A scs concrete filled steel pipe pier with a built-in transverse connection structure at the end

A steel pipe concrete, transverse connection technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of poor connection performance between steel pipe and concrete, prone to buckling at the upper and lower ends, and small hoop effect, etc., to achieve processing and installation Convenient layout, convenient construction, improve the effect of combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

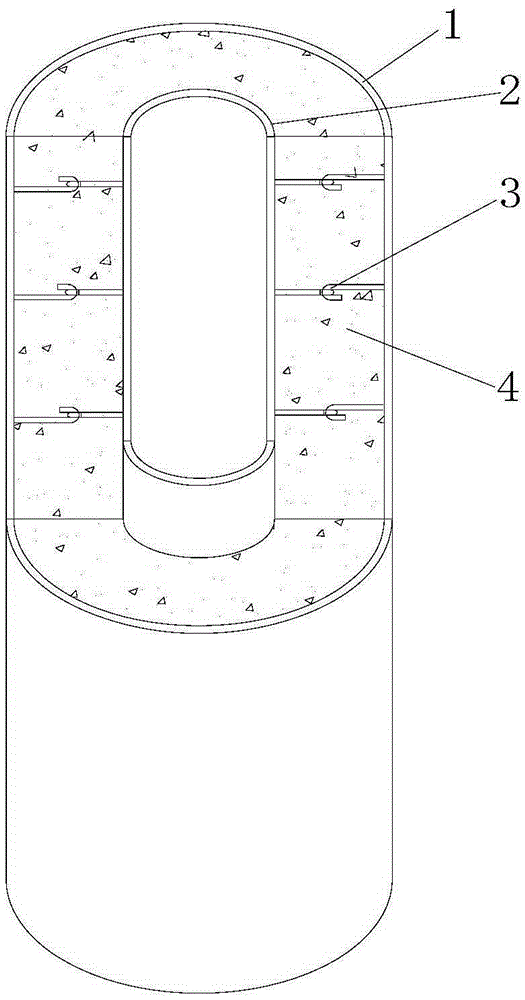

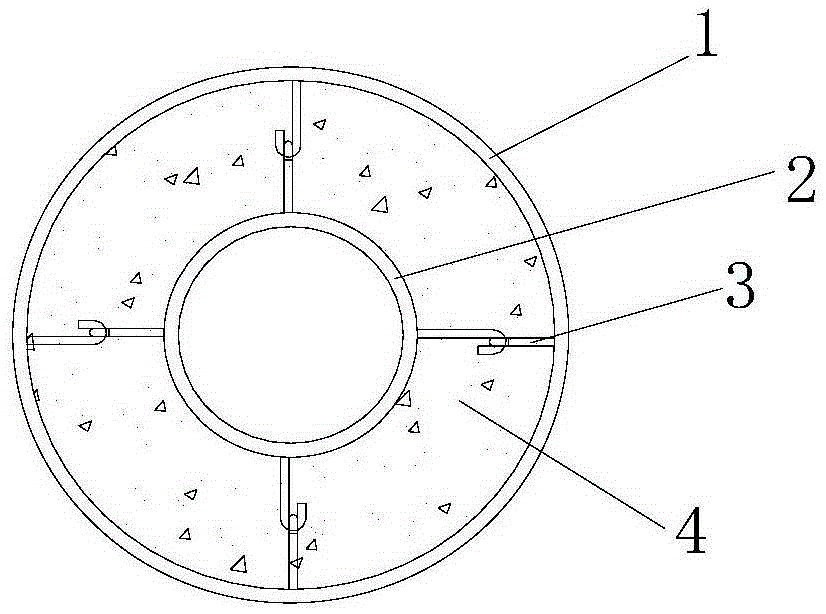

[0038] Such as figure 1 , figure 2 As shown, the present invention includes an outer steel pipe 1, an inner steel pipe set inside the outer steel pipe 1, a top end connection structure arranged between the top end of the outer steel pipe 1 and the top end of the inner steel pipe 2, and a top end connection structure arranged between the bottom end of the outer steel pipe 1 and the inner steel pipe 2. The bottom connecting structure between the bottom ends and the concrete structure 4 formed by pouring the concrete filled in the cavity between the outer steel tube 1 and the inner steel tube 2 after the top connecting structure and the bottom connecting structure are all arranged . The outer steel pipe 1 and the inner steel pipe 2 are arranged vertically and they are arranged coaxially. The vertical height of the outer steel pipe 1 and the inner steel pipe 2 are the same. The top surfaces of the two are flush and the bottom surfaces of the two are flush. The top end connection ...

Embodiment 2

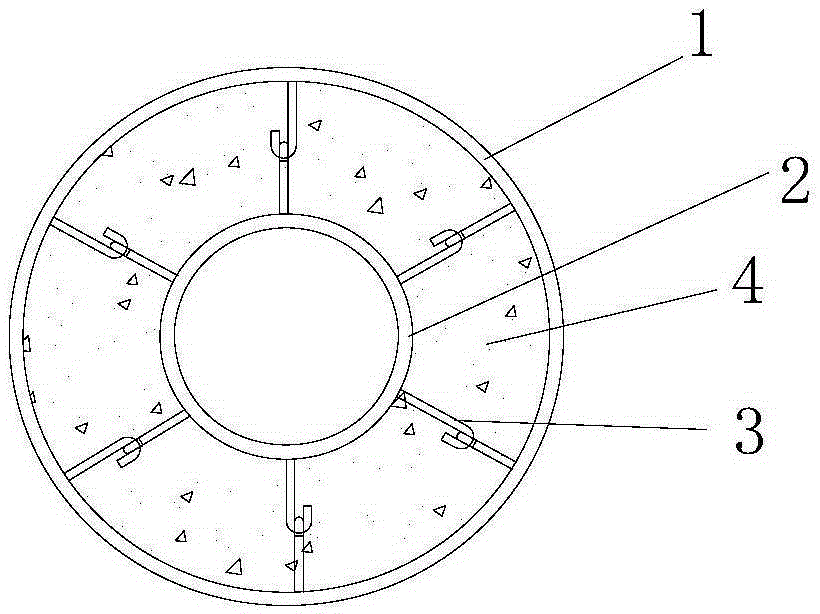

[0069] In this embodiment, such as image 3 As shown, the difference from Embodiment 1 is: the number of groups of transverse connectors included in the transverse connecting structure between the first round steel pipe and the second round steel pipe N=6, the outer steel pipe 1 and the inner steel pipe The wall thickness of the steel pipe 2 is 25 mm.

[0070] In this embodiment, the structure and connection relationship of the remaining parts are the same as those in the first embodiment.

Embodiment 3

[0072] In this embodiment, such as Figure 4 , Figure 5 As shown, the difference from Embodiment 1 is: the outer steel pipe 1 is a regular polygon steel pipe with a regular polygon in cross section, and the cross section of the regular polygon steel pipe is a square, which is arranged on the regular polygon steel pipe and the circle. The N groups of the transverse connecting members in the transverse connecting structure between the two steel pipes are uniformly arranged along the circumferential direction. The number of groups of transverse connecting pieces included in the transverse connecting structure arranged between the regular polygonal steel pipe and the second round steel pipe Where a is the total number of sidewalls of the regular polygonal steel pipe, n=1, 2 or 3, and N groups of the transverse connectors are respectively connected between the second round steel pipe and the N sidewalls of the regular polygonal steel pipe The outer ends of the outer connecting piec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com