Recycled concrete Z-shaped pier stud

A recycled concrete and concrete technology, applied in bridge materials, buildings, bridge construction, etc., can solve the problems of poor shrinkage performance and durability, high water absorption rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

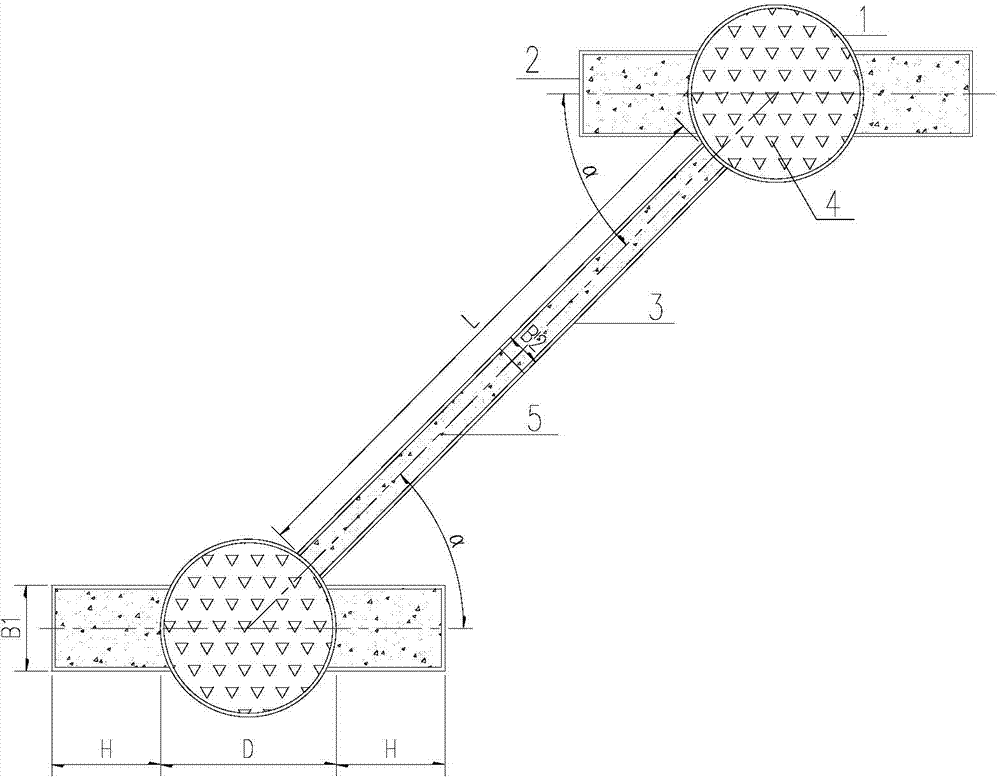

[0016] Such as figure 1 As shown, the recycled concrete Z-shaped pier column of the present invention includes a Z-shaped cross-section pier body, and the Z-shaped cross-section pier body is composed of two steel plates 3 and two circular steel pipes 1 with U-shaped steel channels 2 welded to form, two parallel The steel plate is used as the middle section of the Z-shaped pier body, and two steel pipes are welded at both ends of the middle section respectively. The two circular steel pipes each have two U-shaped steel grooves as the upper and lower limbs parallel to the Z-shaped pier body. The upper and lower limbs are arranged in the In the longitudinal direction of the bridge: ordinary aggregate concrete 5 is poured in the U-shaped steel channel and between two parallel steel plates, and recycled aggregate concrete 4 is poured in the circular steel pipe.

[0017] Production process

[0018] First, the outsourcing steel plate is welded to form a U-shaped steel channel, then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aggregate particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com