Nine-shaft automobile chassis crane and steering control system thereof

An automobile chassis and steering control technology, applied in the field of automobile control systems, can solve the problems of unstable bending, sudden increase in the force of the tie rod assembly, shortening the service life of tires, etc. The effect of avoiding abnormal wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

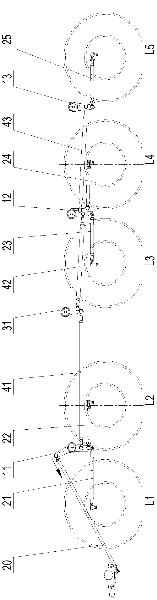

[0032] See figure 1 , The steering control system of the nine-axle truck chassis crane includes a tie-rod steering transmission mechanism that controls the steering of the corresponding wheels on the first to fifth steering shafts and a hydraulic power steering system.

[0033] The tie-rod steering transmission mechanism includes the first, second and third rocker arms 11, 12, 13 and tie rod assembly, the first auxiliary rocker arm 31 and the auxiliary tie rod assembly, and the tie rod assembly includes the first, second and third , the fourth and fifth tie rod assemblies 21 , 22 , 23 , 24 and 25 , and the auxiliary tie rod assembly includes first, second and third auxiliary tie rod assemblies 41 , 42 and 43 .

[0034] The first rocker arm 11 is arranged between the first and second steering shafts L1 and L2, and its middle part is hinged with the chassis of the nine-axle automobile. The second rocker arm 12 is arranged between the third and fourth steering shafts L3 and L4. ...

Embodiment 2

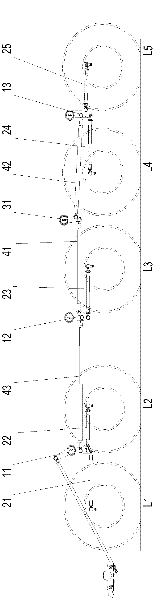

[0043] See figure 2 , the difference between this embodiment and Embodiment 1 is:

[0044] The second rocker arm 12 of the steering control system is arranged between the second and third steering shafts L2 and L3, the third rocker arm 13 is arranged between the fourth and fifth steering shafts L4 and L5, and the first auxiliary rocker arm 31 is arranged between the third and fourth steering shafts L3, L4.

[0045] One end of the third tie rod assembly 23 is hinged to the lower part of the second rocker arm 12, and the other end is hinged to the steering knuckle arm on the third steering shaft; The lower part is hinged, and the other end is respectively hinged with the steering knuckle arms on the fourth and fifth steering shafts L4 and L5; one end of the first and second auxiliary tie rod assemblies 41, 42 is hinged with the lower part of the first auxiliary rocker arm 31, and the other end is They are respectively hinged to the lower parts of the second and third rocker a...

Embodiment 3

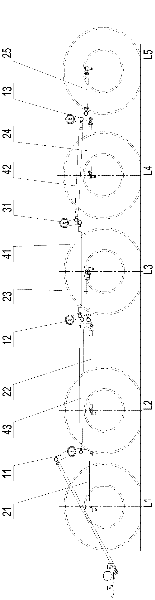

[0048] See image 3 , the difference between this embodiment and embodiment two is:

[0049] One end of the first tie rod assembly 21 of the steering control system is hinged to the lower part of the first rocker arm 11, and the other end is hinged to the steering knuckle arm on the first steering shaft L1; one end of the second and third tie rod assemblies 22, 23 It is hinged with the lower part of the second rocker arm 12, and the other end is hinged with the steering knuckle arms on the second and third steering shafts L2 and L3 respectively. Other configurations and connection relationships of this embodiment are the same as those of the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com