Patents

Literature

38results about How to "Conducive to earthquake resistance of the structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inorganic heat insulation load-bearing concrete

InactiveCN101628797AImprove insulation effectHigh strengthSolid waste managementCeramicwarePulverized fuel ashMix proportion

Owner:李珠 +1

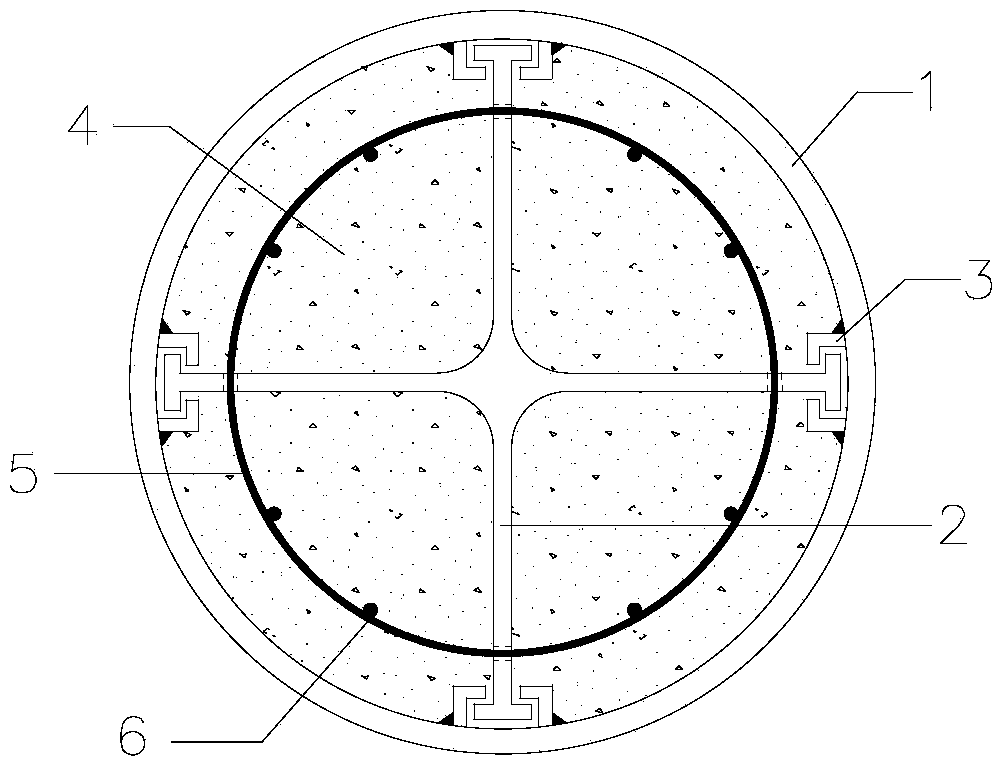

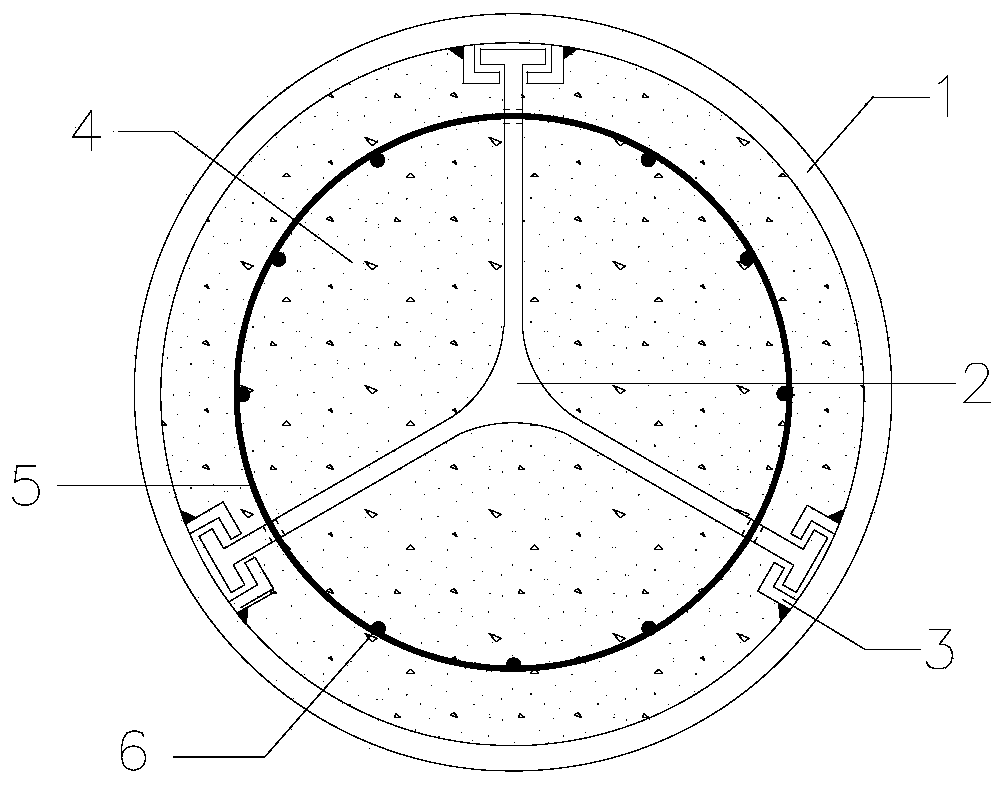

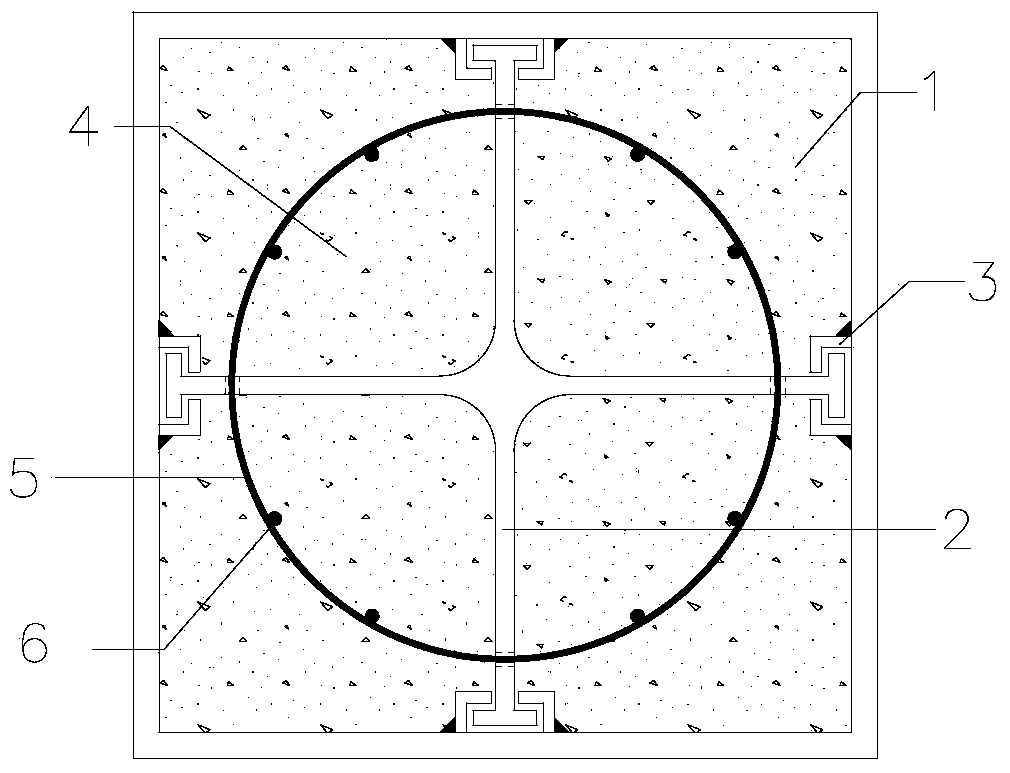

Fiber reinforce plastic (FRP) reinforced concrete-filled steel tube combination column

ActiveCN103899040AEnhanced binding effectDelayed bucklingStrutsBuilding reinforcementsFiberReinforced concrete

The invention aims at providing a fiber reinforce plastic (FRP) reinforced concrete-filled steel tube combination column which comprises a steel tube, a hoop rib, an FRP reinforced rib and a longitudinal reinforcement, wherein the hoop rib and the FRP reinforced rib are arranged in the steel tube; the inner wall of the steel tube is provided with fixed angle iron; the end part of the FRP reinforced rib is fixed on the angle iron; the FRP reinforced rib is provided with a hole, and the hoop rib passes through the hole in the FRP reinforced rib; the longitudinal reinforcement is fixed on the hoop rib; the steel tube is filled with concrete. An FRP reinforced rib plate internally provided with the hoop rib and the longitudinal reinforcement is arranged in the FRP reinforced concrete-filled steel tube combination column, and the concrete can be separated again, so that the restraint effect of the concrete is improved, the bearing capacity of the concrete is improved, and the tube wall on the stressed side is effectively prevented from being bended. By adopting a structure of enabling reinforced concrete, the FRP reinforced rib and the steel tube to cooperative work, the FRP reinforced concrete-filled steel tube combination column is simple in structure and convenient to construct, and has the characteristics of being light in weight, high in carrying capacity and good in ductility and shock resistance.

Owner:HARBIN ENG UNIV

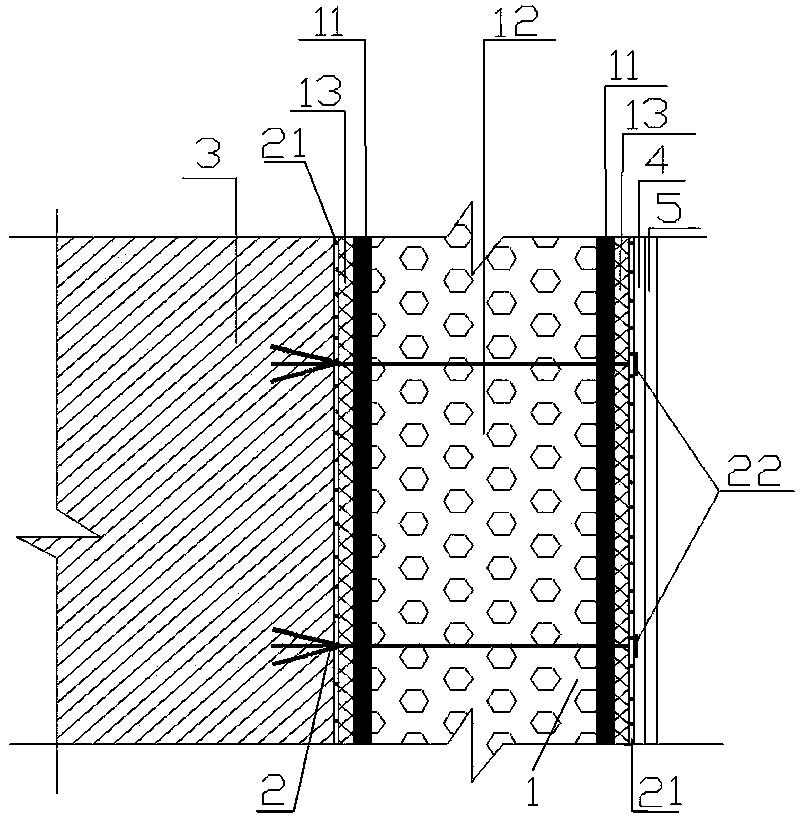

Overlapped shear wall with prefabricated part and cast-in-situ part and manufacturing method thereof

InactiveCN101649656AThe carrying capacity is not lowImprove the level of industrializationWallsCeramic shaping apparatusReinforced concreteSingle level

The invention belongs to the technical field of the civil engineering building structure, in particular to an overlapped shear wall with a prefabricated part and a cast-in-situ part and a manufacturing method thereof. The traditional reinforced concrete shear wall is divided into two parts, wherein one part is prefabricated (a PCF plate) in a factory; the other part is cast in situ in a construction site; and after block cast, the prefabricated part (the PCF plate) and the cast-in-situ part are formed the overlapped shear wall. The plate thickness of the prefabricated PCF plate is commonly controlled at 60-80mm. The plate width of the single PCF plate is not greater than 3.0m, the plate height is not greater than 6.0m, and the plate weight is not greater than 2 tons. A single-layer two-wayreinforced bar net piece is configured in the plate; simultaneously, longitudinal and transverse overlapped reinforced bars are embedded at the inner side according to a distance of 450-600mm in advance, and the exposed parts of the overlapped reinforced bars are anchored into the cast-in-situ part. Compared with a pure external-hanging wall plate of a shear wall structure used at present, the invention lessens the self weight, lowers the construction difficulty, enhances the production efficiency and the construction quality and has energy saving and environmental protection.

Owner:TONGJI UNIV

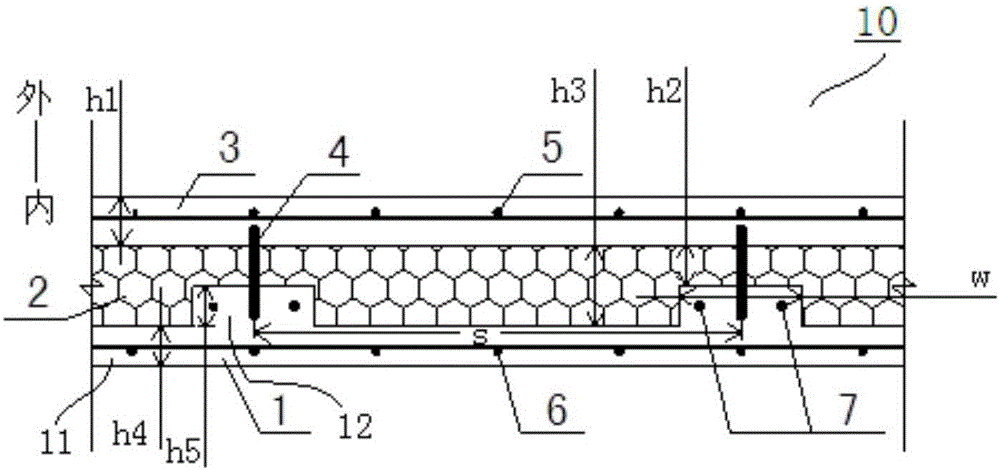

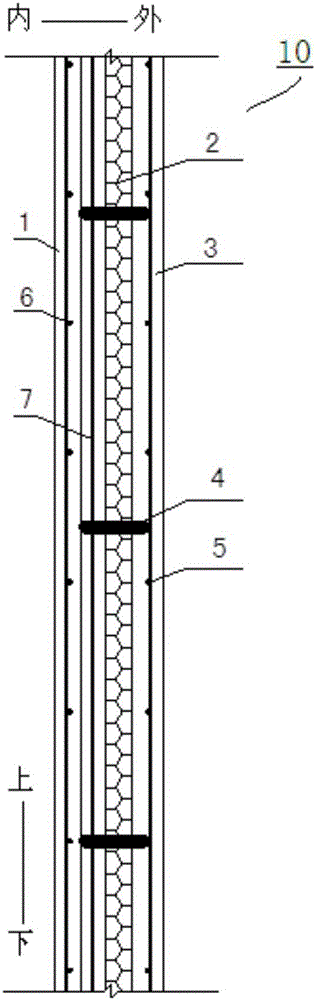

Precast concrete sandwich cladding wall panel provided with ribs

InactiveCN105971189AStable insulation systemImprove insulation effectBuilding componentsThermal insulationUltimate tensile strength

The invention discloses a precast concrete sandwich cladding wall panel provided with ribs. The precast concrete sandwich cladding wall panel sequentially comprises an inner vane board, a thermal insulation layer and an outer vane board from inside to outside, wherein the thermal insulation layer is arranged between the inner vane board and the outer vane board, and the inner vane board, the thermal insulation layer and the outer vane board are integrally connected through pulling parts; the inner vane board comprises a flange plate and the ribs arranged on the flange plate, and the ribs are arranged on one side, facing the outer vane board, of the inner vane board. In the embodiment, the inner vane board is designed to be in a ribbed form, by comparison with common precast concrete sandwich cladding wall panels with inner vane boards being rectangular sections, the rigidity, the strength, the thermal insulation efficiency, the durability performance and the fireproof performance of the wallboard are guaranteed, the thickness of the wall panel is reduced, the effective use space of a building is increased, the use amount of concrete is reduced, the self-weight of the wall panel is reduced, the safety and the seismic performance of connected nodes are improved, and the precast concrete sandwich cladding wall panel is applicable to thermal insulation engineering of external walls of the building.

Owner:ANHUI BAOYE CONSTR ENG GRP CO LTD

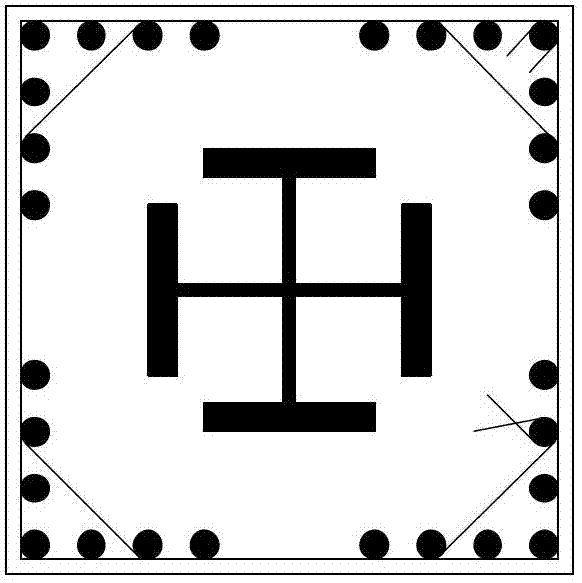

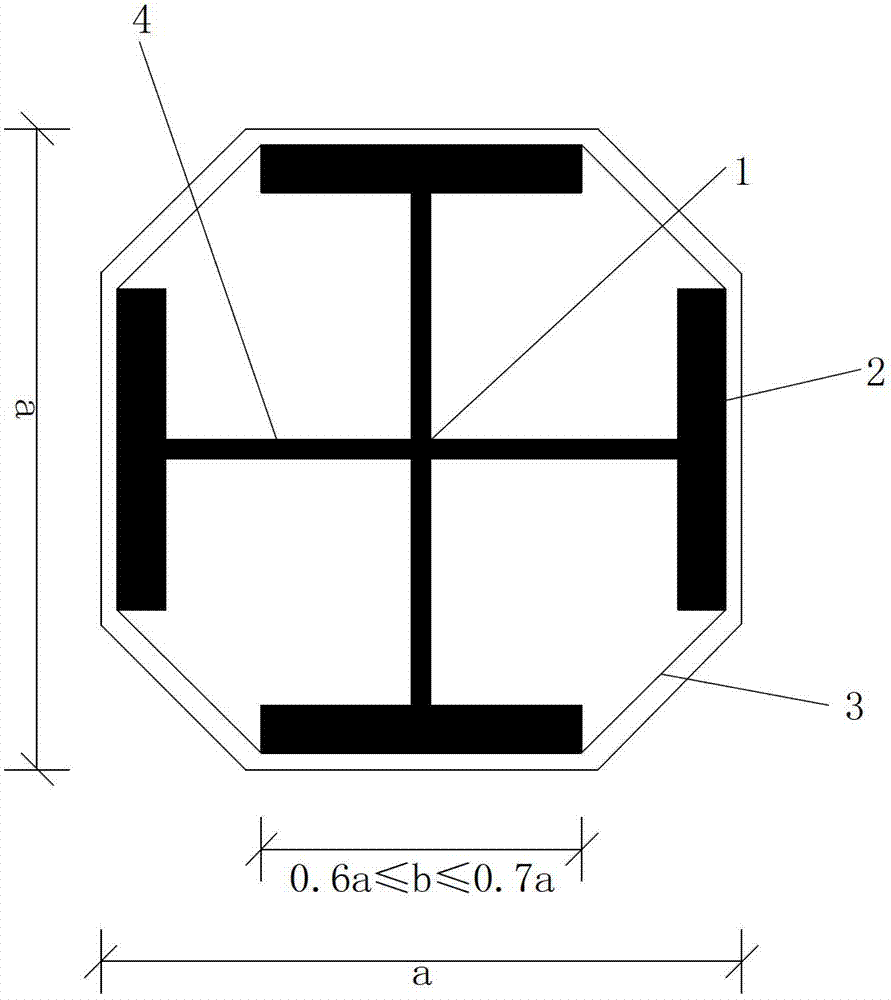

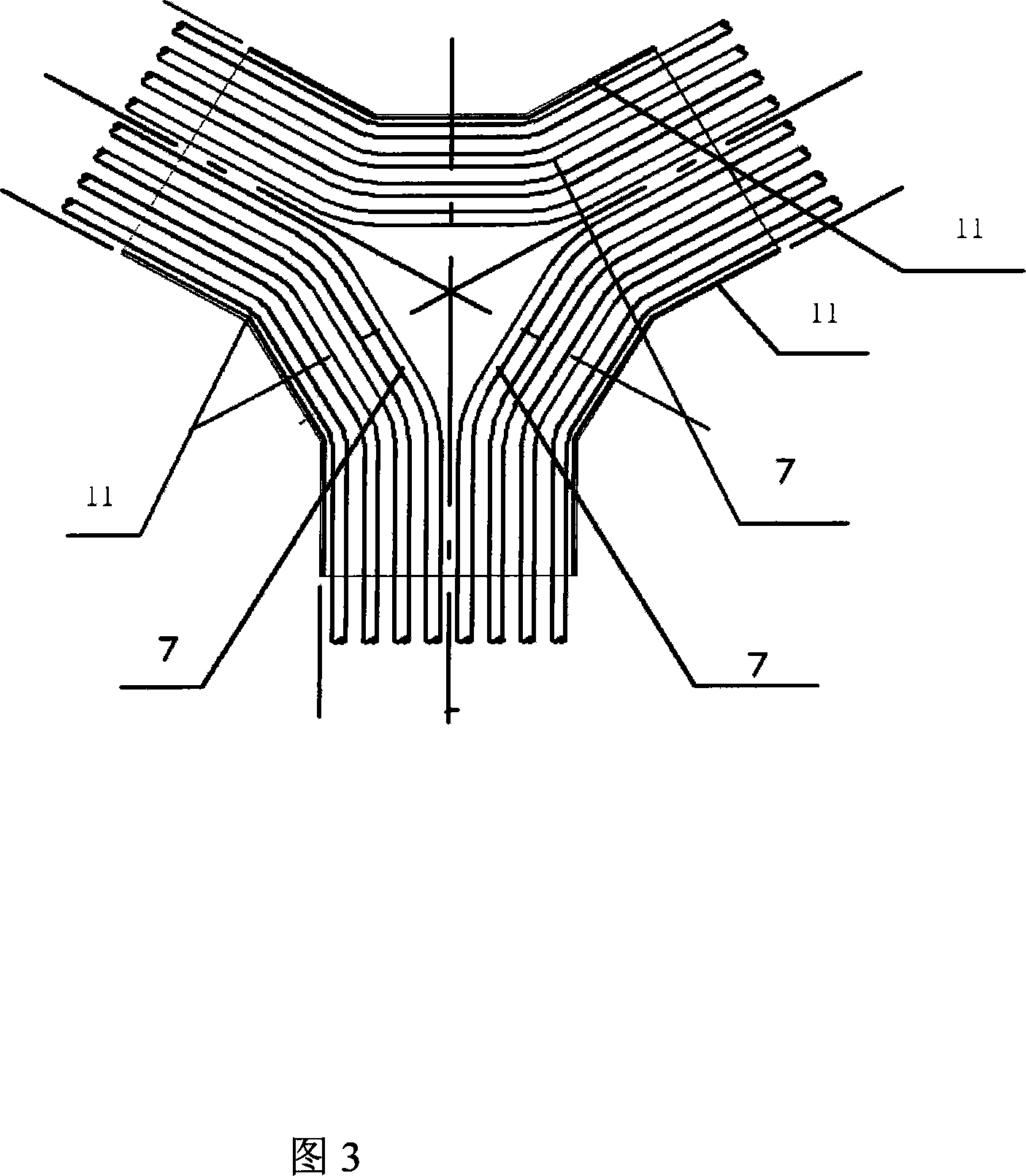

High-strength spiral hoop confined high-strength wide flange cross-shaped steel reinforced octagonal concrete column

InactiveCN102758501AEasy constructionMechanics concept is clearStrutsPillarsReinforced concrete columnSteel bar

The invention relates to steel reinforced concrete columns, particularly to a high-strength spiral hoop confined high-strength wide flange cross-shaped steel reinforced octagonal concrete column, which overcomes the defects of the cross-shaped steel reinforced concrete column that the construction is difficult, the thickness of the concrete protective layer causes the insufficient realization of the bending resistance of the steel reinforced, and the high-strength steel reinforced has high possibility of lateral deflection. As the longitudinal reinforcing steel is removed, the area of the reinforcing steel is converted to the steel reinforced flange, the construction and design of the steel reinforced concrete column are facilitated; the spiral hoop is the high-strength octagonal spiral hoop, the inner side of the spiral hoop of the confined steel reinforced flange is closely attached to the surface of the steel reinforced flange, the unstability critical stress of the steel reinforced flange is improved through the free edge of the confined steel reinforced flange, and the spiral hoop is closely joined with the flange at the same time, so as to realize the action of stud, as a result, the coordination between the concrete and the steel reinforced is better realized; the concrete protective layer of the steel reinforced ranges from 30 to 40mm., so as to meet the requirement of fire prevention and enables the steel reinforced to better realize the action of bending resistance; and as the area cut from the octagonal concrete column is less than 8%, the area can be compensated by improving the concrete strength. The high-strength spiral hoop confined high-strength wide flange cross-shaped steel reinforced octagonal concrete column is applied to the steel reinforced concrete structures.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

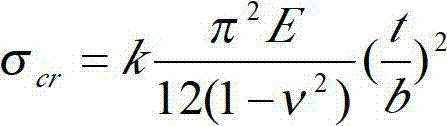

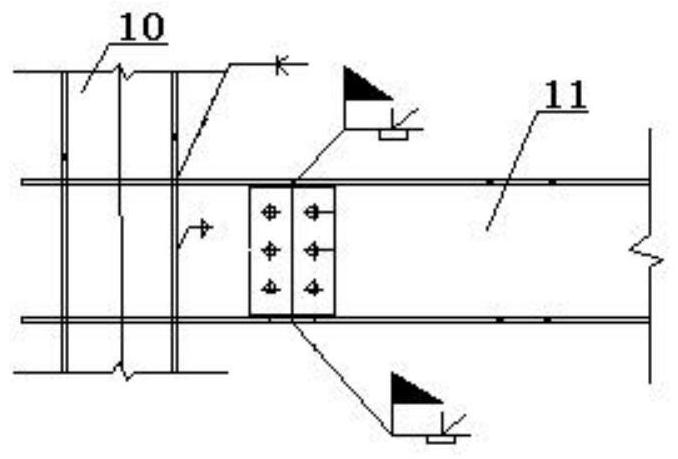

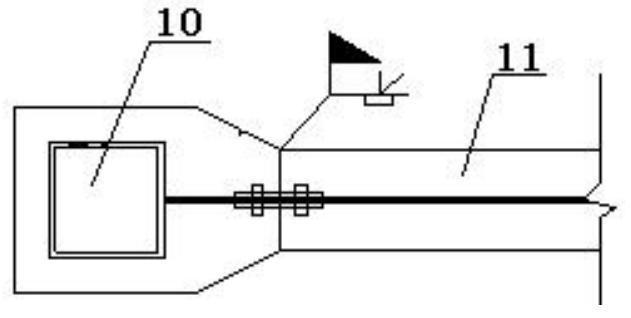

Bolt connection node for bamboo/wood frame structure in which beam and column are clamped outside steel plate

InactiveCN103498513AStrong friction and shear resistanceReduce slipShock proofingSteel platesShear resistance

The invention discloses a bolt connection node for a bamboo / wood frame structure in which a beam and a column are clamped outside a steel plate, and belongs to the field of civil engineering. The bolt connection node for the bamboo / wood frame structure in which the beam and the column are clamped outside the steel plate comprises the beam, the column, the connecting steel plate and bolts. The connecting mode that the beam and the column cover the connecting steel plate is adopted, second bolt holes are formed in the connecting steel plate, first bolt holes are formed in both the beam and the column, and the centers of the first bolt holes are aligned with the centers of the second bolt holes in the corresponding positions of the connecting steel plates. The bolts sequentially penetrate through the second bolt holes of the connecting steel plates, the first bolt holes of the beam or the column and the second bolt holes of the connecting steel plate and then are anchored with nuts into a whole. Friction force shearing resistance is generated by applying precompression to the connecting steel plate by the bolts. The bolt connection node has the advantages of being clear in force transmission, high in shearing resistance, convenient to construct and easy to machine.

Owner:CHANGZHOU INST OF TECH

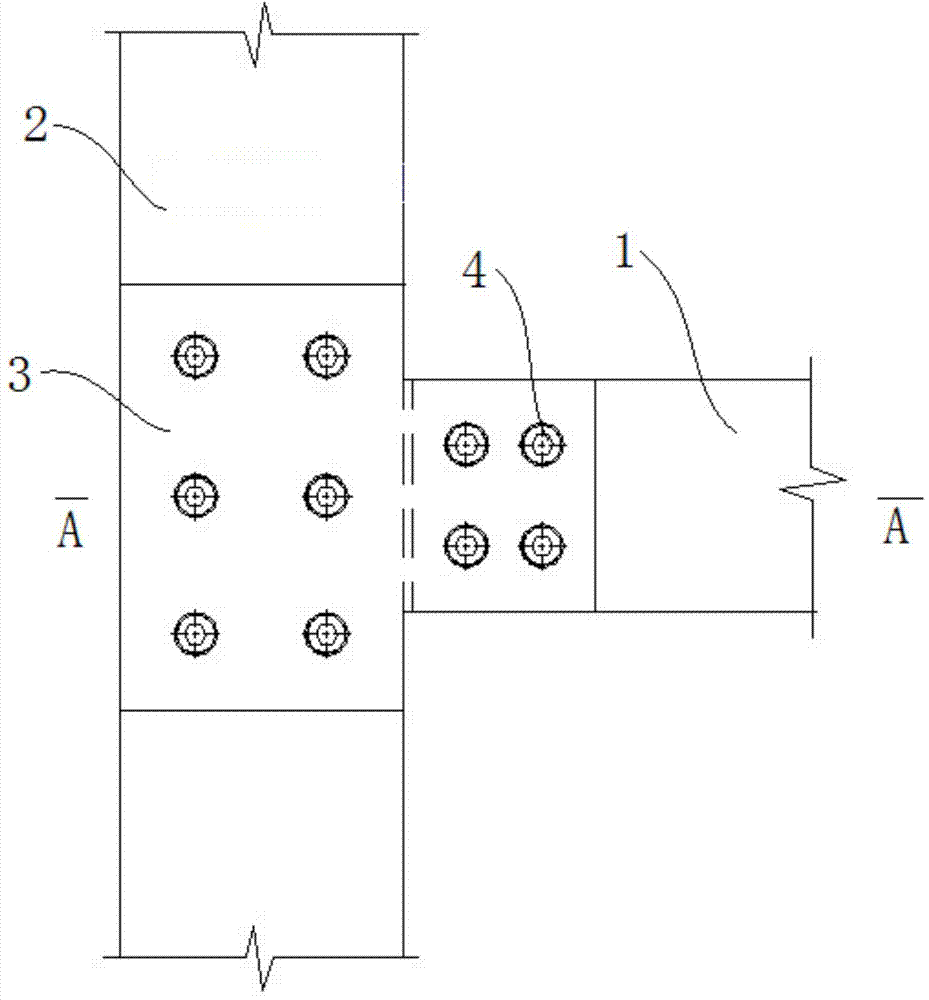

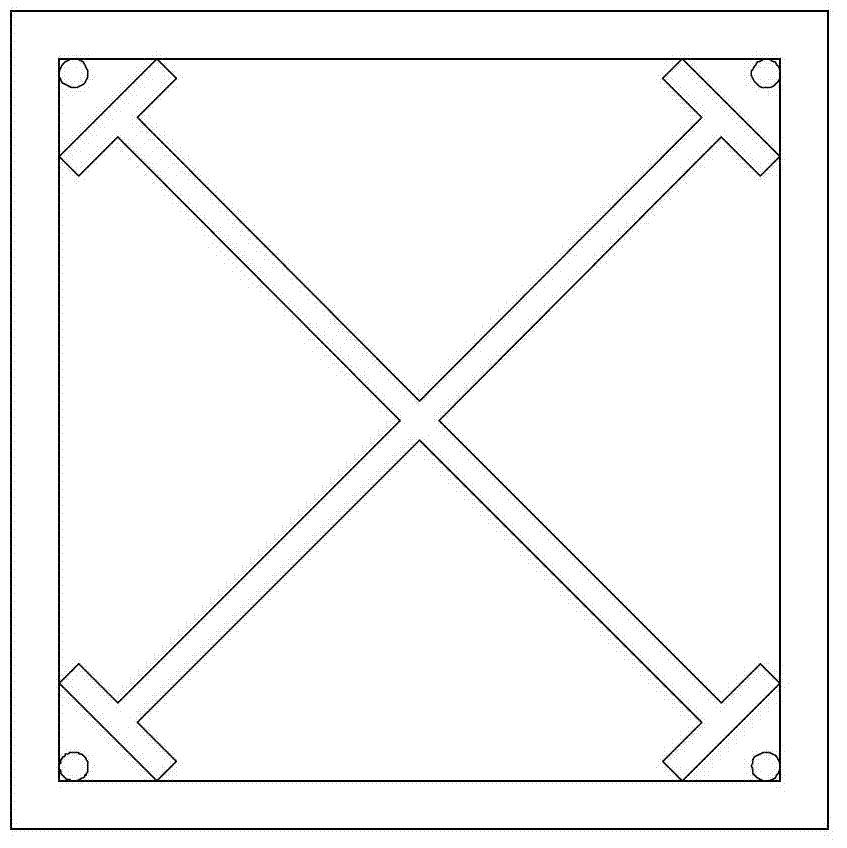

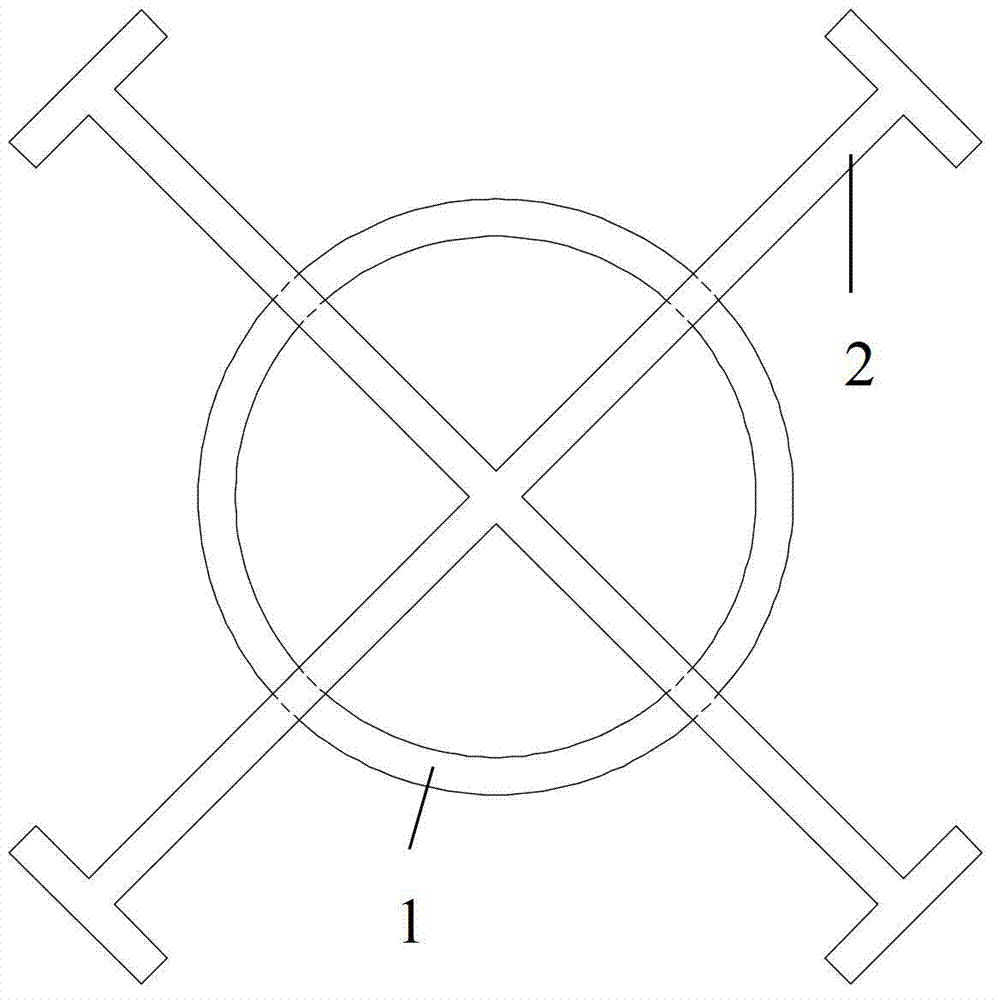

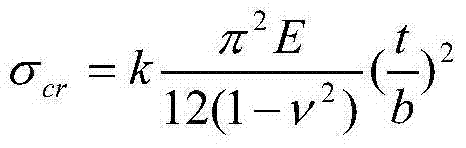

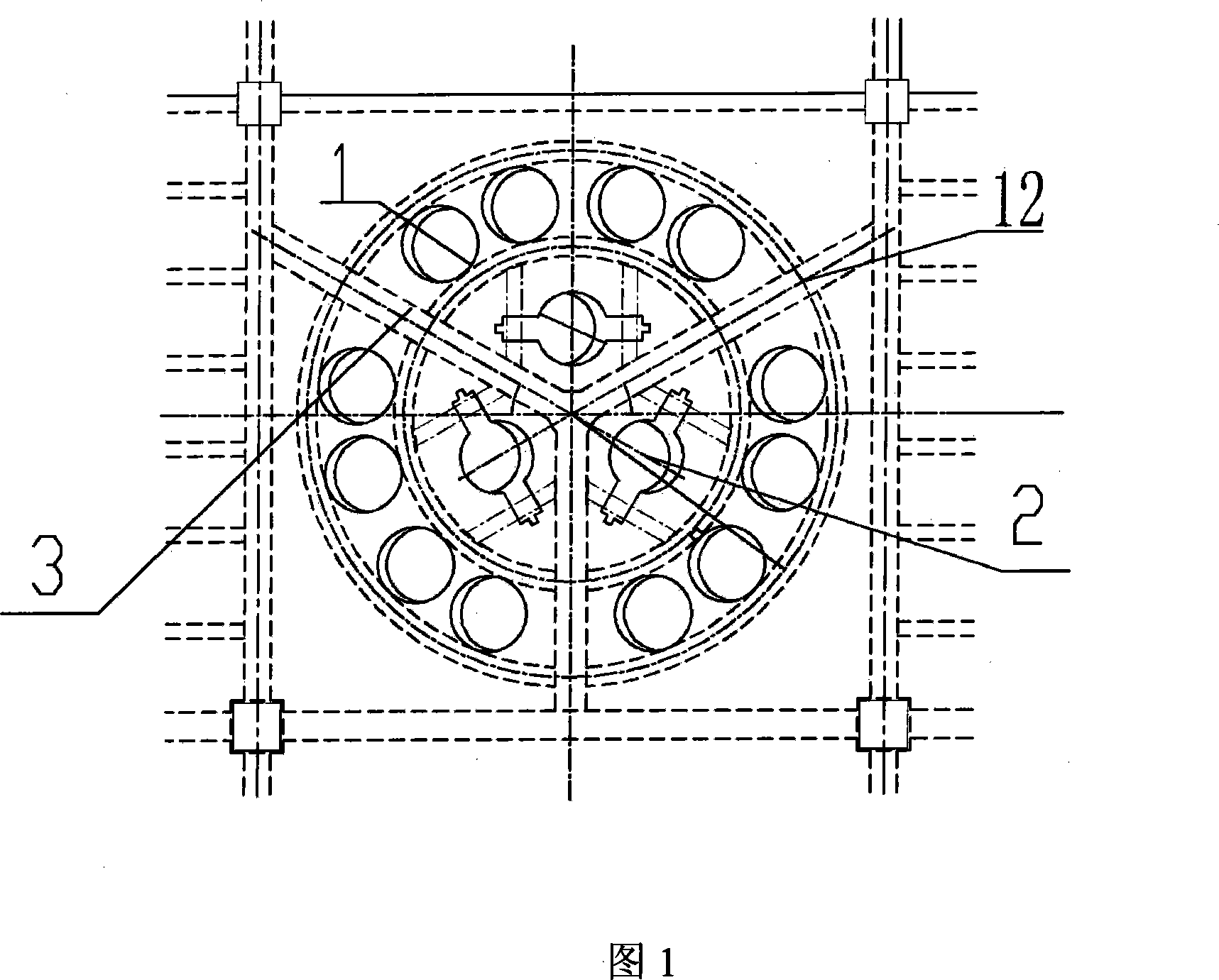

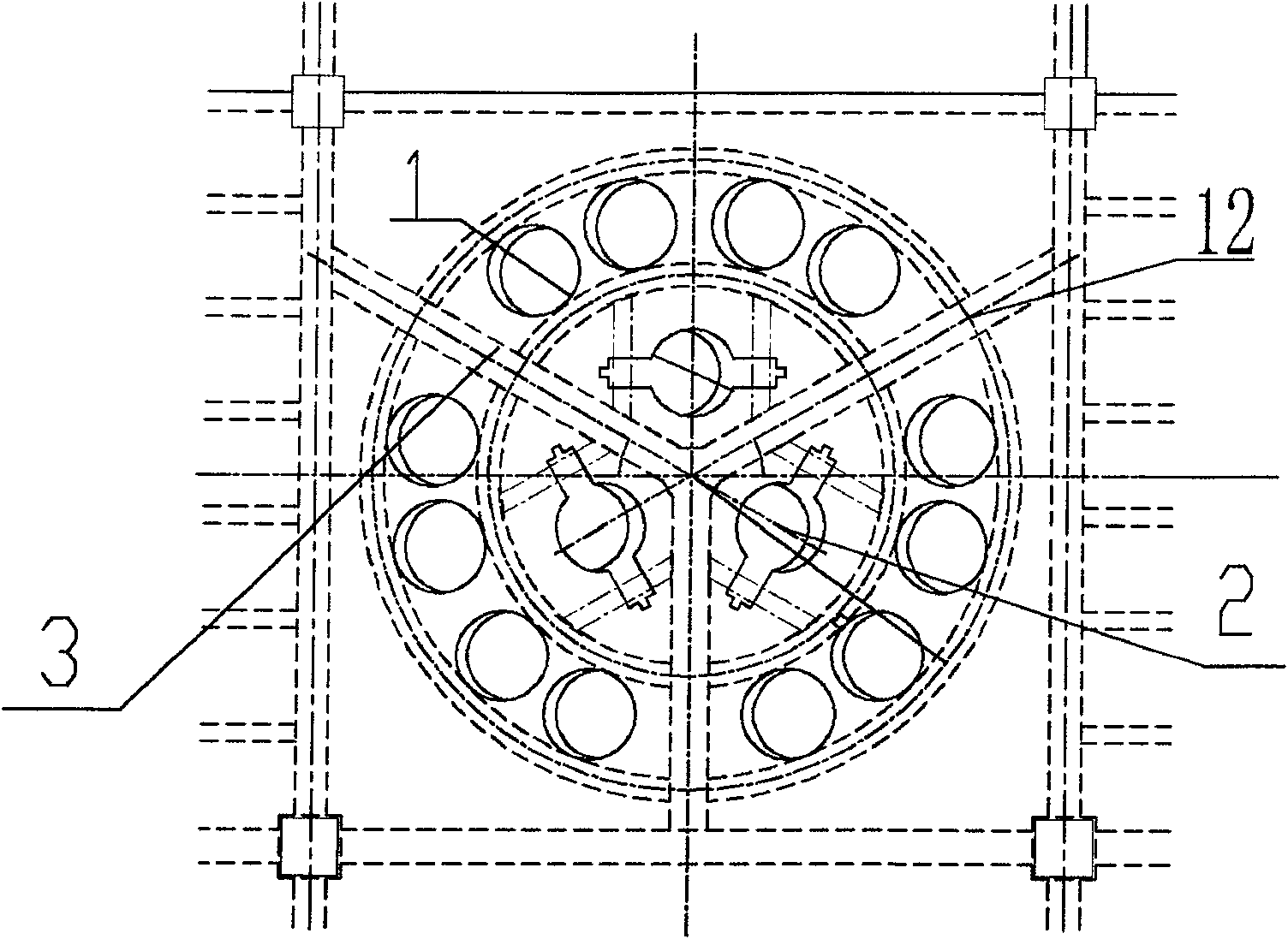

Node for combination beam and 45-degree arranged cross steel reinforced concrete column

InactiveCN102828559ASolve rigid connection problemsBeautiful structureBuilding constructionsReinforced concrete columnEngineering

A node for a combination beam and a 45-degree arranged cross steel reinforced concrete column relates to a steel reinforced concrete structure, and is used for overcoming the defects of the prior art and solving the problem of the rigid connection of the combination beam and the 45-degree arranged cross steel reinforced concrete column with a flange in a project. A circular steel tube is arranged within the height scope of a steel column internal node, so the connection problem of the rigid connection of the combination beam and the 45-degree arranged cross steel reinforced concrete column with the flange is solved. The external diameter of the circular steel tube is 40%-60% of the side length of a square column, the wall thickness of the circular steel tube is larger than or equal to the thickness of the flange edge of a steel beam in the combination beam, moreover, the wall thickness of the steel beam is not less than a half of the diameter of the maximum longitudinal bar of the combination beam, and the height of the circular steel tube needs to be respectively higher than the external longitudinal bars of the combination beam and the lower flange edge of the steel beam by 100 millimeters. The circular steel tube and a steel web in the column are welded through fillet welding, the steel beam in the combination beam is welded on the circular steel tube, the longitudinal bars of the combination beam are in plug welding on the circular steel tube, and the hopping of the node is welded on a steel beam web. The node disclosed by the invention is used for the steel reinforced concrete structure.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

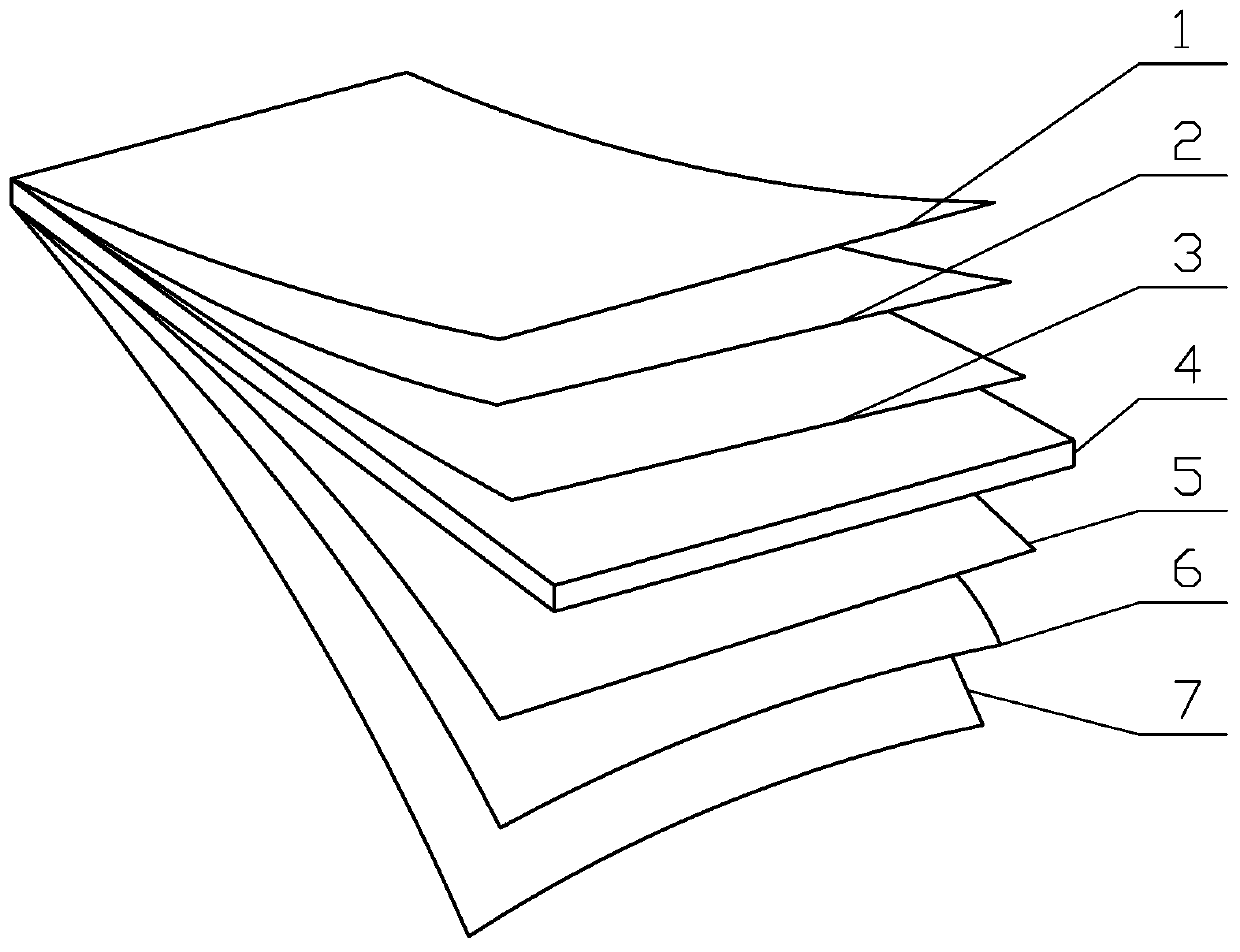

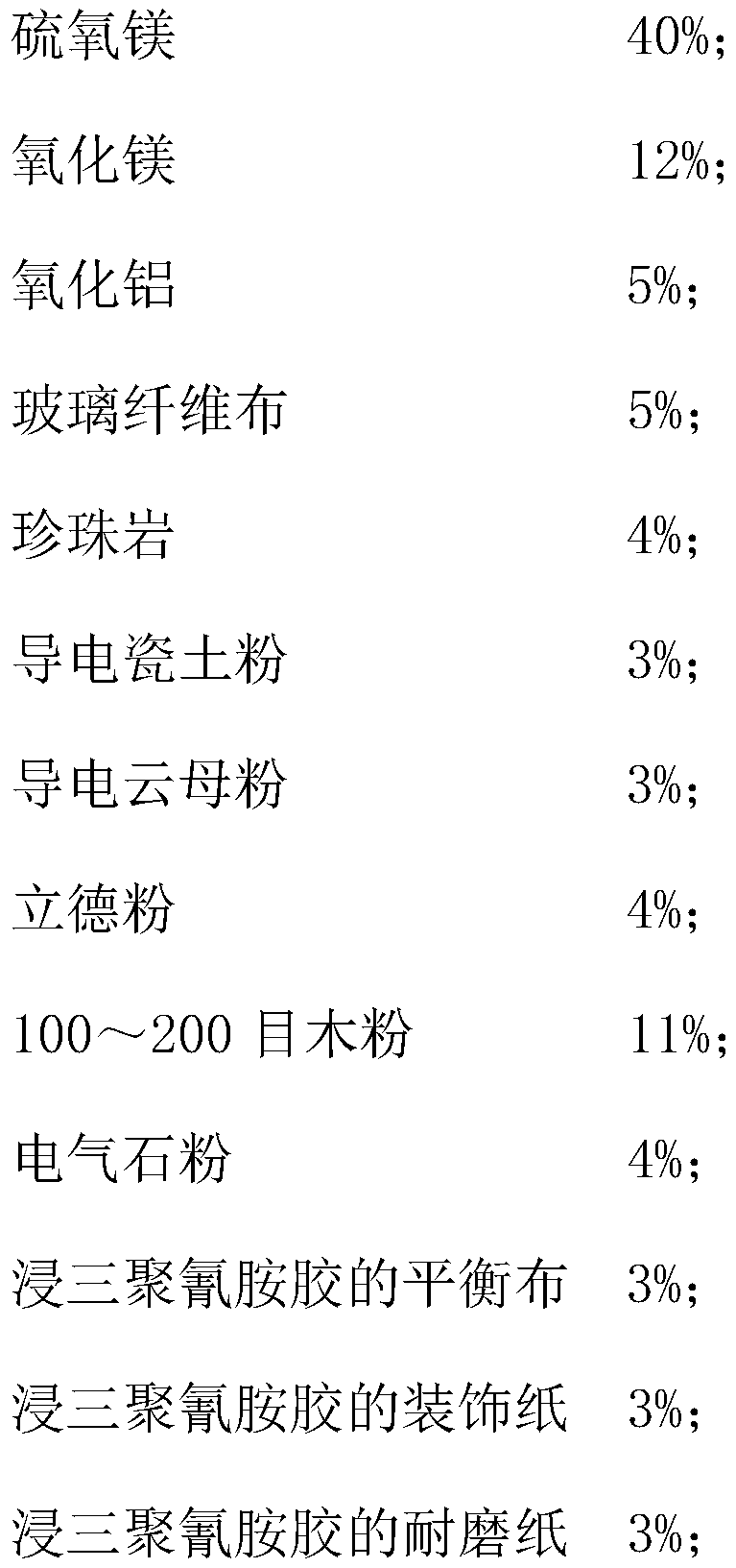

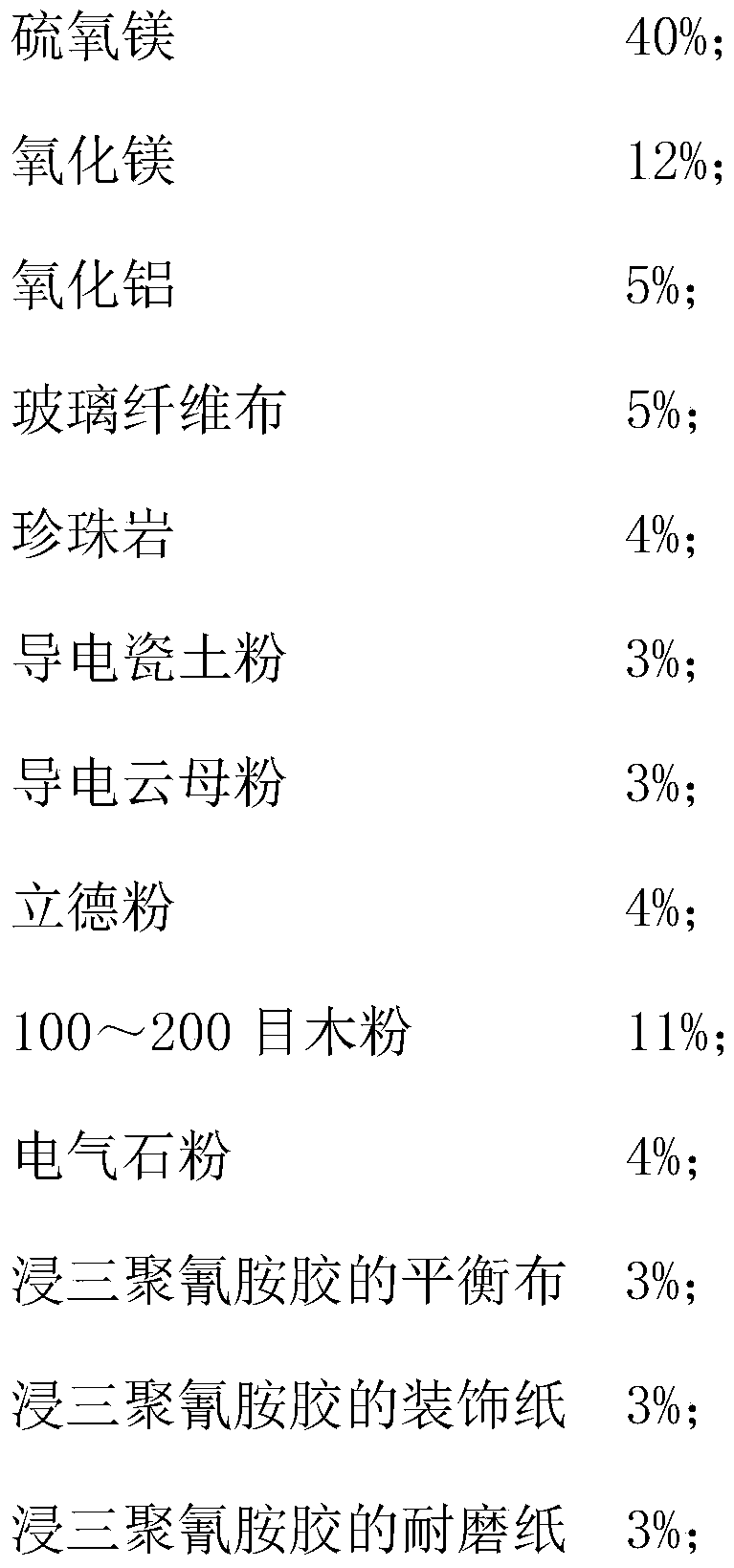

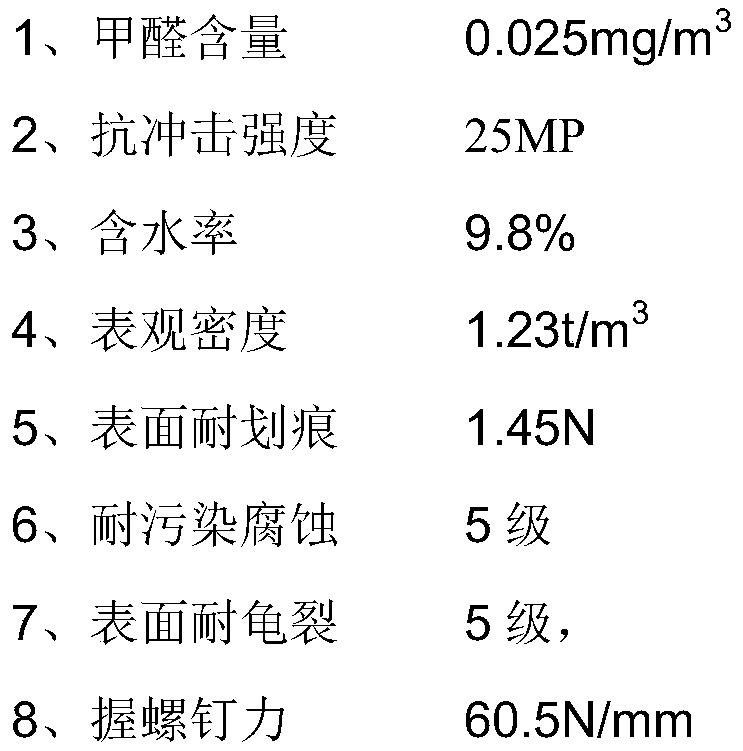

Magnesium oxysulfate melamine paper decoration surface inorganic rock porcelain non-combustible board and production method thereof

PendingCN110091570AImprove insulation performanceStrong weather resistanceCovering/liningsLaminationThermal insulationWear resistant

The invention particularly relates to a magnesium oxysulfate melamine paper decoration surface inorganic rock porcelain non-combustible board and a production method thereof, wherein the raw materialscomprise: 40% of magnesium oxysulfate, 12% of magnesium oxide, 5% of alumina, 5% of a glass fiber cloth, 4% of perlite, 3% of electric-conduction procelain clay powder, 3% of electric-conduction micapowder, 4% of lithopone, 11% of 100-200 mesh wood powder, 4% of tourmaline powder, 3% of a balance cloth immersed with a melamine glue, 3% of decoration paper immersed with a melamine glue, and 3% ofwear-resistant paper immersed with a melamine glue. The production method comprises: 1) preparing a magnesium oxysulfate substrate having a fine pore structure; 2) respectively spreading both surfaces of the magnesium oxysulfate substrate with a balance cloth immersed with a melamine glue, decoration paper immersed with a melamine glue, and wear-resistant paper immersed with a melamine glue; and3) carrying out hot pressing molding. According to the present invention, the magnesium oxysulfate melamine paper decoration surface inorganic rock porcelain non-combustible board has advantages of light weight, smooth surface, high hardness, good fireproof performance, good moisture proof performance, good temperature-difference resistance, strong water resistance, no moisture absorption halogenaccumulation, good thermal insulation effect and wide application range, and does not contain asbestos, formaldehyde and harmful radioactive elements.

Owner:山东凯勒蓝房家居文化发展有限公司

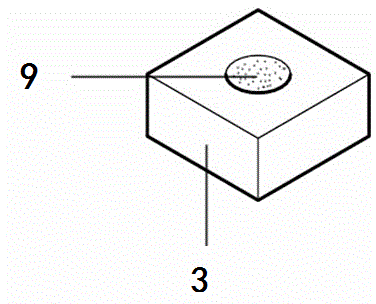

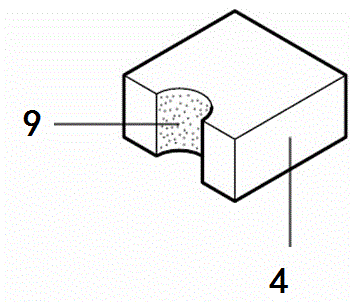

Construction method of adobe wall suitable for seismic fortification high-seismic-intensity area and adobes

ActiveCN104631658AImprove ductilityImprove vertical load carrying capacityWallsShock proofingReinforced concreteRebar

The invention relates to a construction method of an adobe wall suitable for a seismic fortification high-seismic-intensity area and adobes, and belongs to the technical field of constriction engineering. Multiple types of adobes are manufactured, and specific portions of the adobes are painted with water insulation and viscous energy consumption layers. The adobes are laid flatly in a joint staggering mode, two horizontal grooves and a plurality of vertical round holes penetrating through the full height of an adobe wall body are formed within an adobe wall layer high range, and vertical steel bars are embedded in strip foundations at the centers of the round holes. Longitudinal steel bars in the horizontal grooves hook the vertical steel bars in the vertical round holes in the ends of the adobe wall. Adobe wall sedimentation buffer areas are arranged at the intersections of the horizontal grooves and the vertical round holes of the adobe wall. Concrete is poured into the vertical round holes to form embedded columns, and concrete is poured into the positions, outside the sedimentation buffer areas, of the grooves to form embedded ring beams. After adobe wall body sedimentation is stable, the sedimentation buffer areas are filled with concrete, and the embedded ring beams and the embedded columns constitute ferroconcrete reinforcement grids in the adobe wall. The adobes play a role in reinforcing the whole adobe wall and remarkably enhancing seismic capacity.

Owner:KUNMING UNIV OF SCI & TECH

H-shaped steel concrete column with high-strength spiral hoop and restraining high-strength wide flange

The invention provides an H-shaped steel concrete column with a high-strength spiral hoop and a restraining high-strength wide flange and relates to a sectional steel concrete column. The defects of the present I-shaped and H-shaped steel concrete columns that the construction is difficult, the anti-bending function of the sectional steel is not completely utilized because a concrete protecting layer is thick, and the high-strength sectional steel is easy to press and deflect are overcome. A longitudinal reinforcement is abolished, a steel area is converted into the sectional steel flange and the construction and the design of the sectional steel concrete column are convenient to perform. The spiral hoop is a high-strength rectangular spiral hoop; the inner side of the spiral hoop of the restraining sectional steel flange is clung to the surface of the sectional steel flange; and an unstable critical stress of the sectional steel flange is increased by a free edge of the restraining sectional steel flange; the spiral hoop is tightly combined with the flange, so that a function of a bolt is achieved and the concrete can more effectively coordinate with the sectional steel; the concrete protecting layer of the sectional steel is 30-40mm thick, thereby being fireproof requirement and fully utilizing the anti-bending function of the sectional steel; a screw pitch of the rectangular spiral hoop is 0-60mm, so that the restraining condition of the free edge of the restraining sectional steel flange is obviously improved; and the H-shaped steel concrete column provided by the invention is applied to a sectional steel concrete structure.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

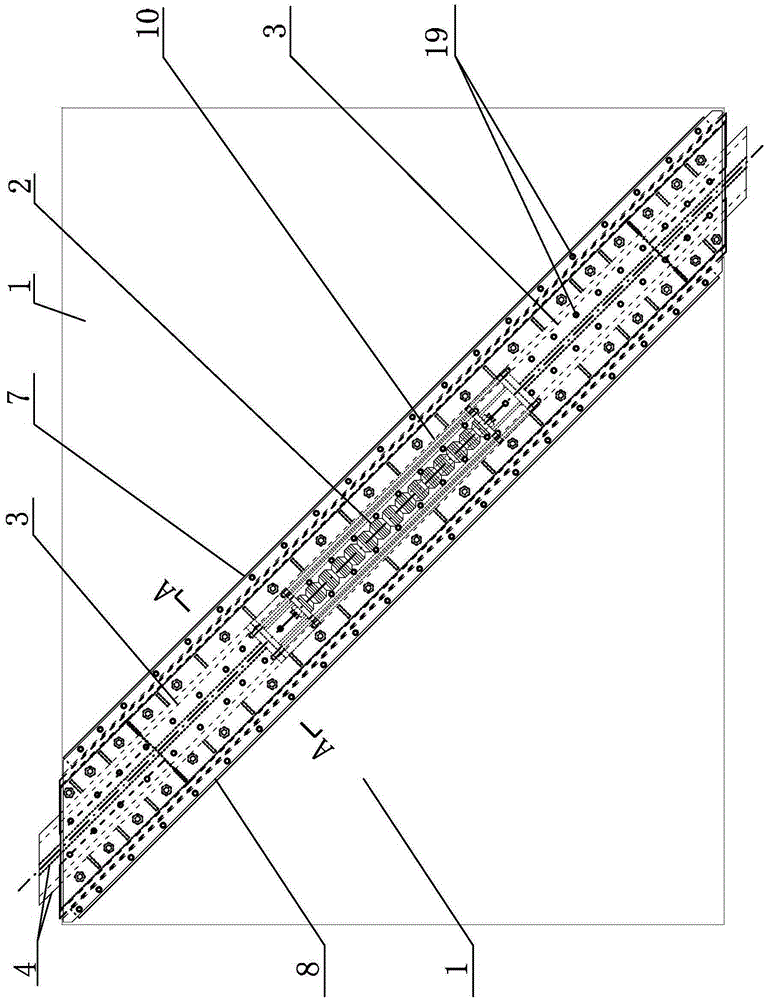

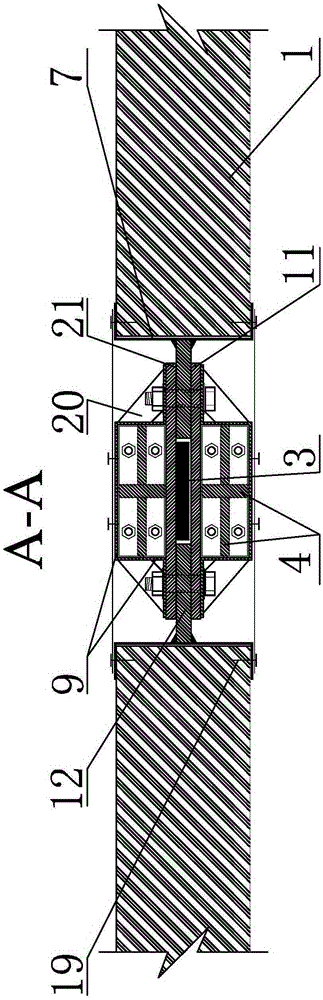

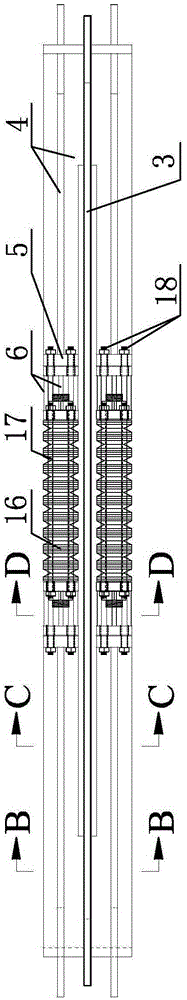

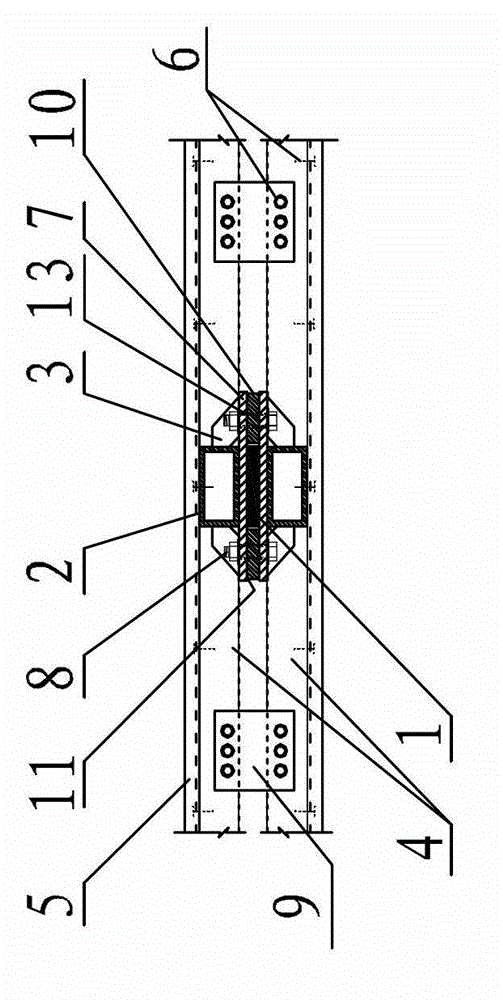

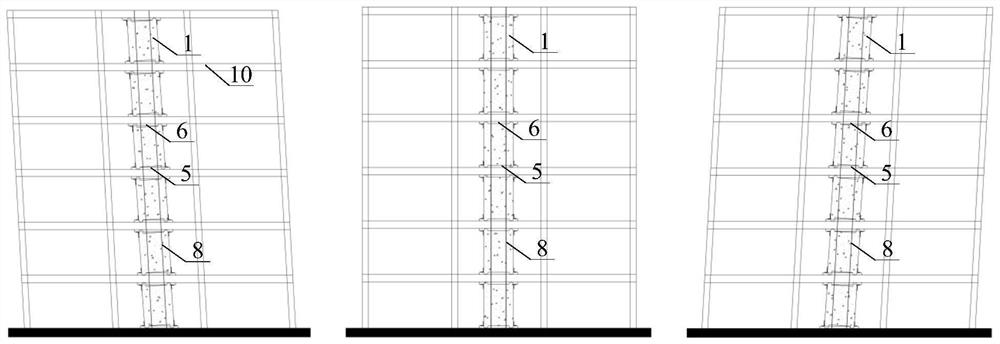

Built-in self-resetting steel plate support of assembling wall plate

The invention provides a built-in self-resetting steel plate support of an assembling wall plate, and relates to a built-in self-resetting support of a wall plate. Problems that residual plastic deformation after supporting axial large yield in a built-in support of a wall plate and a rod-shaped buckling-restrained support in the prior art has adverse effects on using functions of a structure, dead weight of the wall plate is large, a steel plate support is not easy to check and change, ductility and energy-dissipating capacity of the steel plate support are degraded by an existing built-in unbounded support in a concrete wall plate due to punching shear failure, an extra infilled wall is required when the rod-shaped buckling-restrained support is used, and axial deformation capability of the existing rod-shaped self-resetting support is limited by elastic deformation capability of a resetting component are solved. The built-in self-resetting steel plate support of the assembling wall plate comprises a wall and a self-resetting supporting mechanism which comprises a supporting steel plate, a pressed spring assembly, a push-and-pull block, channel steel, a cover plate, cap-shaped steel, a fixing steel plate, a fixing tensioning plate, a push-and-pull rod and end plates. The built-in self-resetting steel plate support of the assembling wall plate is used for the field of machining of built-in self-resetting supports of assembling wall plates.

Owner:HARBIN INST OF TECH

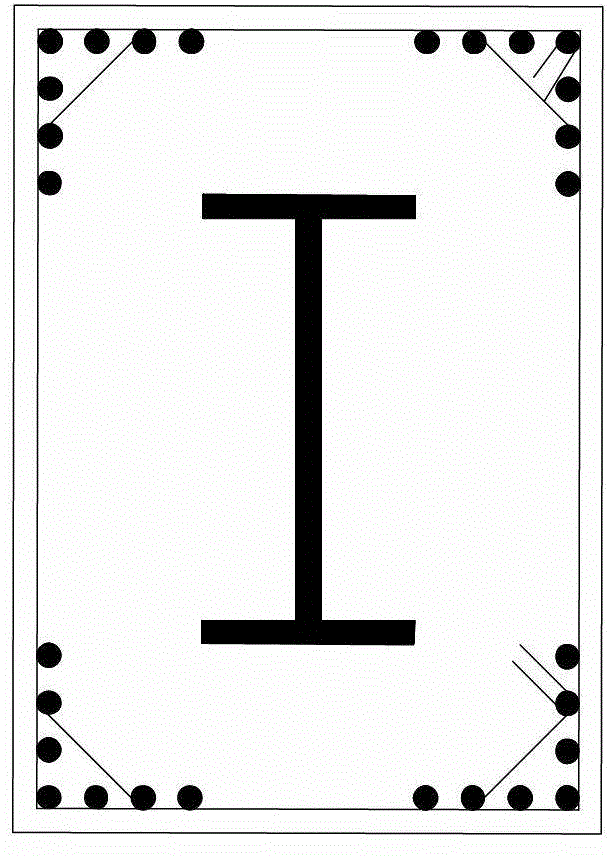

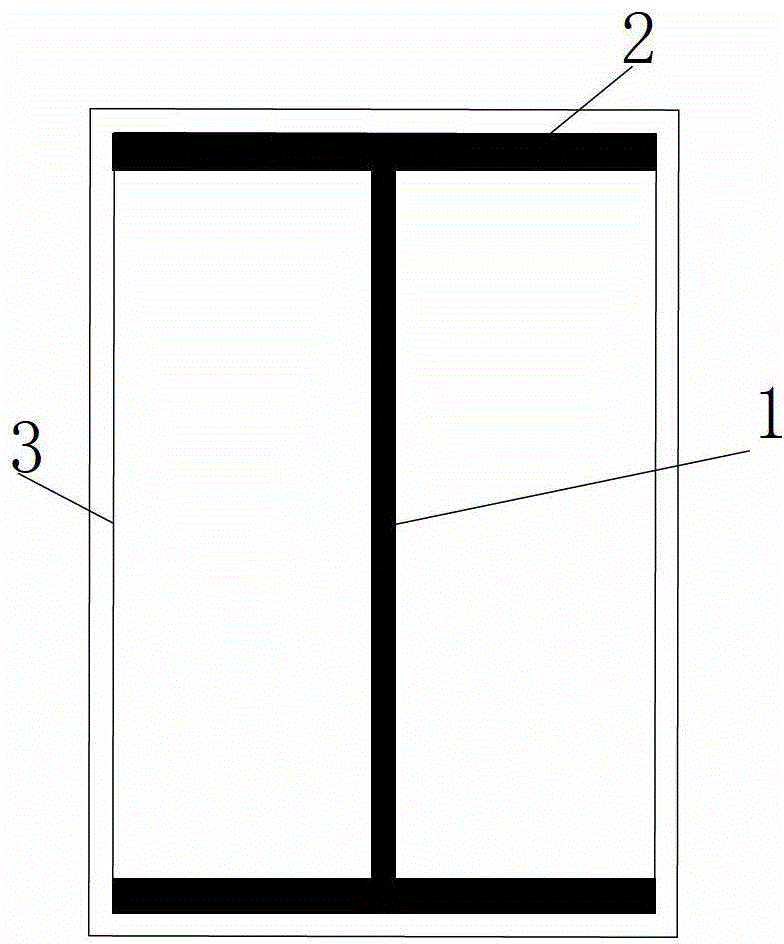

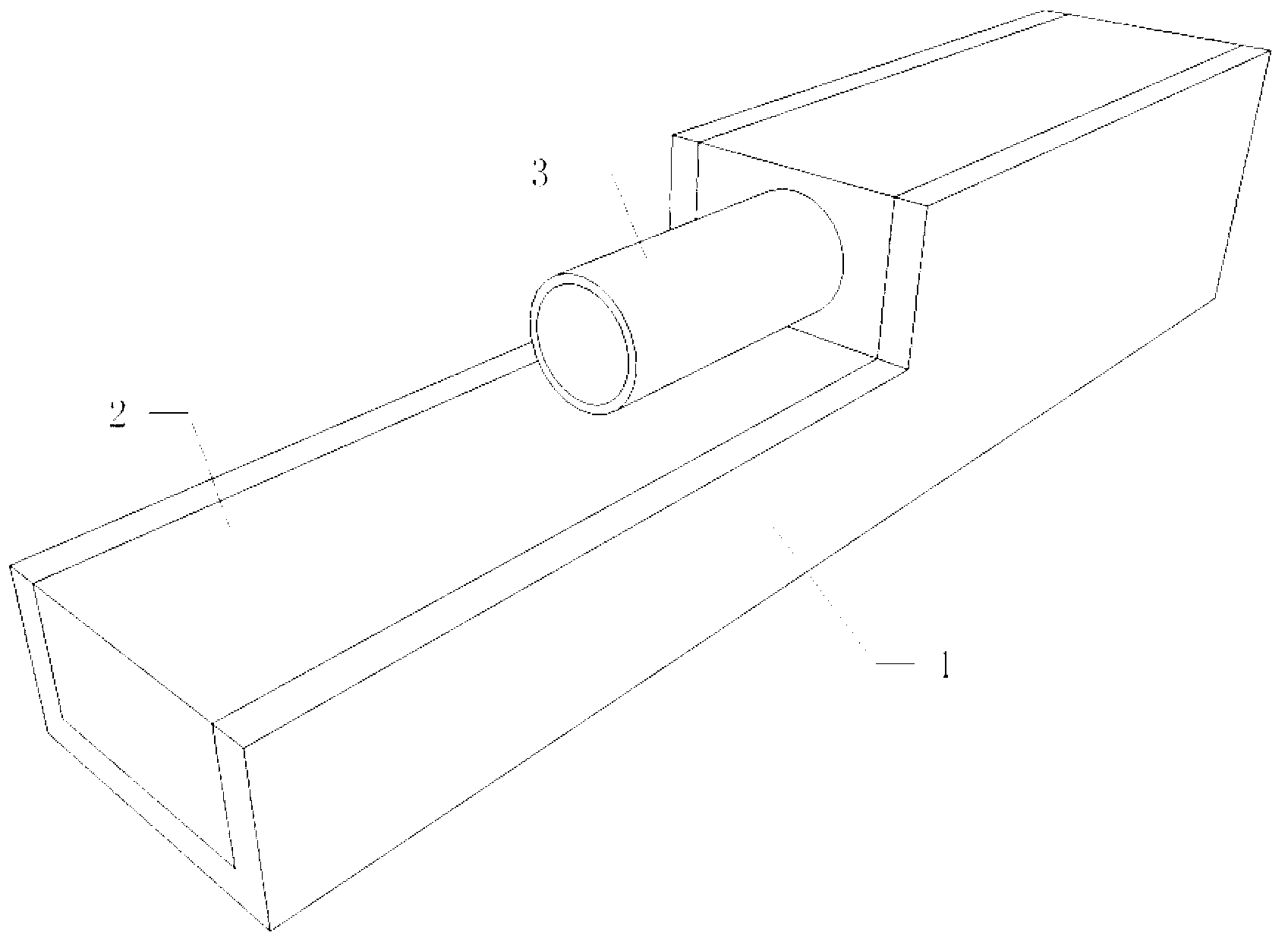

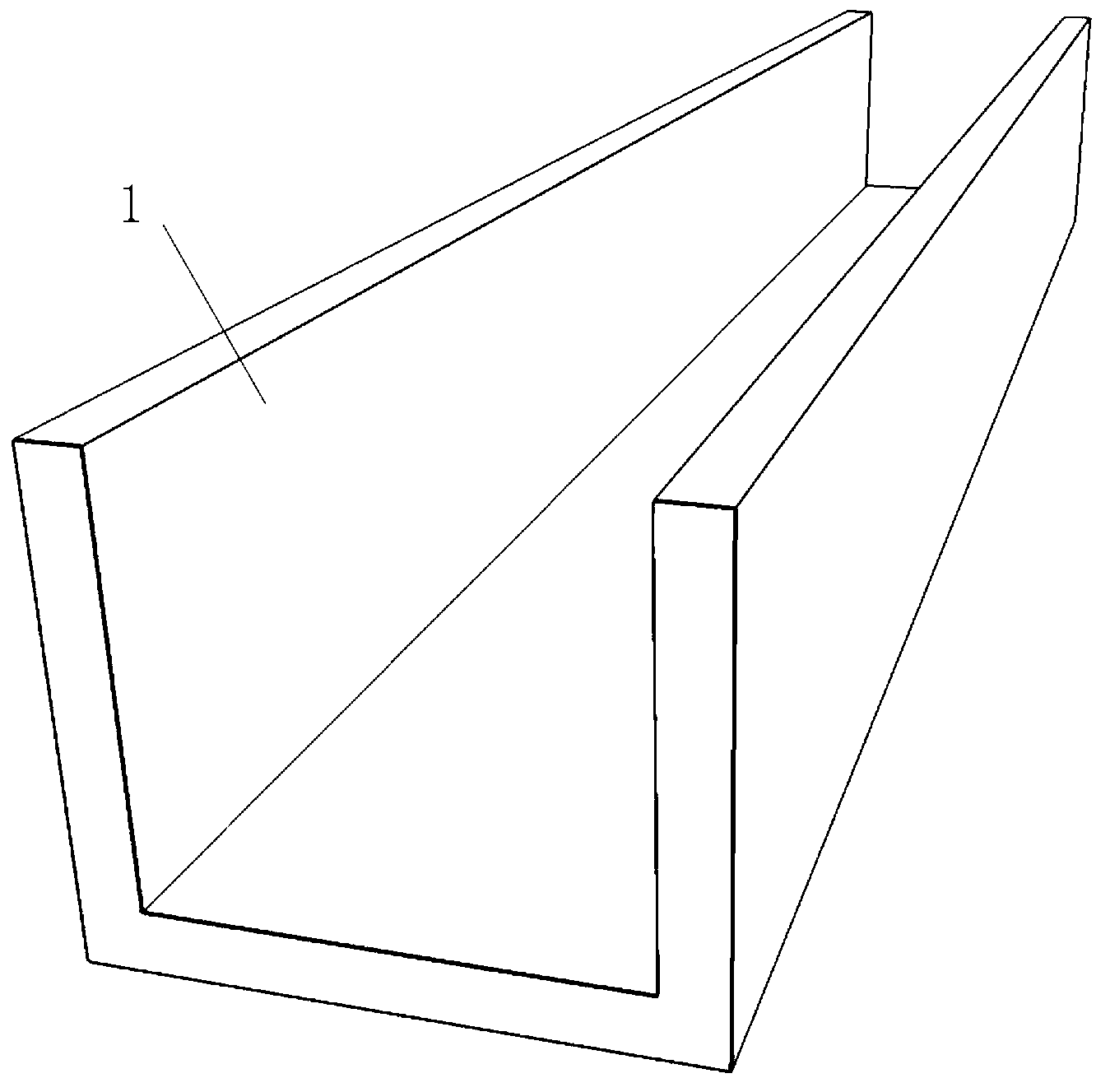

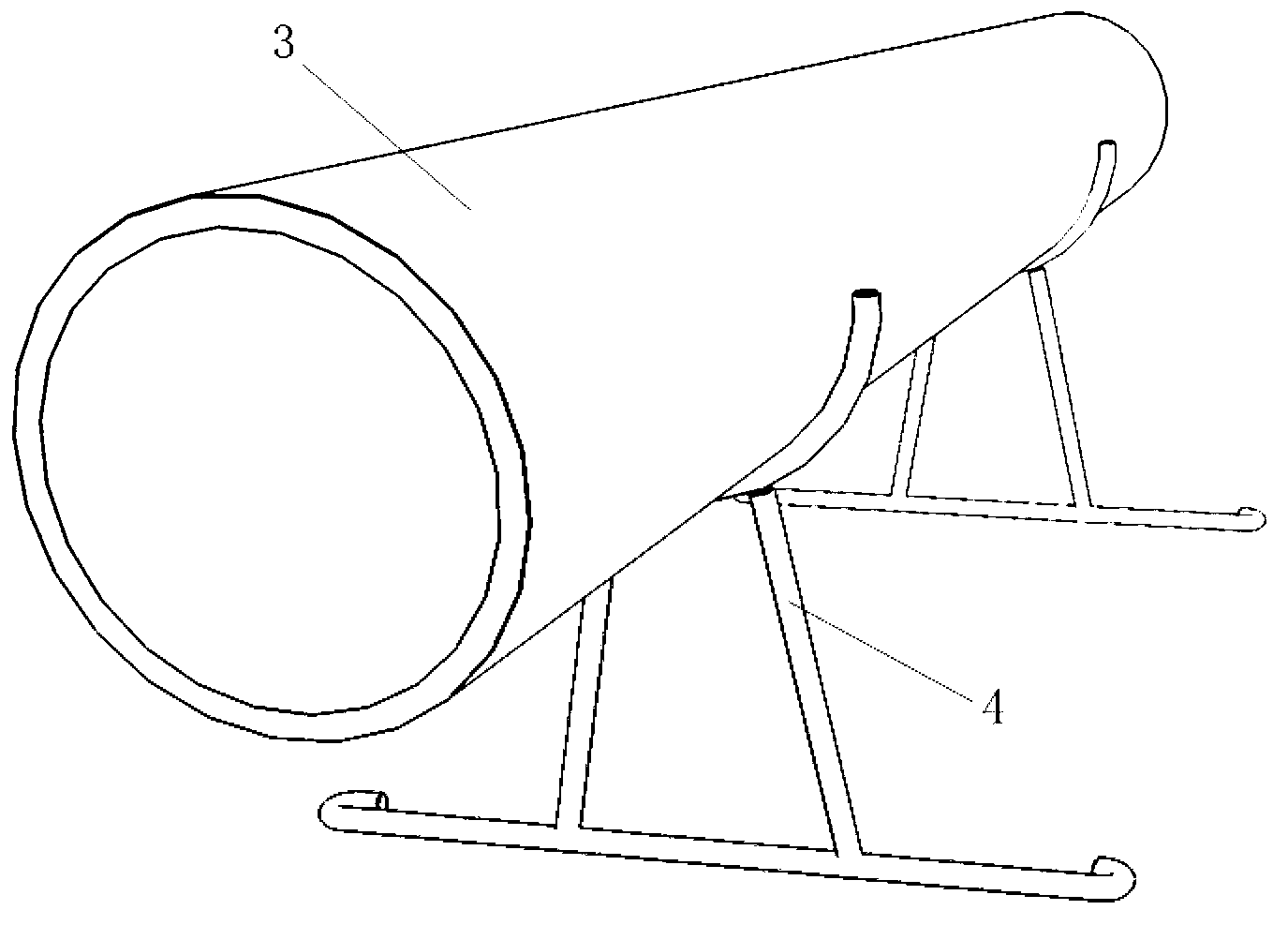

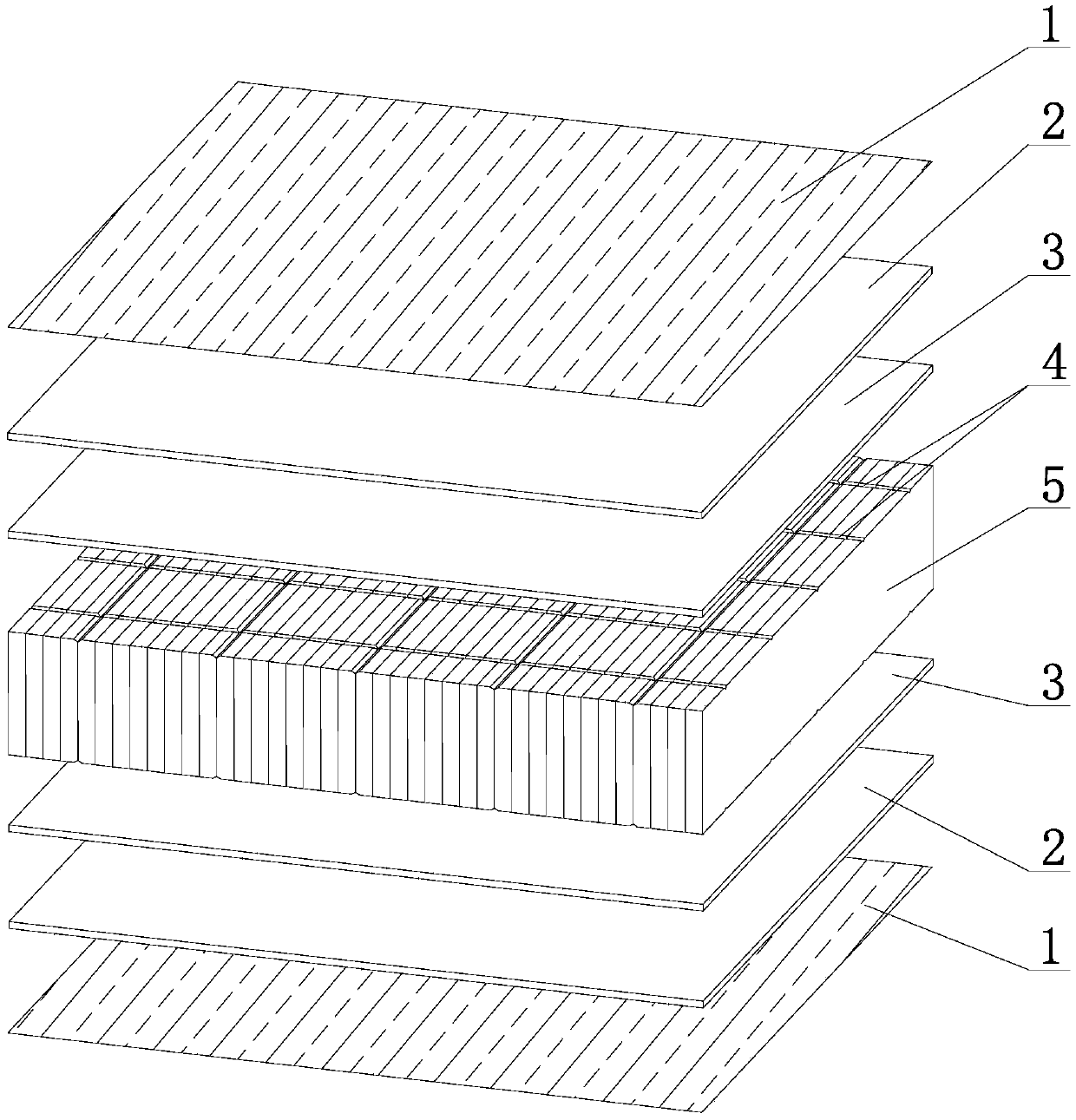

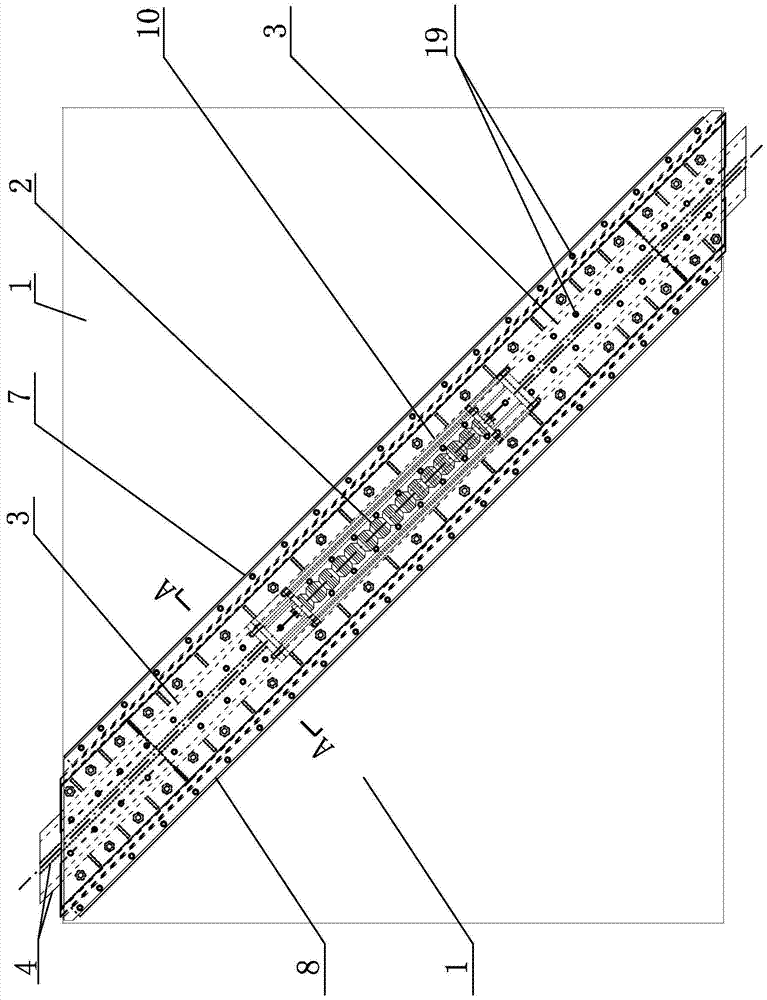

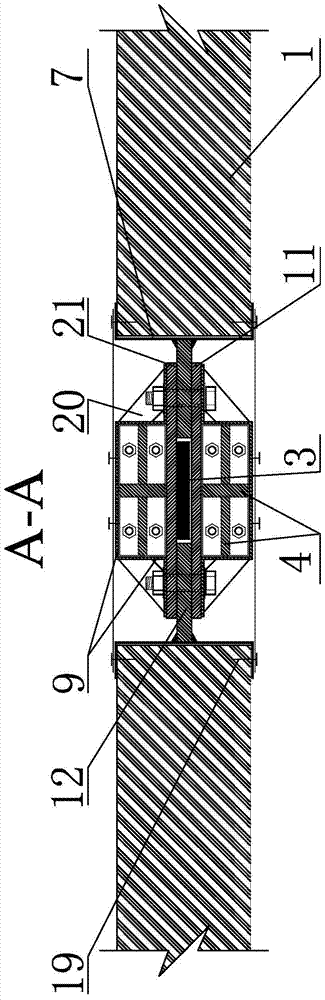

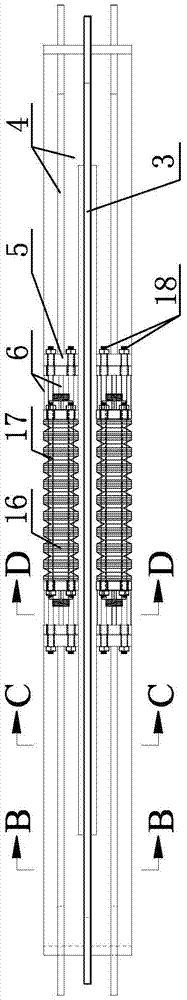

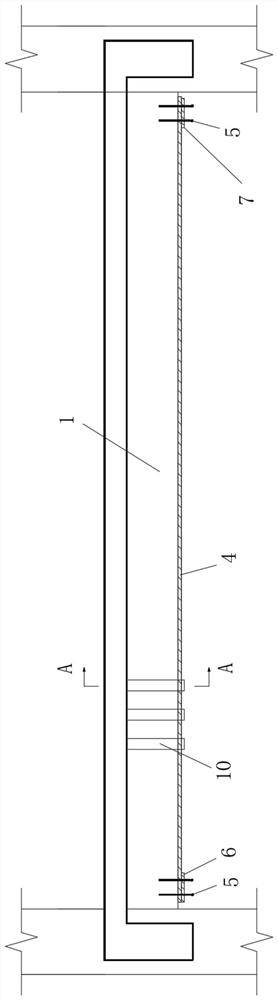

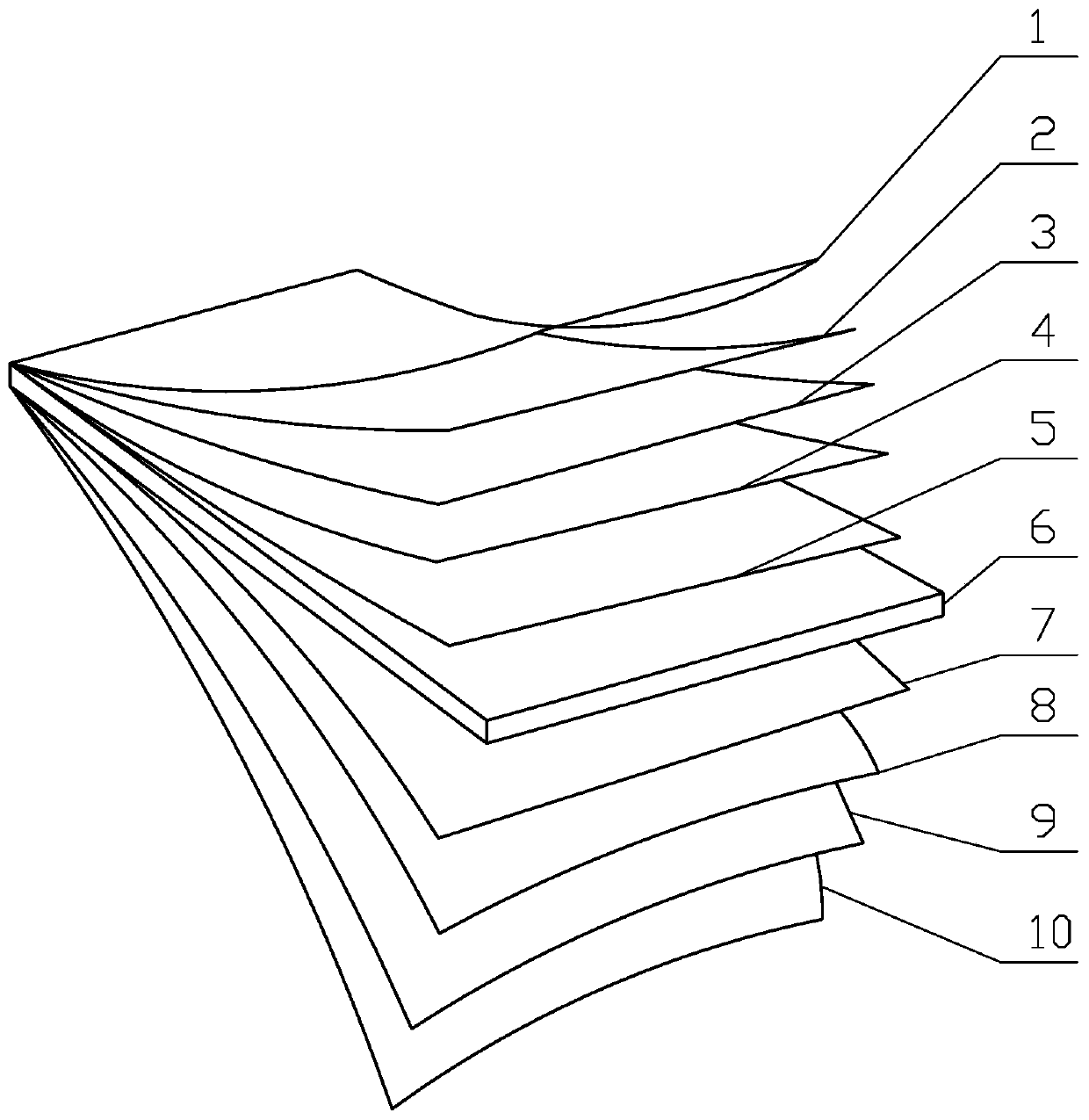

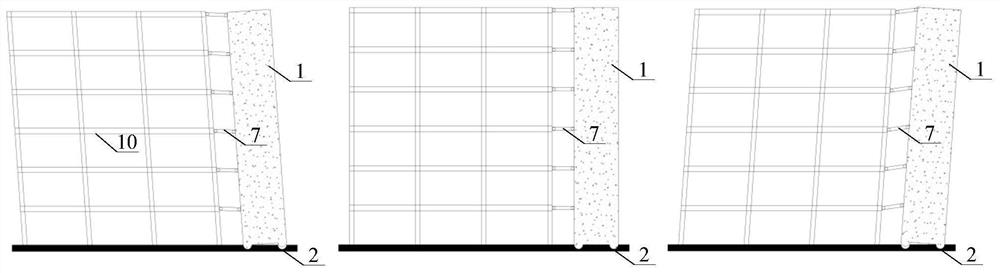

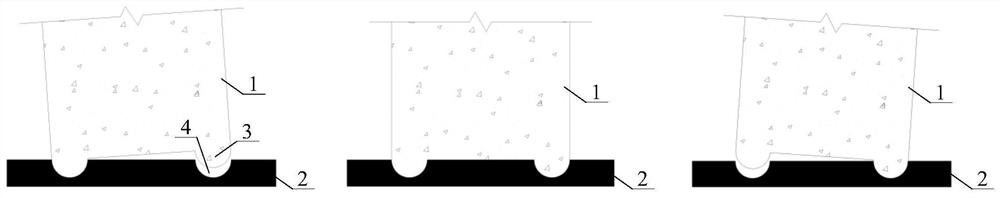

FRP-RC (fiber reinforced polymer-reinforced concrete) combined beam partially constrained by fiber sleeve and construction method of combined beam

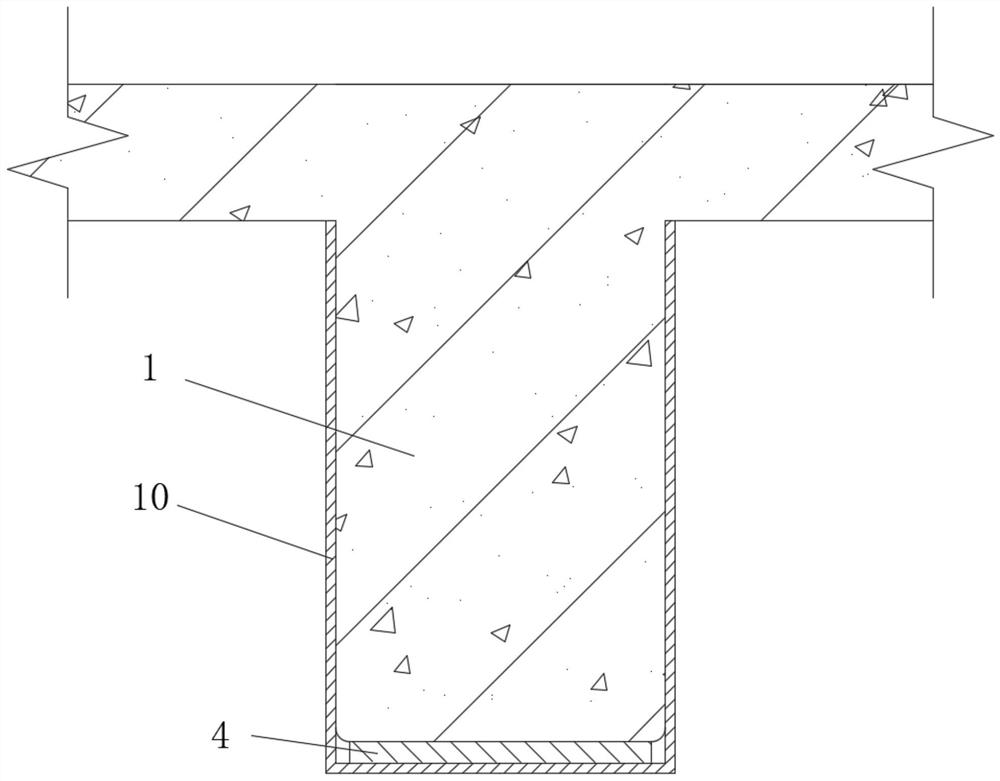

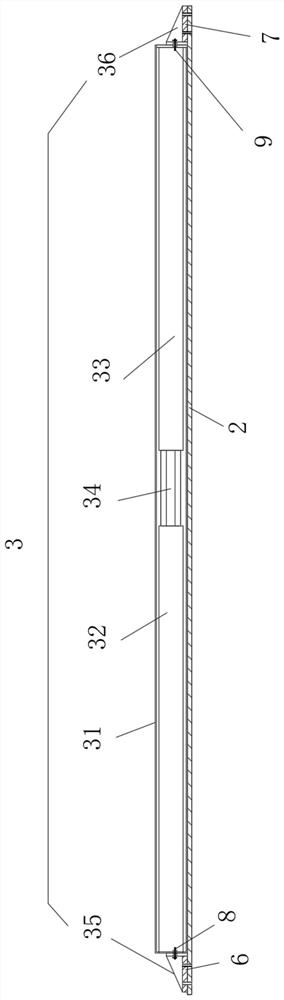

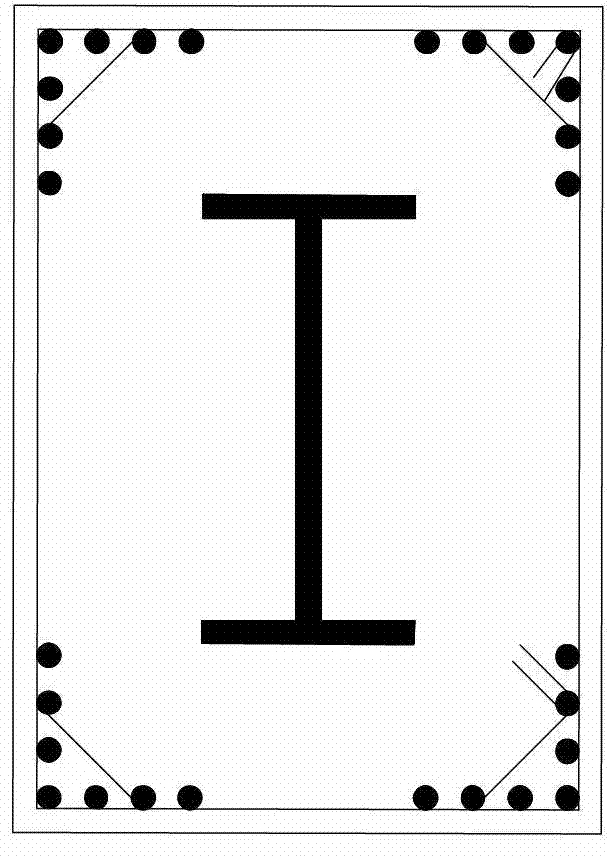

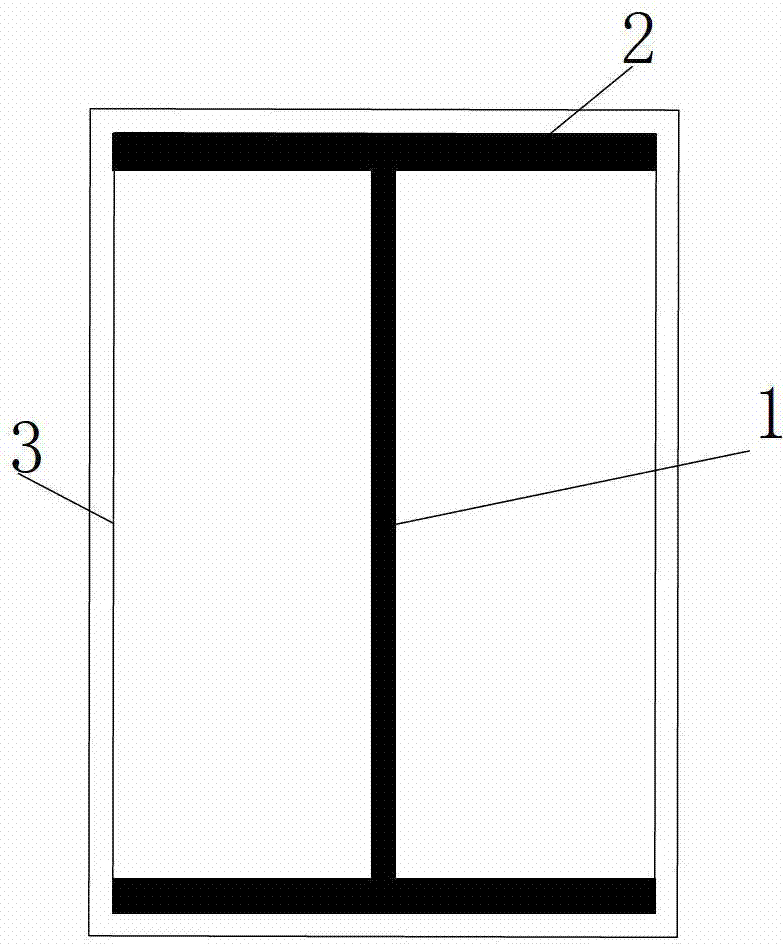

InactiveCN103195211ALow costSave the trouble of tying the steel cageLaminationLamination apparatusFiberReinforced concrete

The invention discloses an FRP-RC (fiber reinforced polymer-reinforced concrete) combined beam partially constrained by a fiber sleeve. The combined beam comprises an FRP formwork (1) for forming, a circular fiber sleeve (3) for improving the compressed property of concrete, and circular-arc-shaped pedestals (4) for fixing the fiber sleeve, wherein the FRP-RC combined beam has a rectangular section, the size of the section and the number of layers of FRP are determined through design calculation, and the length of the circular fiber sleeve is determined through calculation according to design needs. According to the invention, the structural bearing capacity is enhanced, the structural ductility is improved, and the construction progress is accelerated, therefore, the FRP-RC combined beam has relatively low engineering cost and is simple and convenient to construct.

Owner:HUNAN UNIV

Novel fireproof and waterproof composite heat preservation wall structure

InactiveCN104294960AImprove thermal insulation performanceImprove protectionWallsHeat proofingFire protectionAdhesive

The invention provides a novel fireproof and waterproof composite heat preservation wall structure. The novel fireproof and waterproof composite heat preservation wall structure is composed of a composite heat preservation plate and a fixing net rack, wherein the composite heat preservation plate and the fixing net rack are installed on the outer sides of a structural wall. The composite heat preservation plate comprises aluminum foil plate layers on the two sides and a polystyrene board heat preservation layer in the middle, and the aluminum foil plate layers and the polystyrene board heat preservation layer are connected through adhesives. The fixing net rack comprises wire meshes and expansion riveting bolts, wherein the two layers of wire meshes are located on the two sides of the composite heat preservation plate respectively, the bottoms of the expansion riveting bolts are anchored to the structural wall, the middles of the expansion riveting bolts penetrate through the composite heat preservation plate and the wire meshes, the tops of the expansion riveting bolts are connected with the outer wire mesh, an adhesion mortar layer is arranged on the outer portion of the outer wire mesh, and a decoration layer is arranged outside the adhesion mortar layer. The novel fireproof and waterproof composite heat preservation wall structure well solves the problem that due to the fact that the fire protection level is low when a polystyrene board serves as external wall heat preservation materials, using is limited; the novel fireproof and waterproof composite heat preservation wall structure has the advantages of being good in heat preservation and energy saving effect, high in fire protection level, resistant to water and earthquakes and convenient and rapid to construct.

Owner:曹秀玲

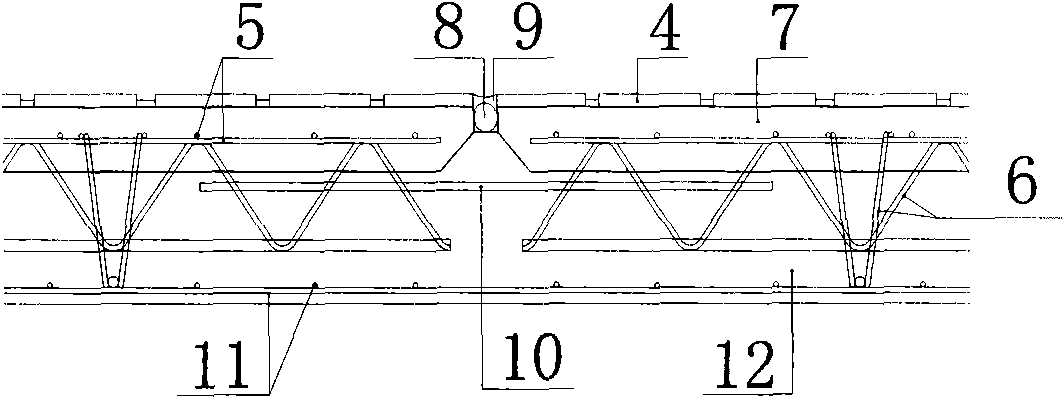

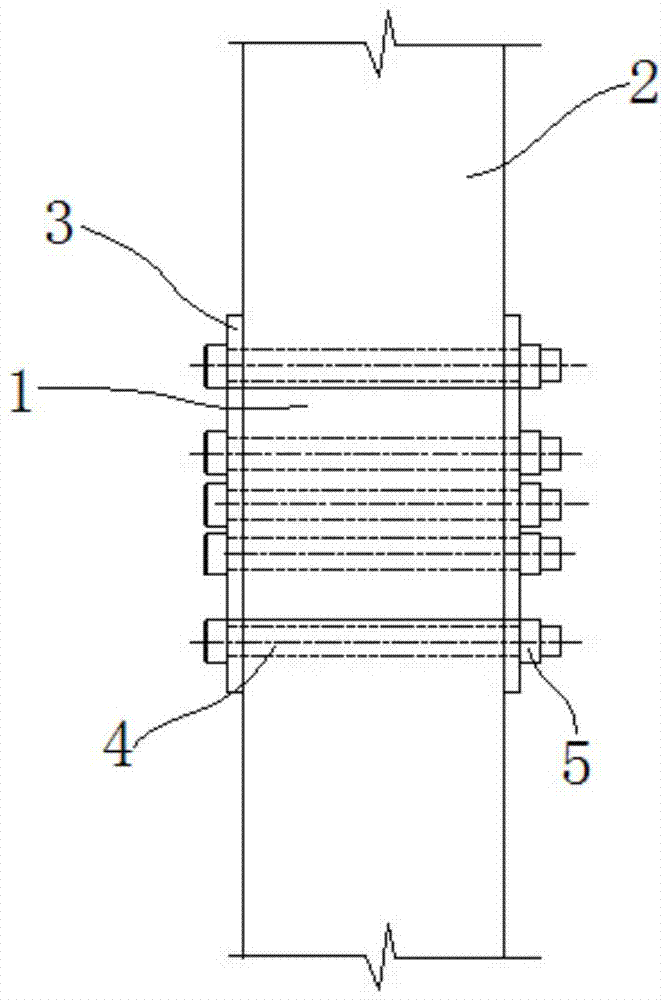

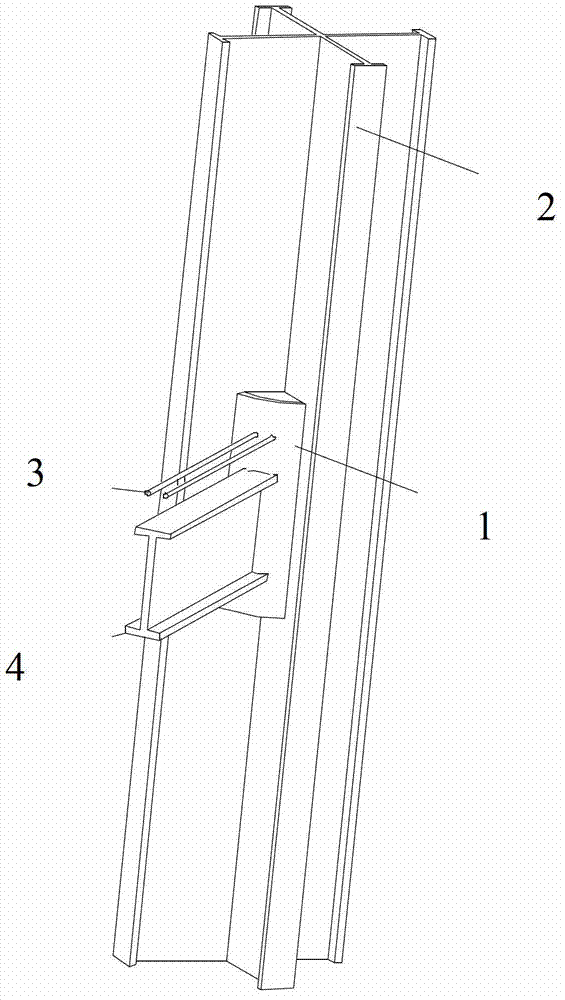

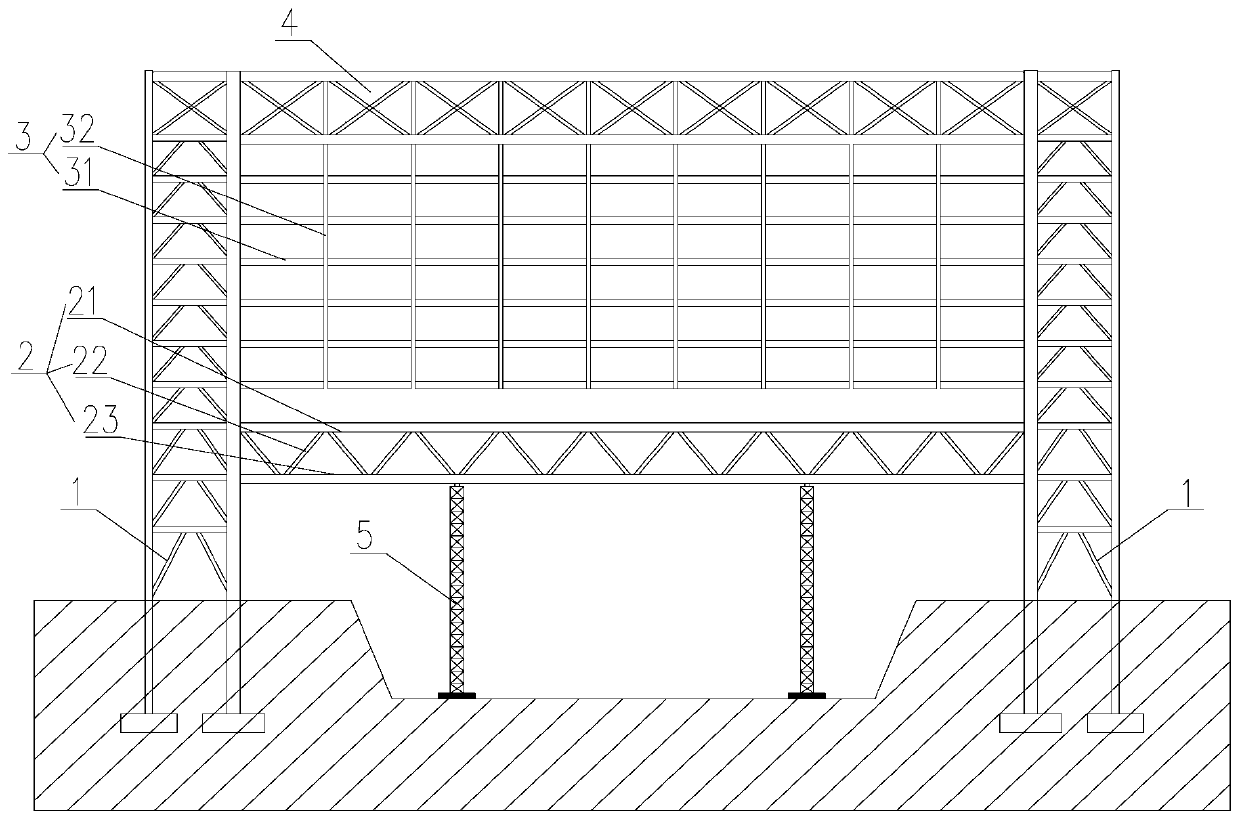

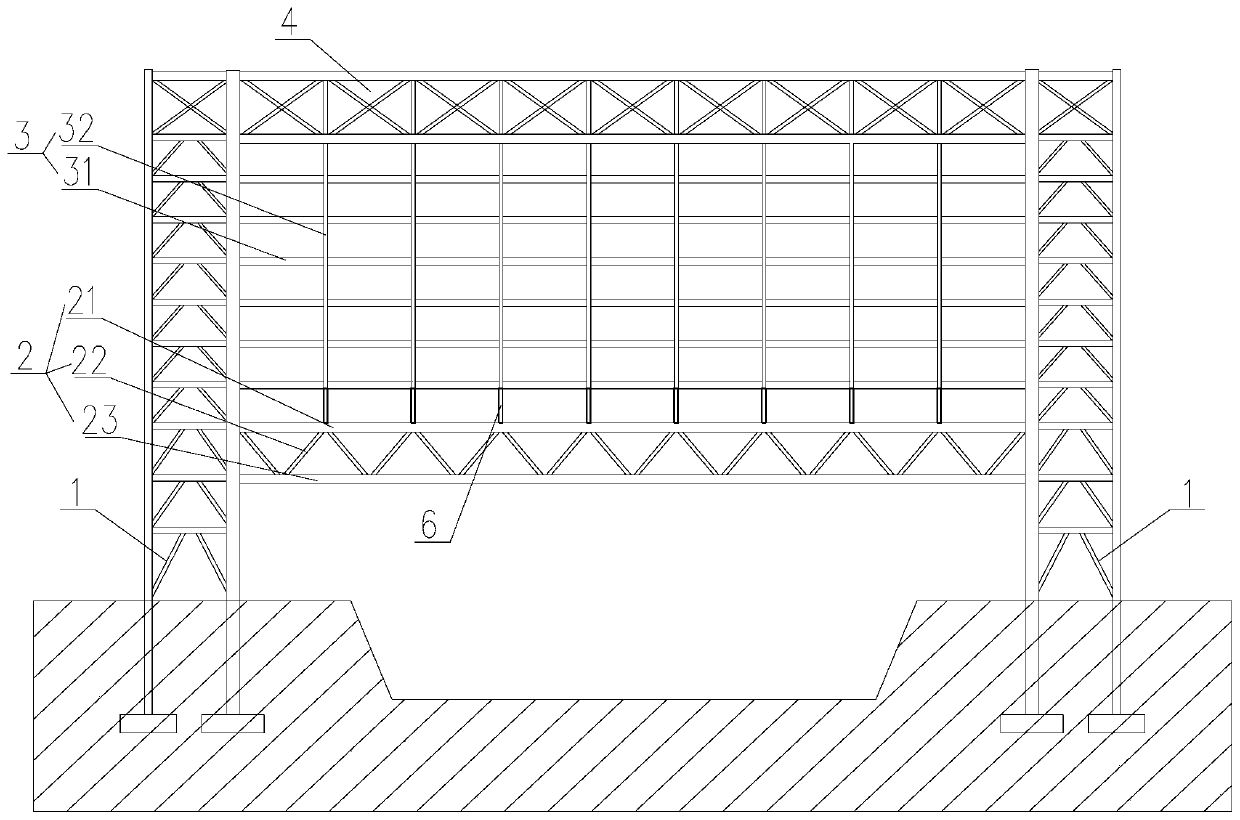

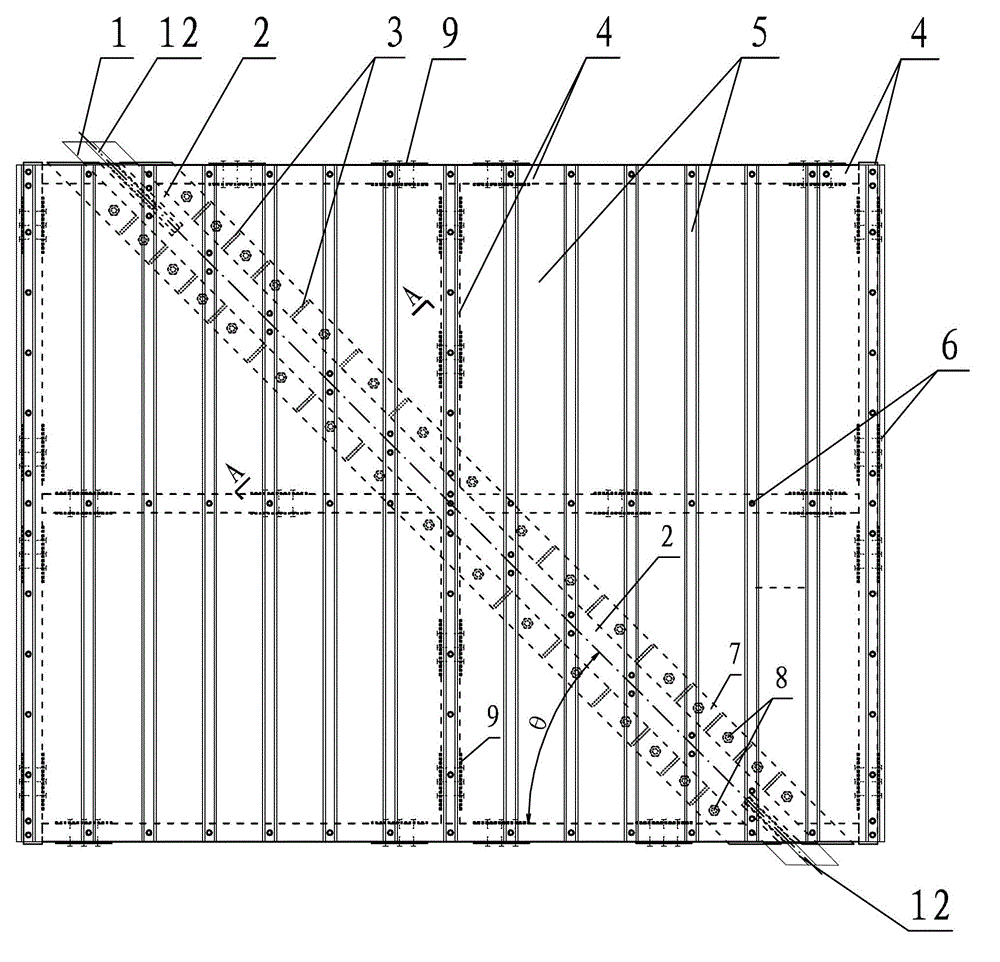

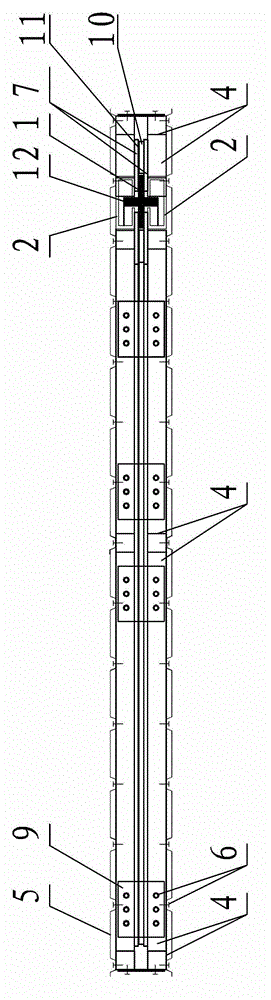

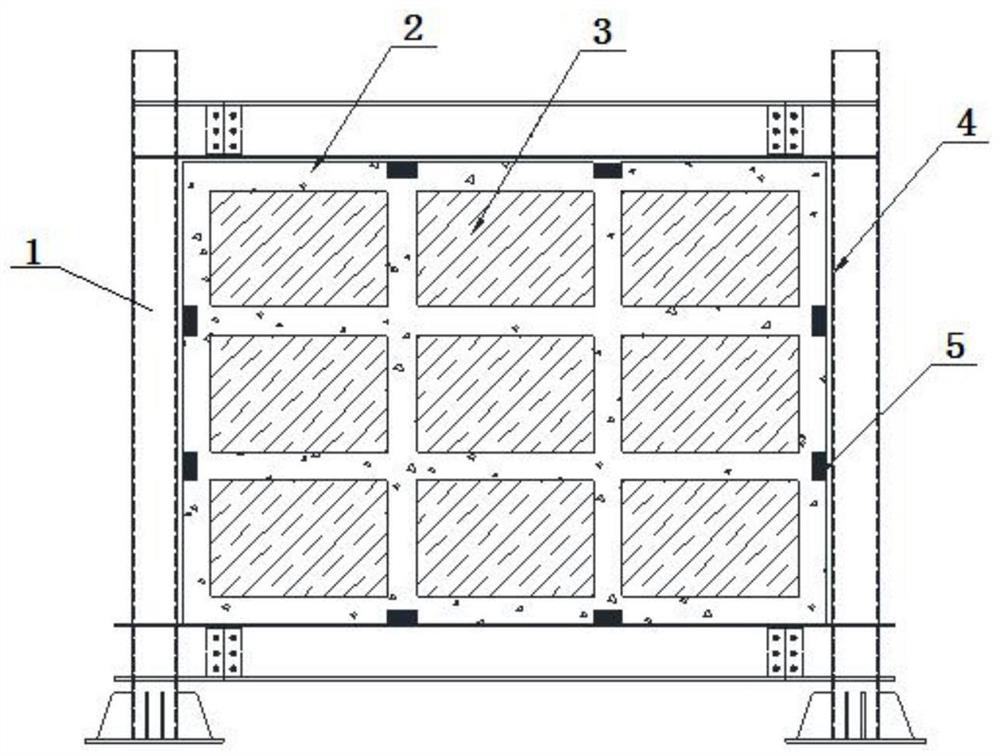

Steel truss suspension hybrid system and construction method

InactiveCN110359548ASmall sizeConducive to earthquake resistance of the structureBuilding constructionsHybrid systemFloor slab

The invention relates to the technical field of building structure construction, in particular to a steel truss suspension hybrid system and a construction method. The system comprises two vertically-arranged vertical frames, an upper truss, multiple layers of suspension units and a lower truss, wherein the upper truss, the multiple layers of suspension units and the lower truss are arranged between the two vertical frames and sequentially arranged in an up-and-down parallel manner. Each layer of suspension unit comprises a horizontally-arranged frame beam, a suspension column vertically arranged between every two adjacent layers of frame beams, and a concrete floor formed on each layer of frame beam. The frame beam in the lowest layer of suspension unit is connected with the lower truss through a supplementary suspension body. According to the system and the method, by the adoption of the structural style of bearing of the upper truss and suspending of the middle suspension units, thesizes of the lower truss and the middle frame columns are reduced, in the construction process of the system, system loads and construction loads can be completely borne by the vertical frames on thetwo sides, or when forward mounting is adopted, the system loads and the construction loads are jointly borne by the vertical frames on the two sides, a first supporting unit and a second supportingunit.

Owner:HEFEI UNIV OF TECH +1

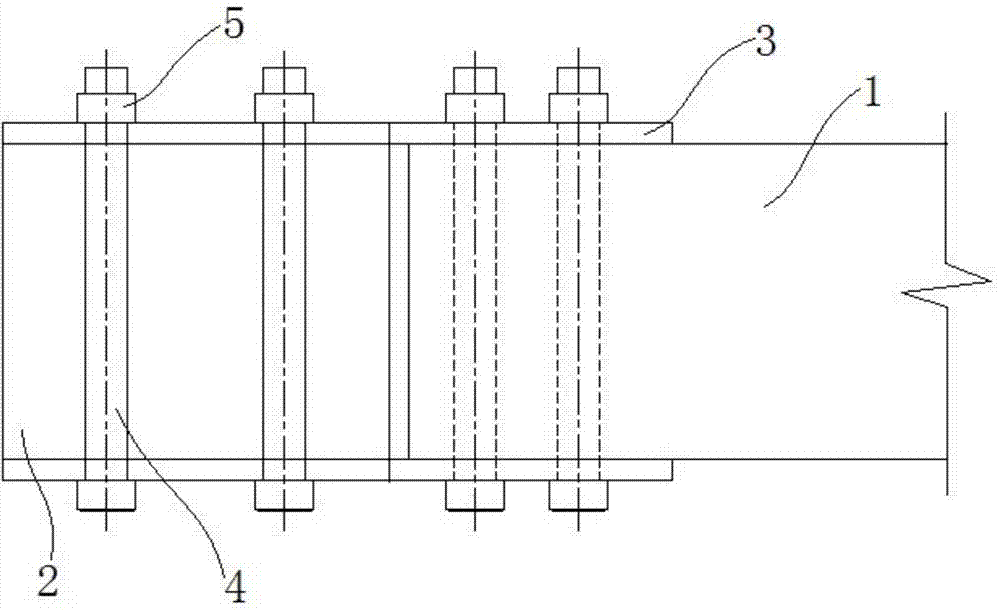

Internally arranged steel plate support for light steel assembled wallboard

The invention relates to a steel support, particularly relates to an internally arranged steel plate support for a light steel assembled wallboard, and aims to solve problems that the wallboard dead weight is large, steel plate supports are not easy to check and change after severe earthquakes, and wallboards cannot be used repeatedly in reinforced concrete wallboard internally arranged un-bonded steel plate supports. Two first stiffening ribs are welded along the support length direction at two ends of a steel plate support body; the steel plate support body and a perforated steel base plate are arranged between two steel plates with rectangular grooves arranged at two ends and fixedly connected through a plurality of high-strength bolts; the first stiffening ribs at two ends of the steel plate support body are inserted into rectangular grooves arranged at two ends of first rectangular steel tubes; a plurality of second rectangular steel tubes form two matts frames, each of the matts frames is fixedly connected with one of the steel plates and one of the first rectangular steel tubes, and the two matts frames are fixedly connected with a plurality of connection steel plates; and profiled color steel sheets are arranged on the outer sides of the first rectangular steel tubes and the second rectangular steel tubes. The internally arranged steel plate support for the light steel assembled wallboard is used as a central support and a partition wall simultaneously in a support steel frame with seismic resistance requirements.

Owner:HARBIN INST OF TECH

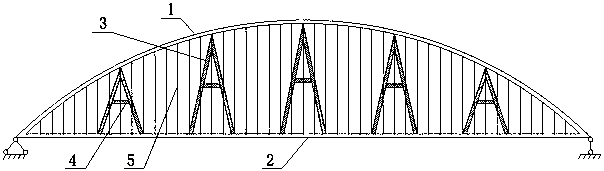

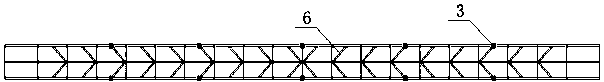

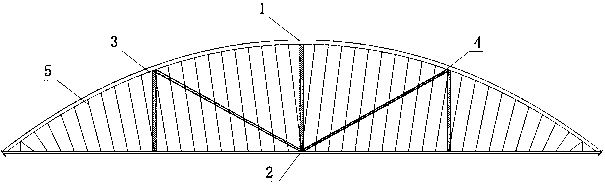

Beam-arch consolidated triangular arch bridge

PendingCN108930222AImprove line stiffnessIncrease stiffnessArch-type bridgeBridge materialsEngineeringStructural engineering

The invention discloses a beam-arch consolidated triangular arch bridge. The beam-arch consolidated triangular arch bridge mainly comprises an arch rib (1), a main beam (2), flexible lifting rods (5)and arch rib transverse braces (6); the flexible lifting rods (5) are placed between the arch rib (1) and the main beam (2), wherein a rigid diagonal rod assembly is also arranged between the arch rib(1) and the main beam (2); the rigid diagonal rod assembly mainly consists of two rigid diagonal rods (3) in an inverted V shape; that is to say that the two rigid diagonal rods (3) and the main beam(2) form a triangular structure; and a diagonal rod cross-link (4) is also arranged between the two rigid diagonal rods. According to the beam-arch consolidated triangular arch bridge, the arch rib and the main beam are restricted by using a triangle; and meanwhile, the linear stiffness of the main beam is enhanced; and therefore, the integral rigidity of the structure is greatly enhanced; and the problem that a see-saw effect of the arch bridge is obvious under the action of half-span load can be greatly solved.

Owner:GUANGXI UNIV

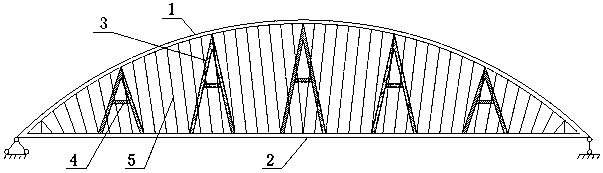

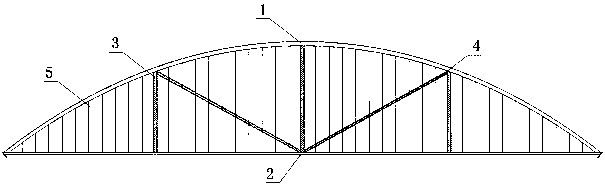

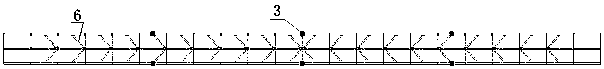

Big trussed arch bridge

PendingCN108374324AImprove mechanical propertiesIncrease vertical stiffnessBridge structural detailsCross bracingMechanical property

The invention discloses a big trussed arch bridge. The arc bridge is mainly composed of arch ribs, a girder, vertical web members, diagonal web members, flexible suspenders and cross bracings; the vertical web members are respectively arranged near the portions of one quarter, one half and three quarters of the arch ribs; two ends of each diagonal web member are respectively connected with the bottom of a middle vertical web member and the tops of vertical web members of two sides; the arch ribs, the girder, the vertical web members and the diagonal web members form a big trusswork with the flexible suspenders, wherein the arc ribs are taken as top chords, and the girder is taken as a lower chord. The big trussed arch bridge cannot damage the stress characteristics of arc structures, has truss features, and can greatly improve the rigidity, stability and dynamic characteristics of the structures. It is due to the fact that the rise span ratio can be made lower, the rise can be effectively reduced, and the construction difficulty is reduced. The big trussed arch bridge has a better mechanical property, can be applied to the bridges requiring high rigidity and high dynamic performance, and has great engineering application value.

Owner:GUANGXI UNIV

LVL structure and melamine paper facing novel plate and manufacturing method thereof

InactiveCN110748074AAchieve structural stabilityReduce chance of deformationConstruction materialWallsProcess engineeringFormaldehyde free

The invention belongs to the technical field of integrated plates, and particularly relates to an LVL structure and melamine paper facing novel plate and a manufacturing method thereof. The LVL structure and melamine paper facing novel plate comprises an LVL structure layer, wherein a wood veneer I, a wood veneer II and a wood veneer are sequentially attached from the LVL structure layer outwards,and melamine paper is attached to the surface of the wood veneer II. According to the LVL structure and melamine paper facing novel plate, the LVL solid wood veneers are used as base materials, a special production process is adopted for machining and compounding to form the novel plate, the novel plate belongs to the novel high-tech building decoration material, the defect problem existing in atraditional plate is overcome, the novel plate has the advantages that the performance is excellent, and the structure is stable, and the deformation warping probability of the plate is greatly reduced; and health and environmental protection are achieved, modern environmental protection requirements are met, non-toxic, odorless, formaldehyde-free and sound-isolating are achieved, and the novel plate can be widely applied to medical spaces, educational spaces, office spaces, business spaces, home spaces and the like.

Owner:山东凯勒蓝房家居文化发展有限公司

Manufacturing process of novel environment-friendly sound-insulating plate

Disclosed is a manufacturing process of a novel environment-friendly sound-insulating plate. The manufacturing process comprises the following steps that 1, after fly ash, glazed hollow beads, water, light-burned magnesium oxide, anti-crack and anti-leakage agents, a tackifying agent, Kaolinite powder and lime putty powder are fully and evenly mixed and stirred, sawdust powder is added, secondary stirring is conducted, and a first mixture is obtained; 2, the first mixture is poured into a mould, the mould is filled, the first mixture is flatly laid, the mould with the first mixture is put into a high-temperature sintering furnace to be sintered, and a base material plate is obtained after sintering; 3, magnesium chloride brine and talc powder are mixed, a pulp material is obtained after uniform stirring, the pulp material is poured on glass-fiber cloth, drying treatment is conducted in a high-temperature and high-pressure environment, and a film material is obtained; 4, the base material plate is wrapped with the film material, high-temperature and high-pressure compression molding is conducted, decorating, grinding and polishing are conducted after compression molding, and a product is obtained. The novel environment-friendly sound-insulating plate has good heat insulation property, sound insulation property and water-proof performance, materials are environmentally friendly and save energy, and the cost is low.

Owner:合肥易美特建材有限公司

Wall body of steel frame filled with phosphogypsum-concrete composite wall and preparation method

PendingCN113789906AImprove production efficiencyIncrease lateral stiffnessConstruction materialCeramic shaping apparatusPhosphogypsumSteel frame

The invention discloses a wall body of a steel frame filled with a ardealite-concrete composite wall and a preparation method, and belongs to the technical field of comprehensive utilization of ardealite. The wall body comprises a steel frame and an ardealite-concrete combined wall, the ardealite-concrete combined wall is arranged in the steel frame, a deformation joint is reserved between the ardealite-concrete combined wall and the steel frame, a flexible plate is arranged in the deformation joint, a plurality of clamping pieces are arranged at the positions, corresponding to the ardealite-concrete composite wall, of the steel frame, and the ardealite-concrete composite wall comprises a concrete frame and an ardealite-based composite cementing material filled in the concrete frame. The wall body can be manufactured only through general assembly on site, and the wall body manufacturing efficiency is high; the steel frame and the ardealite-concrete composite wall are combined into a whole, so that the lateral stiffness of the wall body is greatly improved; and the use amount of semi-hydrated ardealite can be greatly reduced, and the energy consumption of ardealite dehydration is remarkably reduced.

Owner:NO 1 CONSTR ENG CO LTD OF GUIZHOU CONSTR & ENG GRP

Assembled wall panels with built-in self-resetting steel plate supports

The built-in self-resetting steel plate support of the assembled wallboard, the present invention relates to the built-in self-resetting support of the wallboard, and the present invention aims to solve the problem of the residual plastic deformation of the support after the large axial yield of the support in the wallboard built-in support and rod-shaped anti-buckling support in the prior art Adverse effects on the use and function of the structure, the weight of the wall panels is large, and it is not easy to inspect and replace the steel support, and the existing concrete wall panels have built-in unbonded supports that deteriorate the ductility and energy consumption of the steel support due to wall panel punching damage Capability, in the application of rod-shaped anti-buckling braces, it is necessary to make additional filling walls. The axial deformation capacity of the existing rod-shaped self-resetting braces is limited by the elastic deformation capacity of the reset members. It includes walls and self-resetting bracing mechanisms, and self-resetting The supporting mechanism includes a supporting steel plate, a compressed spring assembly, a push-pull block, a channel steel, a cover plate, a hat-shaped steel, a fixed steel plate, a fixed tension plate, a push-pull rod and an end plate. field.

Owner:HARBIN INST OF TECH

A method for externally prestressed steel plate flexural strengthening beam

ActiveCN110173125BIncrease profitSave spaceBuilding repairsProtective buildings/sheltersPre stressClassical mechanics

The present invention relates to the technical field of building beam reinforcement, and in particular to a method for externally prestressed steel plate anti-bending reinforcement beam, including the following steps: (S1), assessing the status quo of the beam to be strengthened, and then selecting the steel plate to be processed according to the design requirements; S2), stretching the steel plate to be treated, so that the elongation of the steel plate to be processed meets the design requirements, and obtain a prestressed steel plate; (S3), grinding and cleaning the bottom surface of the beam to be strengthened, and then The prestressed steel plate abuts against the beam to be strengthened; (S4), fixing the prestressed steel plate to the bottom of the beam to be strengthened. This method improves the bending strength of the beam to be strengthened, improves the utilization rate of the steel plate material, solves the problem of structural stress lag, improves the bearing capacity of the beam to be strengthened, is beneficial to the structure's earthquake resistance, and is conducive to the utilization of building space, without the need for formwork , Simple operation, convenient control, low cost of engineering materials.

Owner:广东中青建筑科技有限公司

Inner wall fireproof decorative plate

The invention relates to an inner wall fireproof decorative plate which comprises the following raw materials in percentage by weight: 18-26% of a magnesium chloride solution, 12-18% of thermal insulation mortar, 21-30% of magnesia powder, 4-8% of rock wool, 4-8% of fly ash, 8-15% of magnesium cement, 3-6% of titanium dioxide, 5-9% of magnesium oxide and 1-3% of nano silicon dioxide. The obtainedinner wall fireproof decorative plate has the advantages of fire resistance, heat resistance, water resistance, moisture resistance, light weight, high shock strength, environmental protection and healthiness.

Owner:ANHUI CHAOYANG DECORATION ENG

H-shaped steel concrete column with high-strength spiral hoop and restraining high-strength wide flange

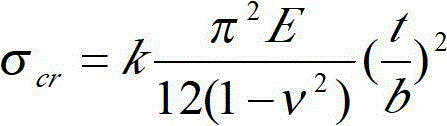

InactiveCN102747810BEasy constructionMechanics concept is clearStrutsPillarsMaterials scienceCritical stress

The invention provides an H-shaped steel concrete column with a high-strength spiral hoop and a restraining high-strength wide flange and relates to a sectional steel concrete column. The defects of the present I-shaped and H-shaped steel concrete columns that the construction is difficult, the anti-bending function of the sectional steel is not completely utilized because a concrete protecting layer is thick, and the high-strength sectional steel is easy to press and deflect are overcome. A longitudinal reinforcement is abolished, a steel area is converted into the sectional steel flange and the construction and the design of the sectional steel concrete column are convenient to perform. The spiral hoop is a high-strength rectangular spiral hoop; the inner side of the spiral hoop of the restraining sectional steel flange is clung to the surface of the sectional steel flange; and an unstable critical stress of the sectional steel flange is increased by a free edge of the restraining sectional steel flange; the spiral hoop is tightly combined with the flange, so that a function of a bolt is achieved and the concrete can more effectively coordinate with the sectional steel; the concrete protecting layer of the sectional steel is 30-40mm thick, thereby being fireproof requirement and fully utilizing the anti-bending function of the sectional steel; a screw pitch of the rectangular spiral hoop is 0-60mm, so that the restraining condition of the free edge of the restraining sectional steel flange is obviously improved; and the H-shaped steel concrete column provided by the invention is applied to a sectional steel concrete structure.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

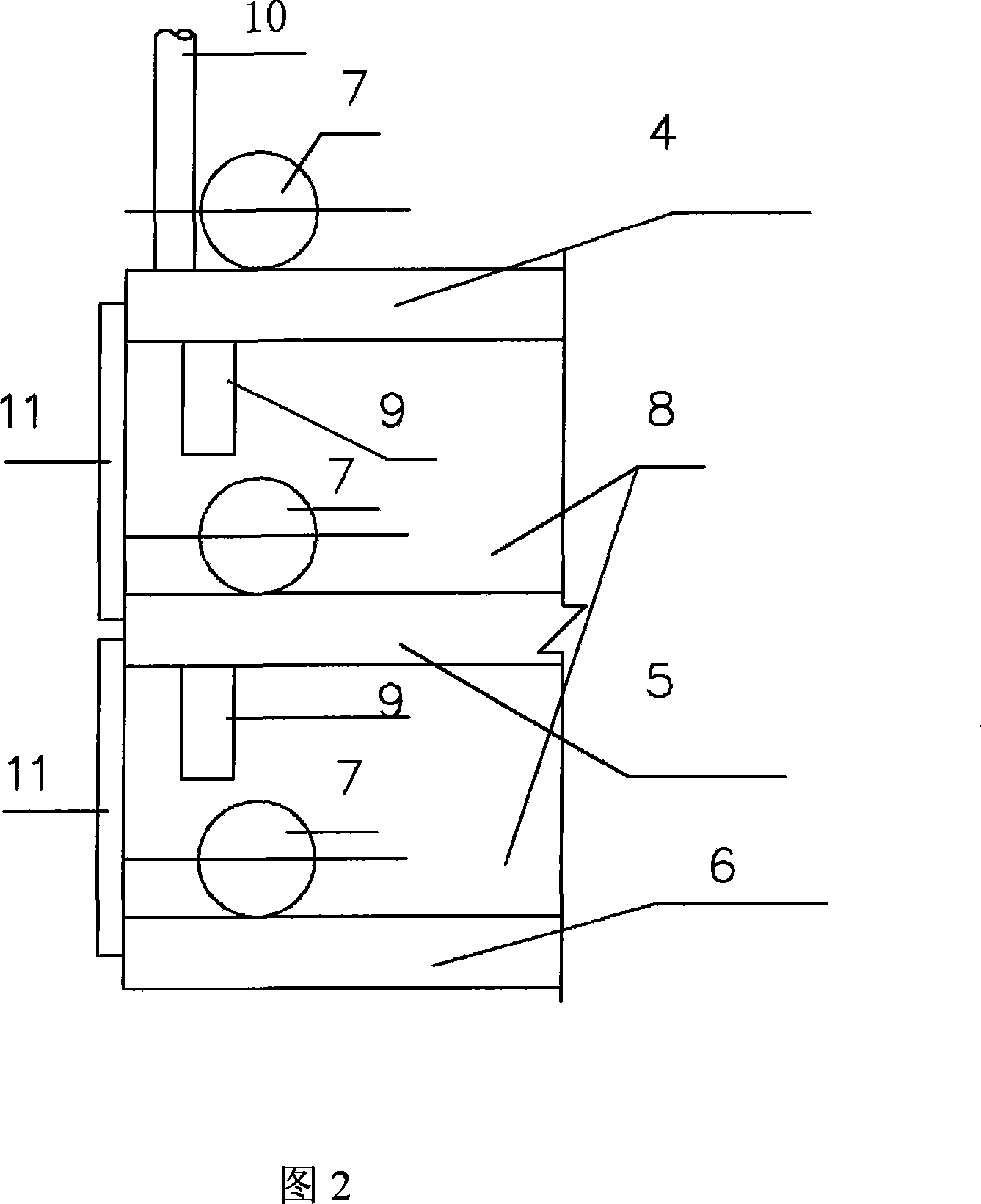

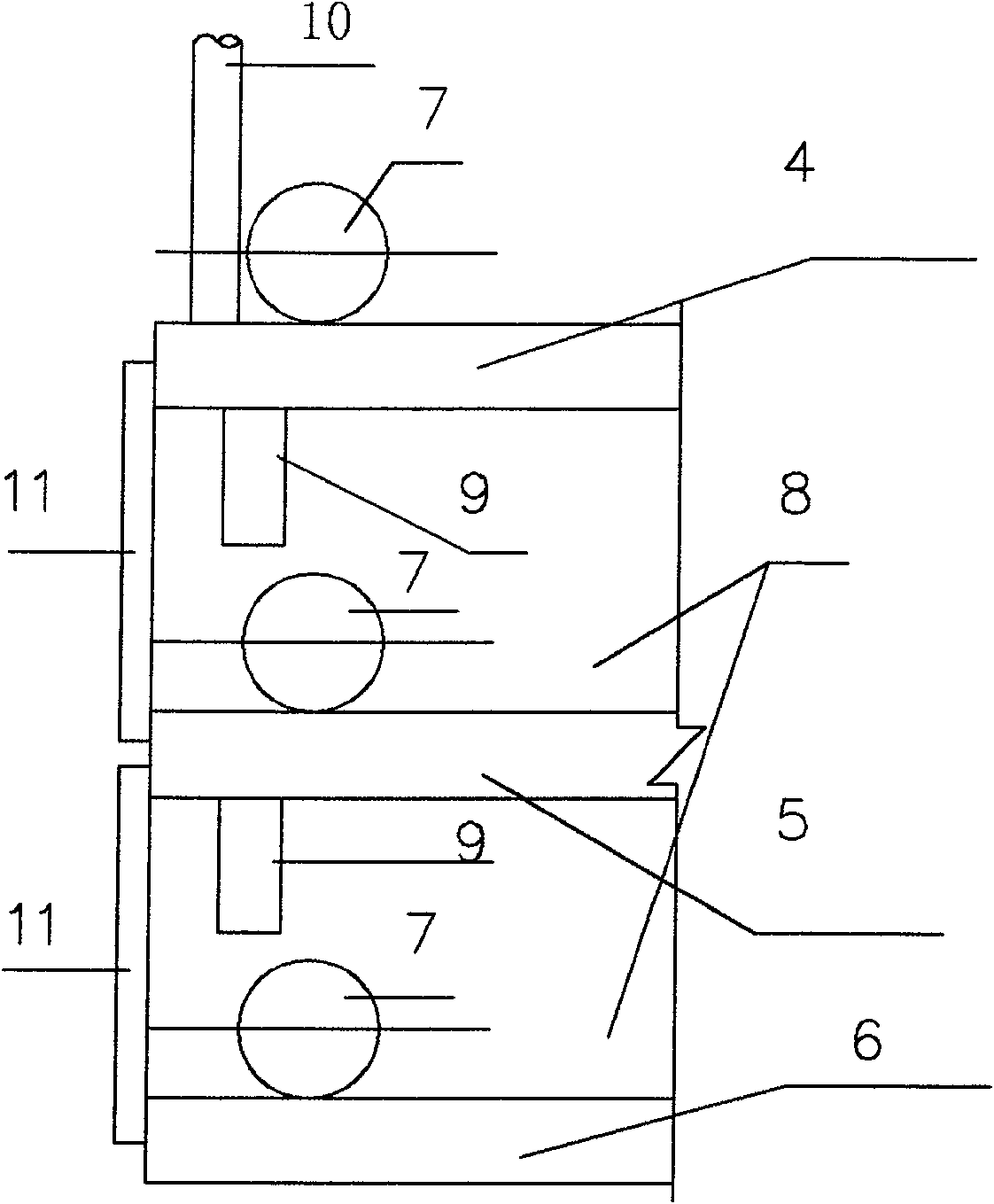

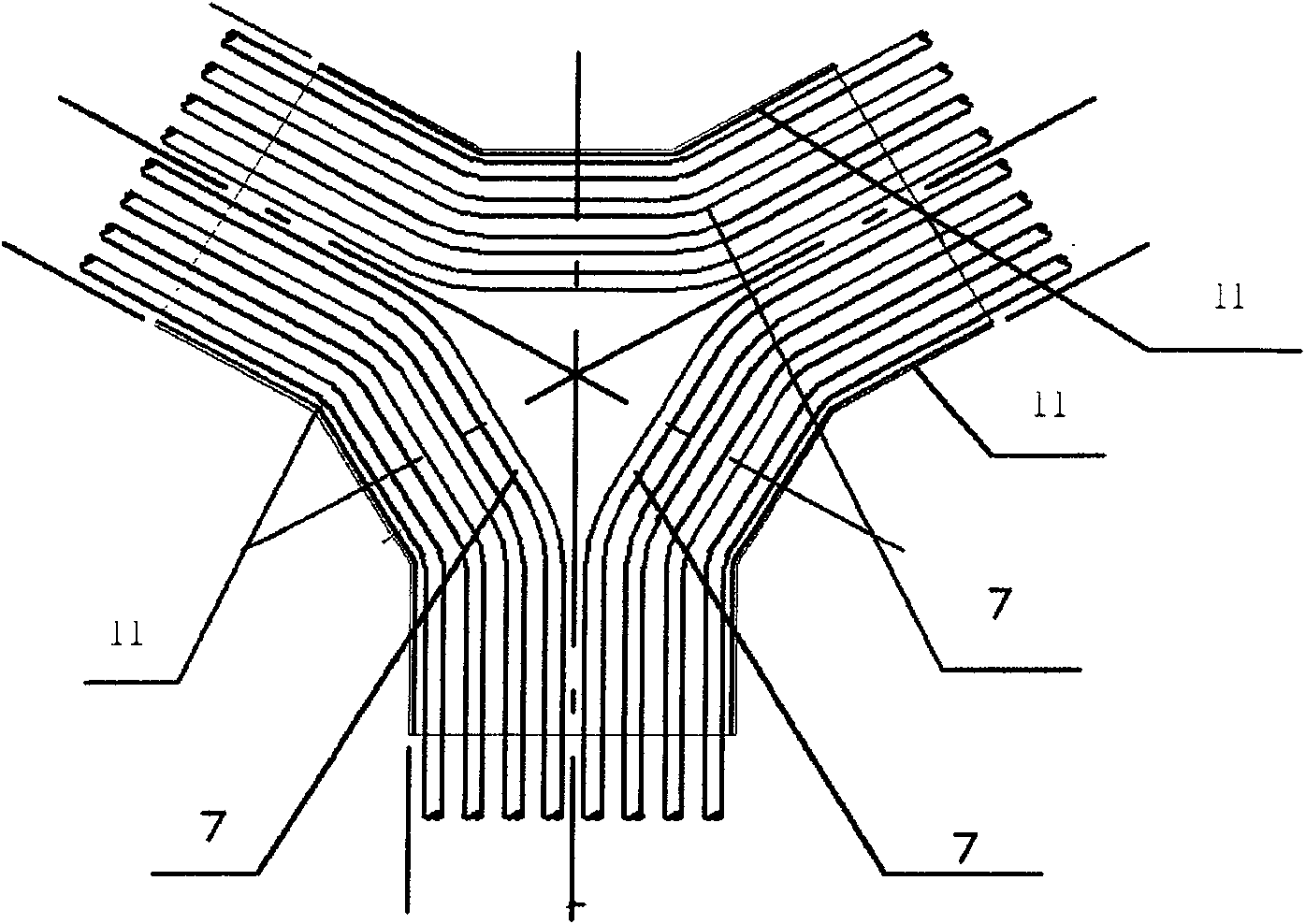

Structure beam in calcium carbide production equipment

ActiveCN101117820ARealize ring feedingCompact layoutCalcium carbideBuilding constructionsSlurryRebar

The present invention discloses a structural beam in a calcium carbide production device, and the structural beam includes a concrete trigeminal beam formed at one point by three extremities in the form of chevron. An angle between adjacent extremities is 120 degrees, and an upper steel plate, an intermediate steel plate and a lower steel plate are arranged at the lower position of each extremity. A plurality of reinforced steel bars are arranged on each layer of the steel plate, the reinforced steel bar are connected with the reinforced steel bar of the other two extremities at the same layer, slurry is poured among the steel plates, the top of the upper layer of the steel plate is welded with stirrups connected with beams, and a lateral wall steel plate is welded on the external side of the adjacent steel plate. The structural beam in the present invention removes the disadvantages of uneven feeding, high and large building in the straight line feeding of the calcium carbide production technology, realizes the loop feeding in the calcium carbide technology production technology; under the prerequisite of meeting the production technology, the present invention has the advantages of compact plane arrangement, reasonable building height, structural shockproof, saving civil engineering investment, etc.

Owner:CHINA TIANCHEN ENG

Structure beam in calcium carbide production equipment

ActiveCN100575629CRealize ring feedingCompact layoutCalcium carbideBuilding constructionsSlurryRebar

Owner:CHINA TIANCHEN ENG

Vitrification micro-sphere heat-preservation sound-insulation board and manufacturing method thereof

InactiveCN101234873BIncreased durabilityFireproofSolid waste managementCeramicwareFiberThermal insulation

The invention relates to a vitrified microsphere thermal insulation acoustical board, which has components as follows: vitrified microsphere, expanded perlite, cement, re-dispersible latex powder, water, methyl hydroxyethylcellulose ether, blended fiber, motor micropore plasticizer and water reducer. The preparation method includes the following steps: the components are evenly mixed; the mixed material is rolled by a roller press and is parched and cut after standing. Through inspection, thermal insulation performance of the vitrified microsphere thermal insulation acoustical board is much better than the prior organic product. Little cement consumption can directly cause reduction of thermal insulation coefficient; at the same time, dead weight is greatly lightened so that the formed sheet with lightened dead weight can improve the stress performance of building structure and is in favor of structural anti-seismic. Furthermore, as the vitrified microsphere and expanded perlite have fireproof, high and low temperature resistant and anti-aging performance, the fireproof performance and durability of the thermal insulation acoustical board can be improved. The vitrified microspherethermal insulation acoustical board can meet the need of structural element for strength and also greatly reduce energy consumption of the building to meet the need of building energy-saving standardof our country.

Owner:张辉

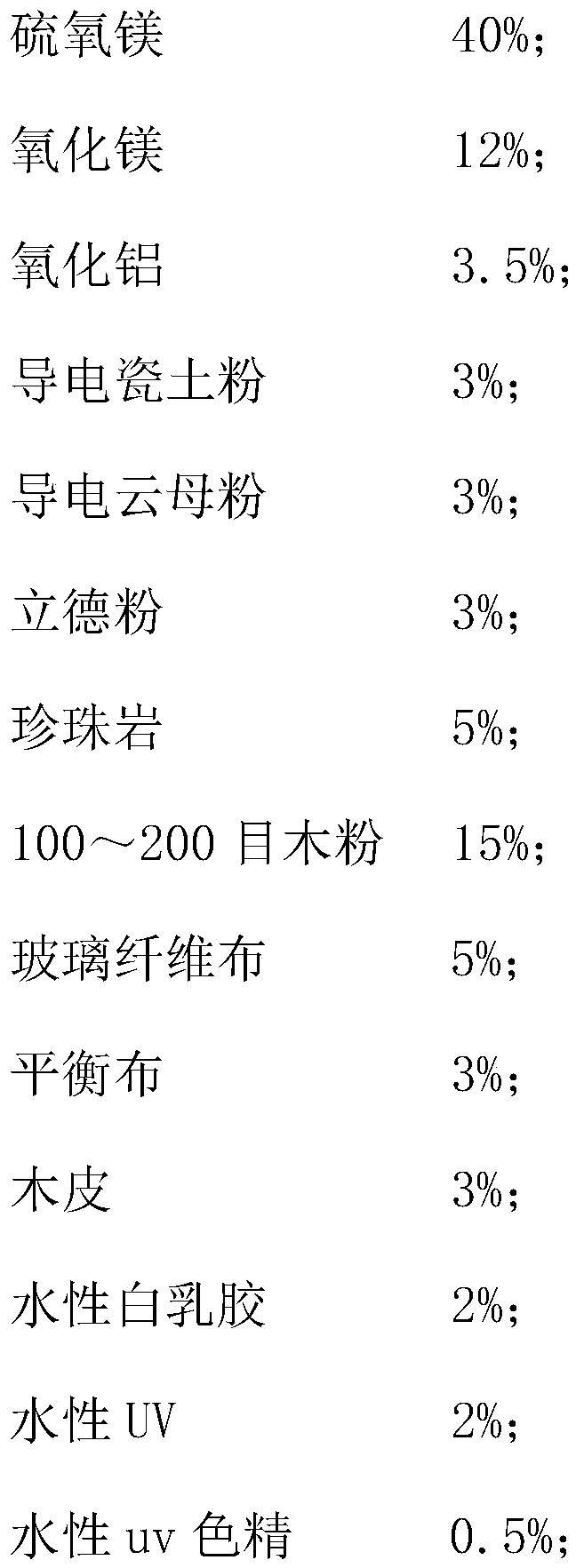

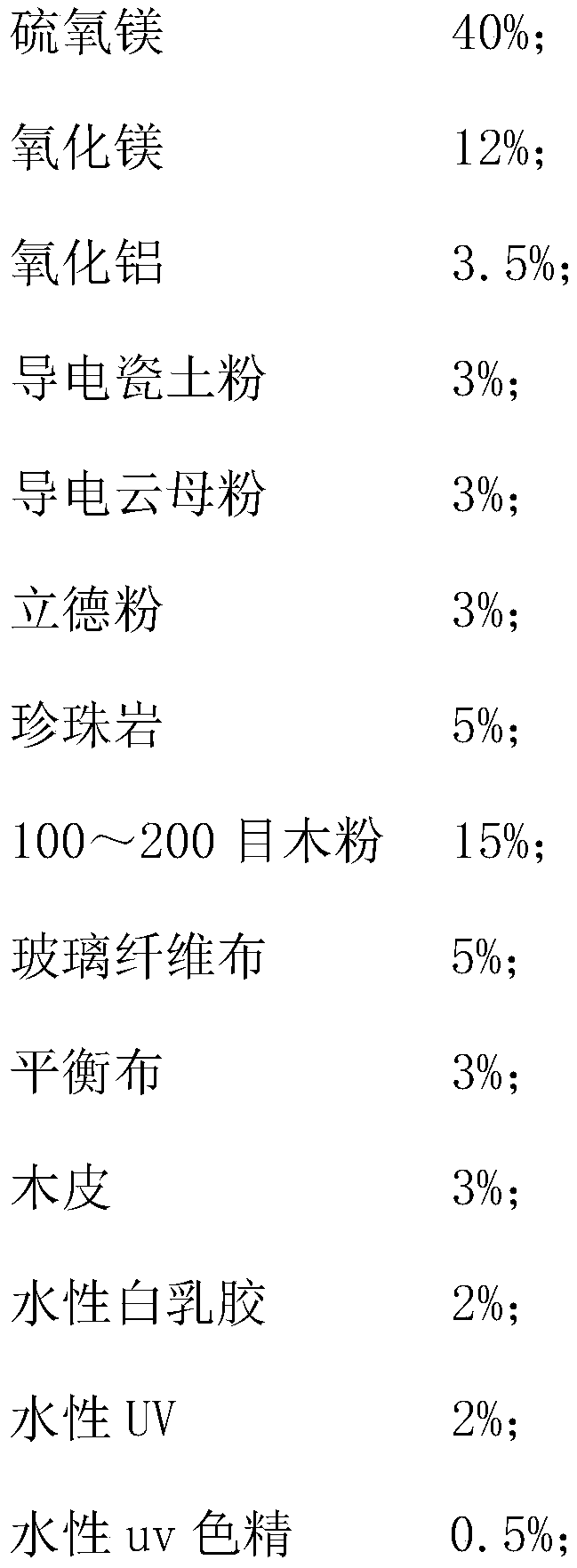

Magnesium oxysulfate pasting wood rock porcelain non-combustible board and manufacturing method thereof

InactiveCN110128097AImprove fire performanceImprove performanceCovering/liningsWood veneer joiningHigh surfaceMoisture absorption

The invention belongs to the field of building decorative boards, and particularly relates to a magnesium oxysulfate pasting wood rock porcelain non-combustible board and a manufacturing method thereof. The raw materials and percentages of the board are as follows: 40% of magnesium oxysulfate; 12% of magnesium oxide; 3.5% of alumina; 3% of an electro-conductive porcelain powder; 3% of an electro-conductive mica powder; 3% of lithopone; 5% of perlite; 15% of a 100-200 mesh wood powder; 5% of a glass fiber cloth; 3% of a balance cloth; 3% of wood veneer; 2% of a waterborne white latex; 2% of a waterborne UV; and 0.5% of a waterborne UV color concentrate. The steps of the manufacturing method are as follows: 1) preparing a magnesium oxysulfate substrate with a fine pore structure; 2) laying the balance cloth and the wood veneer on two sides of the magnesium oxysulfate substrate, and performing hot pressing; 3) performing cold pressing shaping; and 4) performing double sided sanding treatment, and roll coating a waterborne UV color concentrate primer, a waterborne UV primer and a topcoat. The board has light texture, high surface brightness and high hardness, has good fireproof, moisture proof and temperature difference resistant performances, does not contain asbestos, formaldehyde and harmful radioactive elements, is smoke-free, non-toxic, odor-free in fire, has strong water resistance and no moisture-absorption and halogen-returning property, and has good heat preservation effects and wide application range.

Owner:山东凯勒蓝房家居文化发展有限公司

Swinging wall and swinging wall-frame structure

ActiveCN114197695ALarge restoring torqueConducive to earthquake resistance of the structureWallsProtective buildings/sheltersStress concentrationMechanical engineering

The invention discloses a swing wall and a swing wall-frame structure, and relates to the technical field of swing wall structures. The swing wall comprises a swing wall body and a basic unit. The end face of the swing wall body is provided with a first arc piece. The basic unit is connected with the swing wall body, and a second arc piece is arranged on the end face of the basic unit; any one of the first arc piece and the second arc piece is an arc bulge, and the other one is an arc groove; the arc protrusion and the arc groove formed by the first arc piece and the second arc piece can rotate in a matched mode. According to the swing wall, for an external swing wall-frame structure, the self weight of the wall body can be transmitted to a lower foundation through a large contact surface. The hinged position is not located in the middle of the wall any more, in the swinging deformation process, the dead weight of the wall generates large restoring torque, and structural seismic resistance is facilitated. For an embedded swing wall-frame structure, the problem of stress concentration is solved compared with a traditional swing wall corner which is converted from line contact to surface contact in the swing deformation process.

Owner:ANHUI INST OF BUILDING RES & DESIGN

Partition board material

The invention discloses a partition board material, comprising, in percentage by mass, 40-50% of cement, 15-30% of calcium silicate, 5-10% of polyethylene, 5-10% of expanded perlite, 7-10% of fly ash, 2-5% of white emulsion, 1-3% of adhesive 801, 2-4% of adhesive 916, 1-3% of glass adhesive, 1-3% of powder wallpaper adhesive, 1-3% of chopped fibres and 1-4% of gypsum, wherein the materials can be used for preparing the partition board material after being uniformly mixed. The partition board material is heat-insulated and good in fireproof performance.

Owner:湖北博悦佳实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com