Connected node of concrete filled steel tube combination column and reinforced concrete beams

A technology of reinforced concrete beams and steel pipe concrete, which is applied in the direction of architecture and building construction, and can solve the problems of high accuracy requirements for reinforcement ring design and construction manufacturing, difficulty in meeting anchorage length requirements, and affecting the shape of building facades, etc. To achieve the effect of direct force transmission, tight combination and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

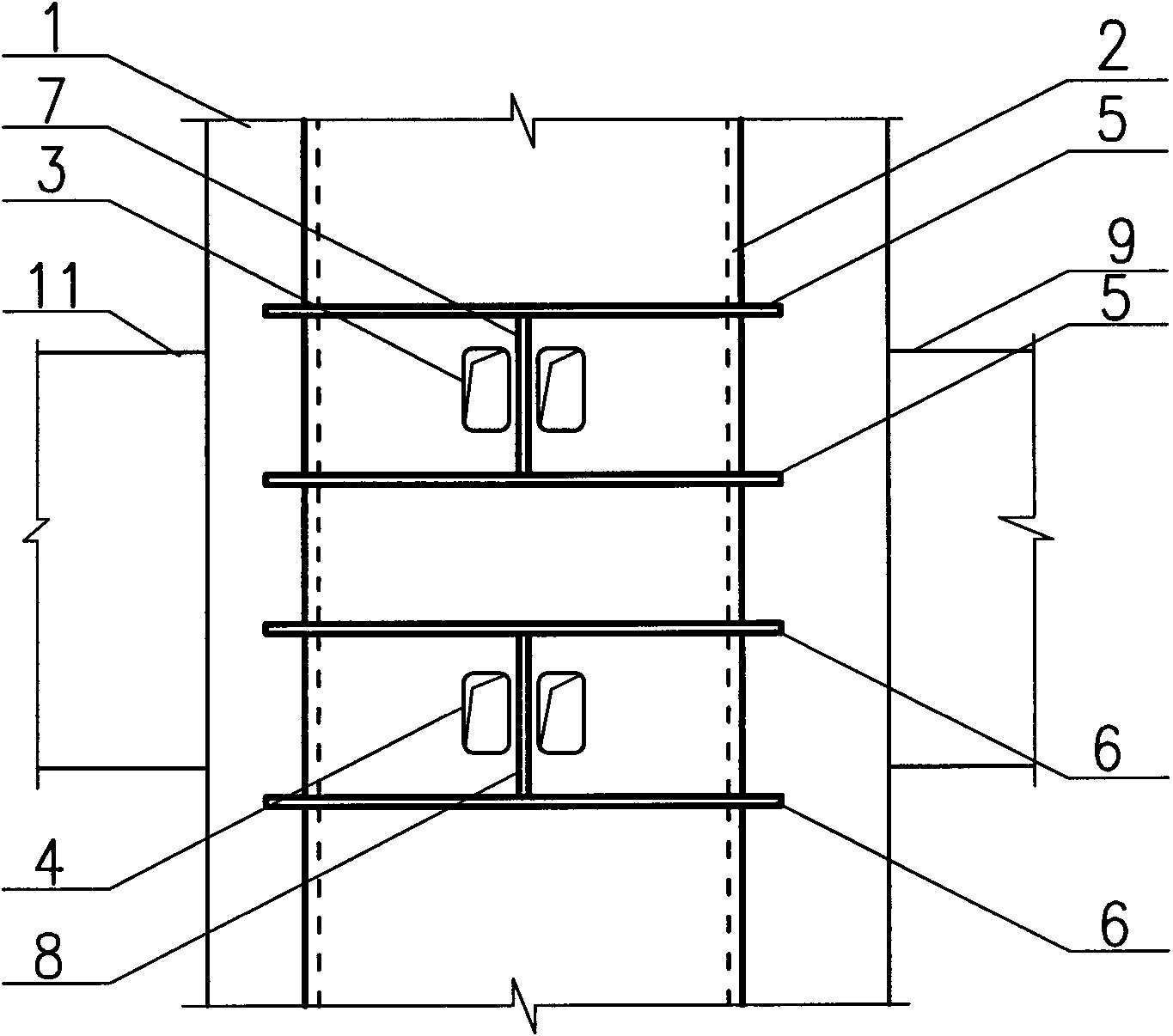

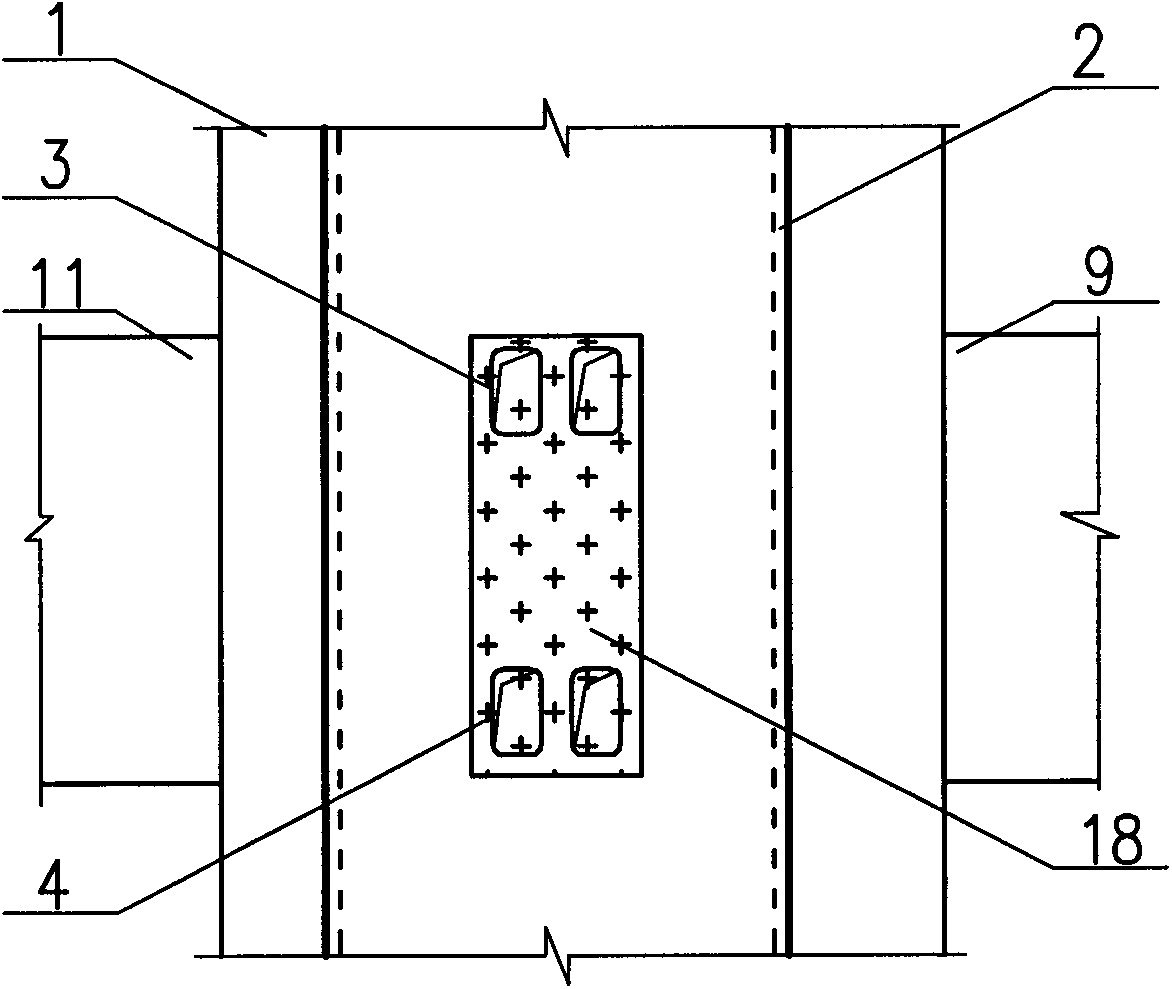

[0019] The schematic diagram of the node structure of the present invention is as figure 1 , 2 , 3, 4, 5, and 6. A steel pipe concrete composite column-reinforced concrete beam connection node of the present invention, wherein the steel pipe 2 in the steel pipe concrete composite column 1 is provided with four large square openings corresponding to each intersecting reinforced concrete beam, see figure 1 . The two upper openings 3 and the two lower openings 4 respectively correspond to the gluten and bottom bars in the longitudinal bars of the reinforced concrete beam. figure 2 The shaded area 18 represents the corresponding figure 1 The relative positions of the reinforced concrete beam sections of the middle upper opening 3 and the lower opening 4. In order to avoid stress concentration at the corner of the hole, it is required to set a round chamfer at the corner of the hole during construction, such as figure 1 shown.

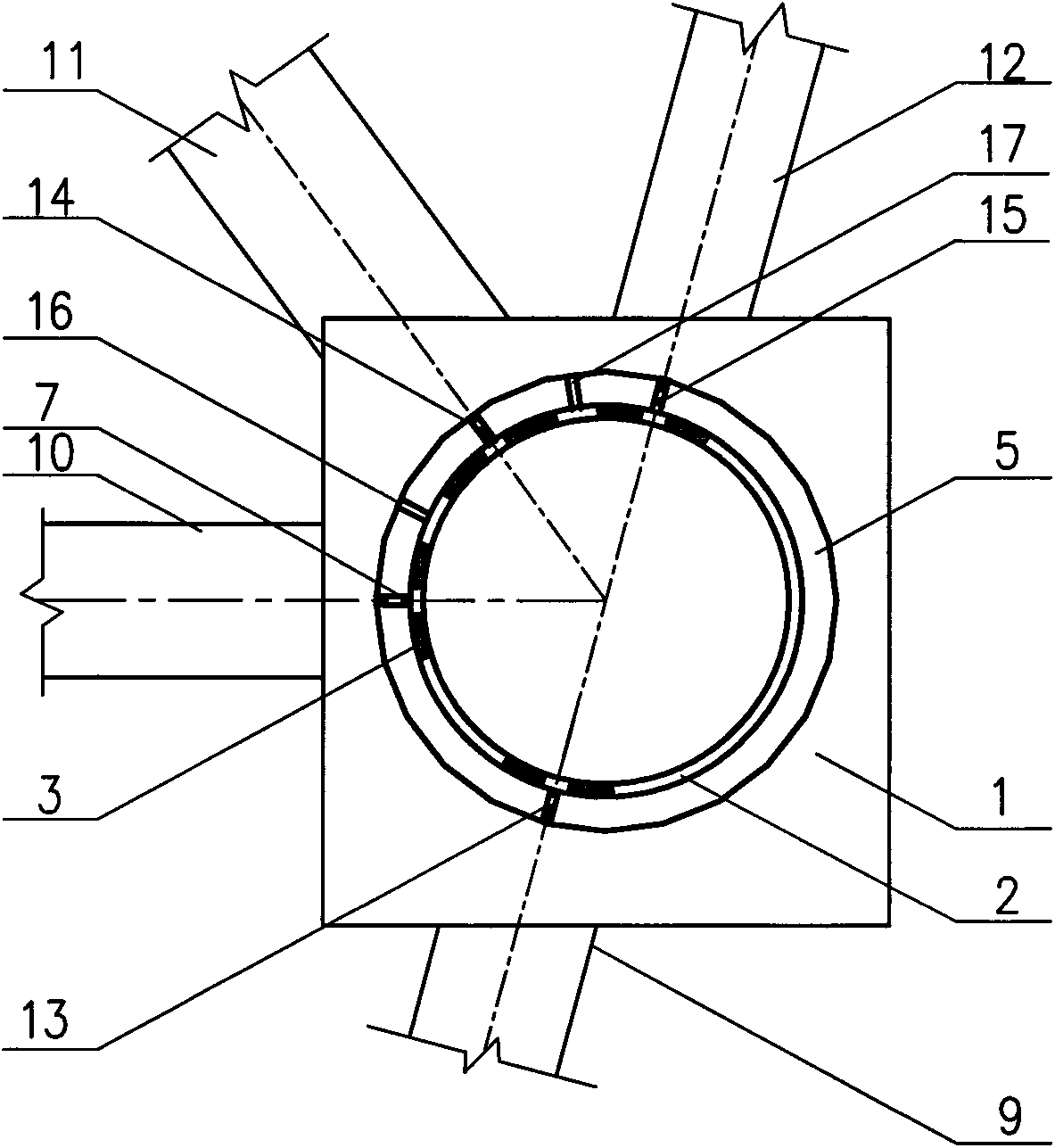

[0020] image 3 Shown is the planar cutout of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com