Inner truss type CFST L-shaped column and its construction method

A steel tube concrete and truss-type technology, applied in the field of special-shaped columns, to achieve the effects of increased bearing capacity, fast and convenient construction, and reduced effective width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

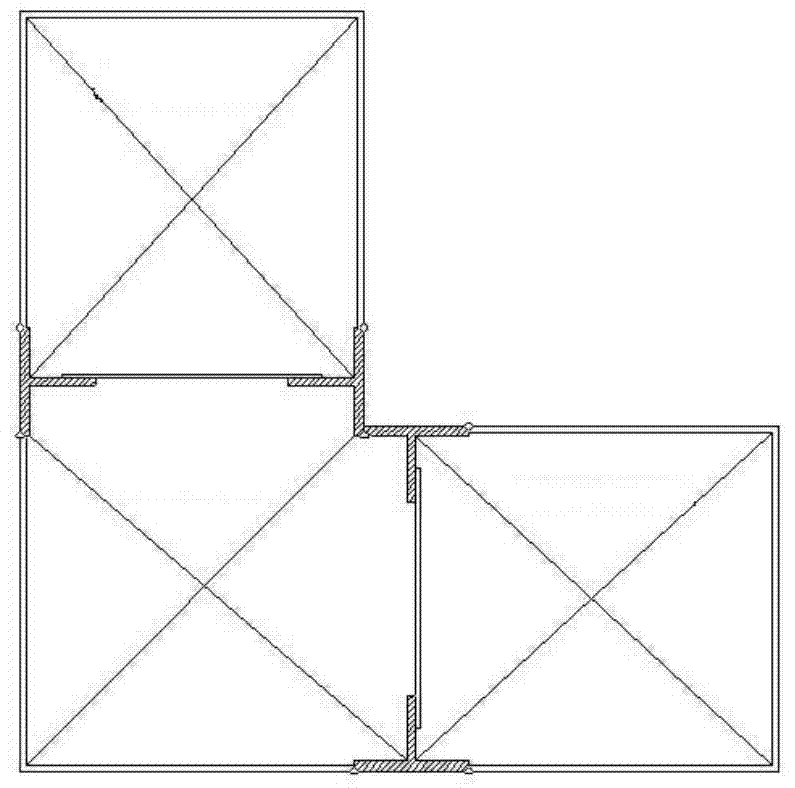

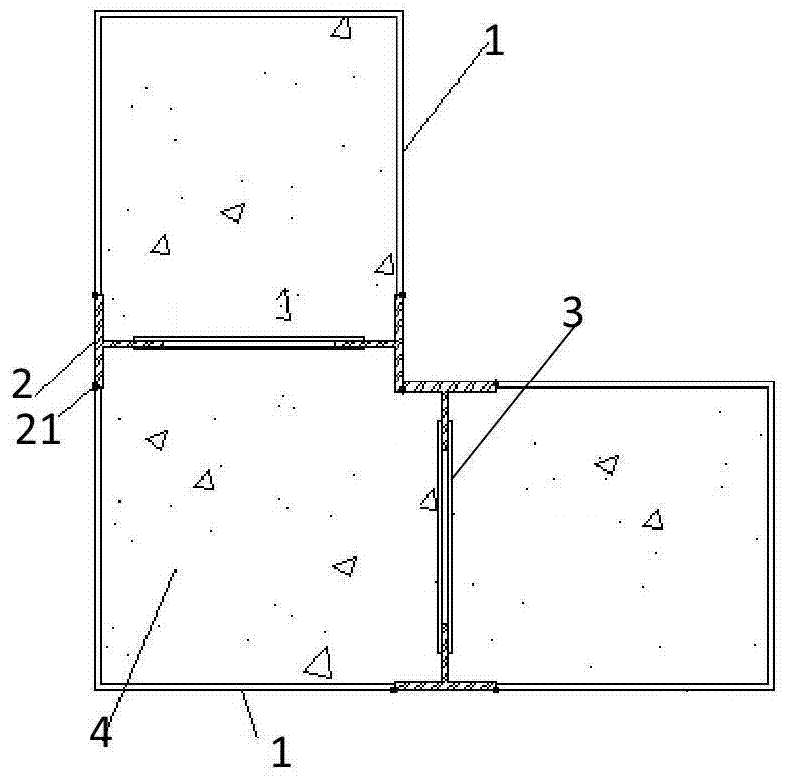

[0019] like image 3 , Figure 4a and Figure 4b As shown, the inner truss-type concrete-filled steel tube L-shaped column of the present invention mainly includes the outer-wrapped steel pipe 1, the inner-filled concrete 4 and the inner truss. Among them, the basic components of the inner truss are T-shaped steel 2 and strip 3. In this embodiment, there is a set of T-shaped steel flange plates welded vertically to form an inner truss subunit. In addition, there are 2 T-shaped steels, the webs of these two T-shaped steels are welded with strips, and the other end of the strips is welded to the T-shaped steel webs in the inner truss subunit.

[0020] like Figure 4b As shown, an L-shaped frame is formed after welding. In other words, the T-shaped steel and the inner truss subunits 2a are located at the three corners of the quadrangle, or in other words, at the three corners of a quadrangular column. from Figure 4a and Figure 4b It can be seen that there are two ∏-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com