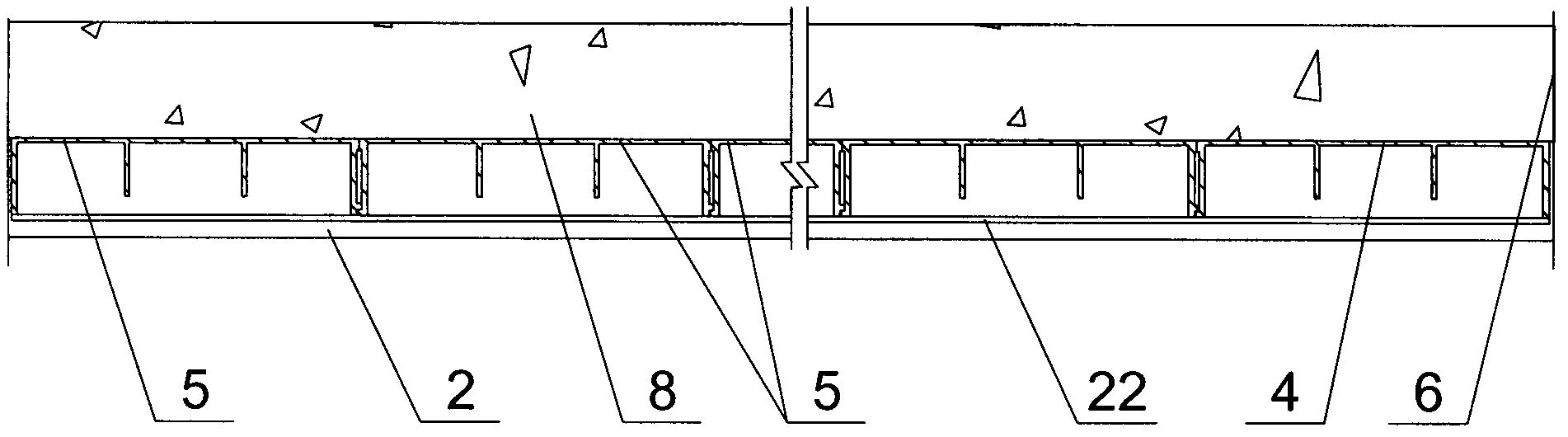

[0024] Such as Figure 1 to Figure 9 As shown, the two-way self-supporting building formwork system of the embodiment of the present invention includes a support column assembly 1, a bearing beam 2, and a bearing plate 3, and the bearing beam 2 is connected with the support column assembly 1 to form several one-way main beams , the bearing plate 3 is arranged between the one-way main beams and together with the one-way main beams form the formwork system surface, the bearing beam 2 includes a top surface 20 and two symmetrical side surfaces 21, two The lower part of the side 21 is respectively provided with beam lugs 22 along the length direction, and the two ends of the bearing plate 3 are respectively lapped on the opposite beam ears 22 of two adjacent and parallel bearing beams 2 , the bearing plate 3 includes a top plate 30 and two first side plates 31 and a second side plate 32 located on both sides of the top plate 30, the first side plate 31 and the second side plate 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com