Fiber reinforced plastics-steel composite pipe restricted structural steel high-strength concrete column

A fiber-reinforced plastic and high-strength concrete technology, which is used in bridge engineering, section steel high-strength concrete columns, high-rise buildings, underground engineering and port engineering fields, can solve the problem of increasing engineering cost and technical difficulty, longitudinal reinforcement and section steel flange instability, protection layer shedding and other problems, so as to avoid local buckling under axial compression, reduce the amount of steel used, and inhibit local buckling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

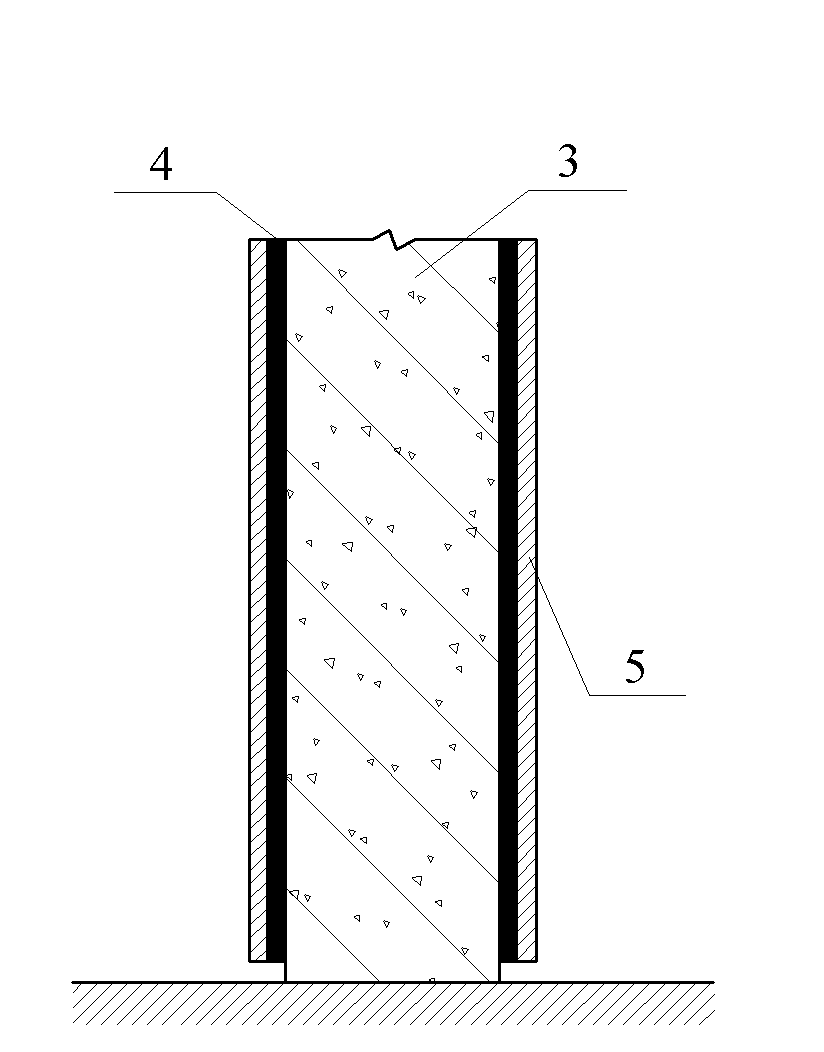

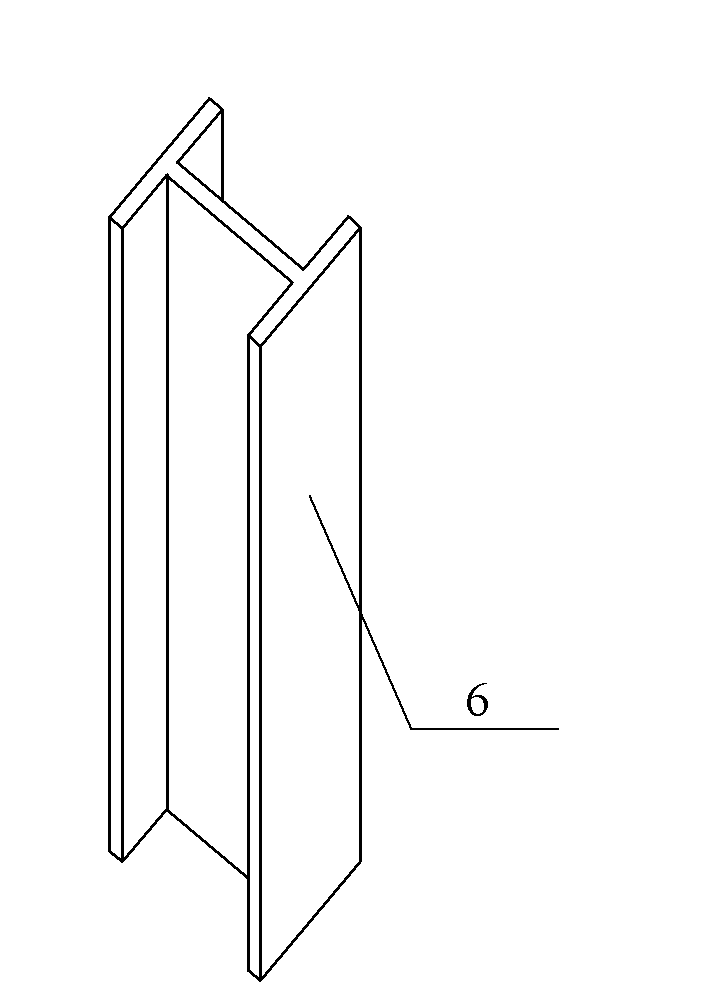

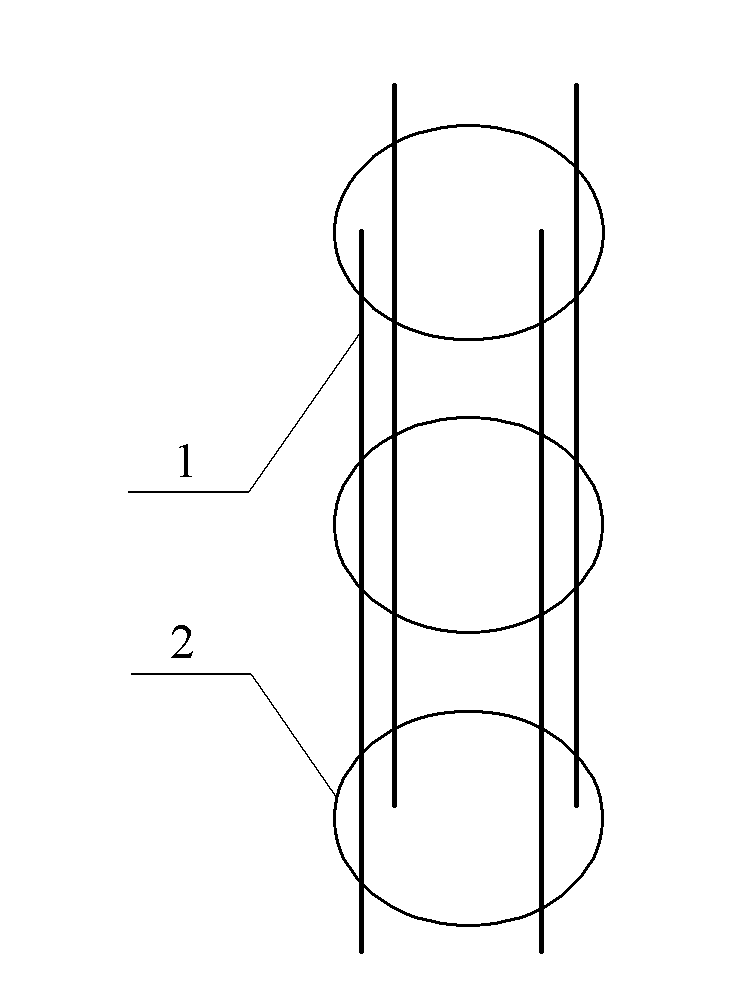

[0047] Such as Figure 1-4As shown, the section of the fiber reinforced plastic-steel composite pipe constrained steel high-strength concrete column provided by the present invention is a circular structure, mainly composed of longitudinal bars 1, stirrups 2, high-strength concrete 3, circular fiber reinforced plastic-steel composite pipes and H-shaped steel 6 components. The specific production method of this embodiment is as follows:

[0048] A. The longitudinal reinforcement 1 is arranged along the height direction of the column, and the longitudinal reinforcement 1 is steel reinforcement 1 or fiber reinforced plastic-steel composite reinforcement;

[0049] B. The hoop stirrup 2 is set in the height direction of the longitudinal reinforcement 1;

[0050] C. A section steel 6 is arranged along the height direction of the column in the stirrup 2, and the section steel 6 can be hot-rolled section steel or welded section steel;

[0051] D. A fiber-reinforced plastic-steel co...

Embodiment 2

[0054] Such as Figure 5 and 6 As shown, the section of the fiber reinforced plastic-steel composite pipe-constrained steel high-strength concrete column of the present invention is a square structure, mainly composed of longitudinal bars 1, stirrups 2, high-strength concrete 3, square fiber reinforced plastic-steel composite pipes and H-shaped steel 6 , its concrete preparation method is identical with embodiment 1.

Embodiment 3

[0056] Such as Figure 7 and 8 As shown, the section of the fiber-reinforced plastic-steel composite pipe-constrained steel high-strength concrete column of the present invention is a rectangular structure, mainly composed of longitudinal bars 1, stirrups 2, high-strength concrete 3, rectangular fiber-reinforced plastic-steel composite pipes and H-shaped steel 6 , its concrete preparation method is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com