Shield vertical shaft assembling type concrete-filled steel tube inner support system and construction method thereof

A technology of concrete filled steel tube and support system, which is applied to shaft equipment, earthwork drilling, wellbore lining, etc., can solve the problems of complicated concrete support construction, poor overall stability, internal corrosion, etc., to save erection time, process quality assurance, and control The effect of shaft deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

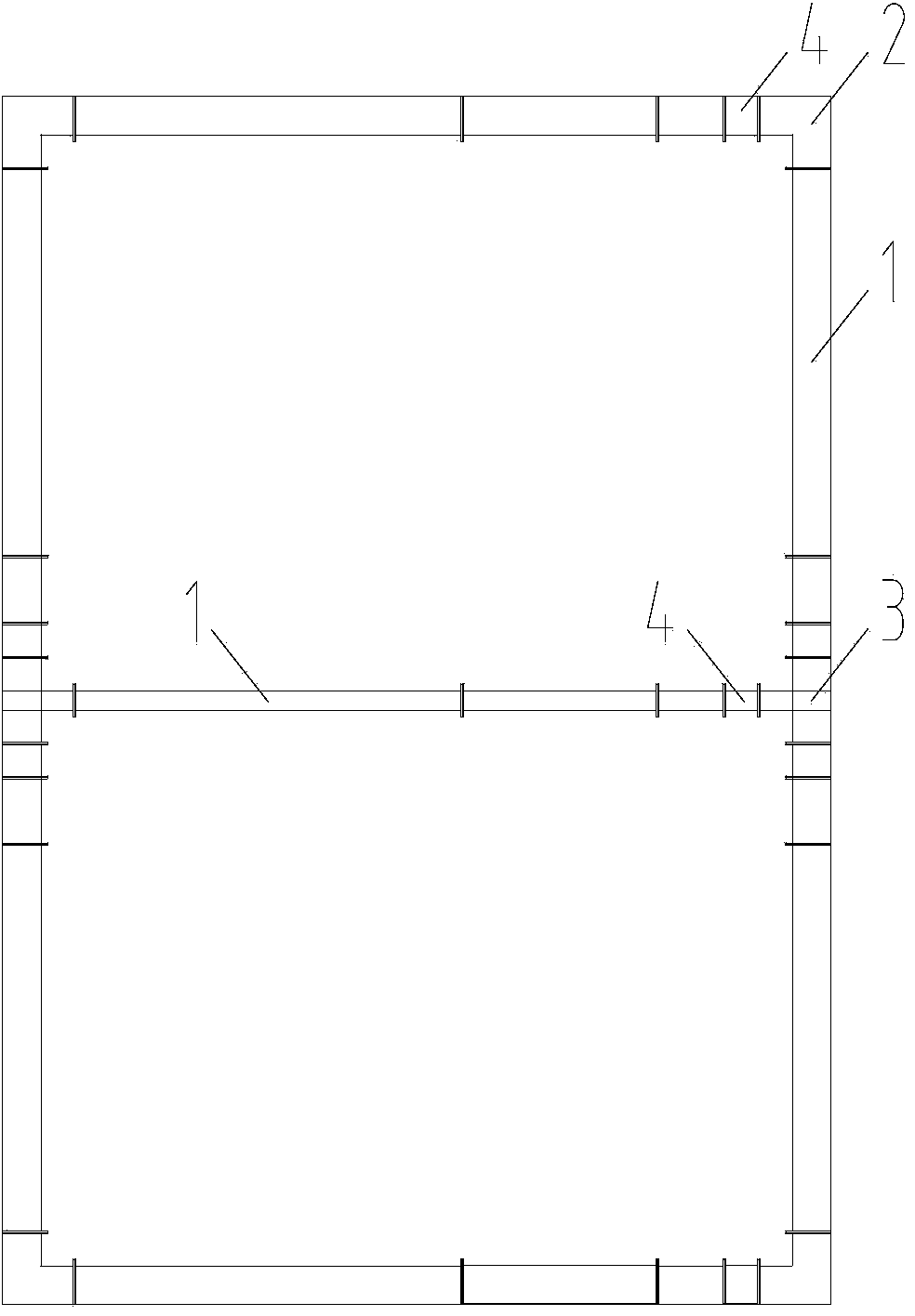

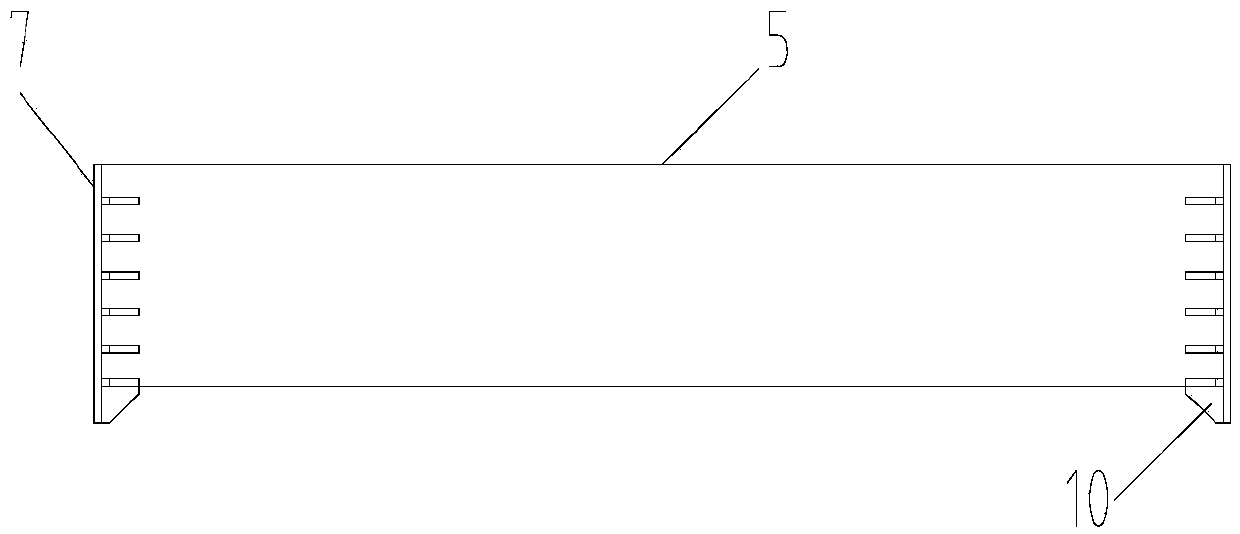

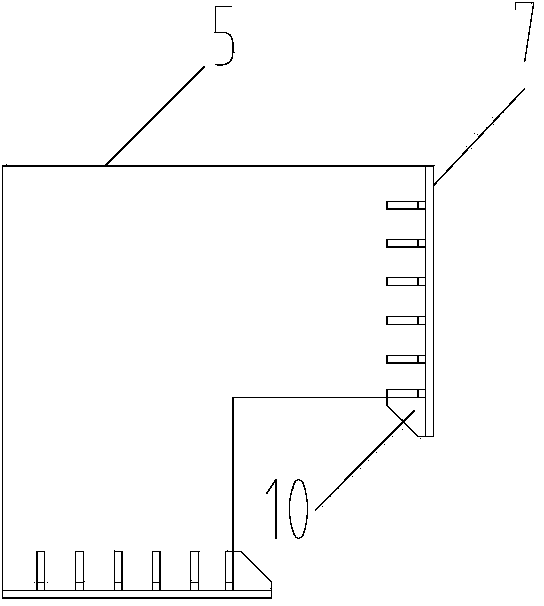

[0048] A shield shaft is 22.8m long, 15.9m wide, and 30.77m deep. The support form of the enclosure structure adopts the fabricated steel pipe concrete inner support system. Including the shield shaft and the concrete-filled steel tube inner support system The concrete-filled steel tube inner support system is composed of a multi-layer concrete-filled steel tube inner support frame 14, including the concrete-filled steel tube purlin and the concrete-filled steel tube inner support, all of which are assembled from rectangular concrete-filled steel tube components. The rectangular concrete-filled steel tube member includes a rectangular concrete-filled steel tube standard straight brace 1, a rectangular concrete-filled steel tube right angle 2, a rectangular concrete-filled steel tube tee 3, and a rectangular concrete-filled steel tube short-circuit straight brace 4. The surrounding rectangular concrete-filled steel pipe standard straight brace 1, rectangular concrete-filled stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Section height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com