Mechanical arm joint quick changing port capable of being replaced on track

A technology of manipulator and interface replacement, which is applied in the field of aerospace, can solve the problems of large-scale space manipulators, in-orbit maintenance, etc., and achieve the effect of large tolerance capability, low tolerance requirements, and reliable locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

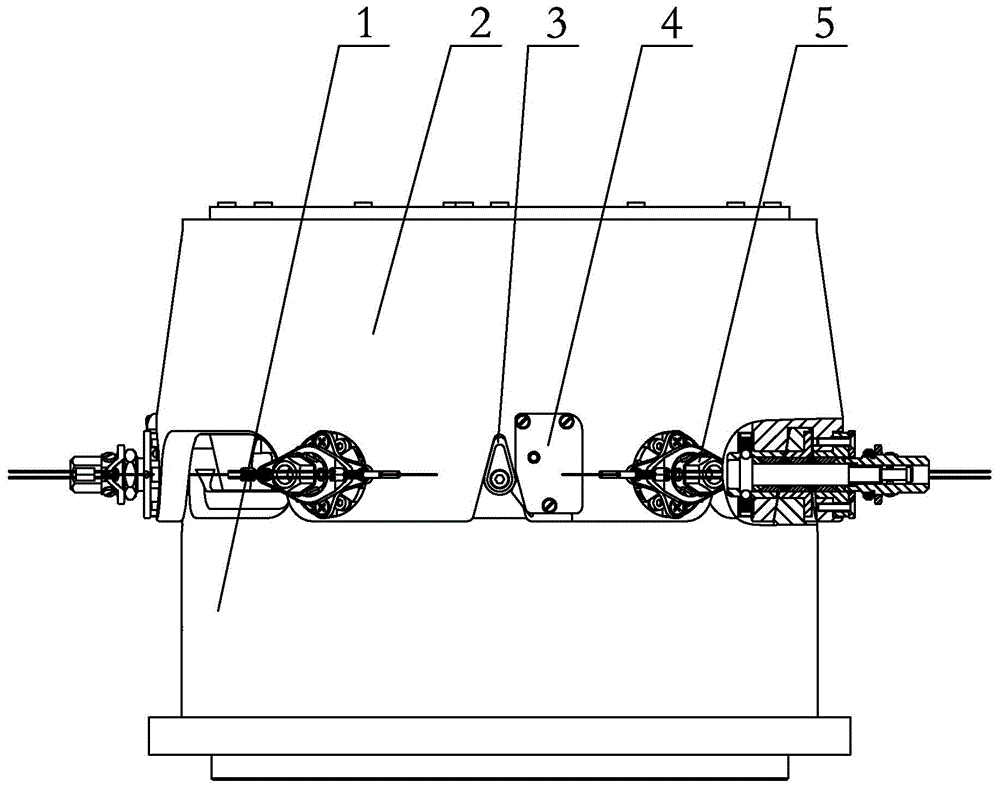

[0009] Specific implementation mode one: combine Figure 1 to Figure 10 Describe the present embodiment. The on-rail replaceable mechanical arm joint quick-change interface described in this embodiment includes a convex body 1, a concave body 2 matching with the convex body, a guide mechanism 3, a positioning mechanism 4, an electrical connector auxiliary The connection mechanism and six quick-disconnect connection mechanisms 5, the positioning mechanism 4, and the auxiliary connection mechanism of the electrical connector are installed on the concave body 2, the guide mechanism 3 is installed on the convex body 1, and the six quick-disconnect connection mechanisms 5 are installed evenly On the female body 2 , the female body 2 is connected to the male body 1 through six quick-disconnect connection mechanisms 5 .

specific Embodiment approach 2

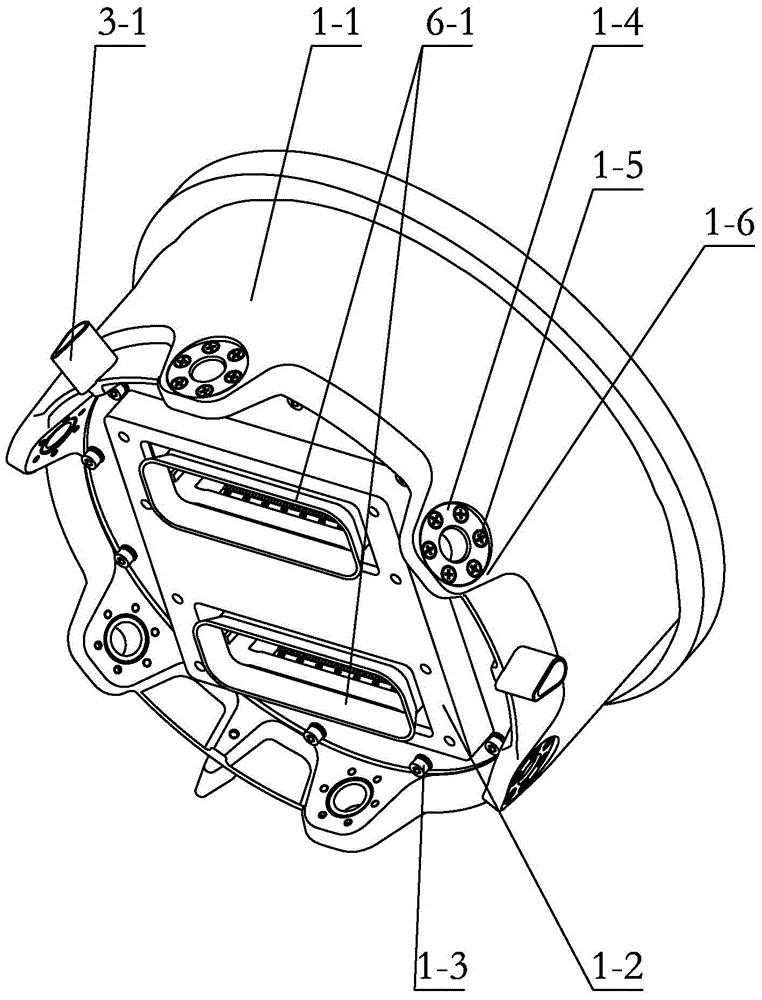

[0010] Specific implementation mode two: combination Figure 1 to Figure 4 Describe this embodiment, the convex body 1 of the on-rail replaceable mechanical arm joint quick-change interface described in this embodiment includes a convex body shell 1-1, a first electrical connector positioning plate 1-2, and six expansion pins Set 1-4, a plurality of first connecting screws 1-3 and a plurality of second connecting screws 1-5, the first electrical connector positioning plate 1-2 is installed side by side on the convex body through a plurality of first connecting screws 1-3 Inside the casing 1-1, six lugs 1-6 are evenly distributed along the circumferential direction on the lower surface of the convex body casing 1-1, and each lug 1-6 is respectively inserted with an expansion pin sleeve 1-4, each Each expansion pin sleeve 1-4 is fixedly connected with the lug 1-6 through a plurality of second connecting screws 1-5.

[0011] The technical effect of this embodiment is: such arran...

specific Embodiment approach 3

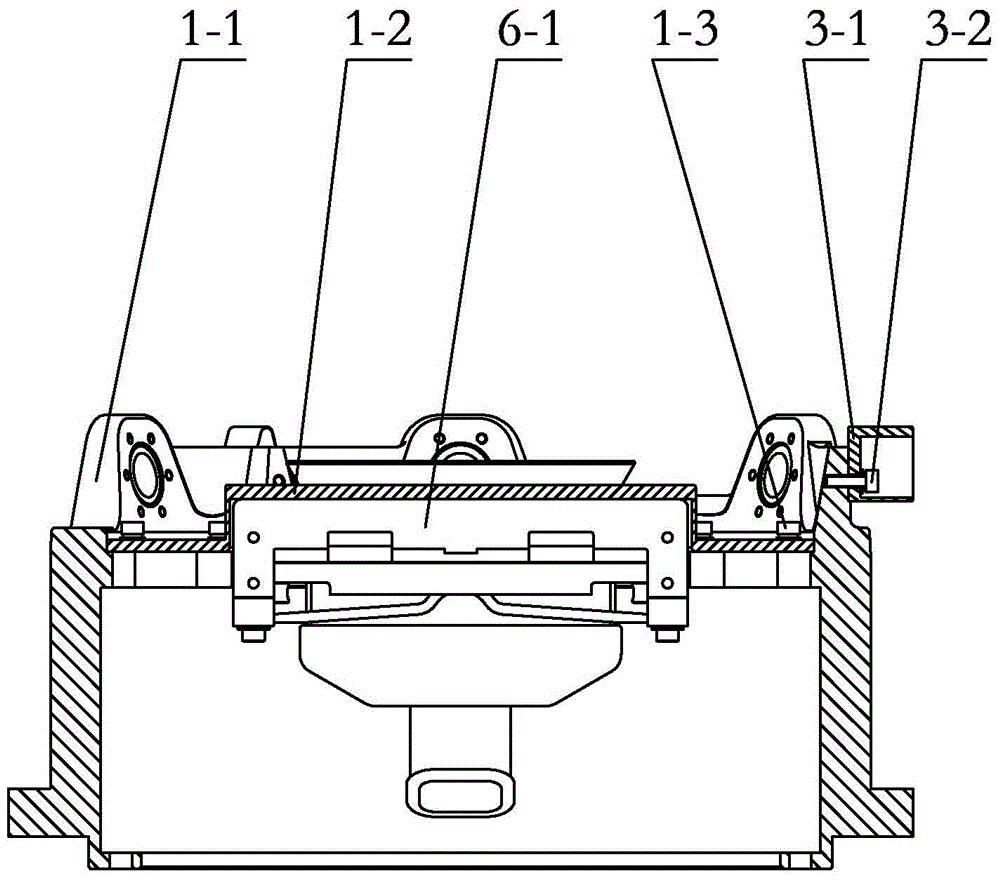

[0012] Specific implementation mode three: combination Figure 5 and Figure 6 Describe this embodiment. The concave body 2 of the on-rail replaceable mechanical arm joint quick-change interface in this embodiment includes a concave body shell 2-1, a bottom plate 2-7, and six outer ring expansion pin sleeves 2-3. , six inner ring expansion pin sleeves 2-5, a plurality of third connecting screws 2-2, a plurality of fourth connecting screws 2-4 and a plurality of fifth connecting screws 2-8, the outer shell of the concave body shell 2-1 Six outer ear plates 2-1-1 are evenly distributed along the circumferential direction on the ring, and six inner ear plates 2-1-2 are evenly distributed along the circumferential direction on the inner ring of the concave body shell 2-1, and each outer ear plate 2- 1-1 and an inner ear plate 2-1-2 form a pair of locking ear plates, each lug 1-6 on the convex body 1 can be inserted into a pair of said locking ear plates correspondingly, each oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com