Hollow building block for building

A hollow block and building technology, which is applied in the direction of building, building components, building structure, etc., can solve the problem of unclear force transmission paths between upper and lower blocks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

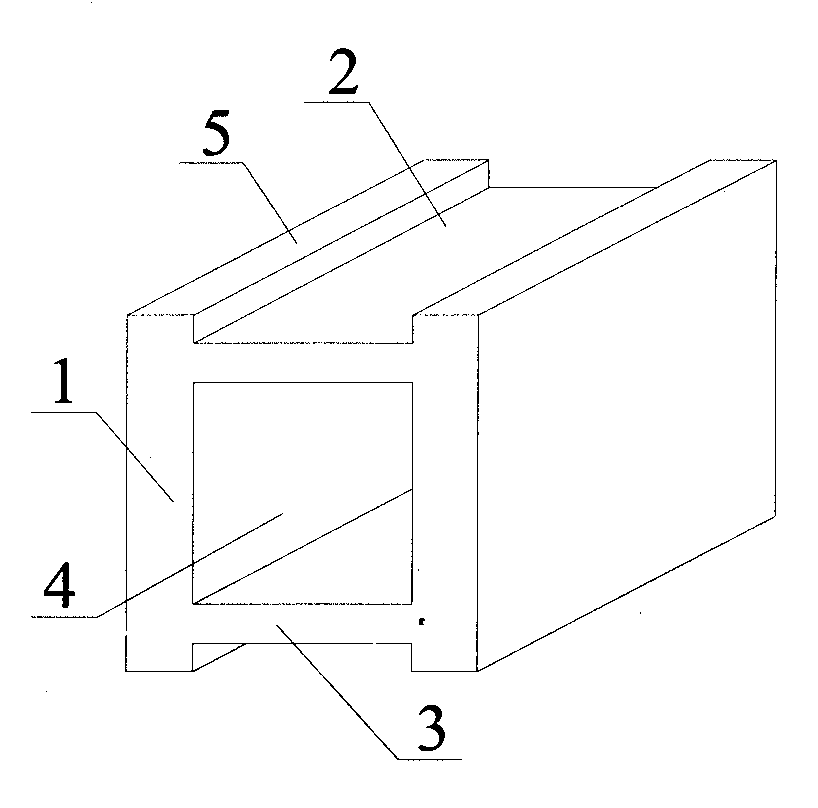

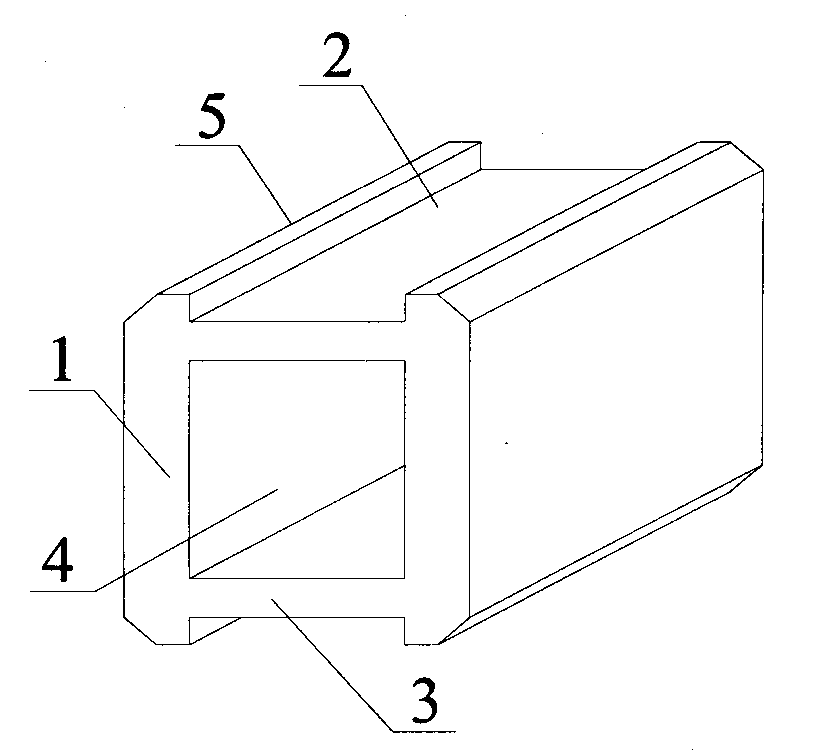

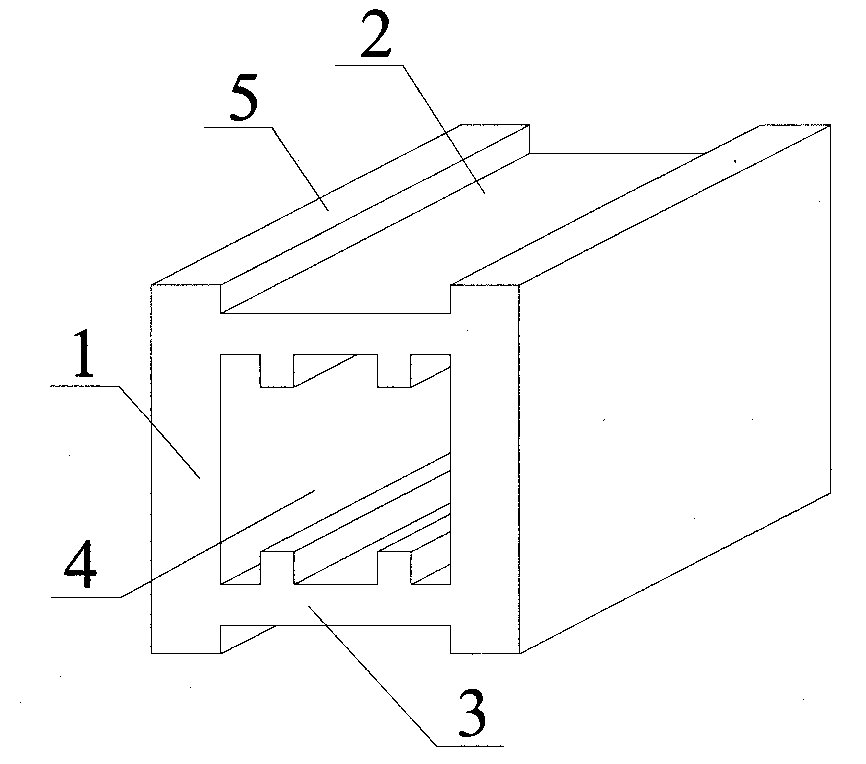

[0012] refer to Figure 1-Figure 7 , the building uses hollow blocks, which are composed of a top plate 2 and supporting legs 1. There are reinforcing ribs 3 between the supporting legs 1. The top plate 2, two supporting legs 1, and reinforcing ribs 3 form a block space 4 around the surrounding area. On the top plate 2, there are There are two or more convex ribs 5, the convex ribs 5 are on the supporting leg 1, the convex ribs 5 and the supporting legs 1 are aligned up and down, and the thickness of the convex ribs 5 is t 1 , the thickness of supporting leg 1 is t 2 , t 1 equal to t 2 . During masonry, the convex ribs 5 on the top plate 2 of the lower block are aligned up and down with the supporting legs 1 of the upper block, and the mortar is applied or sprayed and squeezed in the horizontal grooves and vertical joints formed by the upper block and the lower block 6 Fill up to make the wall bonded into a whole. In this way, under the action of the vertical bearing capa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com