Method for reinforced 3D hybrid printing of shear wall

A hybrid printing and 3D printing technology, applied in the field of 3D printing, can solve the problems of discounted seismic performance of shear wall components, easy tensile damage of the printed layer, unqualified building materials, etc., to improve the degree of construction automation and ensure the reliability of nodes , The effect of fast construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

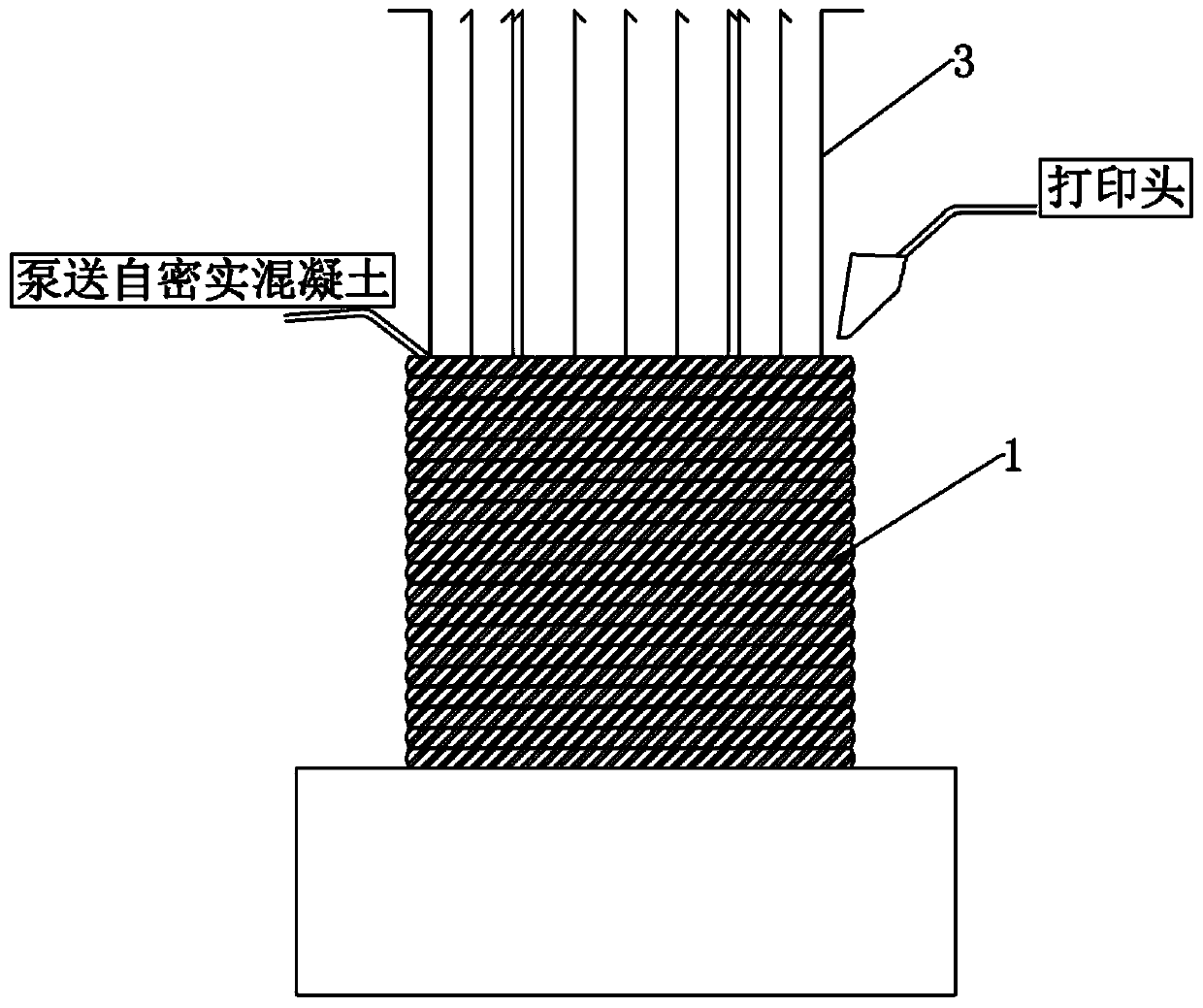

[0019] Such as figure 1 , 2 As shown, a method for reinforced 3D hybrid printing shear wall, including the following steps:

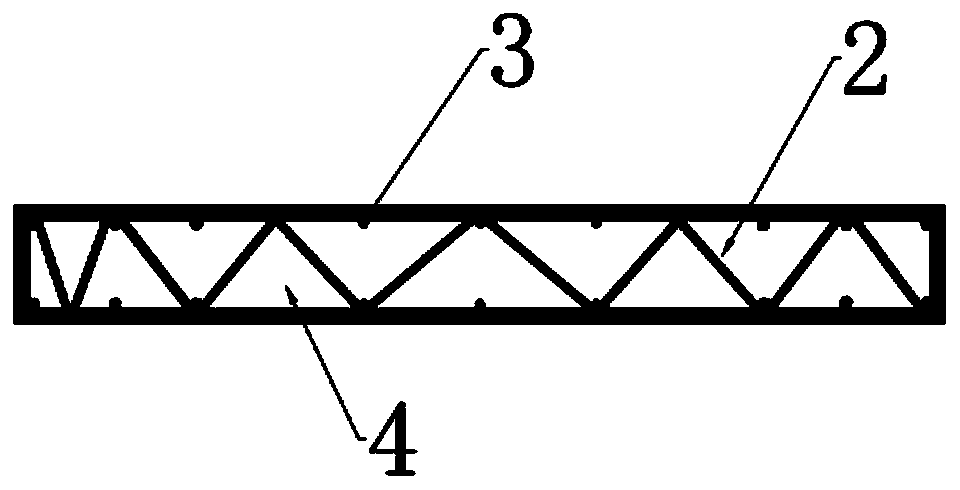

[0020] (1) First, a 3D printer is used to simultaneously print the outer reinforced hoop layer 1 and the inner reinforced truss structure 2 of the shear wall.

[0021] 3D printing reinforced hoop layer 1 is 3D mixed printing reinforced high-toughness cement-based cementitious material. The cement-based cementitious material can be made of cement slurry. Reinforcement is 3D printing toughened long fiber while 3D printing cement slurry 11, so as to enhance the tensile performance of the hoop layer 1, so that the hoop layer 1 has high compressive strength and tensile strength at the same time. The inner layer reinforced truss structure 2 is arranged in a zigzag shape in the hoop layer 1 to enhance the bearing capacity of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com