Hollow block used for building

A technology for hollow blocks and construction, which is applied in the direction of buildings, building components, building structures, etc., and can solve problems such as unclear force transmission paths between upper and lower blocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

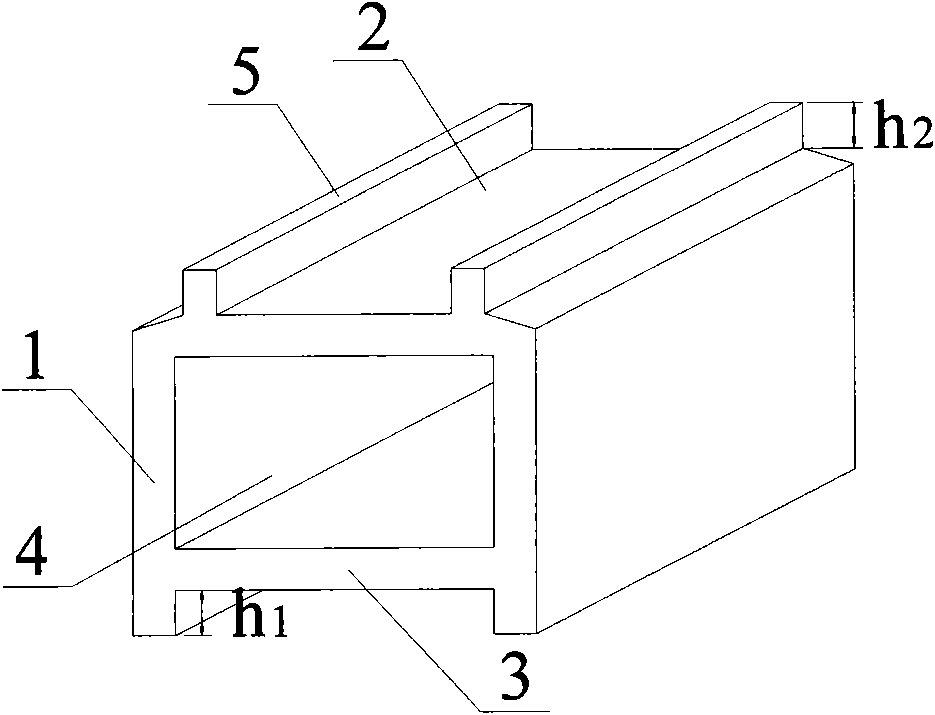

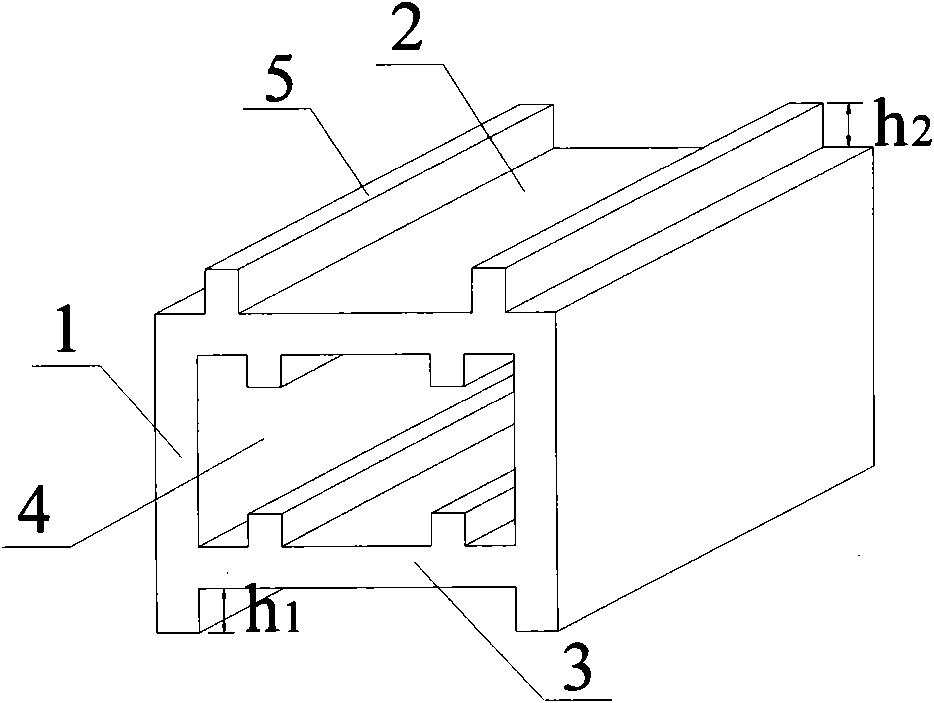

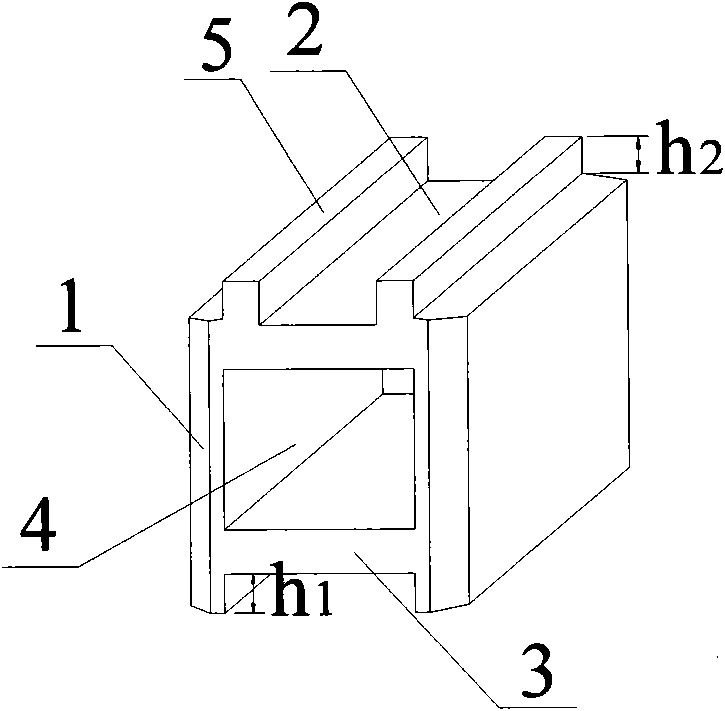

[0010] refer to Figure 1-Figure 5 , the building uses hollow blocks, which are composed of a roof 2 and two supporting legs 1. There is a reinforcing rib 3 between the two supporting legs 1. The roof 2, two supporting legs 1 and reinforcing ribs 3 form a block space 4 around the roof. Two or more convex ribs 5 are arranged on it, and the height of the convex ribs 5 is h 2 , the distance between the rib 3 and the bottom of the supporting leg 1 is h 1 , h 1 greater than or equal to h 2 . During masonry, due to the distance h between the reinforcing rib 3 and the bottom of the supporting leg 1 1 greater than or equal to h 2 , the distance between the convex rib on the top plate of the lower hollow block and the reinforcing rib of the upper hollow block is greater than or equal to zero, and the bearing capacity will not be transmitted between the convex rib on the top plate of the upper block and the reinforcing rib of the lower block, but in the hollow In this way, under t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com