Square battery multifunctional test fixture with adjustable test size and operation method

A multi-functional testing, prismatic battery technology, applied in the direction of measuring electricity, measuring electrical variables, components of electrical measuring instruments, etc., can solve the problem that the test fixture cannot be quickly disassembled and adapted to the square batteries of multiple sizes and specifications, so as to improve the test Efficiency, widening range of use, and effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

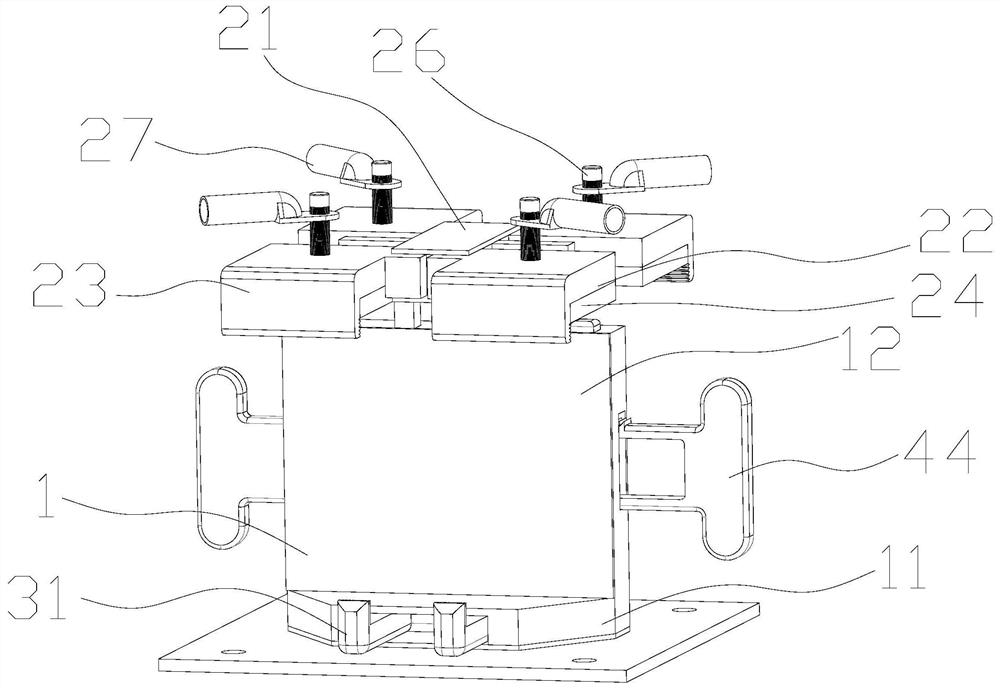

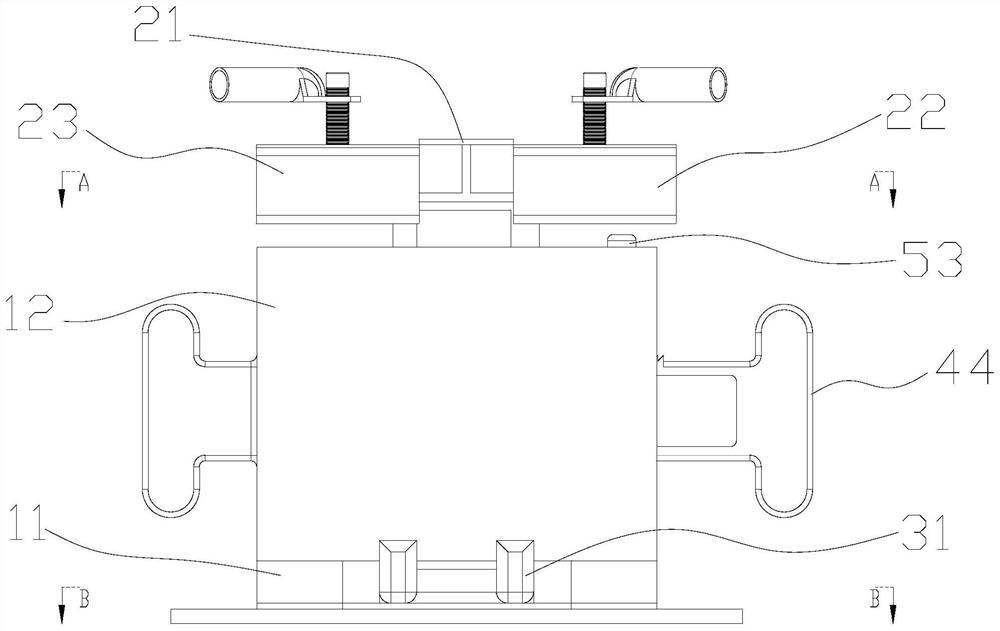

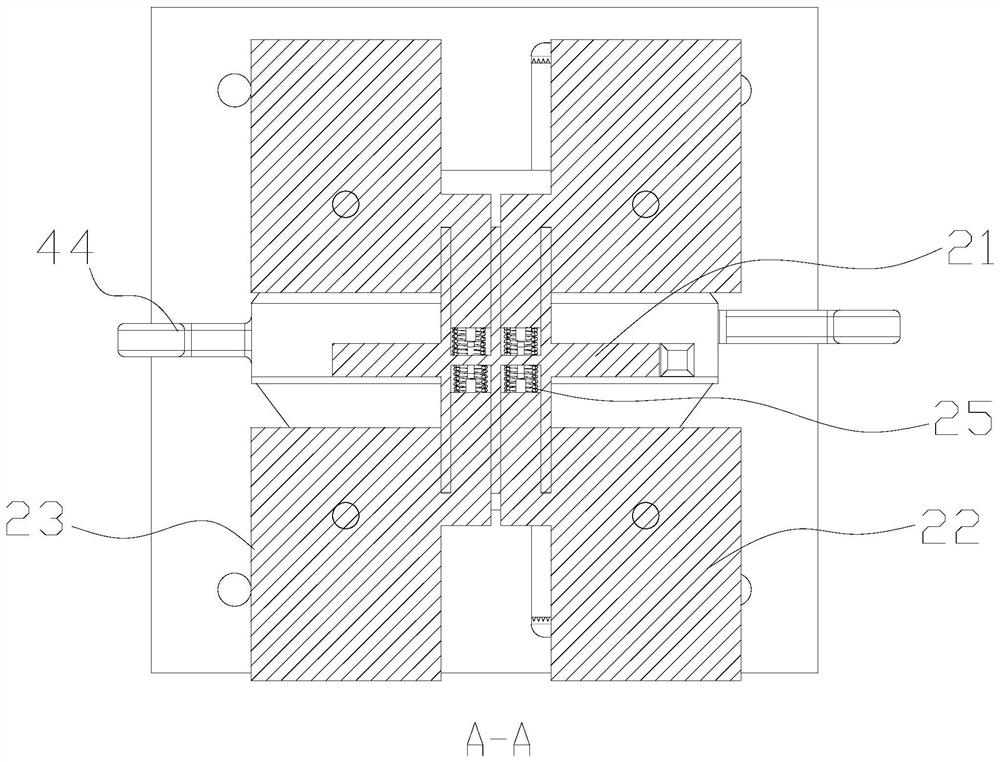

[0030] Such as figure 1 As shown, this embodiment provides a square battery multifunctional test fixture with adjustable test size, including a test seat 1, an upper clamping mechanism, a lower clamping mechanism, a lifting mechanism and a locking mechanism.

[0031] Such as figure 1 and figure 2 As shown, the test seat includes a bottom plate 11 and a back plate 12 which are connected to each other. Both the bottom plate and the back plate are provided with a non-slip insulating layer. The mechanism is movably connected with the bottom plate, and the lower clamping mechanism is used to clamp the bottom of the battery to be tested, such as Figure 4 As shown, the lower clamping mechanism includes a lower insulating splint 31 and a lower connecting spring 32, one end of the lower connecting spring is connected to the bottom plate, the other end is connected to the lower insulating splint, and the end of the lower insulating splint away from the lower connecting spring is pro...

Embodiment 2

[0038] Such as Figure 7 As shown, the square battery multifunctional test fixture with adjustable test size in this embodiment can also be used for battery vibration testing, and only needs to fix the bottom of the fixture on the vibration test platform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com