Rectangular steel pipe column-H steel beam full-bolt connection self-rigidity node and construction method

A rectangular steel pipe, semi-rigid technology, applied in the direction of building components, earthquake resistance, building types, etc., can solve the problems of very high processing and construction precision, damage to the integrity of the original steel pipe, buckling of the steel pipe column wall, etc., and achieve high production efficiency , reliable quality, and the effect of preventing local buckling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

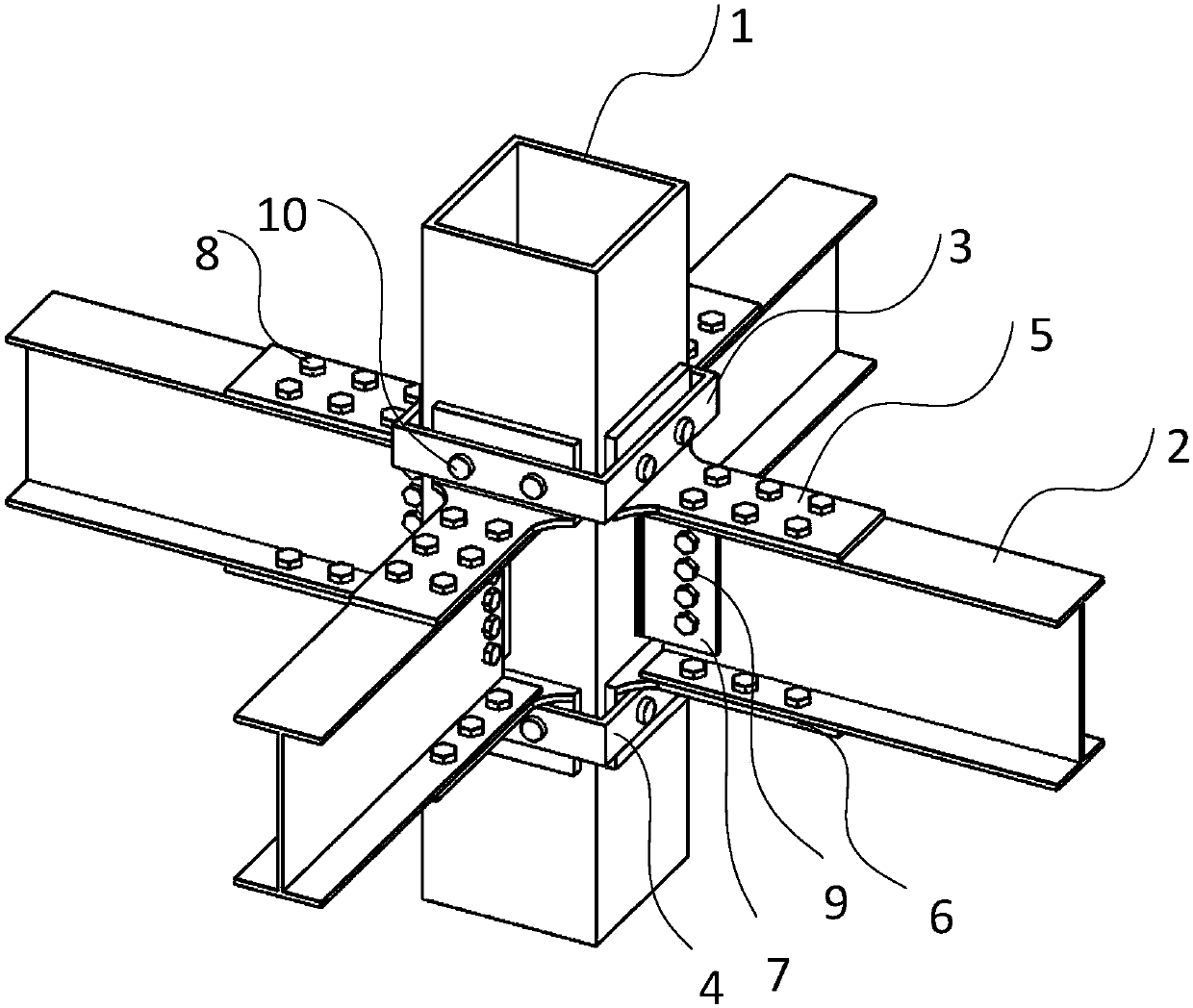

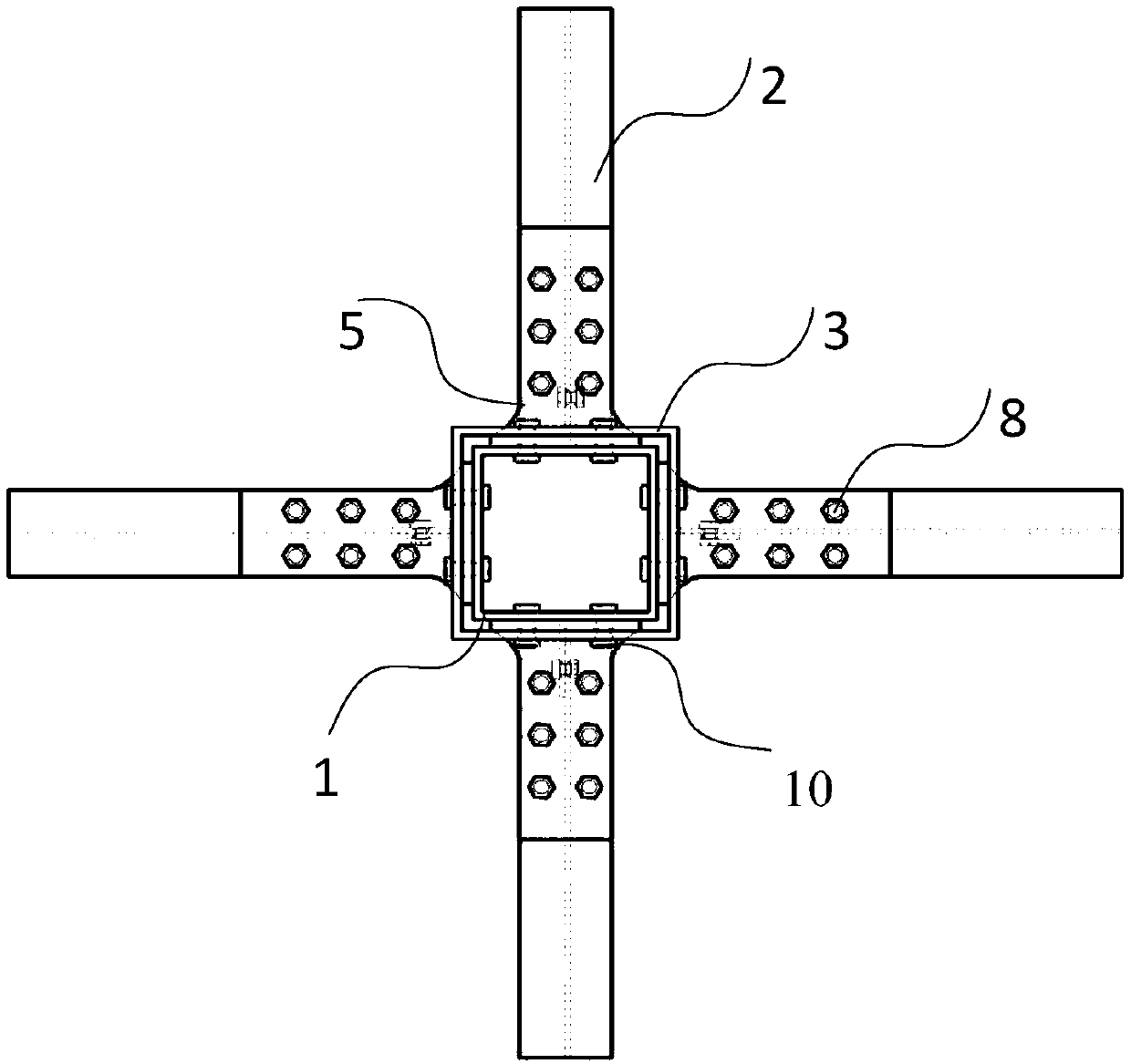

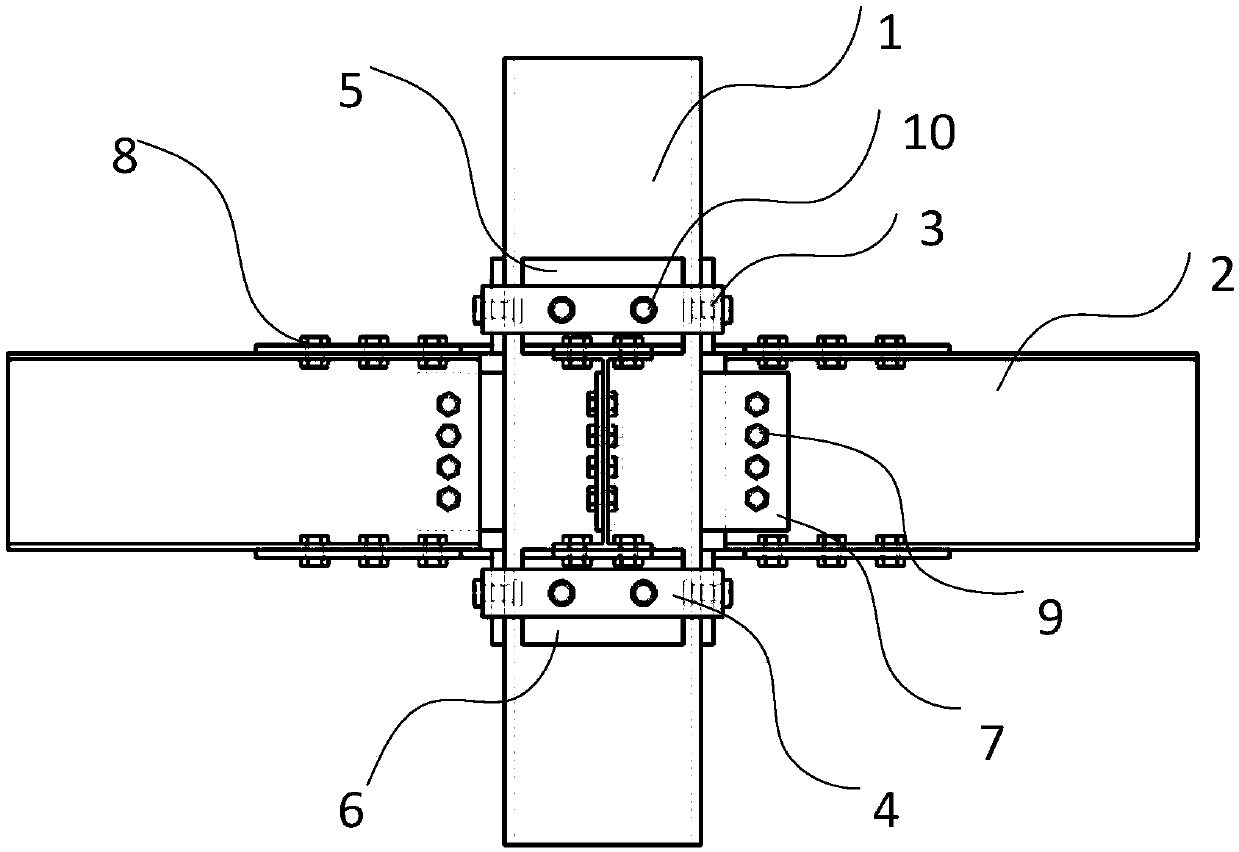

[0044] Such as Figure 1 to Figure 9 As shown, a rectangular steel pipe column-H steel beam fully bolted semi-rigid joint, including a rectangular steel pipe column 1, an H-shaped steel beam 2 and connecting force transmission components.

[0045] The rectangular steel pipe column 1 is a welded box-shaped composite section column, wherein the rectangular steel pipe column 1 is formed by connecting steel wall panels 1a, steel wall panels 1b, steel wall panels 1c and steel wall panels 1d in a certain welding sequence.

[0046] The connecting force transmission parts include upper rectangular hoop 3, lower rectangular hoop 4, upper unequal limb angle steel 5, lower unequal limb angle steel 6, vertical web connecting plate 7, first high-strength ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com