Pushing method and device for middle span of prestressed concrete box girder continuous rigid frame bridge with long span and high pier

A concrete box girder and prestressing technology, which is applied to bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of cumbersome installation of jacking devices, influence of box girders by force, and reduced construction quality, so as to save jacking preparation time, The effect of reducing the additional bending moment and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the objects and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

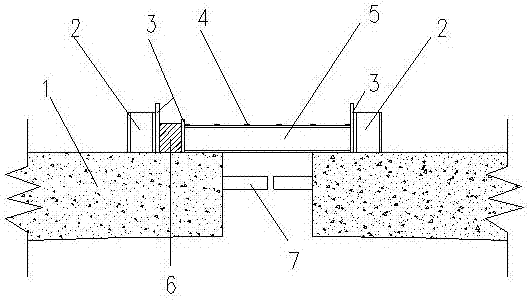

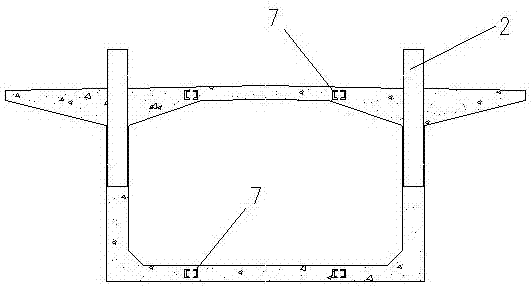

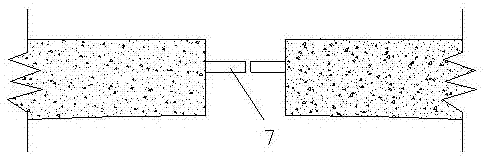

[0027] Such as Figure 1-Figure 4 As shown, the embodiment of the present invention provides a mid-span jacking device for a prestressed concrete box girder continuous rigid-frame bridge with long-span and high pier, which is characterized in that it includes a combined I-shaped steel beam 2, a backing plate 3, and a welded steel plate 4 , combined H-shaped steel beam 5, jack 6, stiff skeleton 7; described combined I-shaped steel beam 2 is welded by two I-shaped steel beams side by side, and described combined H-shaped steel beam 5 is formed by two H-shaped steel girders are welded side by side. The combined I-shaped steel beams 2 are buried ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com