Corrugated aluminum alloy pipe and concrete combination column

A technology of aluminum alloy pipes and concrete, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of local buckling of external steel pipes, achieve the effects of good hoop restraint, improved strength and ductility, and enhanced bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

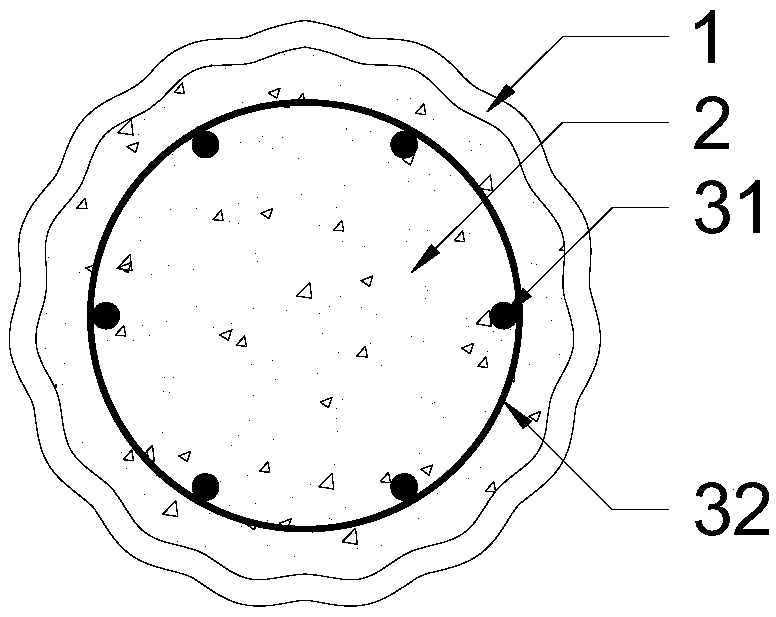

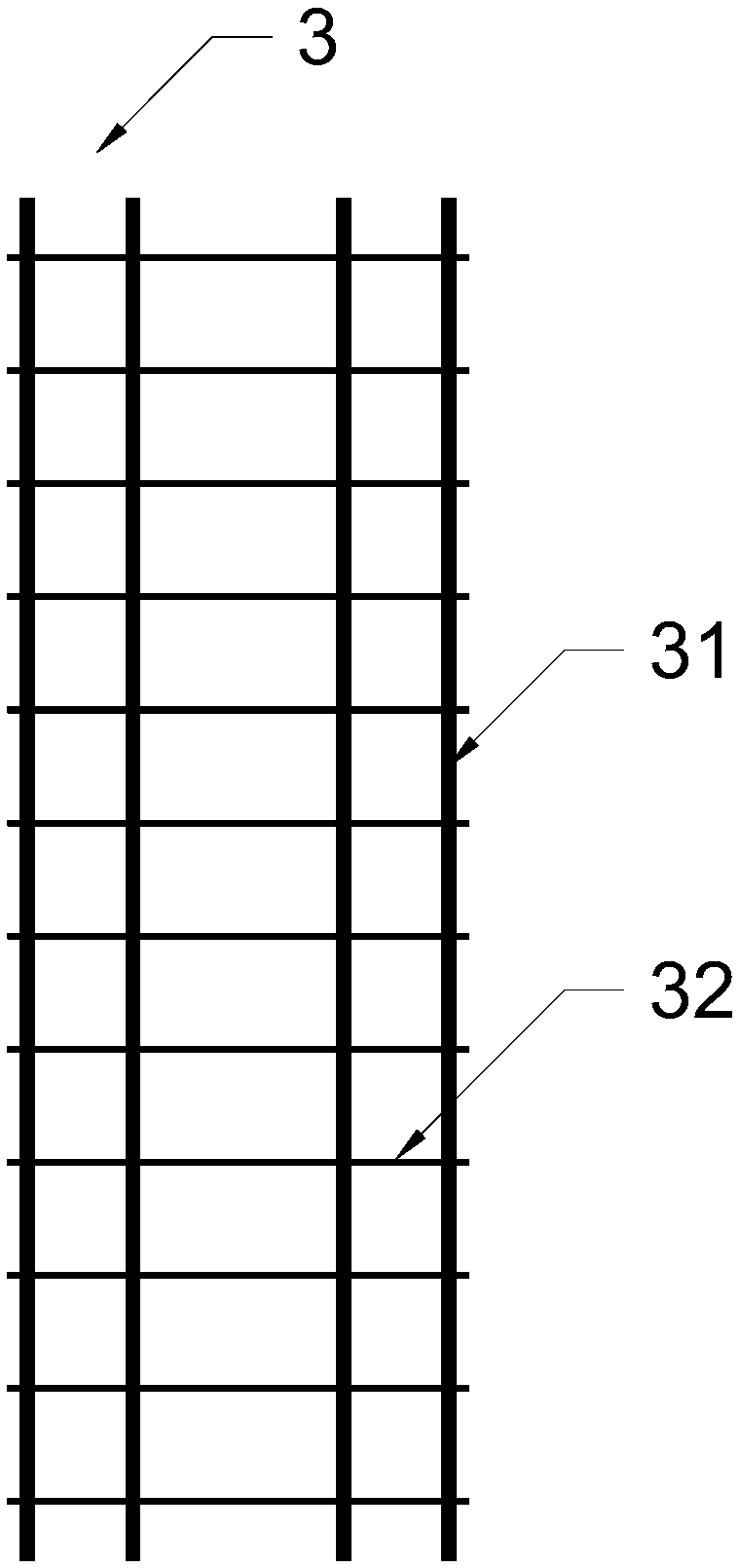

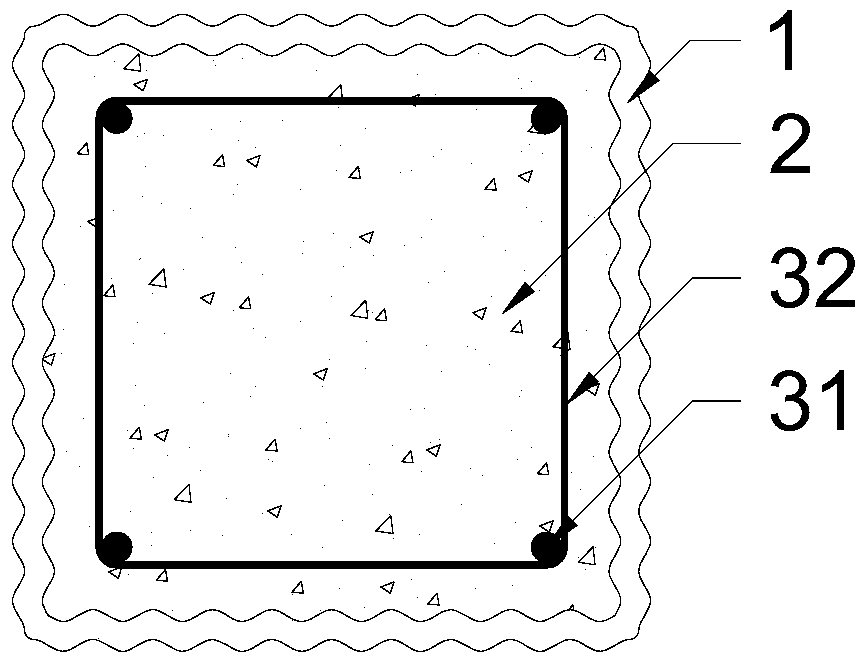

[0031] combine Figure 1 to Figure 6 , The corrugated aluminum alloy tube concrete composite column of the embodiment 1 includes a corrugated aluminum alloy tube 1, concrete 2, and a steel cage 3, and the steel cage 3 is composed of longitudinal steel bars 31 and stirrups 32. For the round corrugated aluminum alloy tube 1, the overall aluminum alloy tube can be made of all aluminum alloy tubes or welded by semi-aluminum alloy tubes; for the square or rectangular corrugated aluminum alloy tube 1, the overall aluminum alloy tube consists of four corrugated aluminum plates Welded. The reinforcement cage 3 is arranged inside the corrugated aluminum alloy pipe 1, and there are at least four longitudinal reinforcement bars 31, and the geometric centroid of the cross section of the reinforcement cage 3 coincides with the geometric centroid of the cross section of the corrugated aluminum alloy pipe. When constructing concrete columns with corrugated aluminum alloy tubes, first fix th...

Embodiment 2

[0033] combine Figure 7 ~ Figure 9 , the corrugated aluminum alloy tube concrete composite column in Example 2 includes a corrugated aluminum alloy tube 1 and concrete 2 filled therein. For the corrugated aluminum alloy tube 1 whose overall aluminum alloy tube is circular, the overall aluminum alloy tube can be a full aluminum alloy tube or welded by semi-aluminum alloy tubes; for square or rectangular corrugated aluminum alloy tube 1, the overall aluminum alloy tube It is welded from four corrugated aluminum plates. During the construction of the corrugated aluminum alloy tube concrete column, the corrugated aluminum alloy tube 1 is fixed first, and then concrete is poured in the corrugated aluminum alloy tube 1 to obtain the corrugated aluminum alloy tube concrete composite column of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com